Table of Contents

Advertisement

ISears]

OWNERS

MANUAL

MODEL NOS.

919.174212

919.174311

919.174320

919.174410

iMPORTANT:

Read the Safety

Guidelines Before

Operating

AiR

COMPRESSOR

DESCRIPTION

ASSEMBLY

OPERATION

MAINTENANCE

REPAIR PARTS

Record

in the spaces

provided

below the model

number,

code

number and manufacturers

hum=

bet of this air compressor.

The

model

number can be found

on

the label on the front

of the air

tank.

The code number

can be

found on the for label on the rear

of the air tank. The manufacturers

number (ASIVlE Code outfits

only)

is located on the metal data plate

on the backside of the air tank.

Model No.

Code No.

Mfgs. No.

Motor Mfg. Name

Motor Mfg. No.

Retain

these numbers for

future

references.

SI-30-14-2-A

Sears,

Roebuck

and Co., Chicago,

IL 60684 U.S.A.

2!85

%

%

%

Advertisement

Table of Contents

Summary of Contents for Craftsman 919.174212

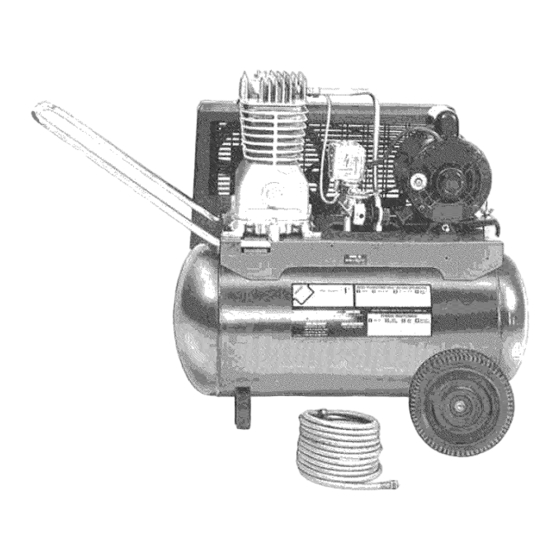

- Page 1 ISears] OWNERS MANUAL MODEL NOS. 919.174212 919.174311 COMPRESSOR 919.174320 919.174410 Record in the spaces provided below the model number, code number and manufacturers hum= bet of this air compressor. model number can be found the label on the front of the air tank.

-

Page 2: Table Of Contents

TABLE OF CONTENTS WARRANTY ............SAFETY GUIDELINES ..........SPECIFICATION CHART ..........GENERAL INFORMATION .......... GENERAL DESCRIPTION OF OPERATION ......ASSEMBLY INSTRUCTIONS ........Tools Needed for Assembly ........Attaching Wheels, Handle, Etc ........installing Regulator ..........Start-Up Procedures ..........OPERATION ............Manifold ............ -

Page 3: Warranty

FULL ONE YEAR WARRANTY AIR COMPRESSOR if this compressor fails due to a defect in material or workmanship within one year from the date of purchase, return it to the nearest Sears Service Center/Department throughout the United States and Sears will repair it, free of charge. if this air compressor is used for commercial or rental purposes, the warranty will apply for ninety days from date of purchase. - Page 4 PLEASE READ THE FOLLOWmNG CHART. HAZARD SAFEGUARDS AREA indicateswhere a hazard indicates how to avoid the hazard and what Indicates what can happen if pre- cautions are not observed. special protective clothing, equipment, and pre- occur. cautions will be used. Moving Parts Loose items, or parts of the body Never operate the compressor with the belt...

-

Page 5: Specification Chart

AREA HAZARD SAFEGUARDS Use of unsuitable solvents The solvents 1,1,1-Trichlorethane This hazard does not affect your compressor and Methylene Chloride outfit - but it may affect the equipment used with the outfit. Read the label or data sheet chemically react with aluminum used in paint spray guns, paint for the material you intend to spray. -

Page 6: General Information

THIS MANUAL IS DESIGNED TO MAKE iT AS EASY AS POSSIBLE FOR YOU TO SET UP, OPERATE AND MAiNTAiN YOUR NEW AiR COMPRESSOR GENERAL iNFORMATiON ASSEMBLY iNSTRUCTiONS You have purchased a complete portable compressor Tools Needed For Assembly outfit consisting of a 2 cylinder single-stage Tools needed are: (1) a 9/_6"... -

Page 7: Installing Regulator

crankcase, the oil flows into it very slowly. If the oil is added too quickly, it will overflow and appear to be full. (Crankcase oil capacity is 16fluid ounces.) Under it may be necessary to brace or support one winter-type conditions use SAE 10W oil. -

Page 8: Safety Valve

Safety Valve Note Avoid using long extension cords. They can cause a power loss to the motor. Add extra air hose instead of extension cords. OVER°PRESSURmZATmON OF THE TANK MAY CAUSE TANK RUPTURE If an extension cord must be used, follow the recom- EXPLOSmONo THE OUTFmT mSPROTECTED mendations listed below using a 3-wire extension cord. -

Page 9: Location Of Air Compressor

Check o illevel i nthecrankcase before eachuse. T heoil Replacing Belt level s hould beeven withthetopofthefirlholeandmust notbeallowed tobelower t han3/8" f romthetopatany time.itis recommended thattheoilinthebase(51)be changed a fterevery100 hours ofoperation. Todrain the oil,remove t heoildrain plug(50)andcollecttheoilina SERIOUS INJURY DAMAGE suitable container. Besure to replace theplugsecurely OCCUR mFPARTS OF THE BODY OR LOOSE... -

Page 10: Air Compressor Diagram

Air Compressor 65_t_ <L _63 ,L_.. 9' "_ C_--s9 a_ss 78 / 30'_I //35 48-I <, <... -

Page 11: Parts List

PARTS LIST PART NUMBER DESCRiPTiON SSF-953-ZN Self tapping screw (8 used) CAC-22 Belt guard CAC-142 Belt guard closure SSF-6627 Stud CAC-2 Bracket SSF-8113-ZN Lock nut 265-18 Filter retainer LA-1575 Label SSF-935 Screw #8-32 x %" (2 used) * 10 9-16279 Kit of two intake filters (1 used) SS-8553 Connector body (Models 919.174410&... - Page 12 PARTS LiST (Continued) DESCRiPTiON PART NUMBER TA-4036 Air tank (Model 919.174212) TA-4038 Air tank ASME (Models 919.174311& 919.174410) TA-4040 Air tank ASME (Model 919.174320) LA-1654 Label (Models 919.174212,919.174311& 919.174410) LA-1682 Label (Model 919.174320) CAC-492 Wheel (2 used) CAC-60 Shoulder bolt (2 used) Hex nut with lock washer STD541437 SS-2707...

-

Page 13: Accessories

PARTS LiST (Continued) PART NUMBER DESCRiPTiON PART NO. DESCRiPTiON 285-2 LA-1704-1 Flywheel Label (Model 919.174212) 265-9 LA-1659-1 End plate Label (Model 919.174311) 265-23 LA-1700 Needle bearing Label (Model 919.174410) * 79 265-13 LA-1660 End plate gasket Label (Model 919.174320) 265-1 Crankshaft SS-2071 Nipple 1/4"NPT x 11/2"... -

Page 14: Troubleshooting Guide

TROUBLESHOOTING GUIDE WARNING PERFORMmNG TROUBLESHOOTING OR REPAIRS MAY EXPOSE VOLTAGE SOURCES, MOVmNG PARTS, OR COM- PRESSED AiR SOURCES. PERSONAL iNJURY MAY OCCUR iF EXPOSED, PRIOR TO ATTEMPTING TROUBLESHOOTING OFt REPAIRS, THE COMPRESSOR MUST BE DmSCONNECTED FROM THE POWER SOURCE. NEVER OPERATE THE OUTFmT WITH THE BELT GUARD REMOVED. THE BELT GUARD SHOULD BE REMOVED ONLY WHEN THE POWER CORD IS DISCONNECTED. - Page 15 TROUBLESHOOTING GUIDE (Continued) PROBLEM CAUSE CORRECTION Air Leaks Tube or hose fittings loose. Tighten fittings with audible leak and check fittings under pressure with soapy water solution. (Do not overtighten). Defective check valve. A defective check valve results in a constant air leak at the pressure release valve...

-

Page 16: How To Order Repair Parts

Sears l OWNERS MANUAL COMPRESSOR SERVICE MODEL NOS. 919.174212 919.174311 919.174320 Now that you have purchased your Sears Air Compressor, should a need ever exist for repair parts or service, simply contact any Sears 919.174410 Service Center and most Sears, Roebuck and Co. stores. Be sure to provide all pertinent facts when you call or visit.