Table of Contents

Advertisement

Available languages

Available languages

Owner's

Manual

CRRFr MRH

1.5 Horsepower

(continuous

duty)

2 Horsepower

(maximum

developed)

3450 R.P.M. (no load R.P.M.)

10-in.

LE SAW

Model No.

152.221140

CAUTION:

FOR YOUR OWN SAFETY;

Read

and follow all of the Safety and

Operating

Instructions

before

Operating

this Table Saw.

Customer Helpline

1-800-897-7709

Please have your Model No.

and Serial No. available.

Sears, Roebuck

and Co., Hoffman

Estates,

IL 60179 U.S.A.

Part No. OR91551

Revision:

D

Espa5ol

pg. 49

Advertisement

Table of Contents

Summary of Contents for Craftsman 152.221140

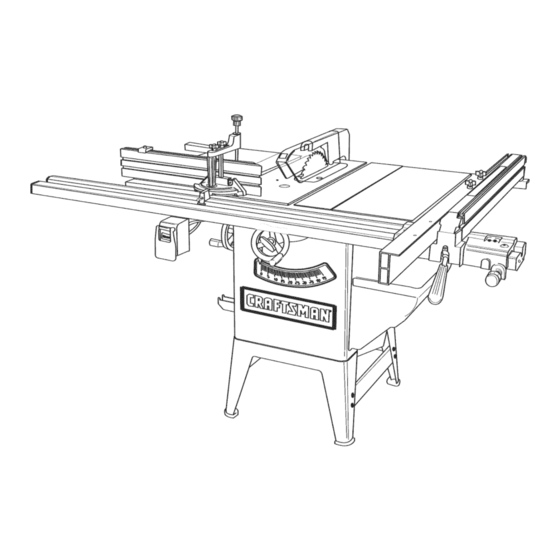

- Page 1 Owner's Manual CRRFr MRH 1.5 Horsepower (continuous duty) 2 Horsepower (maximum developed) 3450 R.P.M. (no load R.P.M.) 10-in. LE SAW Model No. 152.221140 CAUTION: Customer Helpline FOR YOUR OWN SAFETY; Read 1-800-897-7709 and follow all of the Safety and Operating Instructions before Please have your Model No.

- Page 2 SECTION PAGE Warranty ..................................Product Specifications ..............................Glossary of Terms ................................Safety instructions ................................. Guidelines for Extension Cords ........................... Grounding instructions ..............................Specific Safety instructions for Table Saw ........................Accessories and Attachments ............................Carton Contents ................................Know Your Table Saw ..............................Assembly instructions ..............................

- Page 3 Anti-Kickback F ingers - Asafety device attached t othe Kerf- Thematerial removed b ytheblade inthework- blade guard andsplitter a ssembly designed t ostopa piece during anycutting operation. workpiece frombeing thrown backduring a cutting opera- tion. Kickback - When theworkpiece is thrown back towards theoperator during a cutting operation when theworkpiece Arbor- Theshaft o nwhich theblade or accessory cut- initially c ontacts t heblade orif theworkpiece pinches t he...

- Page 4 GENERAL SAFETY INSTRUCTIONS ALWAYS WEAR EYE PROTECTION. Any power tool can throw debris into the eyes during opera- Operating a Table Saw can be dangerous if safety and tions, which could cause severe and permanent common sense are ignored. The operator must be eye damage.

- Page 5 20. EACH GUIDELINES AND EVERY TIME, CHECK FOR DAM= AGED PARTS PRIOR TO USING THE TOOL. EXTENSION CORDS Carefully check all guards to see that they operate properly, are not damaged, and perform their The smaller the gauge-number, the larger diameter of intended functions.

- Page 6 THIS TOOL MUST BE GROUNDED WHILE IN USE USE ONLY A 3-WIRE EXTENSION CORD THAT HAS TO PROTECT THE OPERATOR FROM ELECTRIC A 3-PRONG GROUNDING PLUG AND A 3-POLE SHOCK. RECEPTACLE THAT ACCEPTS THE TOOL'S PLUG. IN THE EVENT OF A MALFUNCTION OR BREAK- REPLACE A DAMAGED OR WORN CORD IMMEDI- ATELY.

- Page 7 It is also necessary to replace the 120 volt plug, sup- MAKE CERTAIN that masks or respirators are plied with the motor, with a UL/CSA Listed plug suitable MSHA/NIOSH approvedl. for 240 volts and rated current of the saw. Contact a The operation of any Table Saw can result in debris local qualified electrician for proper procedures to install being thrown into your eyes, which can result in severe...

- Page 8 14. TheTable Sawis designed f orhomeuseor light 27. NEVER perform layout, a ssembly orset-upworkon commercial dutyONLY. thetable/work a reawhenthemachine is running. 15. CONNECT T able Sawtoa properly grounded o utlet NEVER reset the thermal-overload button before only. S eegrounding instructions. you have turned the table saw "OFF".

- Page 9 AVAILABLE ACCESSORIES Sears may recommend other accessories not listed in this manual. Visit your Sears Hardware Department or see the Sears Power and Hand Tool Catalog for the following acces- See your nearest Sears Hardware Department or Sears sories. Power and Hand Tool Catalog for other accessories. ITEM STOCK NUMBER * Auxiliary Fence, Rip Fence...

- Page 10 CONSTRUCTING A PUSHSTICK When ripping work less than 4 inches wide, a pushstick should be used to complete the feed and could easily be made from scrap material by following the pattern shown in figure 2C. Fig. 2C The Pushstick should be made of 3/4 or 1/2 inch wood or a thickness less than the width of the workpiece to be cut.

- Page 11 UNPACKING AND CHECKING CONTENTS Fig. 3=1 The table saw is a heavy machine, two people are required to unpack and lift the table saw. This table saw will require some amount of assembly. The table saw and fence is shipped in one carton. This carton also contains a box of saw parts.

- Page 12 Fig. 3=2 FENCE 20. Auxiliary fence 21. Rip fence assembly 22. Fence front rail, right 23. Fence front rail, left 24. Fence rear rail (2) 25. Clamp knob with special nut (2) 26. Micro-Adjust assembly 27. Fence rear rail connector 28.

- Page 13 Fig. 3-4 GX GAD _W _'_ x t_'_ SDC_T _RE W _ _ci_ rL^l ¥_r ©I ©I Ore, RInD GAD _Lr-W_ 0===_ GAD _Lr-l._ w _ _ 1_',_ LDL__e _i_" Hardware packs are not identified or labeled. See hardware diagram to help in finding the correct part. See figure 3-4. •...

- Page 14 10. Rear rail 19. Rubber foot 1. Splitter assembly 2. Blade guard 11. Auxiliary fence 20. Blade height handwheel 12. Front rail with scale 21. Handwheel lock knob 3. Anti-kickback fingers 4. Blade 22. Fence hook 13. Micro Adjustment knob 23.

- Page 15 TOOLS REQUIRED Attach two tie bars (F) inside and between front and rear legs already attached to the cabinet with (G) The following tools are needed for assembly and align- ment. Note: Two blade wrenches and five hex wrenches eight 5/16-18 x 5/8" carriage head screws, 5/16" flat washers, 5/16"...

- Page 16 POLY=V BELT ASSEMBLY CAUTION: The extension wings are heavy; two people are required to assemble both extension wings to the table saw. MAKE CERTAIN the table saw is disconnected from Assemble one of the extension wings (A) to the left the power source.

- Page 17 Placeoneofthehandwheels ( A)ontotheshaft(B) Assemble both of the fence hooks (A) to the left ofthebevel s haftlocated onthesideofthecabinet. side of the cabinet (B) using four M4 x 8mm sheet Alignthegroove (C)in thebackofthehandwhee[ metal screw, not shown. See figure 9-1. withthepin(D)through theshaft. Seefigure8-1. Assemble the wrench hook (C) above the fence hooks using two M4 x 8mm sheet metal screws, not Figure...

- Page 18 Figure 10=3 Figure 10=5 Place the front attachment point (D) of the blade Place a square (N) onto the saw table and against guard and splitter assembly (H) down into the tool- the splitter assembly (0) behind the kickback less front attachment point (E) and the rear attach- fingers (P).

- Page 19 RiP FENCE ASSEMBLY Slide the heads of four M8 x 35mm square head screws (F), two from each end of the front rail into the front rail. Note: The front rail is still positioned upside down on the saw table. Position the screws MAKE CERTAIN the table saw is disconnected from so that they will align with the two holes in the front the power source.

- Page 20 Figure 11=6 Figure 11=4 11. Slide the right side rear rail (T) onto rear rail con- nector. Assemble the right rear rail with two M8 x 25mm button head cap screws to the saw table and one M8 x 35mm button head cap screw, M8 flat Using a combination square (K), make sure the washer, M8 lock washer and M8 hex nut to the front rail (L) is level across the saw table and exten-...

- Page 21 17.Assemble t hecursor(U)to the right s ideoffence AUXILIARY FENCE ASSEMBLY crossarmwithtwoM5x 16mmpanheadscrews andM5lockwashers (W).Donotcompletely t ight- enscrews. S eefigure11-7. ALWAYS position auxiliary fence at least 2-inches in 18.Aligncursorwiththescale(Z)sothatthethinblack front of the saw blade when using auxiliary fence as a line(Y)is onthesamenumber a sthedistance stop when crosscutting.

- Page 22 ON/OFF SWITCH Place the left front rail end cap (A) into the end of END CAP ASSEMBLY the front rail (B). Attach end cap to rail with two M4 x 16mm pan head self-tapping screws (C). See figure 14-2. Repeat step above to attach right side front rail MAKE CERTAIN the table saw is disconnected from end cap.

- Page 23 MITER GAUGE ASSEMBLY Figure 16=2 MAKE CERTAIN the table saw is disconnected from the power source. Figure 16=1 Slide both of the square nuts with hex socket head cap screws and flat washer (F) into the lower T-slot (G) of the cross cut fence (H). See figure 16-2. Place the thread section of the hex socket head screws into the grooves (I) of the miter gauge body.

- Page 24 BOLTING TABLE SAW TO THE FLOOR MAKE CERTAIN the table saw is disconnected from the power source. If you wish, the table saw can be permanently mounted to the floor. To attach to the floor, see instructions below. Figure 15A=1 Remove the four rubber footpads (A) from the table saw legs (B).

- Page 25 CAUTION LOCKING ON/OFF SWITCH • A separate electrical circuit should be used for your When the table saw is not in use, the "ON" button table saw. The table saw comes pre-wired for 120-volt should be locked so that it cannot be started. use.

- Page 26 Tolower thesawblade,loosen thehandwheel lock If the blade will not tilt to 90-degree, turn (counter- knob(counterclockwise) andturnthe handwheel clockwise) the set screw (C) in the left hand side of counterclockwise. Whenthesawbladeisat itsdesired the saw table until the blade can be positioned to height, t ighten thehandwheel lockknob(clockwise) 90-degrees.

- Page 27 1. Raise the saw blade to its highest point. Fig. 20=1 2. Place a combination square (A) on the saw table with one edge (B) of the square against the left miter slot (C). See Figure 20A-1. 3. Adjust the square so the rule (D) just touches the saw blade about 1 inch in from the outer diameter.

- Page 28 RIP FENCE OPERATIONS Figure 20B=1 AND ADJUSTMENTS MAKE CERTAIN the table saw is disconnected from the power source. The rip fence can be used on either side of the saw blade. The most common location is on the right hand side.

- Page 29 Figure 21A-1 Figure 21A=3 Make sure that the nylon set screws (A) and nylon Make sure there is a consistent gap between the glide pads (B) are in place and are not damaged, bottom of the fence (F) and the saw table (G). This gouged or have sharp edges.

- Page 30 ADJUSTING RiP FENCE PARALLEL: Figure 21A-5 To adjust the rip fence parallel to the miter gauge Clean and wax groove, position the rip fence (B) along the right side (C) of the right hand miter gauge groove and lock the fence. The rip fence should be parallel to the miter gauge groove.

- Page 31 REARHOLD-DOWN CAUTION It is necessary when performing special operations Tominimize theamount t he rearofthefence(K) such as moulding, to add wood facing (A) to one or comes offthesawtable,simply flipdowntherear both sides of the rip fence (B). A 3/4-inch facing to the holddown(L)sothatit is under the rearrail.This rip fence is suitable for most work although an occa- limitstheamount t hattherearofthefencewilllift.

- Page 32 TABLE iNSERT ADJUSTMENT Figure 25=1 MAKE CERTAIN the table saw is disconnected from the power source when making adjustments. Figure 24=1 "A Make sure switch is "OFF" and disconnect power The table insert (A) must always be level with the saw table (B).

- Page 33 CHANGING THE SAW BLADE Figure 26A=1 • Turn the power switch "OFF" and unplug the power cord from its power source when changing the saw blade. • USE ONLY 10-in. diameter blades with 5/8-in. arbor holes, rated at or higher than 3800 R.P.M. Figure 26=1 To adjust front splitter bracket (A), loosen the two...

- Page 34 MITER GAUGE OPERATION Push in plunger and make adjustments to stop AND ADJUSTMENT screw (G) so that it touches the plunger and tighten lock nut. See figure 27-2. Recheck the positive stop angle to the saw blade. MAKE CERTAIN the table saw is disconnected from Insert the guide bar into the miter gauge groove and slide the miter gauge up to the saw blade.

- Page 35 29=2 Crosscutting requires the use of the miter gauge (A) to position and guide the workpiece (B). See figure 24-1. The use of non-Craftsman attachments and acces- sories may result in risk of injury or damage to the table saw.

- Page 36 Ripping is the operation of making a cut with the grain of the workpiece; the rip fence (A) is used to position An accessory Craftsman Fence Guide can be purchased and guide the workpiece. Since the workpiece is to assist when making narrow cuts. See "ACCESSOR- IES AND ATTACHMENTS"...

- Page 37 DADO BLADE Dado blades and chippers have a set to their teeth. The teeth of the dado blades and chippers must be arranged so that the set of each tooth overlaps the next tooth. The set of the dado blade (C) and chipper (D) The blade guard and splitter assembly cannot be used overlap as shown in Figure 31-3.

- Page 38 Figure 31=5 • The blade guard and splitter assembly cannot be used when dadoing or molding and must be swung to the rear of the saw. Blade guard must be reassem- bled when finished. Figure 32=2 Figure 31-5, shows a typical dado operation using the miter gauge.

- Page 39 Position thewoodfacingoverthecutterhead w iththe CAUTION cutterhead b elowthesurface ofthetable. Turnthesaw When molding end grain, the miter gauge must be onandraisethecutterhead s lowly.Thecutterhead w ill used. The feed should be slowed up at the end of cutitsowngroove inthewoodfacing. the cut to prevent splintering In all cuts, pay attention to the grain, making the cuts in the same direction as the grain whenever possible.

- Page 40 LUBRiCATiON The table saw has sealed lubricated bearings in the Only trained personnel should perform repairs to the motor housing that do not require any additional lubrica- table saw. Contact your nearest Sears Service Center tion from the operator. for authorized service. Unauthorized repairs or replace- ment with non-factory parts could cause serious injury CLEANING...

- Page 41 TOPREVENT I NJURY TO YOURSELF or damage to the table saw, turn the power switch to the "OFF" position and unplug the power cord from the electrical receptacle before making any adjustments. PROBLEM LIKELY CAUSE(S) SOLUTION Motor does not Switch not pressed in far enough or switch Depress switch in 1/2 inch or make sure switch is in the start: in the "OFF"...

- Page 42 1O-IN. T ABLE MODEL NO.152.221140 When servicing, use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause product damage. Any attempt to repair or replace electrical parts on this table saw may create a HAZARD unless a qualified service technician does repairs.

- Page 43 STD852008 LOCK WASHER M8 OR91168 FENCE TOP STD851008 FLAT WASHER M8 405A OR91570 OR91173 DUST CHUTE WELDMENT CRAFTSMAN LABEL, VERTICLE OR91169 FENCE END CAP OR91179 TIE BAR 406A OR91764 HEX SOCKET SET SCREW M5 x 10ram OR91181 CARRIAGE HEAD SCREW 5/16-18 x 5/8"...

- Page 44 >...

- Page 46 406B 411A 445 (8; 459_ 438(2)_ 435_ 434_ 433(2) 432, 419D 420A...

- Page 47 501D 501A 503(3) 504--- 529A(2) 529(6)\ 527\_ 502B /505(4-) 502A(4.)-_ 506(2) 501C "-4 501B I'll...

- Page 48 ,_ NOTES ,_...

- Page 49 anuai dei Proprietario CRRFr MRH 1.5 caballos de fuerza (servicio continuo) 2 caballos de fuerza (ma×imo desarrollado) 3450 R.P.M. (R.P.M. sin carga) de 1 puig. No. de Modelo 152.221140 Linea de Ayuda al Cliente PRECAUCION: 1-800-897-7709 PARA SU SEGURIDAD PERSONAL: Lea y obedezca todas las Instrucciones Sirvase toner listo su...

- Page 50 SECCION P._GINA Garantfa ....................................... Especificaciones del producto ................................GIosario de terminos ................................... Instruccienes de seguridad ................................. Directrices para las extensiones electricas ............................Instrucciones de conexi6n a tierra ..............................Instrucciones especificas de seguridad para las sierras de mesa ..................... Accesorios y aditamentos ...................................

- Page 51 Alefriz - Muesca cuadrada en el borde del material. Fresa rotativa de ranurar - Corte no directo que produce una muesca cuadrada. Una fresa rotativa tiene, tfpicamente, Contragolpe - Cuando el material es arrojado hacia el oper- un ancho de 1/8 a 13/16 pulg. Una fresa rotativa requiere un ario durante una operaci6n de corte en el memento que el conjunte especial de hojas que no estan incluidas con esta material hace contacto inicial con la hoja, o si el material hace...

- Page 52 INSTRUCCIONES GENERALES UTILICE PROTECClON OCULAR SIEMPRE. Cualquier herramienta mecanica puede arrojar escombros hacia los SEGURIDAD ojos durante el funcionamiento, pudiendo esto resultar en El funcionamiento de una Sierra de Mesa puede resultar heridas oculares graves y permanentes. Los anteojos de peligroso si se hace caso omiso de la seguridad y del sentido uso cotidiano NO son gafas de seguridad.

- Page 53 20. REVISE SI HAY PIEZAS DAI_IADAS ANTES DE CADA DIRECTRICES PARA LAS EXTENSIONES USO DE LA HERRAMIENTA. Revise todos los protec- ELECTRICAS tores cuidadosamente para comprobar que funcionan correctamente y que no estan da_ados, y que realizan Mientras menor sea el n0mero de calibre, mayor sera el sus funciones diseRadas correctamente.

- Page 54 REPONGA CUALQUIER CORDON DAI_IADO O GASTADO ESTA HERRAMIENTA DEBE ESTAR CONECTADA TIERRA DURANTE EL USO PARA PROTEGER AL INMEDIATAMENTE. OPERARIO CONTRA LOS CHOQUES ELleCTRICOS. PARA LAS M,_QUINAS CONECTADAS A TIERRA Y CON EN EL CASO DE UN MALFUNCIONAMIENTO O AVERiA, la CORDON DISEhlADAS PARA EL USO EN UN CIRCUITO conexi6n a tierra ofrece el trecho de menor resistencia para la...

- Page 55 ASEGURESE de que las mascaras o respiradores tienen Tambien serA necesario reemplazar el enchufe de 120 voltios suministrado con el motor por un enchufe clasificado por aprobaci6n MSHA / NIOSH. UL/CSA come apropiado para los 240 voltios y la corriente clasificada de la sierra.

- Page 56 27. JAMAS realice labores de trazado, ensamblado o men- 14. La Sierra de Mesa esta diseRada para el use dom4stico o el use comercial ligero SOLAMENTE. taje sobre la mesa / zona de trabaje cuande la maquina se encuentre en funcionamiento. 15.

- Page 57 ACCESORIOS DISPONiBLES Sears podrarecomendarotros accesorios nolistados en este manual. Visite su Departamento de Ferreterfa de Sears o consulte el Catalogo de Herramientas Electricas y de Mano de Sears Consulte su Departamento de Ferreterfa de Sears mas para los siguientes accesorios: cercano o el Catalogo de Herramientas Electricas y de Mano de Sears para otros accesorios.

- Page 58 CONSTRUYENDO UNA VARA DE EMPUJE Durante el corte a Io largo de materiales con menos de 4 pulgadas de ancho, se debe hacer uso de una vara de empuje para com- pletar la alimentaci6n. Puede construirse f_cilmente utilizando material descartado y siguiendo el patr6n ilustrado en la Figura 2C. Fig.

- Page 59 DESEMPACANDO Y REV[SANDO Fig. 3=1 EL CONTEN[DO La sierra de mesa es una maquina pesada. Se requieren dos personas para desempaquetarla y levantar la sierra de mesa. Esta sierra de mesa requerira cierta cantidad de ensamblado. Esta sierra de mesa y su gufa se envfan en una sola caja. Esta caja tambien incluye una caja de piezas para la sierra.

- Page 60 Fig. 3=2 GUiA 20. Gufa auxiliar 21. Ensamblado de la gufa de corte a Io largo 22. Riel delantero de la gufa, derecho 23. Riel delantero de la gufa, izquierdo 24. Riel trasero de la gufa (2) 25. Perilla de abrazadera tuerca especial (2) 26.

- Page 61 Fig. 3=4 TORNILLO DE CABEZAHEXM6 x 12 mm TUERCAHEX TUERCAHEX TORNILLO DE CABEZAHEXM8 x 1.25x 25 mm M8 x 1.25 5/16pulg.-18 © U El TORNILLO DE CABEZAHEXM8 x 1.25x 30 mm TORNILLODECABEZAHUECAHEX TUERCA TUERCA M5 x 20 mm CUADRADA M6 CUADRADA M5 TORNILLO DE CABEZACUADRADA M8 x 1.25 x 35 mm ©...

- Page 62 1. Ensamblado del hendidor 10. Riel trasero 20. Volante de mano de elevaci6n de hoja 11. Gufa auxiliar 2. Protector de hoja 21. Perilla de cierre del volante de 12. Riel delantero con escala 3. Dedos anticontragolpe mano 4. Hoja 13.

- Page 63 HERRAMIENTAS REQUERIDAS Conecte dos tirantes de tracci6n (F) por dentro y entre las patas delanteras y traseras ya conectadas al gabinete Se requieren las siguientes herramientas para el montaje y el con (G) echo pernos de carrocerfa 5/16-18 x 5/8 pulg., alineamiento.

- Page 64 MONTAJE DE LA CORREA POLY-V PRECAUCION: Las alas de extensi6n son pesadas. Se requieren dos personas para ensamblar ambas alas de extensi6n a la sierra de mesa. Monte una de las alas de extensi6n (A) al lado izquierdo ASEGORESE de que la sierra de mesa este desconectada de la sierra de mesa.

- Page 65 Coloque uno de los volantes de mano (A) sobre el eje de Monte ambos ganchos de guia (A) al lado izquierdo del biselado (B) Iocalizado en el lado del gabinete. La ranura gabinete (B) usando cuatro tornillos de chapa metalica (C) en el dorso del volante debe alinearse con el pasador M4 x 8 mm, no ilustrados.

- Page 66 Figura 10=3 Figura 10=5 Coloque el punto de conexi6n delantero (D) del protector de hoja y del ensamblado del hendidor (H) sobre el punto Coloque una escuadra (N) sobre la mesa de la sterra y de conexi6n delantero que carece de herramientas (E). contra el ensamblado del hendidor (O) detras de los Coloque la ranura de conexi6n trasera (F) sobre las...

- Page 67 MONTAJE DE LA GU[A DE CORTE Deslice las cabezas de los cuatro tornillos de cabeza hexagonal M8 x 35 mm (F), dos de cada extreme del riel A LO LARGO delantero, al interior del riel delantero. Aviso: El riel delantero a0n sigue posicionado boca abajo sobre la sierra de mesa.

- Page 68 Figura 11-4 Figura 11-6 12. Utilizando una escuadra de combinaciones, asegurese de que el riel trasero este nivelado con la mesa de la Usando una escuadra de combinaciones (K), asegurese sierra, y que las alas de extensi6n est_n per debajo del de que el riel delantero (L) este nivelado sobre la sierra fondo de las ranuras de la escuadra de ingletes.

- Page 69 ENSAMBLADO DE LA GU[A AUX[L[AR 17. Monte el cursor (U) al lado derecho de la cruceta de la gufa con dos tornillos de cabeza troncoc6nica M5 x 16 mm y arandelas de cierre M5 (W). No apriete los tornillos del todo. Ver la figura 11-7. POSICiONE siempre la gu[a auxiliar al menos 2 pulgadas al 18.

- Page 70 INTERRUPTOR DE ENCENDIDO/APAGADO Coloque el tap6n de extremo del riel delantero izquierdo (A) dentro del extremo del riel delantero (B). Conecte el Y ENSAMBLADO DEL TAP(_N DE tap6n de extremo al riel con dos tornillos autoroscadores EXTREMOS de cabeza troncoc6nica M4 x 16 mm (C).

- Page 71 MONTAJE DE LA ESCUADRA Figura 16-2 [NGLETES ASEGORESE de que la sierra de mesa este desconectada de la fuente de energfa. Figura 16-1 Deslice ambas tuercas cuadradas con el tornillo de cabeza hueca hexagonal y arandela plana (F) hacia la ranura en "T"...

- Page 72 EMPERNANDO LA SIERRA DE MESA AL PiSO ASEGURESE de que la sierra de mesa este desconectada de la fuente de energfa. Si Io desea, la sierra de mesa puede montarse al piso de forma permanente. Para conectarla al piso, consulte las sigu- ientes instrucciones: Fig.

- Page 73 PRECAUCI(_N ENCLAVANDO EL INTERRUPTOR ENCENDIDO/APAGADO Debe hacerse use de un circuito electrico individual para su sierra de mesa. La sierra de mesa viene cableada de Cuando la sierra de mesa no se encuentre en uso, el antemano para el funcionamiento a 120 voltios.

- Page 74 Para bajar la hoja de la sierra, afloje la perilla de cierre del Si la hoja no se inclina a 90 grados, gire el tornillo de volante de mane (en sentido antihorario) y gire el volante de fijaci6n (C) (en sentido antihorario) al lado izquierdo de la mane en sentido antihorario.

- Page 75 Eleve la hoja de la sierra a su punto m_s alto. Figura 20-1 Coloque una escuadra de combinaciones (A) sobre la mesa de la sierra con uno de los bordes (B) de la escuadra contra la ranura de ingletes izquierda (C). Ver figura 20A-1.

- Page 76 OPERACIONES Y AJUSTES DE LA GUiA Figura 20B=1 DE CORTE A LO LARGO ASEGURESE de que la sierra de mesa este desconectada de la fuente de potencia. La guia de corte a Io largo puede set utilizada a cada lado de la hoja de la sierra.

- Page 77 Figura 21A-1 Figura 21A-3 AsegL]rese de que los tornillos de fijaci6n de nylon (A) y las almohadillas de deslizamiento de nylon (B) esten en Asegt_rese de que exista un espacio libre consistente sus sitios y que no esten da5adas, ranuradas o con bor- entre el fondo de la gufa (F) y la mesa de la sierra (G).

- Page 78 AJUSTANDO LA GUJA DE CORTE A LO LARGO Figura 21A-5 PARALELAMENTE: Para ajustar la gufa de corte a Io largo en paralelo con la Limpiar y encerar ranura de la escuadra de ingletes, posicione la gu(a de corte a Io largo (B) a Io largo del lade derecho (O) de la ranura de la escuadra de ingletes derecha y enclave la guia.

- Page 79 RETEN TRASERO: PRECAUCION Durante la realizaci6n de operaciones especiales, come el Para reducir al mfnimo la cantidad en que la gu/a (K) se corte de moldaduras, resulta necesario afiadir un refrentado separa de la mesa de la sierra, sencillamente vire el de madera (A) a uno e ambos lados de la guia de corte ale reten posterior (L) hacia debajo de manera que quede largo (B).

- Page 80 AJUSTE DE LA PIEZA DE INSERCI(_N Figura 25=1 DE MESA ASEGURESE de que la sierra de mesa este desconectada de la fuente de potencia. Figura 24=1 Asegurese de que el interruptor este "APAGADO" y desconecte el eord6n de energ[a de la fuente de energ[a. La pieza de inserci6n de mesa (A) debe estar nivelada siempre con la mesa de la sierra (B).

- Page 81 CAMBIANDO LA HOJA DE LA SIERRA Figura 26A=1 • Conmute el interruptor de energ[a a APAGADO y des- enchufe el cord6n de potencia de su fuente de potencia mientras que efectua el recambio de la hoja de la sierra. SOLO UTlUCE hojas con diametro de 10 pulg.

- Page 82 OPERAC[ON Y AJUSTE DE LA ESCUADRA Empuje el embolo hacia adentro y haga ajustes al tornillo de parada (G) de manera que toque el embolo, apretan- DE [NGLETES do la tuerca de cierre despues. Ver la figura 27-2. Vuelva a revisar el angulo del tope positive con la hoja de la sierra.

- Page 83 (A) para posicionar y guiar el material (B). Ver la figura 29-1. El uso de aditamentos y accesorios que no sean de Craftsman podrb, resultar en el riesgo de lesiones al usuario o dare a la sierra de mesa. Figura...

- Page 84 Figure 30-2 Figura 30-1 Puede comprarse una Gufa Craftsman de accesorio como ayuda cuando vaya a efectuar cortes angostos. Vea la El corte a Io largo es la operaci6n de realizar un corte en secci6n "ACCESORIOS Y ADITAMENTOS"...

- Page 85 CONJUNTO DE FRESAS ROTATIVAS Los dientes de las fresas rotativas y las astilladoras tienen gradaci6n. Los dientes de las fresas rotativas y las astillado- RANURAR ras deben estar dispuestas de tal forma que la gradaci6n de cada diente este solapada con la del pr6ximo diente. Las gradaciones de la fresa rotativa (C) y la astilladora (D) se solapan como se ilustra en la Figura 26-3.

- Page 86 Figura 31-5 El protector de hoja y el ensamblado del hendidor no pueden utilizarse durante el fresado o el moldurado y deben bascu- larse hacia la parte trasera de la sierra. El protector de hoja debe reensamblarse cuando haya terminado. Figura 32-2 La Figura 31-5 muestra una operaci6n tfpica de fresado...

- Page 87 PRECAUCI6N Posicione el refrentado de madera sobre el cabezal de corte con el cabezal de corte per debajo de la superficie de la • Durante el moldurado a contrahilo debe hacerse uso de la mesa. Encienda la sierra y eleve el cabezal de corte lenta- escuadra de ingletes.

- Page 88 LUBRICACK_N La sierra de mesa tiene cojinetes lubricados sellados en la S61o personal competente debe realizar reparaciones a la carcasa del motor que no requieren lubricaci6n adicional per sierra de mesa. Comun[quese con su Centre de Servicio parte del operario. Sears mas cercano para obtener servicio autorizado.

- Page 89 Para evitar herirse a si mismo o daRar la sierra de mesa, conmute el interrupter de energfa a "APAGADO" y desenchufe el cord6n de potencia del tomacorrientes antes de realizar cualquier ajuste. PROBLEMA CAUSAS POSIBLES SOLUCION Motor no arranca: 1. Interruptor no fue oprimido a suficiente profundidad Presione...

- Page 90 ,_ NOTAS ,_...

- Page 92 Your Home For repair - in your home - of all major brand appliances, ........lawn and garden equipment, or heating and cooling systems, ....no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself.

- Page 93 Owner's Manual CRRFr MRH 1.5 Horsepower (continuous duty) 2 Horsepower (maximum developed) 3450 R.P.M. (no load R.P.M.) 10-in. LE SAW Model No. 152.221140 CAUTION: Customer Helpline FOR YOUR OWN SAFETY; Read 1-800-897-7709 and follow all of the Safety and Operating Instructions before Please have your Model No.

- Page 94 SECTION PAGE Warranty ..................................Product Specifications ..............................Glossary of Terms ................................Safety instructions ................................. Guidelines for Extension Cords ........................... Grounding instructions ..............................Specific Safety instructions for Table Saw ........................Accessories and Attachments ............................Carton Contents ................................Know Your Table Saw ..............................Assembly instructions ..............................

- Page 95 Anti-Kickback F ingers - Asafety device attached t othe Kerf- Thematerial removed b ytheblade inthework- blade guard andsplitter a ssembly designed t ostopa piece during anycutting operation. workpiece frombeing thrown backduring a cutting opera- tion. Kickback - When theworkpiece is thrown back towards theoperator during a cutting operation when theworkpiece Arbor- Theshaft o nwhich theblade or accessory cut- initially c ontacts t heblade orif theworkpiece pinches t he...

- Page 96 GENERAL SAFETY INSTRUCTIONS ALWAYS WEAR EYE PROTECTION. Any power tool can throw debris into the eyes during opera- Operating a Table Saw can be dangerous if safety and tions, which could cause severe and permanent common sense are ignored. The operator must be eye damage.

- Page 97 20. EACH GUIDELINES AND EVERY TIME, CHECK FOR DAM= AGED PARTS PRIOR TO USING THE TOOL. EXTENSION CORDS Carefully check all guards to see that they operate properly, are not damaged, and perform their The smaller the gauge-number, the larger diameter of intended functions.

- Page 98 THIS TOOL MUST BE GROUNDED WHILE IN USE USE ONLY A 3-WIRE EXTENSION CORD THAT HAS TO PROTECT THE OPERATOR FROM ELECTRIC A 3-PRONG GROUNDING PLUG AND A 3-POLE SHOCK. RECEPTACLE THAT ACCEPTS THE TOOL'S PLUG. IN THE EVENT OF A MALFUNCTION OR BREAK- REPLACE A DAMAGED OR WORN CORD IMMEDI- ATELY.

- Page 99 It is also necessary to replace the 120 volt plug, sup- MAKE CERTAIN that masks or respirators are plied with the motor, with a UL/CSA Listed plug suitable MSHA/NIOSH approvedl. for 240 volts and rated current of the saw. Contact a The operation of any Table Saw can result in debris local qualified electrician for proper procedures to install being thrown into your eyes, which can result in severe...

- Page 100 14. TheTable Sawis designed f orhomeuseor light 27. NEVER perform layout, a ssembly orset-upworkon commercial dutyONLY. thetable/work a reawhenthemachine is running. 15. CONNECT T able Sawtoa properly grounded o utlet NEVER reset the thermal-overload button before only. S eegrounding instructions. you have turned the table saw "OFF".

- Page 101 AVAILABLE ACCESSORIES Sears may recommend other accessories not listed in this manual. Visit your Sears Hardware Department or see the Sears Power and Hand Tool Catalog for the following acces- See your nearest Sears Hardware Department or Sears sories. Power and Hand Tool Catalog for other accessories. ITEM STOCK NUMBER * Auxiliary Fence, Rip Fence...

- Page 102 CONSTRUCTING A PUSHSTICK When ripping work less than 4 inches wide, a pushstick should be used to complete the feed and could easily be made from scrap material by following the pattern shown in figure 2C. Fig. 2C The Pushstick should be made of 3/4 or 1/2 inch wood or a thickness less than the width of the workpiece to be cut.

- Page 103 UNPACKING AND CHECKING CONTENTS Fig. 3=1 The table saw is a heavy machine, two people are required to unpack and lift the table saw. This table saw will require some amount of assembly. The table saw and fence is shipped in one carton. This carton also contains a box of saw parts.

- Page 104 Fig. 3=2 FENCE 20. Auxiliary fence 21. Rip fence assembly 22. Fence front rail, right 23. Fence front rail, left 24. Fence rear rail (2) 25. Clamp knob with special nut (2) 26. Micro-Adjust assembly 27. Fence rear rail connector 28.

- Page 105 Fig. 3-4 GX GAD _W _'_ x t_'_ SDC_T _RE W _ _ci_ rL^l ¥_r ©I ©I Ore, RInD GAD _Lr-W_ 0===_ GAD _Lr-l._ w _ _ 1_',_ LDL__e _i_" Hardware packs are not identified or labeled. See hardware diagram to help in finding the correct part. See figure 3-4. •...

- Page 106 10. Rear rail 19. Rubber foot 1. Splitter assembly 2. Blade guard 11. Auxiliary fence 20. Blade height handwheel 12. Front rail with scale 21. Handwheel lock knob 3. Anti-kickback fingers 4. Blade 22. Fence hook 13. Micro Adjustment knob 23.

- Page 107 TOOLS REQUIRED Attach two tie bars (F) inside and between front and rear legs already attached to the cabinet with (G) The following tools are needed for assembly and align- ment. Note: Two blade wrenches and five hex wrenches eight 5/16-18 x 5/8" carriage head screws, 5/16" flat washers, 5/16"...

- Page 108 POLY=V BELT ASSEMBLY CAUTION: The extension wings are heavy; two people are required to assemble both extension wings to the table saw. MAKE CERTAIN the table saw is disconnected from Assemble one of the extension wings (A) to the left the power source.

- Page 109 Placeoneofthehandwheels ( A)ontotheshaft(B) Assemble both of the fence hooks (A) to the left ofthebevel s haftlocated onthesideofthecabinet. side of the cabinet (B) using four M4 x 8mm sheet Alignthegroove (C)in thebackofthehandwhee[ metal screw, not shown. See figure 9-1. withthepin(D)through theshaft. Seefigure8-1. Assemble the wrench hook (C) above the fence hooks using two M4 x 8mm sheet metal screws, not Figure...

- Page 110 Figure 10=3 Figure 10=5 Place the front attachment point (D) of the blade Place a square (N) onto the saw table and against guard and splitter assembly (H) down into the tool- the splitter assembly (0) behind the kickback less front attachment point (E) and the rear attach- fingers (P).

- Page 111 RiP FENCE ASSEMBLY Slide the heads of four M8 x 35mm square head screws (F), two from each end of the front rail into the front rail. Note: The front rail is still positioned upside down on the saw table. Position the screws MAKE CERTAIN the table saw is disconnected from so that they will align with the two holes in the front the power source.

- Page 112 Figure 11=6 Figure 11=4 11. Slide the right side rear rail (T) onto rear rail con- nector. Assemble the right rear rail with two M8 x 25mm button head cap screws to the saw table and one M8 x 35mm button head cap screw, M8 flat Using a combination square (K), make sure the washer, M8 lock washer and M8 hex nut to the front rail (L) is level across the saw table and exten-...

- Page 113 17.Assemble t hecursor(U)to the right s ideoffence AUXILIARY FENCE ASSEMBLY crossarmwithtwoM5x 16mmpanheadscrews andM5lockwashers (W).Donotcompletely t ight- enscrews. S eefigure11-7. ALWAYS position auxiliary fence at least 2-inches in 18.Aligncursorwiththescale(Z)sothatthethinblack front of the saw blade when using auxiliary fence as a line(Y)is onthesamenumber a sthedistance stop when crosscutting.

- Page 114 ON/OFF SWITCH Place the left front rail end cap (A) into the end of END CAP ASSEMBLY the front rail (B). Attach end cap to rail with two M4 x 16mm pan head self-tapping screws (C). See figure 14-2. Repeat step above to attach right side front rail MAKE CERTAIN the table saw is disconnected from end cap.

- Page 115 MITER GAUGE ASSEMBLY Figure 16=2 MAKE CERTAIN the table saw is disconnected from the power source. Figure 16=1 Slide both of the square nuts with hex socket head cap screws and flat washer (F) into the lower T-slot (G) of the cross cut fence (H). See figure 16-2. Place the thread section of the hex socket head screws into the grooves (I) of the miter gauge body.

- Page 116 BOLTING TABLE SAW TO THE FLOOR MAKE CERTAIN the table saw is disconnected from the power source. If you wish, the table saw can be permanently mounted to the floor. To attach to the floor, see instructions below. Figure 15A=1 Remove the four rubber footpads (A) from the table saw legs (B).

- Page 117 CAUTION LOCKING ON/OFF SWITCH • A separate electrical circuit should be used for your When the table saw is not in use, the "ON" button table saw. The table saw comes pre-wired for 120-volt should be locked so that it cannot be started. use.

- Page 118 Tolower thesawblade,loosen thehandwheel lock If the blade will not tilt to 90-degree, turn (counter- knob(counterclockwise) andturnthe handwheel clockwise) the set screw (C) in the left hand side of counterclockwise. Whenthesawbladeisat itsdesired the saw table until the blade can be positioned to height, t ighten thehandwheel lockknob(clockwise) 90-degrees.

- Page 119 1. Raise the saw blade to its highest point. Fig. 20=1 2. Place a combination square (A) on the saw table with one edge (B) of the square against the left miter slot (C). See Figure 20A-1. 3. Adjust the square so the rule (D) just touches the saw blade about 1 inch in from the outer diameter.

- Page 120 RIP FENCE OPERATIONS Figure 20B=1 AND ADJUSTMENTS MAKE CERTAIN the table saw is disconnected from the power source. The rip fence can be used on either side of the saw blade. The most common location is on the right hand side.

- Page 121 Figure 21A-1 Figure 21A=3 Make sure that the nylon set screws (A) and nylon Make sure there is a consistent gap between the glide pads (B) are in place and are not damaged, bottom of the fence (F) and the saw table (G). This gouged or have sharp edges.

- Page 122 ADJUSTING RiP FENCE PARALLEL: Figure 21A-5 To adjust the rip fence parallel to the miter gauge Clean and wax groove, position the rip fence (B) along the right side (C) of the right hand miter gauge groove and lock the fence. The rip fence should be parallel to the miter gauge groove.

- Page 123 REARHOLD-DOWN CAUTION It is necessary when performing special operations Tominimize theamount t he rearofthefence(K) such as moulding, to add wood facing (A) to one or comes offthesawtable,simply flipdowntherear both sides of the rip fence (B). A 3/4-inch facing to the holddown(L)sothatit is under the rearrail.This rip fence is suitable for most work although an occa- limitstheamount t hattherearofthefencewilllift.

- Page 124 TABLE iNSERT ADJUSTMENT Figure 25=1 MAKE CERTAIN the table saw is disconnected from the power source when making adjustments. Figure 24=1 "A Make sure switch is "OFF" and disconnect power The table insert (A) must always be level with the saw table (B).

- Page 125 CHANGING THE SAW BLADE Figure 26A=1 • Turn the power switch "OFF" and unplug the power cord from its power source when changing the saw blade. • USE ONLY 10-in. diameter blades with 5/8-in. arbor holes, rated at or higher than 3800 R.P.M. Figure 26=1 To adjust front splitter bracket (A), loosen the two...

- Page 126 MITER GAUGE OPERATION Push in plunger and make adjustments to stop AND ADJUSTMENT screw (G) so that it touches the plunger and tighten lock nut. See figure 27-2. Recheck the positive stop angle to the saw blade. MAKE CERTAIN the table saw is disconnected from Insert the guide bar into the miter gauge groove and slide the miter gauge up to the saw blade.

- Page 127 29=2 Crosscutting requires the use of the miter gauge (A) to position and guide the workpiece (B). See figure 24-1. The use of non-Craftsman attachments and acces- sories may result in risk of injury or damage to the table saw.

- Page 128 Ripping is the operation of making a cut with the grain of the workpiece; the rip fence (A) is used to position An accessory Craftsman Fence Guide can be purchased and guide the workpiece. Since the workpiece is to assist when making narrow cuts. See "ACCESSOR- IES AND ATTACHMENTS"...

- Page 129 DADO BLADE Dado blades and chippers have a set to their teeth. The teeth of the dado blades and chippers must be arranged so that the set of each tooth overlaps the next tooth. The set of the dado blade (C) and chipper (D) The blade guard and splitter assembly cannot be used overlap as shown in Figure 31-3.

- Page 130 Figure 31=5 • The blade guard and splitter assembly cannot be used when dadoing or molding and must be swung to the rear of the saw. Blade guard must be reassem- bled when finished. Figure 32=2 Figure 31-5, shows a typical dado operation using the miter gauge.

- Page 131 Position thewoodfacingoverthecutterhead w iththe CAUTION cutterhead b elowthesurface ofthetable. Turnthesaw When molding end grain, the miter gauge must be onandraisethecutterhead s lowly.Thecutterhead w ill used. The feed should be slowed up at the end of cutitsowngroove inthewoodfacing. the cut to prevent splintering In all cuts, pay attention to the grain, making the cuts in the same direction as the grain whenever possible.

- Page 132 LUBRiCATiON The table saw has sealed lubricated bearings in the Only trained personnel should perform repairs to the motor housing that do not require any additional lubrica- table saw. Contact your nearest Sears Service Center tion from the operator. for authorized service. Unauthorized repairs or replace- ment with non-factory parts could cause serious injury CLEANING...

- Page 133 TOPREVENT I NJURY TO YOURSELF or damage to the table saw, turn the power switch to the "OFF" position and unplug the power cord from the electrical receptacle before making any adjustments. PROBLEM LIKELY CAUSE(S) SOLUTION Motor does not Switch not pressed in far enough or switch Depress switch in 1/2 inch or make sure switch is in the start: in the "OFF"...

- Page 134 1O-IN. T ABLE MODEL NO.152.221140 When servicing, use only CRAFTSMAN replacement parts. Use of any other parts may create a HAZARD or cause product damage. Any attempt to repair or replace electrical parts on this table saw may create a HAZARD unless a qualified service technician does repairs.

- Page 135 STD852008 LOCK WASHER M8 OR91168 FENCE TOP STD851008 FLAT WASHER M8 405A OR91570 OR91173 DUST CHUTE WELDMENT CRAFTSMAN LABEL, VERTICLE OR91169 FENCE END CAP OR91179 TIE BAR 406A OR91764 HEX SOCKET SET SCREW M5 x 10ram OR91181 CARRIAGE HEAD SCREW 5/16-18 x 5/8"...

- Page 136 >...

- Page 138 406B 411A 445 (8; 459_ 438(2)_ 435_ 434_ 433(2) 432, 419D 420A...

- Page 139 501D 501A 503(3) 504--- 529A(2) 529(6)\ 527\_ 502B /505(4-) 502A(4.)-_ 506(2) 501C "-4 501B I'll...

- Page 140 ,_ NOTES ,_...