Table of Contents

Advertisement

Owner's Manual

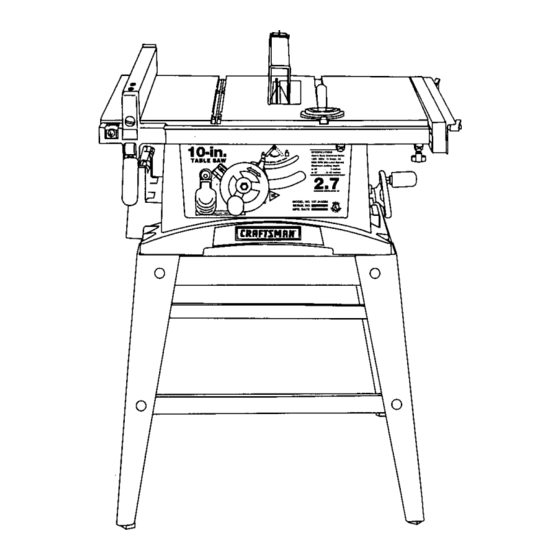

CRRFTSMRN o

2.7 HP (Maximum

Developed)

10" Inch Blade

5000 R.P.M.

TABLE SAW

Model No.

137,218250

E82443

USED 37J2

CAUTION:

Before using this Table Saw,

read this manual and follow

all its Safety Rules and

Operating Instructions.

• Safety Instructions

• Installation

• Operation

• Maintenance

• Parts List

• EspaSol

Customer

Help

Line

1-800-843-1682

Sears,

Roebuck

and Co., Hoffman

Estates,

IL 60179

USA

Part No. 137218250001

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Craftsman 137.21825

- Page 1 10" Inch Blade 5000 R.P.M. TABLE SAW Model No. 137,218250 E82443 USED 37J2 CAUTION: Before using this Table Saw, read this manual and follow all its Safety Rules and Operating Instructions. Sears, Roebuck and Co., Hoffman Part No. 137218250001 • Safety Instructions •...

-

Page 2: Specifications

Universal To avoid electrical hazards, fire hazards, or damage to the tool, use proper circuit protection. Your table saw is wired at the factory for 120V operation. 5000 Connect to a 120V, 15 AMP branch circuit and use a 15 AMP time delay fuse or circuit breaker. - Page 3 Safety is a combination of common sense, staying alert and knowing how to use your table saw. To avoid mistakes that could cause serious injury, do not plug the table saw in until you have read and understood the following: READ and become familiar with this entire instruction manual.

- Page 4 NEVER STAND or have any part of your body in line with the path of the saw blade, Keep your hands out of the line of the saw blade. NEVER REACH behind or over the cutting tool for any reason.

- Page 5 CAUTION: In all cases, make certain the receptacle is properly grounded. If you are not sure have a qualified electrician check the receptacle. This table saw is for indoor use only. Do not expose to rain or use in damp locations. SAVE THESE INSTRUCTIONS Fig.

-

Page 6: In The Box

RECOMMENDED ACCESSORIES Visit your Sears Hardware Department or see the Craftsman Power and Hand Tools Catalog to purchase recommended accessories for this power tool. ,P_l,vlvl_,1 r,|_, I I_[e To avoid the risk of personal injury: Do not use adjustable (wobble) type dadoes or •... - Page 7 UNPACKING YOUR TABLE SAW:...

-

Page 8: Product View

Blade Gl Rip Fence gauge storage Blade bevel lock knob Blade tilt pointer Overload reset switch ON/OFF switch with safety key Blade elevation handwheel Power¢ Blade wrenches Miter gauge Blade tilting handwheel Leg stand Blade Blade Table Extension table Blade bevel scale Kickback pawls Splitter Splitter... -

Page 9: Assembly

SAW TO LEG SET (FIG. B) Before mounting the blade guard, the rip fence and miter gauge to the saw top, invert the saw table so that it is facing the floor. Position the leg set upside down on the saw base. - Page 10 SAW MOUNTEDTO OTHER WORK SURFACES (FIG. C) If the leg set will not be used the saw must be properly secured to a sturdy workbench using the four mounting holes at the base of the saw. The surface of the table where the saw is to be...

- Page 11 Fig. J To avoid injury from a thrown workpiece, blade parts, or blade contact, never operate saw without the proper insert in place. Use the saw blade insert when sawing. Use the dado head insert when using a dado. •...

-

Page 12: Adjustment

Place the oval washer (5) on the pivot rod (6). (FIG. L) Install the bracket assembly (4) into the rear of the saw table. Thread the bolt (3) into the internally threaded pivot rod. NOTE: The splitter is removed from the illustration for clarity. - Page 13 Tighten screw and remeasure with the rule. (FIG. Q) of the saw table. Move the far end of the fence until it is parallel with the miter gauge groove. screw (5) clockwise until the rear clamp is snug.

- Page 14 ADJUSTING THE 90 ° AND 45 ° POSITIVE STOPS (FIG. R, S) Your saw has positive stops that will quickly position the saw blade at 90 ° or 45 ° to the table. These stops were set at the factory. Make adjustments 900 Stop Disconnect the saw from the power source.

- Page 15 Carefully slide the combination square to the rear until the ruler touches the marked tooth. If the ruler touches the marked tooth at the front and rear positions, no adjustment is needed at this time. If not, perform adjustment procedure described in next section.

-

Page 16: Basic Saw Operations

To turn the saw ON, insert key (1) into the slot in the switch (2). Move the switch upward to the ON position. To turn the saw OFF, move the switch downward. - Page 17 Place the workpiece flat on the table and against the fence. Keep the workpiece about 1" away from the blade. Turn the saw ON and wait for the blade to come up to speed. Slowly feed the workpiece into the blade by pushing forward only on the workpiece section (1) that will pass between the blade and the fence.

- Page 18 Move the workpiece to one inch distance from the blade. Start the saw and wait for the blade (1) to come up to full speed. Keep the workpiece (2) against the face of the miter gauge (3) and flat against the face of the gauge and flat against the table.

- Page 19 Blade or chippermust not exceed 1/2". Check saw to ensure that the dado will not strike the housing, insert, or motor when in operation. For your own safety, always replace the blade, blade guard assembly, and blade insert when you are finished with the dado operation.

- Page 20 Clean out all sawdust that has accumulated inside the saw cabinet and the motor. Polish the saw table with an automotive wax to keep it clean and to make it easier to slide the workpiece. Clean cutting blades with pitch and gum remover.

- Page 21 Align splitter with blade. Install and use rip fence. Install and use splitter (with guard). Replace blade. Push material all the way past saw blade before releasing work. Tighten knob. 1. Brush or blow out loose dust and dirt. 1. Replace with adequate size cord.

-

Page 22: Parts List

Key aONo Oescr, ,,on S,z. 2615BBDDS0 Hex head screw M6"1.0-40 & washer 2501MBDN06 Fiat washer 6"13-1 2705FBD106 Nut chuck M6"I.0 T=6 14994501 Warning label 2690MZD514 Rivet 14912206 B1 Blade guard assembly 14912206 Blade guard 14994103 Caution label 2570DBN606 Self-locking ring 14912301 14912906 Splitter... - Page 24 Part Description 14916901 Grip 14911601A1 8olt clamp assembly 14211201 Bolt clamp 2501NBDN16 Flat washer 14911402A5 Mitre gauge assembly 14911402 Mitre gauge 14608001 14911802 Angle pointer 29835L5006 Steel ball 14523301 Com# spring 260388LA38 Hex socket set 14911707 Sheet bar 260888LA32 Hex socket truss he ad so'few 14937101 Wheel...

- Page 25 _106 116/_ lZ9A...

- Page 26 Part No. Description 14930002 Set nut 14930102 Arbor collar 14930203 Blade 141 8387129942 Motor 142 2620BBDC18 Pan head screw & washer 14936201 Bearing seat 14936301 Shaft 14935904 Stiffener 2708FBD107 Serrated toothed hex. flange nut 14921307 Angle rod 14921403 Strap 149 2502NBC406 Spring washer 2708FBD107 Serrated toothed...

- Page 27 "_...

- Page 28 CRAFTSMAN 10" TABLE PARTS LIST FOR SCHEMATIC D Part No. 17050106 2672BBDA54 17050407 2601BBDA69 14000304 2501MBDN 11 2701FBD109 2708FBD112 17050307 2601BBDA57 2501MBDN08 17050209 17050505 STAND Description Cap head square neck bolt Bottom support bracket (long) Hex head bolt Spacer (foot pad)

- Page 29 CRAFTSMAN 10" TABLE SCHEMATIC D MODEL NO. 137.218250 <...

- Page 30 Part No. 2620B8DB26 83871271 2603BBLA23 87840021 83962491A1 83990291A1 83990301 87840081 83870111A2 2662MZDE41 87840131 87840122A2 83871141 2801UBHA07 83871161 2001AH1010 , ,.- 2570BBN117 87840171 83871201 2001 LU6204 83870221 2504MZF004 2636BZDA07 2571MNC252 83870253 Description Size Pan head screw MSX0.8-30 Support plate Hex socket set screw M5X0.8-8 Motor housing Brush holder assembly...

- Page 33 c!tof push 1/4 wood. Cut off here to push 1/2" wood. 1/2" Squares. PUSH STICK Make from 1/2" or 3/4" wood or thickness less than width of material to be cut. Notch to help prevent hand from slipping. Optional hanging hole. CAUTION! Use only good strong wood...

- Page 34 For repair of major brand appliances no matter who made it, no matter who sold it! 1-800-4-MY-HOME (1-800-469-4663) To bring in products such as vacuums, for repair, call for the location of your nearest Sears Parts & Repair Center. !!!!_!i!i!! 1-800-488-1222 For the replacement that you need to do-it-yourself,...

Need help?

Do you have a question about the 137.21825 and is the answer not in the manual?

Questions and answers