Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Nalco 3D TRASAR Series

- Page 1 ® 3D TRASAR Technology Installation and Operation Manual Version 8.0 This manual covers the following models: • 3D TRASAR 5500 Series • 3D TRASAR 3500 Series • 3D TRASAR Technology for Closed Loop Applications • 3D TRASAR Technology for High Fouling Applications 3D TRASAR Models for the •...

- Page 2 5500 - Installation & Operation Manual TRASAR Technology License Nalco has one or more patents and related know-how, which pertain to either TRASAR or 3D TRASAR method of use or practice of technology (“Tracer Technology”). Buyer’s purchase of equipment, software and chemicals from Nalco conveys to Buyer a non-assignable and non-trans-...

-

Page 3: Table Of Contents

Pellet Feeder Best Practices ..................2-24 2.5.3 Liquid Bio-reporter Plumbing ..................2-24 STEP 6 – Install Probes ..................2-25 2.6.1 Fluorometer Installation .................... 2-26 2.6.2 pH Probe Installation ....................2-27 Technical Help 521-OM0108.88 TOC-1 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 4 2.7.18 Ethernet (Direct Connect to 3D TRASAR 5500) ............2-48 2.7.19 LAN Connections ..................... 2-48 2.7.20 SCADA Connections (Modbus RTU) ............... 2-48 2.7.21 Nalco Global Gateway ....................2-48 STEP 8 – Calibration & System Checkout ............2-49 2.8.1 Establish Sample Flow & Apply Power..............2-49 2.8.2...

- Page 5 4.10.11 System Startup Screens ..................4-29 4.10.12 Test Email Screen ....................4-29 4.10.13 Service Email Screen ....................4-29 4.11 The Alarms Key ....................4-30 4.11.1 Sensor Alarms ......................4-30 Technical Help 521-OM0108.88 TOC-3 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 6 4.11.8 Failsafe Mode ......................4-32 4.11.9 Startup Mode ......................4-32 Section 5: 3D TRASAR Scale Control Nalco Scale Index (NSI) Measurement ..............5-1 5.1.1 3D TRASAR Scale Blowdown Control – Uses NSI to Adjust the Blowdown Setpoint ... 5-1 5.1.2 3D TRASAR Scale Tagged Polymer Control –...

- Page 7 Cleaning Basket / Wye Strainer ................8-3 Pellet Feeder Maintenance ................... 8-3 Check / Refill Pellet Feeder ................... 8-3 Section 9: Troubleshooting General Troubleshooting ..................9-1 Alarm Screen Troubleshooting ................9-7 Technical Help 521-OM0108.88 TOC-5 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 8 Appendix G: 3D TRASAR Technology for Closed Loop Applications Appendix H: 3D TRASAR Technology for High Fouling Applications Appendix I: Halogen Analyzer Control Appendix J: 3D TRASAR Models for the Pacific Appendix K: Warranty Policy Glossary Technical Help 521-OM0108.88 TOC-6 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 9: Section 1: Introduction

Keep in mind, as you begin, that your Nalco T echnical Representative has already done some of the preliminary configuration work for you. Don’t hesitate to contact that person if you have a question or problem, as they are familiar with your situation and can be very helpful in addressing any specific needs you may have. - Page 10 3D TRASAR Starter 3500 and 3D TRASAR 5500 Models and Optional Components (con’t) The 3D TRASAR 3500 and 5500 are available in a variety of models. T a lk to your Nalco representative about which model is right for your application.

-

Page 11: Trasar 3500 And 3D Trasar 5500 Overview

The 3D TRASAR Starter 3500 utilizes proven TRASAR technology to monitor and control chemical feed. Features of the 3D TRASAR 5500 are available as upgrades to the 3D TRASAR Starter 3500. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 12: How The 3D Trasar 5500 System Works

The patented 3D TRASAR on-line fluorometer consists of a “Flow Cell”, an LED light source, filters, and detectors. The filters and detectors are tuned to specific light frequencies unique to Nalco products and resultant process reactions. The LED light source is extremely bright at the appropri- ate frequencies to reliably and repeatably measure the chemical properties of the flowing water . -

Page 13: Data Storage / Reporting And Communications

3D TRASAR Bio-Control is the only bio-control system available that adjusts system operation in response to changes in bio-activity . This unique Nalco innovation delivers comprehensive, continuous control of both sessile and planktonic bio-popula- tions. -

Page 14: Safety

NOTE: Both the 3D TRASAR controller and the Bio-reporter Pellet Feeder operate well below an 85 db noise level. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 15: Section 2: Installation And Start-Up

Enter set points. Wire pumps using supplied pigtails (or hardwire). Connect You are up and running! screen. 85 to 250 VAC @ 20 amps power using supplied power cord (or hardwiring). Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 16: Step 1 - Unpack And Identify

Frame Mount wi th Junction Box 060-TR3520.88 060-TR5520.88 Enclosed Wall Mount wi th Junction Box 060-TR3522.88 060-TR5522.88 Enclosed Wall Mount wi th Junction Box and Pre-Installed Nalco Global Gateway 060-TR3521.88 060-TR5521.88 Enclosed Frame Mount with Junction Box 060-TR3523.88 060-TR5523.88 Enclosed Frame Mount with Junction Box and Pre-Installed Nalco Global Gateway 060-TR3530.88... - Page 17 Model Number Description system sizes: 060-TR5120.88 Pellet Feeder Assembly 12,000 gallons and larger 141-PJ4035.88 Liquid Bio-reporter pump, Iwaki 3,000 to 12,000 gallons 6008505 Liquid Bio-reporter pump, Grundfos Less than 3,000 gallons Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 18: Pre-Installed Items (All Models)

Part # 400-NCMP7B.88 - 443 Brass (optional) Part # 060-TR5421.88 Part # 6016180 - 6061 Aluminum (optional) Part # 6016182 - 1 100 Aluminum (optional) Part # 400-NCMP10.88 Galvanized steel (optional) Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 19: Pellet Feeder Assembly (Optional)

NCM probe, Copper, with ferrule 400-NCMP2B.88 Plastic beakers, qty 3, 500 mL 500-P0116.88 (includes 2 of each NCM probe) Plastic syringe, qty 3, 60 cc 500-P2147.88 Fluorometer desiccant cannister 060-TR5222.88 Fluorometer desiccant indicator 060-TR5223.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 20: Step 2 - Mount The Controller

7. If using liquid bio-reporter, mount the feed pump in a location convenient to the bio-reporter tank and the 3D TRASAR controller . 8. Chemical feed pumps should also be mounted conveniently to the 3D TRASAR controller and chemical feed tanks. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 21: Trasar Controller Dimensions

® 3D TRASAR 5500 - Installation & Operation Manual 2.2.2 3D TRASAR Controller Dimensions Mount controller Wall Mount Small Backboard 060-TR3500.88, 060-TR5500.88 Frame Mount Small Backboard 060-TR3501.88, 060-TR5501.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 22 ® 3D TRASAR 5500 - Installation & Operation Manual Wall Mount with Junction Box 060-TR3510.88, 060-TR5510.88 Mount controller Frame Mount with Junction Box 060-TR3511.88, 060-TR5511.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 23 3D TRASAR 5500 - Installation & Operation Manual Enclosed Wall Mount with Junction Box 060-TR3520.88, 060-TR3522.88, Mount controller 060-TR5520.88, 060-TR5522.88 Enclosed Frame Mount with Junction Box 060-TR3521.88, 060-TR3523.88 060-TR5521.88, 060-TR5523.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 24 5500 - Installation & Operation Manual Air Purged Wall Mount with Junction Box 060-TR3530.88, 060-TR3532.88 Mount controller 060-TR5530.88, 060-TR5532.88 Air Purged Frame Mount with Junction Box 060-TR3531.88, 060-TR3533.88 060-TR5531.88, 060-TR5533.88 Technical Help 521-OM0108.88 2-10 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 25: Wall Mounting Templates

(approximate weight 75 lbs). Note: For ease of installation, use 3D TRASAR easy mounting bracket Part # 060-TR5245.88. For models 060-TR3500.88 and 060-TR5500.88 only . Dimensions shown are in inches Technical Help 521-OM0108.88 2-11 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 26 5500 - Installation & Operation Manual Use the template below to locate and drill mounting holes Model #s 060-TR3510.88 and 060-TR5510.88 Mount controller (approximate weight 90 lbs). Dimensions shown are in inches Technical Help 521-OM0108.88 2-12 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 27 060-TR5522.88, 060-TR5530.88, 060-TR5532.88 (approximate weight 200 lbs.) Exact hole locations for these units are not available due to variations in manufacturing runs from the enclosure supplier. Dimensions shown are in inches Technical Help 521-OM0108.88 2-13 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 28: Frame Mount Template

5500 - Installation & Operation Manual 2.2.4 Frame Mount Template Mount controller For models: 060-TR3501.88, 060-TR5501.88 060-TR3511.88, 060-TR5511.88 060-TR3521.88, 060-TR5521.88 060-TR3523.88, 060-TR5523.88 060-TR3531.88, 060-TR5531.88 060-TR3533.88, 060-TR5533.88 Dimensions shown are in inches Technical Help 521-OM0108.88 2-14 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 29: Step 3 - Install Bio-Reporter Feeder

(2) by removing the base feet and bolting to the floor. Note: The Overflow Container (P/N 060-TR5350.88) shown in the photo must be ordered separately . Technical Help 521-OM0108.88 2-15 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 30 ® 3D TRASAR 5500 - Installation & Operation Manual Technical Help 521-OM0108.88 2-16 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 31: Install Liquid Bio-Reporter Pump

For cooling systems with volumes less than 3,000 gallons, use Grundfos pump (P/N 6008505). For cooling systems with volumes between 3,000 and 12,000 gallons, use Iwaki pump (P/N 141-PJ4035.88). Technical Help 521-OM0108.88 2-17 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 32: Step 4 - Plumb Controller

However , in cooling systems, the effects of long lag times can be compensated for by decreasing the feed rate of the chemical pump, which will reduce set-point overshoot. Consult your Nalco representative for the appropriate sample point location for your system. Technical Help 521-OM0108.88 2-18 Copyright ©... - Page 33 TRASAR system. In this case, all controlling relays will continue to function causing an overfeed of chemical or excessive blowdown. Refer to Section 2.7.14 for System Interlock wiring details. Technical Help 521-OM0108.88 2-19 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 34 Drain (not recommended) IMPORTANT: Do not connect the sensor outlet plumbing to the fluorometer outlet plumb- ing – this may impair the flow through the fluorometer when inlet flow pressure varies. Technical Help 521-OM0108.88 2-20 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 35: Chemical Feed Pumps

• Avoid feeding biocides near the injection point of the bio-reporter • Ensure that the suction side of the pump is always flooded. Note: Acomplete line of chemical feed pumps is available through the Nalco Global Equipment Solutions Group (NGES). Please call (800)323-8483 or (630) 848-3387 for assistance with selecting the right pump for your application. -

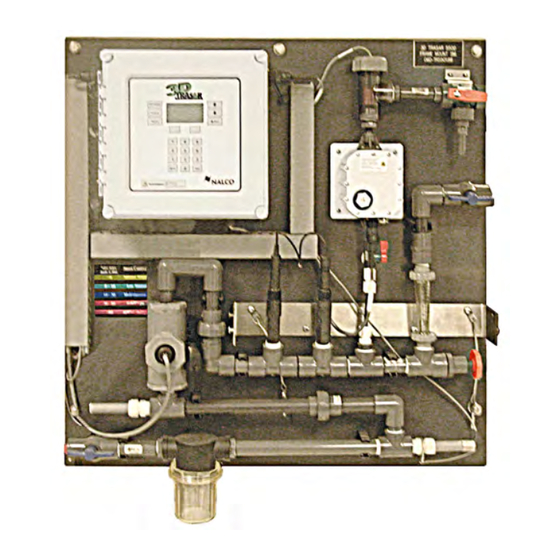

Page 36: Typical Installation Drawing

® 3D TRASAR 5500 - Installation & Operation Manual 2.4.5 Typical Installation Drawing Technical Help 521-OM0108.88 2-22 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 37: Step 5 - Plumb Bio-Reporter Feeder

Connect pellet feeder overflow to tubing and route to drain, or attach the Bio-reporter (P/N 060-TR5350.88) as shown below. The Overflow Liquid Overflow Container Container must be ordered separately . Technical Help 521-OM0108.88 2-23 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 38: Pellet Feeder Best Practices

(mixing) sufficiently away from any biocide feed points. For system volumes be- For system volumes tween 3,000 and 12,000 less than 3000 gallons, gallons, use Iwaki pump use Grundfos pump (P/N 141-PJ4035.88). (P/N 6008505). Technical Help 521-OM0108.88 2-24 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 39: Step 6 - Install Probes

Corrosion Probe #1 pH Probe ORP Probe WARNING: Always turn off power before making any electrical connections, which in- cludes all interconnecting cables, otherwise permanent damage may occur to system components. Technical Help 521-OM0108.88 2-25 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 40: Fluorometer Installation

Adjust the position of the ball valve as needed to maintain proper alignment with the flow switch assembly (slotted holes are provided on the three-way valve bracket for adjustments.) STEP 7 - Connect the pre-installed fluorometer cable to the fluorometer . Technical Help 521-OM0108.88 2-26 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 41: Ph Probe Installation

STEP 4 - Connect pH probe to pH cable (cable Install probes and attach Install probes and attach is labeled pH.) connectors. connectors as shown. Tighten swage fitting fully. Technical Help 521-OM0108.88 2-27 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 42: Orp Probe Installation

STEP 4 - Connect the ORP probe to ORP Install probes and attach Install probes and attach cable (cable is labeled ORP). connectors. connectors as shown. Tighten swage fitting fully. Technical Help 521-OM0108.88 2-28 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 43: Conductivity Probe Installation

Verify probe is hand tight in the tee and the cable is firmly connected to the controller and ORP Probe probe. Install probes and attach Install probes and attach connectors. connectors as shown. Tighten swage fitting fully. Technical Help 521-OM0108.88 2-29 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 44: Ncm Corrosion Probe Installation

. WARNING: The probe restraint must be installed on all 3D TRASAR units at all times. Technical Help 521-OM0108.88 2-30 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 45 Connect the corrosion probe cables to either of the two controller inputs (there is one input connection on each side of the controller). The 3D TRASAR controller automatically recognizes the probe metallurgy – no calibration is required. Technical Help 521-OM0108.88 2-31 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 46: Step 7 - Wiring

In cases where more amperage is required, the control relays can be wired as dry contacts for motor starters. • Alarm outputs are fused at 1 amp. • Refer to the following diagrams and charts for details on wiring connections. Technical Help 521-OM0108.88 2-32 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 47: Controller Box Layout

® 3D TRASAR 5500 - Installation & Operation Manual 2.7.2 Controller Box Layout pH and ORP cables are not pre-wired on 3D TRASAR Starter models. Technical Help 521-OM0108.88 2-33 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 48: Controller Wiring Details

® 3D TRASAR 5500 - Installation & Operation Manual 2.7.3 Controller Wiring Details pH and ORP cables are not pre-wired on 3D TRASAR Starter models. Technical Help 521-OM0108.88 2-34 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 49 3. Alarm relay fused at 1.0 amps. 5. Board traces and contacts rated at 5 amps (85-250 VAC). 6. For motor driven pumps a separate motor starter must be used. Technical Help 521-OM0108.88 2-35 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 50: Junction Box Layout

® 3D TRASAR 5500 - Installation & Operation Manual 2.7.4 Junction Box Layout Technical Help 521-OM0108.88 2-36 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 52: System Power Connections

(Factory Wired in Controller Box) Connection Controller Box Controller Box Wire Color Description Board Reference Terminal Black-1 Power Switch Neutral Black-2 Power Switch Line Black-3 Switched AC Neutral Black-4 Switched AC Line Technical Help 521-OM0108.88 2-38 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 53: Control Relay Connections - Powered (120 Vac Fused @ 2.5 Amps)

Contact Contact Controller Controller LINE Typical Powered Relay Jumper Output from Controller Box Junction Controller Box supplies Line, Neutral, & Earth Gnd Typical Powered Relay Output from Junction Box Technical Help 521-OM0108.88 2-39 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 54: Control Relay Connections - Non-Powered (Fused @ 2.5 Amps)

Controller Box supplies Line, Neutral, & Earth Junction External Motor External Motor Starter Neutral (-) Starter Power (+) Motor Starter External Motor External Motor Starter Power (+) Starter Neutral (-) Technical Help 521-OM0108.88 2-40 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 55: Control Relay Connections - Termination Details

Oxidizing Biocide TB4-1 OXIDE BIOCIDE - NO4 Feed - Relay 4 TB4-2 OXIDE BIOCIDE - N TB4-3 Ground Bar TB4-4 OXIDE BIOCIDE - L TB4-5 COM4 OXIDE BIOCIDE - COM4 Technical Help 521-OM0108.88 2-41 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 56 Control Feed - TB7-1 pH CONTROL - NO7 Relay 7 TB7-2 pH CONTROL - NO7 TB7-3 Ground Bar TB7-4 pH CONTROL - L TB7-5 COM7 pH CONTROL - C OM7 Technical Help 521-OM0108.88 2-42 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 57: Pellet Feeder Connections

Orange with White stripe TB15 Blue with White stripe TB15 White with Blue stripe Conductivity J7-1 White J7-2 Black J7-3 Shield J7-4 J7-5 Black J7-6 Shield J7-7 Green J7-8 Black J7-9 Shield Technical Help 521-OM0108.88 2-43 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 58 IMPORTANT: Make sure the pH and ORP probes are connected to the appropriate terminals as they look very similar and will display a reading even if connected improperly . Technical Help 521-OM0108.88 2-44 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 59: Analog I/O Connections

The analog outputs are internally powered for a max. load of 600 ohms. The analog outputs can be used to transmit any of the following variables: TRASAR product dosage, Tag Polymer product dosage, Cell Fouling, Nalco Scale Index, Nalco Bio-Index, Conductivity, pH, ORP, Corrosion #1, Corrosion #2, and Sample Water Temperature. -

Page 60: Factory Wired Digital Inputs

Board Reference Terminal Connector) Digital Input 3 TB10 3 (+) DI3 (+) TB10 3 (-) DI3 (-) Digital Input 4 TB10 4 (+) DI4 (+) TB10 4 (-) DI4 (-) Technical Help 521-OM0108.88 2-46 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 61: Alarm Output Connections

1 and 2. The modem input is not polarity sensitive, so it does not matter which order the wires are connected. Hard Wire Analog Phone Connection* Technical Help 521-OM0108.88 2-47 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 62: Ethernet (Direct Connect To 3D Trasar 5500)

Controller Box Terminal Junction Box Description Board Reference (Removable Connector) Terminal SCADA TB12-1 Rx/A TB12-2 Tx/B TB12-3 Call 630-305-CHEM for assistance. 2.7.21 Nalco Global Gateway See Section 7.7 for details. Technical Help 521-OM0108.88 2-48 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 63: Step 8 - Calibration & System Checkout

“F”. 11. Verify that a “System Interlock” alarm does not exist on the 3D TRASAR controller display . System Interlock alarms are indicated by a flashing “I”. Technical Help 521-OM0108.88 2-49 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 64: Calibrate Probes

6. Refer to Section 4.10.6 for details. Note: 1-point calibration can be used after the initial 2-point calibration has been performed. 2-point calibration should be performed when- ever a replacement conductivity probe is installed. Technical Help 521-OM0108.88 2-50 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 65: Checkout Control Relays

IMPORTANT: Make sure all relays are in “Auto” mode after checkout. Pumps or valves left in “Man-On” mode will result in excessive waste of chemical and water which may cause damage to the cooling system. Technical Help 521-OM0108.88 2-51 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 66: Step 9 - Start-Up System

IMPORTANT: Every 3D TRASAR controller is configured uniquely for each application through Enter Set Points You are up and running! Nalco’s “Configurator” software. Y our Nalco representative will have created your system configuration prior to installation. STEP 2 - Verify control settings, setpoints and alarms. -

Page 67: Section 3: 3D Trasar Configurator

For Windows 2000 users, insert the CD and double click on the Setup.exe icon. Follow the on screen steps to complete the installation. For Nalco Windows XP users, the configurator program should be pre-installed. T o open click Start, Programs, Nalco Software, 3D TRASAR, 3DT Configurator. -

Page 68: Configurator Support

Important configurator information can be located in the help screen by pressing the F1 function key. A keyword search can also be performed to locate information on a specific topic. 3.3.1 Sample Help Screen 3.3.2 Sample Search Screen Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 69: Section 4: Controller Settings

Menu....Provides contact information help Help....Used for menu navigation Up/Down..Returns to previous screen Back....Used to make selections shown on the Soft Keys..display panel Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 70: The Graphical Icons

• One or more alarms is active (press Alarms to view) • Modem connection is established (incoming or outgoing) • No flow condition exists (delay for alarm) • Interlock contact is opened (immediate alarm) Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 71: Menu, Information, Actions And Alarms Flow Diagram

Email Email SCADA SCADA External External External External Baud Baud Inputs Inputs Inputs Inputs Product Product Product Product Factors Factors Factors Factors Diagnostic Diagnostic Diagnostic Diagnostic Data Data Data Data Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 72: The Menu Key

Alarm Network Manual System Preferences Settings Settings Relay Info This submenu is used to access the system control settings. Only items that have been configured as “controlling” will display . Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 73: Background Correction Screen

TAG Ratio is between 1.41 and 1.71. Fixed TAG Method can be used for any T AG Ratio value. IMPORTANT: Periodically check the T agged Polymer level on the controller against the level determined by the Nalco DR/2800 or DR/890 Active Polymer T est (Reagent P/N 460-S0811.75). -

Page 74: Trasar (Relay 1) Product Screen

NOTE: Control ranges will only be displayed if applicable. Control range is not displayed if 3D Scale Index schemes are used. In these cases, the ranges are determined by the control algorithm. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 75: Alarm Settings Submenu

NOTE: The duty cycle percentages for high and low alarms can be set to different values if needed via the Configurator . 4.5.3 Performance Alarms Screen Corrosion 1, Corrosion 2, Nalco Bio-Index, and Nalco Scale Index high alarm thresholds. To change, arrow down and press Edit. Technical Help 521-OM0108.88... -

Page 76: Relay Alarms Screens

High and low alarm thresholds for 4-20mA input signals. Press Edit to modify. Note: Make sure all alarm parameters have been set prior to startup. Improper settings will adversely affect performance of controller and cooling system. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 77: Preferences Submenu

SCADA is used. The SCADA communication mode (RS-232 or RS-485). SCADA Mode……………………… Selects the SCADABaud rate (1200, 2400, 4800, 9600, 19200). SCADA Baud……………………… Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 78: Network Submenu

This submenu is used to display the start-up system parameters as entered by the user. This is the starting point for the water and energy calculations. Estimate of system volume in gallons. System Volume……………………….. Measured (microsiemens) Makeup Conductivity..…………….…. Temperature drop across cooling towers. Delta T………....……………. Technical Help 521-OM0108.88 4-10 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 79: The Information Key

The System Performance screens display measurements for corrosion, scale, and microbial foul- ing. The values that appear here depend on the configured control modes (i.e. Nalco Bio-Index will only appear if the controller is set in 3D TRASAR bio-control mode). -

Page 80: Operating Data Screens

4.9.3 Product Usage Screens These screens indicate chemical feed rates in gallons per day calculated from pump run time and pumping rate. Pumping rates should be based on actual pump draw down. Technical Help 521-OM0108.88 4-12 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 81: Water And Energy Screens

- Calculated system volume based on feed rates and residuals. System Volume 4.9.5 Plot Data Screens These screens are used to display stored data in a graphical form. All of the data shown below can be plotted: Technical Help 521-OM0108.88 4-13 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 82: Control Methods Screens

The previous 90-days of data may be displayed. 4.9.6 Control Methods Screens These screens display the control configurations for each controlled variable. Refer to the Configurator help screens for more details. Technical Help 521-OM0108.88 4-14 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 83: Timer Status Screens

External inputs can be used as a control signal for pH, ORP , and Conductivity. Refer to page 2-45. 4.9.9 Product Factors Screen Displays TRASAR and T agged Polymer product factors. Technical Help 521-OM0108.88 4-15 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 84: Diagnostic Data Screen

5500 - Installation & Operation Manual 4.9.10 Diagnostic Data Screens The Diagnostic screens are used primarily by Nalco Service T echnicians to ascertain the status of raw signals from the sensors. NOTE: The NDM is not yet a commercial option. -

Page 85: The Actions Key

- Sends a test data e-mail and alarm e-mail to the 3D TRASAR Web. Test Email - Sends one of ten service e-mails to the 3D TRASAR Web. Service Response Email Technical Help 521-OM0108.88 4-17 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 86: Password Screen

The need for cleaning or calibration is usually indi- cated by a drift in readings or an error between test results and readings. Technical Help 521-OM0108.88 4-18 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 87: Fluorometer Calibration Screens

T urn valves back to operating positions. A failed calibration is most likely caused by insufficient flush- ing, contaminated/incorrect standards, introduction of air bubbles, excessive cell fouling, or a bad probe connection. Technical Help 521-OM0108.88 4-19 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 88: Ph Calibration Screens

If probe calibration is unsuccessful, check standards, wiring connections, or handheld pH meter for accuracy . Soak probe in standard extra 5-10 min or clean probe tip and recalibrate. Technical Help 521-OM0108.88 4-20 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 89: Orp Calibration Screens

STEP 7 - After successful calibration reinstall probe and open valves. If probe calibration is unsuccessful, check standards, wiring connections, or handheld ORP meter for accuracy . Clean the ORP probe tip and recalibrate. Technical Help 521-OM0108.88 4-21 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 90: Conductivity Calibration Screens

STEP 8 - Wait six minutes. Accept the new value if successful, or Retry if failed. If probe calibration failed, clean the probe, check wiring con- nections, or handheld conductivity meter for accuracy and recalibrate. Technical Help 521-OM0108.88 4-22 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 91 Firmware Version's 6.0 and prior 2-Point 3-point Curve Setting Calibration 1-point calibration offset Standard Solutions (Need true conductivity value) TemCoEff Access Data Weighted Filter 500-99,999 uS/cm 500-15,000 uS/cm Recommended Range Built-in Instructions Technical Help 521-OM0108.88 4-23 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 92 NOTE: Conductivity fluctuations that do not consistently correlate with tempera- ture changes may indicate other issues such as probe malfunction, loose wire connections, etc. Call the Nalco Help Desk for assistance. Adjust the TempCoEff value To adjust the temperature coefficient of your conductivity detection system: •...

-

Page 93: Probe Calibration / Maintenance List

4 0 0 - N C M P 1 0 .8 8 G a lva n i z e d S te e l * For a detailed maintenance schedule, see Section 8. Technical Help 521-OM0108.88 4-25 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 94: Manual Relay Control Screens

Enter the Auto After value in hours and minutes using the keypad (0-4-2-5 equals 4 hours 25 minutes). Entering 00:00 will put the relay in the selected mode continu- ously. STEP 1 STEP 3 STEP 2 STEP 4 Technical Help 521-OM0108.88 4-26 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 95: Pumping Rates Screens

For specific directions on proper calibration techniques, refer to the pump manufacturers instruc- tions supplied with the pumps. The calibrated cylinder draw-down method is suggested for greatest accuracy. Technical Help 521-OM0108.88 4-27 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 96: Slug Feed Biocide Screens

Note: If feeding Glutaraldehyde the configured oxidizing feed will be suspended for 8 hours. 2. Use Hand Feed Oxidizer to physically add an oxidizer by an operator to the cooling system. 3. Use Relay Feed Oxidizer to energize the oxidizer relay. Technical Help 521-OM0108.88 4-28 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 97: System Startup Screens

• ORP Cal Check Pass • ORP Cal Check Fail • Cond Cal Check Pass • Cond Cal Check Fail • Routine Service Performed • Site Audit Completed • Technical Help 521-OM0108.88 4-29 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 98: The Alarms Key

Interlock alarm. If this feature is not needed, the Interlock input must be shorted with a wire jumper so the contact is always closed. Technical Help 521-OM0108.88 4-30 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 99: Communication Errors

Low alarms via the configurator . In monitoring mode, the parameter monitored may be sepa- rated from the relay that is on timer control for a different product. Technical Help 521-OM0108.88 4-31 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 100: Relay Timeout Alarms

When a system is first started up with a new product, it is often desirable to suppress alarms for a period to allow the 3D TRASAR controller to bring the system under control. See section 4.5.4. Technical Help 521-OM0108.88 4-32 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 101: Section 5: 3D Trasar Scale Control

> 75%. Refer to Section 4.4.1 for more details. Nalco Scale Index (NSI) Measurement The Nalco Scale Index (NSI) is a calculated variable that compares the current rate of polymer consumption against the learned average rate of polymer consumption. The NSI number has a direct correlation to cooling system stress level as shown in the table below . -

Page 102: Trasar Scale Blowdown Control

Step 4 Advanced 3D TRASAR Scale Blowdown Control Mode – This step adds to 3D TRASAR Scale Blowdown Control the feature of increasing the blowdown setpoint during low scale stress conditions to maximize system water and chemical efficiencies. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 103: Start-Up Procedure For 1-Drum 3D Trasar Scale Blowdown Control

3. Click the Inhibitor tab, change the Product Control Method to Tagged Polymer Control, enter the last month average Tagged Polymer level as the Inhibitor 1 Set Point, and accept the default control range. • Do NOT change any other settings. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 104 IMPORTANT: The blowdown set point will now be decreased by as much as 30% in response to high system stress AND will be allowed to go above the user-entered set point by as much as 10% in response to low system stress. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 105: Trasar Scale Blowndown Control: 2-Drum Program Overview

Step 4 Advanced 3D TRASAR Scale Blowdown Control Mode - This step adds to 3D TRASAR Scale Blowdown Control the feature of increasing the blowdown setpoint during low scale stress conditions to maximize system water and chemical efficiencies. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 106: Start-Up Procedure For 2-Drum 3D Trasar Scale Blowdown Control

This example shows that the T agged Polymer product Pumping Rate should be 5.53 times the TRASAR product Pumping Rate (i.e. TRASAR Pumping Rate = 1 gpm; T agged Polymer Pumping Rate = 5.53 gpm). 5. Click OK. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 107 8 HTI’s if the system HTI is < 72 hours, and 22 days if the HTI is > 72 hours. The “Learning Period” is over when NSI values start to appear . Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 108 IMPORTANT: The blowdown set point will now be decreased by as much as 30% in response to high system stress AND will be allowed to go above the user-entered set point by as much as 10% in response to low system stress. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 109: Trasar Scale Tagged Polymer Control

Step 4 Advanced 3D TRASAR Scale Tagged Polymer Control Mode - This step adds to 3D TRASAR Scale T agged Polymer Control the feature of decreasing the T agged Polymer setpoint during low scale stress conditions to maximize chemical efficiency . Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 110: Start-Up Procedure For 2-Drum 3D Trasar Scale Tagged Polymer Control

This example shows that the T agged Polymer product Pumping Rate should be 5.53 times the TRASAR product Pumping Rate (i.e. TRASAR Pumping Rate = 1 gpm; T agged Polymer Pumping Rate = 5.53 gpm). 5. Click OK. Technical Help 521-OM0108.88 5-10 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 111 8 HTI’s if the system HTI is < 72 hours, and 22 days if the HTI is > 72 hours. The “Learning Period” is over when NSI values start to appear . Technical Help 521-OM0108.88 5-11 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 112 IMPORTANT: The T agged Polymer set point will now be increased by as much as 30% in response to high system stress AND will be allowed to go below the user-entered set point by as much as 10% in response to low system stress. Technical Help 521-OM0108.88 5-12 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 113: Trasar Scale Control - Frequently Asked Questions

The key is to know when the scaling stress is changed, the magnitude of the change in scaling stress (upsets) compared to the normal operating conditions and the timely corrective actions that need to be taken to prevent scaling. Technical Help 521-OM0108.88 5-13 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 114 Yes. 3D TRASAR Scale Control can be run with 3D TRASAR Bio and Corrosion Inhibitor pro- grams. Note: Nalco 90005 for algae may cause interference with 3D TRASAR Scale Control due to foam- ing. The interference can be avoided/minimized by using antifoams.

- Page 115 If foaming occurs on application, loss of TRASAR 2 (PTSA) or polymer may be observed. Follow 90005 use recommendations to avoid foaming. Corresponds to a 10% loss of fluorescence when exposed to halogen for 24 hrs. Technical Help 521-OM0108.88 5-15 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 116 9. What is Nalco Scale Index (NSI)? The Nalco Scale Index (NSI) is a calculated variable that compares the current rate of polymer consumption against the learned average rate of polymer consumption. NSI has a direct correla- tion to the cooling system stress level. 3D TRASAR Scale control uses NSI to make set point adjustments in response to both high and low stress conditions.

- Page 117 13. Can 3D TRASAR Scale Control be operated in Monitoring Mode only (monitoring Nalco Scale Index, but without Setpoint adjustments)? Yes. 3D TRASAR Scale Control can be operated in the Monitoring Mode to monitor the Nalco Scale Index (NSI) without setpoint adjustments.

- Page 118 16. How do I know if I have completed the Learning Period? • Check the 3D TRASAR controller display . Press Information key, select System Performance. If a numerical value appears after Nalco Scale Index, the learning period has completed. If "------" appears, the system is still in Learning Mode.

- Page 119 If the "-a reading" is significantly greater than the "-i reading", it is also possible that: 1. Fluorometer requires recalibration, and/or 2. Background correction settings (TRA, T AG) and/or TAG ratio factor and T AG correction method are incorrect. Technical Help 521-OM0108.88 5-19 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 120 If Calibration check is okay, check if the entered background fluorescence is correct. Collect/send water samples for background analyses if necessary . Technical Help 521-OM0108.88 5-20 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 121 • In case of running NSI control, the set point may have been adjusted to a higher value. 25. Where can I call for help? Call (630) 305-CHEM for help/questions. Technical Help 521-OM0108.88 5-21 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 122 Towerbrom (Towerbrom 991 Lil’ & Mini-Slugger; Towerbrom 960 in 3D TRASAR Bio-Shock • Mode ) BCDMH (use Easibrom feeder) • Note: Stabilized Chlorine, aka N-2818 and N-7345 CANNOT be used. If using Chlorine Dioxide, call 630-305-CHEM. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 123: Nalco Bio-Index Measurement (Nbi)

5500 - Installation & Operation Manual Nalco Bio-Index Measurement (NBI) The Nalco Bio-Index measurement is a calculated variable used to measure the historical system response to biocide feed. It is NOT used to control the feed of oxidizing biocide. The table below shows the correlation between cooling system biological stress level and the Nalco Bio-Index number. -

Page 124: Trasar Bio-Control And Overlaid Ox Slugs

<Hand Feed Ox> If biocide is applied with pumps or means not controlled by the controller <Relay Feed Oxidizing Biocide> In the relay feed option, the controller applies the oxidizing biocide for the slug. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 125: Trasar Bio-Shock Mode

Under 3D TRASAR Bio-Shock Mode, the Nalco Bio-Index will give an indication of how close the system is to an oxidant slug. When the bio-reporter dye is first dosed, the Nalco Bio-Index will be very negative (-100 to -70). As the bio-reporter reacts with microbes, the Nalco Bio-Index number will slowly (dependent on the overall microbial activity within the system) increase. -

Page 126: Bio-Reporter Selection

3DTBR10 Liquid (10%) >5,000,000 Important! 3DTBR10 is formulated in concentrated sulfuric acid. Please contact your Nalco Representative for recommendations on fluid handling equipment compatible with concentrated acid. 3D TRASAR Bio-Control/3D TRASAR Bio-Shock Start-Up Procedure We recommend running a system under ORP control with a control range of ±20mV for a week before proceeding to 3D TRASAR Bio-Control. - Page 127 Manually turn on pump from the keypad to verify operation (see Section 4.10.8 for manual • relay control). • Set pump feed rate between 0.1 and 0.2 gpd. Make sure pump does not lose prime at this low rate. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 128 The A TF will feed one dump of product when in manual mode. Each dump is either two pounds or ten pounds depending on the ATF model. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 129: Pellet Feeder Operation

NOTE: Verify oxidant residual is below 0.1 ppm TRH before proceeding any further! Use DPD Total Colorimetric Test (P/N 460-S0461.87) with the Nalco DR/890 or DR/2800. STEP 3 - Using the Configurator , set up the controller for 3D TRASAR Bio-Control or 3D TRASAR Bio-Shock mode. -

Page 130: Filling The Pellet Feeder

5. Turn on power NOTE: It is very important that the feed hopper remain dry . Moisture or water in the hopper can cause pellet degradation and possible jamming. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 131: Bio-Reporter Initial System Dosing

(do not dump into a slow flowing area in the tower basin). System Volume 3DTBR40 Weight of Pellets (gallons) (# of pellets) (grams) 200,000 500,000 750,000 1,000,000 2,000,000 Technical Help 521-OM0108.88 6-10 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 132: Pellet Feeder Cleaning

Tighten Valve Seat - Section 6.9.2 Indicated by alarm or excessive weeping of water from pellet feeder. Replace Pellet Shield - Section 6.9.3 Indicated by alarm, pellet feeder jamming, or visual inspection. Technical Help 521-OM0108.88 6-11 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 133: Cleaning Pellet Feeder Exit Tube

At the pellet feeder diagnostic screen, verify that ‘ S en’ value is in the range of STEP 8 - 3 to 7. If not, re-clean the tube and check again until satisfactory . Technical Help 521-OM0108.88 6-12 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 134: Tighten Valve Seat

Upper to drain Union Figure PF3 Note: Under normal operation, the side drain port should be plumbed to drain, or connected to the bio-reporter Liquid Overflow Container ( 060-TR5350.88). Technical Help 521-OM0108.88 6-13 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 135 At the pellet feeder diagnostic screen, verify that ‘ B all’ value is in the range of STEP 7 - 400 to 600. If not, repeat steps until satisfactory . Technical Help 521-OM0108.88 6-14 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 136: Pellet Shield Replacement

The figures below show a new shield and a pellet shield that requires replacement. Figure PF5 Figure PF6 New Shield Distorted Shield STEP 1 - Obtain a replacement Pellet Feeder Shield Kit (P/N 060-TR5313.88). Figure PF7 Pellet Feeder Shield Kit Technical Help 521-OM0108.88 6-15 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 137 Note the orientation to the ‘Exit T ube’ (shown in drawings). STEP 5 - Remove the pellet shield, rotor retainer, and screws/washers as a unit. Exit tube covered by shield Remove these four screws Figure PF8 Technical Help 521-OM0108.88 6-16 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 138 Be sure the washers are in place. STEP 11 - Secure the assembly with the screws. Do not over-tighten as the plastic can be damaged. STEP 12 - Turn on power. Technical Help 521-OM0108.88 6-17 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 139 Addition- ally, if alga has been a known issue, an algaecide such as NALCO 90005 must be used routinely . 2. How does 3D TRASAR Bio-Control measure bio-activity in a cooling system? 3D TRASAR Bio-Control works by the addition of a micro-biological activity sensor into the recircu- lating cooling water.

- Page 140 3D TRASAR Bio-Control is completely compatible with the scale and corrosion inhibitor compo- nents of the 3D TRASAR program. In fact, 3D TRASAR Bio-Control has a beneficial impact on corrosion and scale inhibition. Technical Help 521-OM0108.88 6-19 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 141 An example: power plants where the time of oxidizing biocide feed is limited by regulatory constraints. Another example: the amount of halogen fed is limited by how much money is allocated towards microbial control. Technical Help 521-OM0108.88 6-20 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 142 Compatible only with 3D TRASAR Bio-Shock mode. Field tests in progress or trial sites needed. Call 630-305-CHEM. 0.5 ppm as Fe2+, but cooling towers are oxidizing environments and Fe2+ is not generally found. Technical Help 521-OM0108.88 6-21 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 143 10. Can 3D TRASAR Bio-Control be operated in monitor mode only? No. Nalco Bio-Index is a measure of how far the Rf/Rz ratio is compared to the set point. W hen ratio exceeds set point + deadband, 3D TRASAR Bio-Control feeds oxidant. W hen ratio falls below the deadband, 3D TRASAR Bio-Control stops the feed of oxidant (since the oxidant first reacts with microbes and then with Rf and Rz).

- Page 144 For systems where control of Legionella and health related risks is a water treatment program goal, Nalco Environmental Hygiene Services should be contacted for risk assessment and management. 13. Does 3D TRASAR Bio-Control control SRB’s (Sulfate Reducing Bacteria)? The bio-reporter can respond to anaerobic bacteria such as SRB’s.

- Page 145 • 3D TRASAR Bio-Control is not the same as maintaining a fixed halogen residual. The measured TRH levels depend upon the system microbiological activity and demand. In fact, measured TRH levels may be zero during a significant portion. Technical Help 521-OM0108.88 6-24 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 146 A goodness of fit criteria (chi-square) is used to evaluate if the data is too noisy or the fit is unsuitable. The oxidizing biocide pump is turned on/off depending on the value of the calculated ratio and the slope of the fit. Technical Help 521-OM0108.88 6-25 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 147 Positive Legionella counts require regular slug dose of Oxidizing biocide into the system • System needs to respond to a process leak • Bio-Reporter is being used to control feed of T owerbrom 991 • Technical Help 521-OM0108.88 6-26 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 148 Thereafter when the ORP signals returns to preslug values and the recovery period is complete, bio-reporter is again dosed into the system and the ratio is monitored. Technical Help 521-OM0108.88 6-27 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 149 18. What is 3D TRASAR Bio-Shock Mode? (con’t) The figure below shows the ORP signal and the Nalco Bio-Index during a slug. During the slug the Nalco Bio-Index reads -999. After bio-reporter feed has resumed the Nalco Bio-Index shows low values (-200) which slowly increase with monitored microbial activity and reaches zero around the time for the Oxidant slug trigger.

- Page 150 It’s a good idea to monitor the halogen residual in the tower at a particular ORP and fine tune the settings. Maintenance and frequent calibration is critical for good control. Technical Help 521-OM0108.88 6-29 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 151 (residual halogen). Under 3D TRASAR Bio-Control, the halogen residual may be between 0.8 ppm to 0.02 ppm as measured by a total halogen DPD test. Technical Help 521-OM0108.88 6-30 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 152 Bio-Control is superior to ORP control because it 1) reduces the variation in oxidant concentration, 2) reduces the average oxidant concentration and 3) reduces copper corrosion rates by eliminating high ORP levels. Technical Help 521-OM0108.88 6-31 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 153 50 ppm of N90005 (quaternary amine algaecide). The algaecide is also a surfactant and a slow acting bactericide. There is an initial increase in Nalco Bio-Index followed by a 21 hr period during which no STA-BR-EX is fed into the tower . Compare this to normal operation period (08/20/ 04-08/22/04).

- Page 154 Application of an oxidizing biocide is only one component of an effective chemical Bio-Manage program. For a complete list of available 3D TRASAR products, please contact your Nalco Sales Represen- tative.

- Page 155 3D TRASAR Bio-Control data file (through data download screen). The file can be opened in Excel and the Nalco Bio-Index can be reviewed along with the ‘ox pump on time’. The ox pump on time is the length of time (in seconds) the 3D TRASAR Bio- Control turned the oxidant pump on each 20 minute decision interval.

- Page 156 (below set point) and no true measure of microbial activity (Nalco Bio-Index) will be obtained. Nalco Bio-Index can only work by applying mini slugs of oxidizing biocide. The extent and timing of the slug has to be controlled by the controller .

- Page 157 0.0 - 0.4 ppm (total). 3D TRASAR Bio-Control adjusts halogen dosage based on demand. There is thus seasonal and diurnal variations in the concentration. Technical Help 521-OM0108.88 6-36 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 158 As the microbes convert some of the bio-reporter the Ratio will come up to the set point. The Nalco Bio-Index is calculated from the averaged value of the Ratio and is not a good indicator of the Bioactivity in the system at system startup.

- Page 159 Nalco Bio-Index. 43. My Nalco Bio-Index is negative. Why is my oxidizing biocide pump on? Nalco Bio-Index (NBI) value is NOT used to make decisions on oxidant feed and is for display purposes only. NBI represents the average value of the Rf/Rz Ratio with respect to the control band over the past 6 hours.

- Page 160 This is detailed in the manual. If the drain line is leaking when no pellets are being fed, or if large amounts of water are being expelled during a feed, the seals should be adjusted. Technical Help 521-OM0108.88 6-39 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 161 A separate flow switch on the feeder line (with a 3 to 5 gpm cut-off) could be added in series with the controller flow switch if intermittent flow is a problem. Technical Help 521-OM0108.88 6-40 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 162: Section 7: Communication And Data Management

The 3D TRASAR Optimizer is a software program used to determine the right treatment program for your cooling system. Information entered in the 3D TRASAR Optimizer can be transferred to the 3D TRASAR Configurator to avoid duplicate data entry . Contact your Nalco representative for questions about the 3D TRASAR Optimizer . -

Page 163: Trasar Web

3D TRASAR controller via e-mail. 7.5.1 3D TRASAR Web Set Up 3D TRASAR Web is accessed through Nalco's website (www .nalco.com). You must have a Nalco Extranet Account to enter the site. Contact your Nalco representative for information on how to obtain an extranet account. -

Page 164: Create/Edit Users

5500 - Installation & Operation Manual 7.5.1a Create/Edit Users Create and edit user profiles in the personal information page. Select which e-mail addresses are to receive reports and or alarm messages. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 165: Assign Controllers (Data Sources)

® 3D TRASAR 5500 - Installation & Operation Manual 7.5.1b Assign Controllers (Data Sources) Assign users access to view data on the website. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 166: Manage Controller (Data Source) Setup Information

5500 - Installation & Operation Manual 7.5.1c Manage Controller (Data Source) Setup Information The data source management screen provides a view of important controller information such as facility location, serial number and communication settings. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 167: Trasar Web Data

The “Performance Summary” page provides a high-level view of the state of every controller assigned to a user. The “Data Dashboard” displays detailed information for a specific controller. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 168 15 minute intervals. Reports can be emailed to the customer, exported to spread- sheet, or saved for future use (schedule reports to generate automatically and email on a routine basis.) Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 169: Trasar Web Alarms

3D TRASAR web site where it will be forwarded to the specified user’s email address. Details on the last 50 alarms will also be available on the 3D TRASAR Web, along with information on probable causes and troubleshooting tips. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 170: Vantage V100

5500 - Installation & Operation Manual Vantage V100 Vantage V100 is Nalco’s field data management software program. It allows users to trend opera- tional data, create Statistical Process Control graphs, and report corrective actions. 3D TRASAR files can be downloaded into V antage V100 by either: •... - Page 171 V antage V100 database, and can be archived for long term storage. The 3D TRASAR controller will only store up to 65 days worth of data. Technical Help 521-OM0108.88 7-10 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 172: Vantage V100 3D Trasar Ez Reports

(with optional statistics range) for data that you wish to include in your report. STEP 2 – Select the graphs you wish to include in your report. Each row in the grid represents one graph in the report. Technical Help 521-OM0108.88 7-11 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 173 STEP 3 – Click on Make to create the report in Excel. Save report template in V antage V100 by clicking on the Batch Menu and saving to a Batch File in the database. Technical Help 521-OM0108.88 7-12 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 174 System Setup as shown below . STEP 1 – Click System Setup STEP 2 – Select the appropriate 3D TRASAR Data Source and double-click the measurement in the grid. Technical Help 521-OM0108.88 7-13 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 175 7.6.3 Vantage V100 3D TRASAR Spec Limits (con’t) STEP 3 – Type in the Specification Limits into the appropriate fields in the Edit Measurement form. Repeat with all 3D TRASAR measurements. Technical Help 521-OM0108.88 7-14 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 176: Nalco Global Gateway

It is important to verify that the Nalco Global Gateway is right for your application before purchasing. Verifying the site for the Nalco Global Gateway is similar to finding a place in an industrial environ- ment to make a cell phone call. Even the best cell phone on the market is of little use without an adequate, interference free, stable signal. -

Page 177: Section 8: Maintenance

Replacement pH Probe (1), Replacement ORP Probe (1), Re- placement Mild Steel and Copper NCM Probes (2 of each), P/N 060-TRMNKIT.88 Fluorometer Desiccant Canister, Fluorometer Desiccant Indica- Maintenance Value Package tor. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 178: Clean Fluorometer Flow Cell

Monthly, to fine-tune calibration to compensate for mi nor drifting. Conductivity After installation of new probe, or if probe readings become erratic due to fouling/degradation. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 179: Probe Replacement Schedule

Pellets and replace the desiccant pack in the lid with the new one provided. Re- placement desiccants are included with each container of pellets. Refer to Section 6 for detailed pellet feeder maintenance. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 180: Section 9: Troubleshooting

Bio- Index. 3D TRASAR Starter 3500 system requires Purchase 3D TRASAR fluorometer fluorometer upgrade to measure Nalco Bio- upgrade P/N 060-TR3200.88 Index. This measurement does not appear in System Select 3D Scale Control as the... - Page 181 Relay Control, return the bi o-reporter to Auto mode. The oxidizing biocide is in a failsafe mode due Check the active alarms and resolve to an alarm conditi on. the alarm condition(s) as needed. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 182 Tools/Internet Options and cli ck on the Connections tab. Cli ck the LAN Settings button, and uncheck "Use Proxy Server". Be sure to return this setting when fi nished if required for other applications. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 183 This will cause the 10-minute delay No Flow Alarm is switch, resulting in i ntermittent flow/no flow timer to reset each time flow is not active. indications. detected, preventing the alarm. Increase the flow. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 184 A comma ',' may be used as a pause. ISP settings are incorrect. Check the following settings provided by your Nalco Rep: username, password, access phone number. Analog phone line is not connected. Check all connections and replace the Controller data phone line if damaged.

- Page 185 65 Manual on status fields. 64 Manual off 33 Failsafe on 32 Failsafe off 16 Forced off 9 Flow failsafe on 8 Flow failsafe off 0 Not controlled Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 186: Alarm Screen Troubleshooting

2) Low Alarm threshold set too high. 2 ) Readjust alarm threshold. below Low 3) Cooling system problem. Note: Freezing will burst 3) Diagnose and resolve cause of low bulk water Alarm threshold piping. temperature. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... - Page 187 2) High Alarm threshold set too low. 2) Readjust alarm threshold. Alarm threshold 3) Corrosion treatment program needs adjustment. 3) Consult your Nalco Representative. Cell Fouling Mesurement 1) Fluorometer flow cell is fouled. 1) Clean flow cell with supplied brush and cleani ng...

- Page 188 Help Desk at 630-305-CHEM for assistan ce. High control 3) Biocide program requirements have changed. 3) Reassess biocide program with your local Nalco Representative. 1) Biocide pump rep/stroke are set too high , or pump 1) Adjust feed rate downward or replace with a lower is too large for system.

- Page 189 1) System stress is high compared to learned stress. 1) If lo wer cycles are required, enter lower Cond. Setpoint conductivity setpoint and relearn system stress. Adj. adjusted to the Otherwise, no acti on is required. minimum Technical Help 521-OM0108.88 9-10 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 190 Additional Calculated Variables • Holding Time Index • System Volume • Blowdown Rate • Heat Rejection (Btus) • Makeup Water Rate • Recirculation Rate • Pump Duty • Product Usage Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 191 Maximum water pressure 90 psi Display/Keypad Numeric keypad plus specialty keys, graphical display with plotting functions Security Password protected (user assignable) Data management All variables are data logged in spreadsheet format Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 192 Communications • Ethernet port for direct PC connection • Built-in modem for direct remote connection or access to 3D TRASAR web via Internet (requires ISP) • Optional Nalco Global Gateway with monthly service package. Approvals UL, CUL, CE Software • 3D TRASAR configurator for system configuration and data transfer •...

- Page 193 Air Purged Wall Mount with Junction Box 060-TR5530.88 060-TR5532.88 060-TR3531.88 060-TR3533.88 Air Purged Frame Mount with Junction Box 060-TR5531.88 060-TR5533.88 060-TR5120.88 Pellet Feeder B-10 060-TR5540.88 High Pressure Water Reinjection System B-11 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 202 Model #060-TR5120.88 Pellet Feeder Plumbing Assembly B-10...

- Page 203 Model 060-TR5540.88 High Pressure Water Reinjection System B-11...

- Page 204 Bio-reporter, Pellet Feeder Assembly, for system sizes > 12,000 gallons 141-PJ4035.88 Bio-reporter, Liquid Feed pump, for system sizes 3,000 to 12,000 gallons 6008505 Bio-reporter, Liquid Feed pump, for system sizes up to 3,000 gallons Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 205 Corrosion Probe w/ ferrule, C uNi 70/30 400-NCMP7B.88 Corrosion Probe w/ ferrule, 443 Admiralty Brass 6016180 Corrosion Probe w/ ferrule, 6061 Aluminum 6016182 Corrosion Probe w/ ferrule, 1100 Alumi num 400-NCMP10.88 Corrosion Probe Package, Galvanized Steel Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 206 Available October 1st, 2009 International Wireless 1-year contract renewal (SIM not i ncluded) 060-NGG200R.88 Available October 1st, 2009 060-TR5284.88 External Antenna for Nalco Global Gateway (Cable sold separately) 060-TR5284C100.88 100-foot cable for 060-TR5284.88 060-TR5284C25.88 25-foot cable for 060-TR5284.88 060-TR5270.88 LAN Router...

- Page 207 Corrosion Probe Restraint D evice 6000668 Replacement F lowswitch 060-TR5224.88 Fluorometer, up per adapter fitting 060-TR5225.88 Fluorometer, lo wer adapter fitting 991-05055272.88 Controller S crews TK -135 Configurator Software C D Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 208 Conductivity C alibration Solution, 3000 uS, 1L * This part is available as an optional accessory, but is not included with either the Start-up Kit or the Maintenance Value Package. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 209 ® 3D TRASAR 5500 - Installation & Operation Manual Hardware Piping Layout Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 210 ® 3D TRASAR 5500 - Installation & Operation Manual Pellet Feeder Piping Layout - Lower Assembly 060-TR5334.88 Pellet Feeder Piping Layout - Upper Assembly 060-TR5332.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 211 ® 3D TRASAR 5500 - Installation & Operation Manual High Pressure Water Reinjection System 060-TR5540.88 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 212 A copy of the manual shown below is included with models 060-TR3530.88, 060-TR3531.88, 060-TR3532.88, 060-TR3533.88, 060-TR5530.88, 060-TR5531.88, 060-TR5532.88 and 060-TR5533.88. Use this manual for start-up of the Air Purge System. Call 630-305-CHEM for more assistance. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 213 Coil, Word, Long, and Float blocks (to minimize Controller communication traffic). Floating point numbers are formatted using the Modicon Protocol convention (two consecutive 16-bit registers. Note: Daniel’s Floating Point Extension is not supported. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 214 System Volume Average 3000 999.0 Blowdown Rate 3000 999.0 Makeup Rate 3000 999,999.0 kBTU/day Heat Rejected 3000 999.0 Recirculation Rate 3000 -99,999 99,999.0 Analog Input 1 3000 -99,999 99,999.0 Analog Input 2 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 215 Input registers contain the same information as the Floating Point Input registers. T ables 3, 4, 5 & 6 document all registers currently supported by the 3D TRASAR Controller . Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

-

Page 216: Control Relay 1 - Trasar 00000

Actions à Manual Relay Control à “Product Name” State Control Relay3 - Bioreporter Actions à Manual Relay Control à “Product Name” State Control Relay 4 – Oxid Biocide Actions à Manual Relay Control à “Product Name” State Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 217: Control Relay 5 - Nonox Biocide 00000

Information à Diagnostic Data à Fluorometer Data à Rz Rs (Bioproduct) Information à Diagnostic Data à Fluorometer Data à Rs Turbidity Information à Operating Data àTurbidity OR, Information à Diagnostic Data à Fluorometer Data à Turbid Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 218: Corrosion 1 (Right Side Of Controller) 3000

Information à System Performance à N Scale Index* *Controller must be configured for 3D Bio Control to be visible Polymer Consumption Information à System Performance à Consumption Information à Operating Data à HTI Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM... -

Page 219: Analog Input 2

• Mail Server Name/IP: (Supplied by customer IS Department) • Alarm Email Address: alarms@3dtrasar.com (Alarm Server address located at Nalco Company) • Data Email Address: data@3dtrasar.com (Data Server address located at Nalco Company . This email address is not changeable without contacting Nalco T echnical Support) Technical Help 521-OM0108.88... - Page 220 The 3D TRASAR Controller sends data and alarms to Nalco via email. All that is required is that the customer’s SMTP server grants access to the 3D TRASAR Controller and allows it to send out- bound email to the Nalco mail server (3dtrasar .

- Page 221 Appendix F: 3D TRASAR Starter Upgrade Procedures There are four different upgrades available for the 3D TRASAR Starter system: 3D TRASAR Fluorometer upgrade, P/N 060-TR3200.88 • Nalco NCM Corrosion Measurement upgrade, P/N 060-TR3205.88 • 3D TRASAR pH upgrade, P/N 060-TR3211.88 •...

- Page 222 In order to complete the registration, you will need the following information: controller serial number and sales order and SAP Sold to numbers that appear on upgrade order . Registration be completed before proceeding to next step. Important! must 48 hours Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 223 4. Replicate Computer with Nalco LAN. 48 hours after completion of web registration (step 3) your upgrade will become available on the Nalco LAN. Y ou must replicate your computer in order to automatically receive the upgrade. 5. Configure New Hardware Connect computer to controller, and the upgrade will appear in the Manage Controller button on the Configurator home page.

- Page 224 Order the 3D TRASAR Starter NCM Corrosion Measurement Upgrade, P/N 060-TR3205.88 along with required probes (sold separately.) Order through Nalco customer service, or through the Order Wizard. 2. Unpack and Identify Components The 3D TRASAR NCM technology upgrade includes the following: Patented NCM technology upgrade procedure •...

- Page 225 4. Replicate Computer with Nalco LAN. 48 hours after completion of web registration (step 3,) your upgrade will become available on the Nalco LAN. Y ou must replicate your computer in order to automatically receive the upgrade. 5. Configure New Hardware Connect computer to controller, and the upgrade will appear in the Manage Controller button on the Configurator home page.

- Page 226 Order the 3D TRASAR Starter pH Upgrade, P/N 060-TR3211.88 (includes pH probe, cable and installation instructions.) Order through Nalco customer service, or through the Order W izard. 2. Install New Hardware Install the pH probe as follows: STEP 1 - Carefully unpack the pH probe.

- Page 227 Order the 3D TRASAR Starter ORP Upgrade, P/N 060-TR3221.88 (includes ORP probe, cable and installation instructions.) Order through Nalco customer service, or through the Order W izard. 2. Install New Hardware Install the ORP probe as follows: STEP 1 - Carefully unpack the ORP probe.

- Page 228 Continuous corrosion rate measurement is available using Nalco’s NCM technology . For systems requiring routine feed and control of treatment chemicals, 3D TRASAR technology is the most advanced system of its type available, providing mea-...

- Page 229 White – Power Light • Red – Alarm Light • Green – Pump Running Light • Refer to operation manual shipped with high pressure water reinjection system for more details. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 230 Identify Hardware Model Wall Mount Frame Mount Description Model Model 060-TR5515.88 060-TR5516.88 3D TRASAR for High Fouling Applications 060-TR5525.88 060-TR5526.88 Enclosed 3D TRASAR for High Fouling Applications Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 231 (used with the fluorometer cleaning system.) Analog output 1 is pre-wired (jumpered) to Analog input 1 for the purpose of monitoring and logging flow cell fouling data (every 15 minutes.) Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 232 1. #1 Name select Cell Fouling 2. 4 mA Value enter 0 3. 20 mA Value enter 100 4.3 Select Alarm Settings. For system alarms: 1. Cell-fouling % High enter 25 Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 233 Take proper precaution in handling and disposal. The automated fluorometer cleaning system is designed to work with cooling water system sizes 25,000 gallons or larger . For smaller systems or to request a MSDS, please contact Nalco at 1-630-305- CHEM.

- Page 234 After start up, check basket strainer , magnet and rotometers weekly . Determine appropriate • maintenance schedule based on degree of fouling. Check pump tubing of automated fluorometer cleaning system for wear monthly , • replace if necessary. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 235 Enclosed Wall Mount for 060-TR5525.88 36 7/8 x 13 7/8 x 62 5/8" High Fouling Applications Enclosed Frame Mount for 060-TR5526.88 36 7/8 x 28 x 65 3/4" High Fouling Applications Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 236 Different wire colors are also used in the control box. Specifications are shown below . Connection Controller Box Controller Box Wire Color Description Board Reference Terminal Ground TB9-4 Not used Green with Ground TB9-3 Yellow Stripe Neutral TB9-2 Blue Line Power TB9-1 Brown Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 237 OBC based on set-point control using the signal from the halogen analyzer. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 238 OBC. IMPORTANT: Disabling of halogen analyzer control of oxidant feed must be done through the Analog Input Selection Screen and not through the Biocide Control Settings Screen. Technical Help 521-OM0108.88 Copyright © 2009 Nalco Company (630) 305-CHEM...

- Page 239 , refund of or credit for the product price excluding shipping. Nalco DISCLAIMS ALL OTHER WARRANTIES INCLUDING WARRANTIES OF MERCHANT- ABILITY AND FITNESS FOR A PARTICULAR PURPOSE. In no event shall Nalco be liable for any consequential or indirect damages. Non-Warranty Equipment Returns...

- Page 240 3D TRASAR System The Nalco 3D TRASAR system is the most advanced water treatment control system on the market today. It represents a total system approach, encompassing service, innovative chemistry , ad- vanced software and sophisticated equipment, that allows you to manage stresses in cooling tower systems on a continuous, ongoing basis.

- Page 241 As the Nalco Bio-Index increases the relative microbial control decreases. Nalco Scale Index The Nalco Scale Index (NSI) is a calculated variable that compares the current rate of polymer consumption against the learned average rate of polymer consumption. NSI has a direct correla- tion to the cooling system stress level.

- Page 242 (user set.) Tagged Polymer A new component of TRASAR cooling water programs (ie. Nalco’s Prism polymer or High Stress Polymer (HSP.)) The concentration of the “tag” equals the concentration of available, un-reacted dispersant polymer. The 3D TRASAR algorithm compares the inert TRASAR signal to that of the tagged signal, and then makes appropriate control decisions, either to increase or decrease the treatment concentration or increase or decrease the conductivity set-point.

- Page 243 Latin America: Av das Nações Unidas 17.891 ٠ 6° Andar 04795-100 ٠ São Paulo ٠ SP ٠ Brazil www.nalco.com Nalco, the logo, PRISM, Vantage, 3D TRASAR, STA٠BR٠EX, ACTI-BROM, are Registered Trade- marks of Nalco Company. Towerbrom is a Registered Trademark of Occidental Chemical Corporation.

Need help?

Do you have a question about the 3D TRASAR Series and is the answer not in the manual?

Questions and answers

dcs operator is not getting a signal from the field

Check the following:

1. Ensure the conductivity or fluorometer sensor connections are secure in the controller.

2. Replace the sensor cable if damaged.

3. Power off and on to reset the system.

4. Verify ISP settings (username, password, access phone number).

5. Confirm the controller is registered with 3D TRASAR Web.

6. If using a GSM/GPRS connection, check signal strength and consider using a high-gain antenna if necessary.

This answer is automatically generated

How do I switch 4-20ma output AO5 Port right now its sending 4ma out for 100% of span and 20ma out for 0%. I Would like to switch it to 4ma 0% and 20ma 100% of span so if it looses power out bleach pump does not continuously run.

The provided context does not include specific steps for configuring the 4-20mA output on the Nalco 3D TRASAR Series. However, based on standard practices, configuring the 4-20mA output typically involves accessing the controller’s settings through its interface or software and adjusting the output scaling. You would set the lower range (0%) to output 4mA and the upper range (100%) to output 20mA. If the controller has a calibration or configuration menu, navigate to the analog output settings and enter the desired span values accordingly.

If further details are required, refer to the controller’s installation and operation manual.

This answer is automatically generated