Summary of Contents for Thytronic NA10

- Page 1 NA10 PHASE & RESIDUAL OVERCURRENT PROTECTION RELAY MANUAL NA10 - Manual - 04 - 2022...

-

Page 2: Table Of Contents

CT supervision - 74CT ....................................19 Pilot wire diagnostic ....................................19 Demand measures ....................................... 19 Oscillography (DFR) ..................................... 20 PLC and PLC2 (Programmable Logic Controller) ............................. 20 3.9 MEASURES ........................................21 Accuracy (type tests)....................................21 Measures ........................................21 NA10 - Manual - 04 - 2022... - Page 3 Oscillography - DFR ......................................91 6 INSTALLATION 6.1 PACKAGING ........................................93 6.2 MOUNTING ........................................93 6.3 ELECTRICAL CONNECTIONS ..................................97 6.4 NOMINAL CURRENT I AND I SETTING ..............................107 6.5 LED ALLOCATION ......................................110 6.6 FINAL OPERATIONS ...................................... 110 NA10 - Manual - 04 - 2022...

- Page 4 8.5 APPENDIX B2 - Interfaces ................................... 138 8.6 APPENDIX B3 - Connection diagrams ............................... 139 8.7 APPENDIX C - Dimensions ................................... 143 8.8 APPENDIX D - Setting table ..................................144 8.9 APPENDIX E - EC Declaration of conformity ..............................176 NA10 - Manual - 04 - 2022...

-

Page 5: Introduction

I N T R O D U C T I O N Scope and liability This document describes the functions, the technical data of NA10 devices; instructions for mount- ing, setting and commissioning are included. This manual has been checked out, however, deviations from the description cannot be completely ruled out, so that no liability in a legal sense for correctness and completeness of the information or from any damage that might result from its use is formally disclaimed. -

Page 6: Product Identification

• Test label with following informations: data, serial number and test operator signature. Environment The NA10 device must be employed according to the environment conditions shown (see technical data). In case of different environment conditions, appropriate provisions must be provided (conditioning system, humidity control, etc...). - Page 7 Setting and monitoring software Log file A text file that lists actions that have occurred (ThyVisor). J2SE Java Platform Standard Edition Subnet Mask (Ethernet nomenclature) Software Firmware Upgrade Firmware upgrade eXtensible Markup Language NA10 - Manual - 04 - 2022 INTRODUCTION...

- Page 8 ON delay timer with reset ( delay) OUTPUT RESET RESET INPUT ON delay timer without reset ( delay) OUTPUT INPUT DROP OFF delay timer (dropout) without reset ( delay) DROP DROP OUTPUT Symbols.ai NA10 - Manual - 04 - 2022 INTRODUCTION...

- Page 9 DROP INPUT Minimum pulse width operation for output relays ( OUTPUT INPUT Latched operating mode for output relays and LEDs Latched OUTPUT INPUT Pulse operating mode for output relays OUTPUT Symbols1 .ai NA10 - Manual - 04 - 2022 INTRODUCTION...

-

Page 10: General

G E N E R A L Preface The relay type NA10 can be used in radial networks as feeder or power transformer protection. In solidly grounded systems the residual overcurrent protection can be used on feeders of any length, while in ungrounded or Petersen coil and/or resistance grounded systems, the residual over- current protection can be used on feeders of small length in order to avoid unwanted trippings due to the capacitive current contribution of the feeder on external ground fault. -

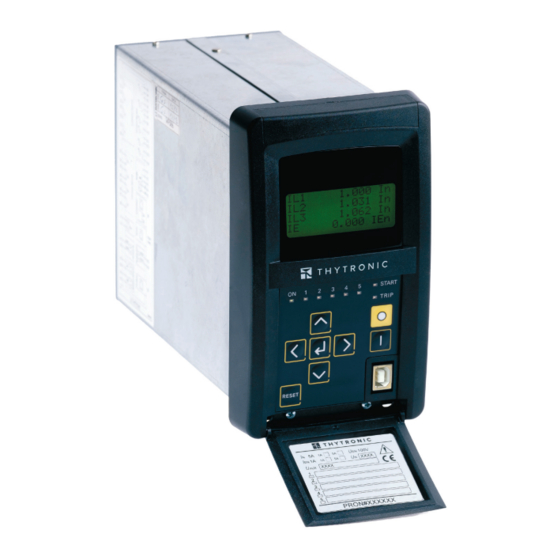

Page 11: Main Features

• USB front serial port (local communication for ThyVisor). • Real time clock with super capacitor backup. The most significant constructive features of the NA10 protection relay are: • Galvanically insulated input and output circuits (communication and binary circuits included). -

Page 12: Technical Data

• Air discharge 8 kV Reference standards EN 60255-22-3 IEC 60255-22-3 EN 61000-4-3 IEC 61000-4-3 Radiated radio-frequency fields • 80...1000 MHz AM 80% 10 V/m • 900 MHz Pulse modulated 10 V/m NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 13: Emission

Reference voltage 250 V Overvoltage category ‡ Certifications Reference standards Product standard for measuring relays EN 50263 CE Conformity • EMC Directive 2014/30/EC • Low Voltage Directive 2014/35/EC IEC 60255-1 Type tests NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 14: Input Circuits

300 mW (5 V/ 5 mA) Life: • Mechanical operations • Electrical operations ‡ Block output (Logic selectivity) Quantity Type optocoupler Note 1 The different versions must be select on order NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 15: Mmi

Note 3 The nominal current settings doesn’t concern the protection elements; they must agree with hardware setting (dip-switch 1 A or 5 A) . Note 4 1 - 5 A selection is meaningful for standard CTs versions; the computed residual current is employed for NA10 protection relays equipped with... - Page 16 Asymptotic reference value: 1.1 I> Minimum operate time: 0.1 s Equation is valid for 1.1 ≤ I/I> ≤ 20 With I> pickup ≥ 2.5 I , the upper limit is 50 I NA10 - Manual - 04 - 2022 TECHNICAL DATA...

-

Page 17: Residual Overcurrent - 50N/51N

Asymptotic reference value: 1.1 I > Minimum operate time: 0.1 s Equation is valid for 1.1 ≤ I > ≤ 20; with I > pickup ≥ 0.5 I , the upper limit is 10 I NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 18: Breaker Failure - Bf

>Pickup accuracy ± 0.5% con 0.1 I ± 0.2% con 1 I >Pickup accuracy ± 0.5% con 0.01 I ± 0.2% con 1 I Operate time accuracy 5% or ± 10 ms NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 19: Control And Monitoring

F I X ) • Rolling on demand period (t 1...60 min (step 1 min) ROL ) • Number of cycles for rolling on demand (N. 1...24 (step 1) ROL ) NA10 - Manual - 04 - 2022 TECHNICAL DATA... -

Page 20: Oscillography (Dfr)

Note 1 For the DFR function a licence is required; call Thytronic for purchasing. Note 2 The measured residual current is available only for NA10 protection relays equipped with standard CTs sensor inputs Note 3 The measured residual current is available only for NA10 protection relays equipped with standard CTs sensor inputs... -

Page 21: Measures

Temperature PT8 Note 1 The computed residual current (vector sum of the phase currents) is provided for NA10 protection relays equipped with LPCT sensor inputs Note 2 The temperature measuring is acquired by means of RTD probes Pt100 (eight Pt100 inputs with one MPT module); if the module is not available the concerning measure is meaningless. -

Page 22: Function Characteristics

F U N C T I O N C H A R A C T E R I S T I C S F U N C T I O N C H A R A C T E R I S T I C S HARDWARE DESCRIPTION The following figure illustrates the basic structure of the NA10 relay LEDs ETHERNET... -

Page 23: Power Supply Board

The removable plug allows separation of the MMI module for free access to the CPU board when DIP-switch setting is required. Note 1 The phase and residual nominal currents must be adjusted by means dip-switch. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 24: Software Description

Example are: • Keyboard management • RTC (Real Time Clock) updating • RAM/EEPROM updating • Diagnostic • Input acquisition • Output relay management • MMI • I/O updating • DSP data processing NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 25: Drivers

Xml files used for communication. The automatic code generation criteria ensures the quality of the result in terms of the reusability, verifiability and maintainability of the software life cycle. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 26: I/O Description

From the sampled quantities, several measures are computed for protection, monitoring and meter- ing purposes. • Direct • Calculated • Harmonics • On demand Direct • Power frequency. ACQUISITION ≈ ≈ (Hz) ≈ F. a i NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 27 Maximum value of averages inside time interval Average inside time interval L1ROL R OL R OL L 2 ROL ∑ ∑ L x ROL L x k L 3 ROL Rol-Demand.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 28 Average inside time interval L1MIN L 2 MIN R OL L 3 MIN ∑ L x MIN L x n Reset Min-Demand.ai Use of over-described measures is shown in the following tables. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 29: Conventions

L1, L2, L3 ordered, while an inverse cyclic sequence is defined when the three phases are L1, L3, L2 ordered.. D i re c t se q u ence cy cl i c order I nv er s e s equence cy cl i c order fasori1.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 30: Use Of Measured Values

Record 2 Record ... NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 31: Binary Inputs

Open CB Close CB Remote trip Reset on demand measures Note 1 to be select on order NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 32 Note 1 To enable the profile switching the “Input-selected” parameter must be set inside the “Profile selection” submenu. If multiple setting groups are not required, Group A is the default selection NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 33 Note 4 The activation of one binary input produces indiscriminately a block of all protective elements programmed for being blocked from Block1 NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 34 Binary input INx Binary input allocation for CB state acquisition CB-pos.ai Open CB Note 1 The reset of the total counters is practicable by means ThyVisorcommand with Session Level 1 (available with password) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 35 Remote trip n.c. INx t INx t n.o. Binary input INx Binary input allocation for remote trip Remote-trip.ai Reset demand measures The input activation makes a reset of all demand measures. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 36: Output Relays

- No-latched , in order that it stays ON for normal conditions and the other way round it goes OFF if any fault is detected and/or the auxiliary supply turns OFF. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 37 Close CB command relays (CBclose-K) Remote tripping relays (RemTrip-K) Not received pulses at BLIN signalling relays (PulseBLIN-K) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 38: Led Indicators

Note 1 The START and the TRIP LED are user assignable to any function; other than starting and tripping information can be assigned to them too, just the same for L1...L5 Note 2 All LEDs are unassigned in the default setting. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 39 Close CB command LEDs (CBclose-L) Remote tripping LEDs (RemTrip-L) Not received pulses at BLIN signalling LEDs (PulseBLIN-L) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 40: Communication Interfaces

• RS485 port on the rear side for bus communication. • Ethernet port on the rear side for bus communication. To connect the local port you need to use a cable USB Type B - Type A; the Thytronic cable code L10042 can be supplied. -

Page 41: Protective Elements

The residual CT primary current I must be set as: I = 100 A Note 1 The computed residual current is available for NA10 protection relays equipped with LPCT sensor inputs NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 42 Measures may be displayed according the following operating modes: - With RELATIVE setting all measures are related to the nominal value, - With PRIMARY setting all measures are related to the primary value. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 43: Thermal Protection With Rtd Thermometric Probes - 26

0 . 2 5 s 0 . 2 5 s 0 . 2 5 s Pt1...8 update t-refresh-F26.ai Note 1 The 26 menu is available when the MPT module is enabled NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 44 - 26 \ PTx Probe \ ThALx Trip where x = 1...8. Note 1 The common settings concerning the Breaker failure protection are adjustable inside the Breaker Failure - BF menu. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 45: Phase Overcurrent - 50/51

Phase overcurrent-50/51 \ I> Element \ Setpoints menu. Note 1 When the input value is more than 20 times the set point , the operate time is limited to the value corresponding to 20 times the set point NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 46 Set \ Profile A(or B) \ Phase overcurrent-50/51 \ I> Element (I>> Element, I>>> Element) \ Setpoints menus. Note 1 The common settings concerning the Breaker failure protection are adjustable inside the Breaker Failure - BF menu. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 47 & & Block1 I>>>BF I>>>BF Trip I>>> & Start I>>> I>>>BLK2IN BLK2INI>>> & & Block2 I>>>BLK2OUT BLK2OUT Start I>>> & General logic diagram of the phase overcurrent elements - 50/51 all-F50-51.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 48 Note 1 The exhaustive treatment of the logical block (Block 1) function may be found in the “Logic Block” paragraph inside CONTROL AND MONITOR- ING section Note 2 The exhaustive treatment of the selective block (Block 2) function may be found in the “Selective Block” paragraph inside CONTROL AND MONITORING section NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 49 CB OPEN CB CLOSED CB OPEN 0.1 s CLP> Output t CLP> HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Phase overcurrent (50/51) - First element logic diagram (I>) Fun_50-51S1.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 50 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50-51S1_BL-diagram.ai Phase overcurrent (50/51) - Logic diagram of the blocking signals concerning the first element (I>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 51 CB OPEN CB CLOSED CB OPEN 0.1 s CLP>> Output t > > HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Phase overcurrent (50/51) - Second element logic diagram (I>>) Fun_50-51S2.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 52 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50-51S2_BL-diagram.ai Phase overcurrent (50/51) - Logic diagram of the blocking signals concerning the second element (I>>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 53 CB OPEN CB CLOSED CB OPEN 0.1 s CLP>>> Output t CLP>>> HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Phase overcurrent (50/51) - Third element logic diagram (I>>>) Fun_50-51S3.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 54 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50-51S3_BL-diagram.ai Phase overcurrent (50/51) - Logic diagram of the blocking signals concerning the third element (I>>>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 55: Residual Overcurrent - 50N/51N

>>>) by setting Note 1 When the input value is more than 20 times the set point , the operate time is limited to the value corresponding to 20 times the set point NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 56 Note 1 The common settings concerning the Breaker failure protection are adjustable inside the Breaker Failure - BF menu. Note 2 The exhaustive treatment of the logical block (Block 1) function may be found in the “Logic Block” paragraph inside CONTROL AND MONITOR- ING section NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 57 \ Selective block OUT menu. Note 1 The exhaustive treatment of the selective block (Block 2) function may be found in the “Selective Block” paragraph inside CONTROL AND MONITORING section NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 58 & & Block1 IE>>>BF IE>>>BF & Trip IE>>> Start IE>>> IE>>>BLK2IN BLK2INIE>>> & & Block2 IE>>>BLK2OUT BLK2OUT Start IE>>> & General logic diagram of the residual overcurrent elements - 50N/51N all-F50N-51N.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 59 CB OPEN CB CLOSED CB OPEN 0.1 s ECLP> Output t ECLP> HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Residual overcurrent (50N/51N) - First element logic diagram (IE>) Fun_50N-51NS1.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 60 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50N-51NS1_BL-diagram.ai Residual overcurrent (50N/51N) - Logic diagram of the blocking signals concerning the first element (IE>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 61 CB CLOSED CB OPEN 0.1 s E CLP>> Output t > ECLP > HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Residual overcurrent (50N/51N) - Second element logic diagram (IE>>) Fun_50N-51NS2.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 62 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50N-51NS2_BL-diagram.ai Residual overcurrent (50N/51N) - Logic diagram of the blocking signals concerning the second element (IE>>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 63 CB CLOSED CB OPEN 0.1 s ECLP>>> Output t >> ECLP > HIGH THRESHOLD/ LOW THRESHOLD/ HIGH THRESHOLD/ BLOCK UNBLOCK BLOCK Residual overcurrent (50N/51N) - Third element logic diagram (IE>>>) Fun_50N-51NS3.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 64 >> Blk2 OUT F-IE ≥1 BLOUT1 >>> Blk2 OUT Pilot wire output ST-IE BLK2 Block2 output 50N-51NS3_BL-diagram.ai Residual overcurrent (50N/51N) - Logic diagram of the blocking signals concerning the third element (IE>>>) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 65: Breaker Failure - Bf

(52nd or 52b ) may suffice Note 2 The exhaustive treatment of the logic block (Block 1) function may be found in the “Logic Block” paragraph inside CONTROL AND MONITORING section NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 66 BLK1 BF & Block1 Logic INx t INx t n.c. INx t Block1 input (ON≡Block) INx t Block1 n.o. Binary input INx Logic diagram concerning the breaker failure element -BF Fun-BF_Pro-n.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 67: Control And Monitoring

Note 1 In the following treatment, the logical block is defined as “Logical block” or “Block1” Note 2 The Block 1 signal forces a timer reset NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 68 INx t INx t BLK1 S< 74CT element n.o. BLK1 BF BF element Binary input INx Block1 info Block1 (internal state) Logic diagram concerning the logic block element -Block1 Block1_L.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 69: Selective Block -Block2

INx tOFF time delays must be reset to zero; the Logic parameters (ON/OFF) must be programmed in the same way of the related output relay connected with-it. Note 1 The “Logic selectivity” and “Block2“ terms are employed without distinction NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 70 Note 1 In the absence of suitable provisions, a short circuit on a pilot wire causes the block of the receiving relay, so a possible fault (contemporary or following) inside the protected zone, cannot be cleared that being the case the protective relay blocked. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 71 (the selectivity will be lost). Start xx (internal elements) BLK2OUT-Iph BLK2OUT-IE BLK2OUT-Iph/IE F-IPh, F-IE, F-IPh/IE F-IPh, F-IE, F-IPh/IE tF timers TF-timer.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 72 Note 1 Full diagnostic of pilot wires is only available when committed pilot wire input/outputs are employed Note 2 When several outputs are parallel linked the pulse emission must be enabled inside one device only, sooner inside the outermost device NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 73 = 0.100 s • I>>BLK2IN = ON • I>>BLK2OUT = ON • PulseBLIN1 = 1 s • PulseBLOUT1 = OFF • t = 0.25 s F-IPh • t = 0.30 s B-IPh NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 74: Remote Tripping

Remote trip Remote trip Logic INx t O N INx t O F F Remote trip RemTrip-K n.c. INx t INx t n.o. RemTrip-L Binary input INx Remote trip logic diagram Fun-Remote-trip.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 75: Frequency Tracking

54 Hz 63Hz 0.25 I Locked frequency (Displayed value) 60 Hz (0 Hz) f (Hz) Frequency tracking IF.ai All protective elements are always operative; accuracy is guaranteed inside locked frequency band. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 76: Second Harmonic Restraint - 2Ndh-Rest

Since an high second harmonic component is always present in the inrush current, to avoid unwant- ed tripping, the second harmonic restraint is available to restraint any selected threshold of NA10 protective relay: •... -

Page 77: Cold Load Pickup - Clp

Profile A(or B)\ Phase overcurrent - 50/51\ I> Element \ Definite time menu. CB position can be acquired by means one or two binary inputs; allocation of 52a and 52b func- tions is available inside the Set\Inputs\Binary input IN1...INx menu. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 78: Ct Supervision - 74Ct

CT monitoring logic diagram - 74CT Fun-74CT.ai Note 1 The exhaustive treatment of the logic block (Block 1) function may be found in the “Logic Block” paragraph inside CONTROL AND MONITORING section NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 79: Trip Circuit Supervision - 74Tcs

(Block 1) function may be found in the “Logic Block” paragraph inside CONTROL AND MONITORING section Note 2 Following assumption are considered for the framework: Logic: ON, Timers t and t reset to zero OFF: TRIP contact of the protection: DE-energized, No latched NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 80 Outputs are reset to zero after 6 s from the TRIP contact open. Note 1 The trip contact (TRIP) of the protection relays must be set with automatic reset (No-latched operating mode). NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 81 ) / 2 = (103.7 + 30425) / 2 = 15264 Ω ~ 15 k Ω (Power dissipated by the R resistor) = U /R = 110 / 15000 = 0.8 W NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 82: Circuit Breaker Supervision

All the named parameters are available inside the Set\Circuit Breaker supervision\CB Diagnostic menu. Tutti i suddetti parametri, nonché l’associazione delle uscite ai relè finali ed ai LED, sono presenti nel menù Set\Monitoraggio interruttore\Diagnostica interruttore. NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 83 SumIL1^2t SumIL2^2t SumIL3^2t CB Diagnostic - Cumulative tripping energy I2t Mode-tOpen State tbreak Ktrig-break break tbreak-K & tbreak-L ≥ From CB position Opening transition CB Diagnostic - CB operating time Fun-CB-diagnostic.ai NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 84: Virtual I/O

The setting is available inside the Set \ Virtual Inputs \ Settings menu. Richiusura automatica per fotovoltaico (opzionale) Note 1 For a detailed description please refer to the application notes NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... - Page 85 NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

- Page 86 IN33 IN34 IN35 IN36 IN37 IN38 IN39 IN40 IN41 IN42 NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS...

-

Page 87: Demand Measures

Note 1 The temperature measure is acquired by means of Pt100 probes (eight inputs on MPT module) Note 2 The output relay K7...K10 and binary input INx...IN42 states is meaningful when the I/O circuits are present (MRI and MID16 modules) NA10 - Manual - 04 - 2022 FUNCTION CHARACTERISTICS... -

Page 88: Measures, Logic States And Counters

• Remote trip ON/OFF • Reset on demand measures Note 1 The third harmonic component of the residual current is available for NA10 protection relays equipped with CT inputs NA10 - Manual - 04 - 2022 MEASURES, LOGIC STATES AND COUNTERS... -

Page 89: Relays

OK/NOT OK • MID16-1 module Run-time Note 1 The relays are being switched in rest position (ON if set with Energized logic - OFF if set with De-energized logic) NA10 - Manual - 04 - 2022 MEASURES, LOGIC STATES AND COUNTERS... -

Page 90: Pilot Wire Diagnostic

Note 4 Event 0 is the newest event, while the Event 299 is the oldest event Note 5 Counter is updated at any new record; it may be cleared by means ThyVisor NA10 - Manual - 04 - 2022 MEASURES, LOGIC STATES AND COUNTERS... -

Page 91: Oscillography - Dfr

(34 + 20 · 4 + 4 · 4 + 2) · (0.25 + 0.25) Note 1 Data are stored into non-volatile memory; they are retained once power is turned off. NA10 - Manual - 04 - 2022 MEASURES, LOGIC STATES AND COUNTERS... - Page 92 50 (Hz) N = int · = 75 60 (Hz) (34 + 20 · 4 + 4 · 4 + 2) · (0.50 + 0.50) Phase/to/phase fault record oscillo-phase.ai NA10 - Manual - 04 - 2022 MEASURES, LOGIC STATES AND COUNTERS...

-

Page 93: Installation

The depth dimension, as indicated in the drawing, must be increased by as much as needed to allow room for the wiring. START TRIP 102.5 ±0.3 N.4 holes ø 3,5 Flush-mount.ai Flush mounting NOTE Separation of fixed and removable parts is NOT required NA10 - Manual - 04 - 2022 INSTALLATION... - Page 94 START TRIP Projecting mounting Projecting.ai NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 95 Cutout dimension and mounting steps concerning the separate operator panel are the same for the flushing mounting (see previous pages). 212.5 128.5 START TRIP N.4 fori ø 4,5 Separate operator panel Separate-mount.ai A standard direct shielded cable with RJ45 connectors must be used for connections. Separate-mount1.ai NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 96 482.6 START START START START TRIP TRIP TRIP TRIP Rack mounting Rack-mount_en.ai To allow opening of the keyboard door a one unit space must be provided when several rack are overlapping mounted. NA10 - Manual - 04 - 2022 INSTALLATION...

-

Page 97: Electrical Connections

Examples of connection diagrams are reported on Appendix to this manual. CAUTION Devices must be installed by qualified personnel only. No liability is accepted from Thytronic due to improper use. For the A1...A22 connections, screw terminals with following characteristics are available: •... - Page 98 The same considerations also apply when the sensor is positioned near bends in the cabling. It is recommended that the transformer be placed away from bends in the conductors). Fig. 2a Fig. 2b Fig. 2c Current balanced transformer Toroide.ai NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 99 Output relay K5 and K6 have one make contact (SPST-NO, type A for K5), one break contact (SPST- NC, type B for K6) and a common reference (A13 terminal). All contacts are shown in de-energized state for standard reference. NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 100 The link must be enabled by means ThyVisor sw and USB connection: • Set the IP address (Host IP address e IP net mask) in order that the NA10 and PC parameters are matched; the parameters are inside the Communication \ Ethernet submenu.

- Page 101 It is recommended to terminate the line at the extremities of the same; this must be performed on the RS485 line control unit and on the NA10 device placed at the furthest point connecting the specially provided resistor; termination can be made by means a jumper between the F2-F3 terminals.

- Page 102 THYBUS OUTPUT 54 53 42 41 38 37 36 35 IN10 OUTPUT INPUT IN11 MODULO INGRESSI REMOTI MID-16 IN12 IN13 1 2 3 4 5 6 7 8 9 IN14 IN15 IN16 NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 103 One MRI module, two MID16 modules, one MPT module, one MCI module and one MMI module (separate operator panel) can be connect at the same time to the Thybus port (maximum expansion). NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 104 A ring network example is shown on the following pages. Block out signals concerning the NA10 devices (S3.1, S3.2 e S3.3) are split on two isolated outputs by means of MRB devices (B2.1, B2.2 and B2.3) to allow proper selectivity logic operation..

- Page 105 Selectivity logic example NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 106 Accelerated logic example Selectivity logic example NA10 - Manual - 04 - 2022 INSTALLATION...

-

Page 107: Nominal Current I N And I En Setting

Unplug the RS485 and RJ45 cables (Ethernet and/or Thybus) • Remove the upper tile and open the little door to access the fastening screws. Removing tie to access the fastening screws Remove-tile.ai NA10 - Manual - 04 - 2022 INSTALLATION... - Page 108 • Unscrew gradually back to back the four fastening screw in order avoid loss of the internal washer. Unmounting of the case from the switchboard is not needed. Unmounting set-in.ai • Split the MMI module and disconnect cable Split MMI module from fixed module Split-MMI.ai NA10 - Manual - 04 - 2022 INSTALLATION...

- Page 109 - eliminate any potential differences between the human body and the device by touching the metallic case, - avoid touching the printed circuit and connections (tracks, component terminals), - avoid handing the device to others, - set the programming DIPs by using antistatic tools. NA10 - Manual - 04 - 2022 INSTALLATION...

-

Page 110: Led Allocation

• The auxiliary voltage in the panel falls within the operative range of Pro_N relays. • The rated current (1 A or 5 A) of the line CT’s corresponds to the setting of Pro_N relays. • All wirings are correct. • All screws are tightly screwed. NA10 - Manual - 04 - 2022 INSTALLATION... -

Page 111: Programming And Settings

SW ThyVisor The ThyVisor sw is a “browser” of data (setting, measure, etc..); it implements an engine that is afford to rebuild the menu set up and the relationships to data concerning all Thytronic protective relays by means of XML files. -

Page 112: Mmi (Man Machine Interface)

>>” “SELECTIVE BLOCK BLOCK2 >>” “FAULT RECORDING >>” “EVENTS RECORDING >>” Setting modifying (SET) Note 1 Setting changes are enabled when the La mEnabling setting by MMI parameter is set NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING... - Page 113 • Press the Enter button for a few seconds; new message appears: “Confirm settings?” • Answer to the message ENTER: YES to confirm changes or RESET: NO to abort. The end of the LED blinking points out the end of procedure. NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING...

-

Page 114: Test

• Answer to the message ENTER: YES to confirm changes or RESET: NO to abort. The end of the LED blinking points out the end of procedure. Note 1 Instantly all the relays are switched in rest state, including relays programmed as “normally energized” NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING... -

Page 115: Circuit Breaker Commands

START and TRIP LEDs and by appearance of the pointer on the bottom • Change the parameters by means the Up (increment) or Down (decrement) buttons, using the Left and Right keys to move to the previous or next character NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING... -

Page 116: Modules Management

IN14...IN29 with one MID16 module IN30...IN45 with two MID16 modules Output relays K1...K6 on board K7...K10 with MRI module LEDs: ON, START, TRIP, L1...L5 on board L6...L10 with MRI module NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING... -

Page 117: Maintenance

NA10 - Manual - 04 - 2022 SETTING AND COMMISSIONING... -

Page 118: Appendix

Nota 3 With setting more than 2.5 In for the 50/51 elements and 0.5 IEn for the 50N/51N elements, the upper limit of the measuring range is limited to 50 In and 10 IEn respectively. NA10 - Manual - 04 - 2022 APPENDIX... -

Page 119: Phase Overcurrent 50/51 - Standard Inverse Time Curve (Iec 60255-3/Bs142 Type A)

= 0.2 s t> = 0.1 s t> = 0.02 s 0.01 I /I>inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> = 700 F_51-IECA-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 120: Phase Overcurrent 50/51 - Very Inverse Time Curve (Iec 60255-3/Bs142 Type B)

= 0.1 s t> = 0.2 s t> = 0.02 s 0.01 I /I>inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> = 14.5 F_51-IECB-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 121: Phase Overcurrent 50/51 - Extremely Inverse Time Curve (Iec 60255-3/Bs142 Type C)

= 0.1 s t> = 0.2 s t> = 0.5 s I /I >inv 0.01 7 8 9 10 Note: match of operating and setting time takes place when I/I> F_51-IECC-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 122: Residual Overcurrent 50N/51N - Standard Inverse Time Curve (Iec 60255-3/Bs142 Type A)

= 0.2 s E>inv = 0.1 s E>inv = 0.02 s E>inv 0.01 >inv 7 8 9 10 Note: match of operating and setting time takes place when I > = 700 F_51N-IECA-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 123: Residual Overcurrent 50N/51N - Very Inverse Time Curve (Iec 60255-3/Bs142 Type B)

= 0.1 s E>inv = 0.2 s E>inv = 0.02 s E>inv 0.01 >inv 7 8 9 10 Note: match of operating and setting time takes place when I > = 14.5 F_51N-IECB-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 124: Residual Overcurrent 50N/51N - Extremely Inverse Time Curve (Iec 60255-3/Bs142 Type C)

= 0.02 s E> = 0.1 s E> = 0.2 s E> = 0.5 s >inv 0.01 7 8 9 10 Note: match of operating and setting time takes place when I > F_51-IECC-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 125: Appendix A2 - Inverse Time Ansi/Ieee Curves

Nota 3 With setting more than 2.5 In for the 50/51 elements and 0.5 IEn for the 50N/51N elements, the upper limit of the measuring range is limited to 50 In and 10 IEn respectively. NA10 - Manual - 04 - 2022 APPENDIX... -

Page 126: Phase Overcurrent 50/51 - Moderately Inverse Time Curve (Ansi/Ieee Type Mi)

= 0.5 s t> = 0.2 s t> = 0.02 s 0.01 I /I >inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> = 1.664 F_51-ANSIMI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 127: Phase Overcurrent 50/51 - Very Inverse Time Curve (Ansi/Ieee Type Vi)

= 0.2 s t> = 0.5 s = 1 s t> 0.01 I /I >inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> = 2.306 F_51-ANSIVI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 128: Phase Overcurrent 50/51 - Extremely Inverse Time Curve (Ansi/Ieee Type Ei)

= 0.5 s = 5 s t> t> = 1 s 0.01 I /I >inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> = 2.789 F_51-ANSIEI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 129: Residual Overcurrent 50N/51N - Moderately Inverse Time Curve (Ansi/Ieee Type Mi)

= 0.5 s > = 0.2 s > = 0.02 s 0.01 >inv 7 8 9 10 Note: match of operating and setting time takes place when I > = 1.664 F_51N-ANSIMI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 130: Residual Overcurrent 50N/51N - Very Inverse Time Curve (Ansi/Ieee Type Vi)

= 0.2 s > = 0.5 s = 1 s > 0.01 >inv 7 8 9 10 Note: match of operating and setting time takes place when I > = 2.306 F_51N-ANSIVI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 131: Residual Overcurrent 50N/51N - Extremely Inverse Time Curve (Ansi/Ieee Type Ei)

= 0.5 s = 5 s > > = 1 s 0.01 >inv 7 8 9 10 Note: match of operating and setting time takes place when I > = 2.789 F_51N-ANSIEI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 132: Appendix A3 - Inverse Time - Rectifier, I T And Em Curves

Nota 3 With setting more than 2.5 In for the 50/51 elements and 0.5 IEn for the 50N/51N elements, the upper limit of the measuring range is limited to 50 In and 10 IEn respectively. NA10 - Manual - 04 - 2022 APPENDIX... -

Page 133: Phase Overcurrent 50/51 - Rectifier Curves

= 0.1 s t> = 0.02 s t> = 0.1 s 0.01 I /I >inv 7 8 9 10 Note: match of operating and setting time takes place when I/I> F_51-RI-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 134: Phase Overcurrent 50/51 - I T Inverse Curves (I2T=K)

= 0.2 s t> = 0.02 s t>> = 0.02 s t> = 0.1 s t>> = 0.1 s 0.01 Note: match of operating and setting time takes place when I/I> F_51-I2t-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 135: Phase Overcurrent 50/51 - Electromechanical Inverse Curves (Em)

10000 0.28 t =t> · [-0.236 (I/I> + 0.339] · 1000 t> = 0.02 s t> = 0.1 s 0.01 Note: match of operating and setting time takes place when I/I> F_51-EM-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 136: Residual Overcurrent 50N/51N - Electromechanical Inverse Curves (Em)

Residual overcurrent 50N/51N - Electromechanical inverse curves (EM) t [s] 10000 1000 > = 0.02 s > = 0.1 s 0.01 Note: match of operating and setting time takes place when I > F_51N-EM-Char.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 137: Appendix B1 - I/O Diagram

APPENDIX B1 - I/O Diagram NA10 THYBUS BLOUT- BLOUT+ ≅ FRONT PANEL Input-output circuits (five binary input version) NA10-I-O.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 138: Appendix B2 - Interfaces

OUTPUT INPUT MODULO 4 RELE’ + 8 INGRESSI DIGITALI MID8 MODULO INGRESSI REMOTI 4 RELAYS + 8 BINARY INPUTS MODULE 1 2 3 4 5 6 7 8 9 FRONT PANEL Interfaces.ai NA10 - Manual - 04 - 2022 APPENDIX... -

Page 139: Appendix B3 - Connection Diagrams

For all diagrams the output contacts are shown in de-energized state for standard reference. NA10 74CT 50/51 50BF 50N/51N CB position Three phase CTs and residual current from core balanced CT NA10-SCH.ai NA10 - Manual - 04 - 2022 APPENDIX... - Page 140 NA10 74CT 50/51 50BF 50N/51N CB position Two phase CTs and residual current from core balanced CT NA10-SCH2.ai NA10 - Manual - 04 - 2022 APPENDIX...

- Page 141 NA10 74CT 50/51 50BF 50N/51N CB position Three phase CTs and residual current from common return of phase CTs (Holmgreen) NA10-SCH4.ai NA10 - Manual - 04 - 2022 APPENDIX...

- Page 142 L1 L2 L3 NA10 74CT 50/51 50BF 50N/51N CB position Trasnformer protection - low voltage side NA10-SCH5.ai NA10 - Manual - 04 - 2022 APPENDIX...

-

Page 143: Appendix C - Dimensions

SEPARATE PROJECTING MOUNTING PROJECTING MOUNTING (Separate operator panel) (Stand alone) OPERATOR PANEL RACK MOUNTING FLUSH MOUNTING CUTOUT 482.6 102.5 ±0.3 START START START START TRIP TRIP TRIP TRIP N.4 holes ø 3.5 NA10 - Manual - 04 - 2022 APPENDIX... -

Page 144: Appendix D - Setting Table

Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset on demand measures | None Binary input IN4 NA10 - Manual - 04 - 2022 APPENDIX... - Page 145 Logic Active-ON | Active-OFF IN4 tON 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 IN4 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN4 matching Trip ProtExt | Reset counters | Reset CB Monitor |...

- Page 146 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN8 matching Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset on demand measures | None...

- Page 147 Binary input IN13 IN13 Logic Active-ON | Active-OFF IN13 tON 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 IN13 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN13 matching Trip ProtExt | Reset counters | Reset CB Monitor |...

- Page 148 IN17 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN17 matching Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset...

- Page 149 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN21 matching Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset on demand measures | None Binary input IN22 IN22...

- Page 150 IN26 Logic Active-ON | Active-OFF IN26 tON 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 IN26 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN26 matching Trip ProtExt | Reset counters | Reset CB Monitor |...

- Page 151 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN30 matching Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset on demand measures | None...

- Page 152 Binary input IN35 IN35 Logic Active-ON | Active-OFF IN35 tON 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 IN35 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN35 matching Trip ProtExt | Reset counters | Reset CB Monitor |...

- Page 153 IN39 tOFF 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 Reset LEDs | Set profile | Fault trigger | Block2 IPh/ IE | Block2 IPh | Block2 IE | Block1 | TCS1 | TCS2 | IN39 matching Trip ProtExt | Reset counters | Reset CB Monitor | 52a | 52b | Open CB | Close CB | Remote trip | Reset...

- Page 154 Minimum pulse width 0 ... 500 step = 5 Logic De-energized | Energized Operation MODE No-latched | Pulse | Latched Minimum pulse width 0 ... 500 step = 5 Logic De-energized | Energized Operation MODE No-latched | Pulse | Latched Minimum pulse width 0 ...

- Page 155 Loop 1 Sign Loop1-Sign Unipolar | Bipolar Loop 1 Nominal multiplier Loop1-M 0.01 ... 100.00 step = 0.01 Current loop 2 Loop 2 Measure assigned Loop2-Mis Frequency | IL1 | IL2 | IL3 | IE | IL | PLC | None 0-2 mA | 0-4 mA | 0-5 mA | 1-5 mA | 0-6 mA | 1-6 Loop 2 Output range Loop2-Range...

- Page 156 Value 0 ... 100 step = 1 Th>2 Breaker failure Th>2BF OFF | ON Th>2 Trip relays Th>2-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 Th>2 Trip LEDs Th>2-L | L10...

- Page 157 ThAL6 Alarm ThAL6 Enable ThAL6 Enable OFF | ON 26 PT6 Alarm threshold ThAL6 0 ... 200 step = 1 ThAL6 Operating time Value 0 ... 100 step = 1 ThAL6 Alarm relays ThAL6-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 ThAL6 Alarm LEDs ThAL6-L...

- Page 158 I> Enable I> Enable OFF | ON IEC/BS A | IEC/BS B | IEC/BS C | ANSI/IEEE MI | I> Curve type I>Curve ANSI/IEEE VI | ANSI/IEEE EI | RECTIFIER | I2t | EM | DEFINITE ICLP> Mode ICLP> Mode OFF | ON - Element blocking | ON - Change setting ICLP>...

- Page 159 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 I>> Start LEDs I>>ST-L | L10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 I>>...

- Page 160 IEC/BS A | IEC/BS B | IEC/BS C | ANSI/IEEE MI | IE> Curve type IE>Curve ANSI/IEEE VI | ANSI/IEEE EI | EM | DEFINITE IECLP> Mode IECLP> Mode OFF | ON - Element blocking | ON - Change setting IECLP>...

- Page 161 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 IE>> Trip LEDs IE>>TR-L | L10 Definite time 50N/51N Second threshold definite time State OFF | ON 0.010 ... 0.999 step = 0.001 Pickup value 1.00 ...

- Page 162 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 74TCS Trip LEDs 74TCS-TR-L | L10 Selective block - BLOCK2 Selective block IN BLIN1 Selective block operating mode ModeBLIN1 OFF | ON IPh/IE | ON IPh | ON IE BLIN maximum activation time for phase protections Value...

- Page 163 Th>1 Enable Th>1 Enable OFF | ON 26 PT1 Trip threshold Th>1 0 ... 200 step = 1 Th>1 Operating time Value 0 ... 100 step = 1 Th>1 Breaker failure Th>1BF OFF | ON Th>1 Trip relays Th>1-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 Th>1 Trip LEDs Th>1-L...

- Page 164 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 Th>4 Trip LEDs Th>4-L | L10 PT5 Probe ThAL5 Alarm ThAL5 Enable ThAL5 Enable OFF | ON 26 PT5 Alarm threshold ThAL5 0 ...

- Page 165 ThAL8 Operating time Value 0 ... 100 step = 1 ThAL8 Alarm relays ThAL8-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 ThAL8 Alarm LEDs ThAL8-L | L10...

- Page 166 0.02 ... 9.99 step = 0.01 I>inv Operating time t>inv 10.0 ... 60.0 step = 0.1 I>> Element Setpoints I>> Enable I>> Enable OFF | ON I>> Curve type I>>Curve I2t | DEFINITE ICLP>> Mode ICLP>> Mode OFF | ON - Element blocking | ON - Change setting ICLP>>...

- Page 167 I>>> Start relays I>>>ST-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 I>>> Trip relays I>>>TR-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 I>>>...

- Page 168 IE>> Element Setpoints IE>> Enable IE>> Enable OFF | ON IECLP>> Mode IECLP>> Mode OFF | ON - Element blocking | ON - Change setting IECLP>> Activation time 0.00 ... 9.99 step = 0.01 Value 10.0 ... 100.0 step = 0.1 tE>>...

- Page 169 IE>>>def Operating time Value 0.03 ... 10.00 step = 0.01 Second Harmonic Restraint - 2ndh-REST Second harmonic restraint threshold State OFF | ON Pickup value 10 ... 50 step = 1 I2ndh> reset time delay 0.00 ... 9.99 step = 0.01 Value 10.0 ...

- Page 170 BF Start from circuit breaker CB Input OFF | ON BF Start relays BF-ST-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 BF Trip relays BF-TR-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 BF Start LEDs BF-ST-L...

- Page 171 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 | 32 | 33 | 34 | 35 | 36 | 37 | 38 | 39 | 40 | 41 | 42 | 43 | 44 | 45 | 46 | 47 | 48 | 49 | 50 Switch 31...

- Page 172 0 ... 59 step = 1 Timer 18 60 ... 3540 step = 60 3600 ... 86400 step = 600 0 ... 59 step = 1 Timer 19 60 ... 3540 step = 60 3600 ... 86400 step = 600 0 ...

- Page 173 0.03 ... 9.99 step = 0.01 Value 10.0 ... 99.9 step = 0.1 100 ... 200 step = 1 S< Logical block S<BLK1 OFF | ON S< Trip relays S<TR-K K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 START | TRIP | L1 | L2 | L3 | L4 | L5 | L6 | L7 | L8 | L9 S<...

- Page 174 Frequency | IL1 | IL2 | IL3 | IE | IL1-2nd | IL2-2nd | Analog 6 IL3-2nd | I-2nd/IL | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | Off Frequency | IL1 | IL2 | IL3 | IE | IL1-2nd | IL2-2nd | Analog 7 IL3-2nd | I-2nd/IL | T1 | T2 | T3 | T4 | T5 | T6 | T7 | T8 | Off...

- Page 175 K1 | K2 | K3 | K4 | K5 | K6 | K7 | K8 | K9 | K10 | IN1 | IN2 | IN3 | IN4 | IN5 | IN6 | IN7 | IN8 | IN9 | IN10 | IN11 | IN12 | IN13 | IN14 | IN15 | IN16 | IN17 | IN18 Binary 7 | IN19 | IN20 | IN21 | IN22 | IN23 | IN24 | IN25 |...

-

Page 176: Appendix E - Ec Declaration Of Conformity

Issue Title EN 60255-1 2011 Electrical relays Part 6: General requirements for measuring relays and protection equipment Year of CE marking: 2005 Signature ..........Name FIORE Mattia Title Managing director Date 12-2005 NA10 - Manual - 04 - 2022 APPENDIX... - Page 177 Headquarter: 20139 Milano - Piazza Mistral, 7 - Tel. +39 02 574 957 01 ra - Fax +39 02 574 037 63 Factory: 35127 Padova - Z.I. Sud - Via dell’Artigianato, 26 - Tel. +39 049 894 770 1 ra - Fax +39 049 870 139 0 www.thytronic.it thytronic@thytronic.it...

Need help?

Do you have a question about the NA10 and is the answer not in the manual?

Questions and answers