Table of Contents

Advertisement

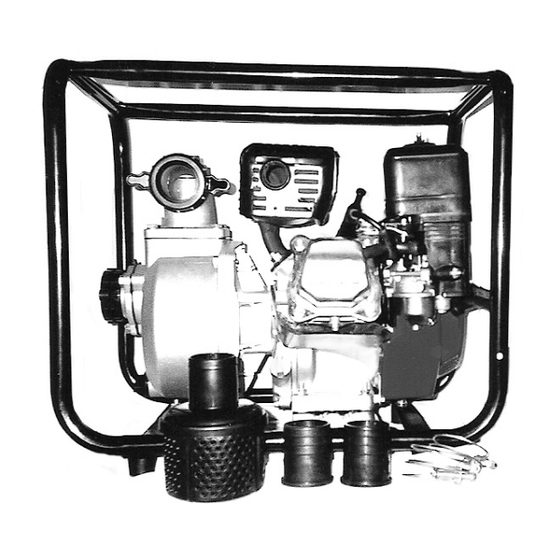

2" CLEAR WATER PUMP

5.5 HP - OVERHEAD VALVE ENGINE

ASSEMBLY AND OPERATING INSTRUCTIONS

Diagrams within this manual may not be drawn proportionally.

Due to continuing improvements, actual product may differ slightly from the product described herein.

Distributed exclusively by Harbor Freight Tools

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright

2005 by Harbor Freight Tools

©

manual or any artwork contained herein may be reproduced in any shape or form

without the express written consent of Harbor Freight Tools.

For technical questions or replacement parts, please call 1-800-444-3353.

Model 93662

3491 Mission Oaks Blvd., Camarillo, CA 93011

. All rights reserved. No portion of this

®

.

®

Advertisement

Table of Contents

Summary of Contents for Harbor Freight Tools 93662

- Page 1 2005 by Harbor Freight Tools © manual or any artwork contained herein may be reproduced in any shape or form without the express written consent of Harbor Freight Tools. For technical questions or replacement parts, please call 1-800-444-3353. Model 93662 .

-

Page 2: Specifications

Keep bystanders, children, and visitors away while operating a power tool. Distractions can cause you to lose control. Protect others in the work area from debris such as chips and sparks. Provide barriers or shields as needed. SKU 93662 For technical questions, please call 1-800-444-3353. SPECIFICATIONS... -

Page 3: Personal Safety

Do not use the Water Pump if the Engine’s Power Switch (98A) does not turn it on or off. Any tool that cannot be controlled with its power switch is dangerous and must be replaced. -

Page 4: Specific Safety Rules And Precautions

Running the Engine with low or no oil will permanently damage the unit. Maintain labels and nameplates on the Water Pump. information. If unreadable or missing, contact Harbor Freight Tools for a replace- ment. Make sure the Water Pump is located on a flat, level, sturdy surface capable of supporting the weight of the Water Pump and any additional tools and equipment. -

Page 5: Mechanical Precautions

Engine and Water Pump to completely cool. Then, remove the spark plug from the Engine. Do not alter or adjust any part of the Water Pump or Engine that is assembled and supplied by the manufacturer. Always follow and complete scheduled Water Pump and Engine mainte- nance. - Page 6 14 and 15 are included. If any parts are missing or broken, please call Harbor Freight Tools at the number shown on the cover of this manual as soon as possible. SKU 93662 For technical questions, please call 1-800-444-3353.

- Page 7 To Add Engine Oil: IMPORTANT! Prior to first using the Water Pump, the Engine MUST be filled with a high quality 10W-30 grade engine oil. (See Figure A.) To do so, unscrew and remove the Engine Oil Dipstick (65A). Pour approximately 2/3 quart of engine oil into the Dipstick Hole.

- Page 8 FUEL TANK (84A) Prior to first using the Water Pump, the Fuel Tank (84A) MUST be filled with high octane unleaded gasoline. (See Figure B.) To do so, remove the Fuel Tank Cap (83A) and fill the Fuel Tank with unleaded gasoline.

- Page 9 HOSE GASKET CLAMP HOSE HOSE COUPLING JOINT HOSE COUPLING CLAMP GASKET INTAKE FLANGE (14) SKU 93662 For technical questions, please call 1-800-444-3353. 2” DIAMETER INTAKE HOSE (NOT INCLUDED) 2” DIAMETER DISCHARGE HOSE (NOT INCLUDED) DISCHARGE FLANGE (10) INTAKE FILTER (21)

-

Page 10: Operating Instructions

Engine can create sparks which may ignite the dust or fumes. Make sure the Water Pump is located on a flat, level, sturdy surface capable of sup- porting the weight of the Water Pump and any additional tools and equipment. - Page 11 Once the Engine is started, the Water Pump will run continuously until the Engine is turned off. When finished using the Water Pump, turn off the Engine. Make sure to allow the Water Pump and its Engine to completely cool before moving the Water Pump or storing the unit.

-

Page 12: Inspection, Maintenance, And Cleaning

Pump and activate the unit once every three months. In cold weather, when if the Water Pump is not in use, protect the interior of the Pump from freezing by draining any remaining water and pumping a permanent type automotive antifreeze containing a rust inhibitor through the system. A 50% mixture with clean water is recommended. -

Page 13: Troubleshooting

INSTALLATION OF REPLACEMENT PARTS THERETO. SKU 93662 For technical questions, please call 1-800-444-3353. TROUBLESHOOTING 1. Take the engine to a qualified service technician. NOTE: If the water pump still does not operate properly, take the pump to a qualified service technician. Page 13... - Page 14 PARTS LIST & ASSEMBLY DIAGRAM - WATER PUMP Part Description Cover Hex Bolt O-Ring Mechanical Seal Impeller Casing Pump Housing Discharge Packing Intake/Discharge Union Set Discharge Flange Priming Cap Bolt Note: Some parts are listed and shown for illustration purposes only, and are not available individually as replacement parts.

-

Page 15: Parts List - Engine

Valve clearance is 0.15mm, Exhaust Valve clearance is 0.20mm. The valve clearance needs to be ad- justed after 100 hours. Change the engine oil after 20 hours or internal one month. SKU 93662 For technical questions, please call 1-800-444-3353. PARTS LIST - ENGINE Qty. -

Page 16: Assembly Diagram - Engine

ASSEMBLY DIAGRAM - ENGINE REV 08c SKU 93662 For technical questions, please call 1-800-444-3353. Page 16... -

Page 17: Emission Control System Warranty

Service department at the number below to make shipping arrangements. The warranty repairs should be completed in a reason- able amount of time, not to exceed 30 days. If you have any questions regarding your warranty rights and responsibilities, you should contact the Harbor Freight Tools Customer Service Department at 1-800-444-3353. -

Page 18: Pump Performance Flow Chart

Emission Control System Warranty Harbor Freight Tools Emission Control Defects Warranty Provisions 5. Service and Maintenance Component parts which are not scheduled for replacement as required maintenance or are scheduled only for regular inspection to the effect of “repair or replace as necessary” are warranted for the warranty period. Any warranted part which is scheduled for replacement as required maintenance is warranted for the period of time up to the first scheduled replacement point for that part.

Need help?

Do you have a question about the 93662 and is the answer not in the manual?

Questions and answers