Table of Contents

Summary of Contents for Plockmatic BK5030

- Page 1 BOOKLET MAKER BK5030 Operating Instruction Stapler Folder Reference Read this manual carefully before you use this product and keep it handy for future reference. For safety, please follow the instructions in this manual. 13 August 2015...

- Page 2 Part no: 102-106761 Doc no: x04092 13 September 2011 Warning: This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be required to take adequate measures. The product (System) which is connected to this machine will be class A Note The domestic environment is an environment where the use of broadcast radio and television receivers may be expected within a distance of 10 m of the apparatus concerned.

- Page 3 Introduction This manual contains instructions on the operation and maintenance of this machine. To get the maximum versatility from this machine all operators should carefully read and fol- low the instructions in this manual. Keep this manual in a handy place near the machine. Please read the Safety Information before using this machine.

- Page 4 Safety Information When using this machine, following safety precautions should always be followed. Safety during operation WARNING: • To avoid hazardous situations like for instance electric shock or danger while exposed to moving, rotating or cutting devices, do not remove any covers, guards or screws other than those specified in this manual.

- Page 5 General safety, continued CAUTION: • The machine and its peripherals must be installed and maintained by a customer service repre- sentative who has completed the training course on those models. • Always follow all warnings marked on, or supplied with, the equipment. •...

- Page 6 Page intentionally blank.

-

Page 7: Table Of Contents

TABLE OF CONTENTS What You Can Do With This Machine ......................9 Guide To Components ..........................11 Booklet Maker ................................11 Options ................................14 Cover Feeder ................................14 Trimmer ..................................15 Book Folder .................................. 17 Control Panel ..............................19 1. Basics ....................... 21 Docking / Undocking ............................. - Page 8 Maintaining Your Machines .......................... 54 Book Folder .................................. 54 Cleaning feed belts ..........................54 Limitations in the BK5030 system ....................... 55 Best practice for the BK5030 system ......................56 8. Specification ................... 57 Machine Specifications ..........................57 Booklet Maker BK5030 ..............................57 Cover Feeder CF5030 (option) .............................

-

Page 9: What You Can Do With This Machine

Copier. The print-outs from the Copier are collected in the finisher and then transported into the BK5030 Booklet Maker to the staple area. From the CF5030 Cover Feeder (optional), if present, any type of covers, colored or black and whites, can be added to the printed set. - Page 10 The BK5030 Booklet making system is controlled from a user interface/control panel located on the Booklet Maker. The control panel will allow you to easily set up, adjust and operate the complete system. The user interface/control panel is of touch screen type.

-

Page 11: Guide To Components

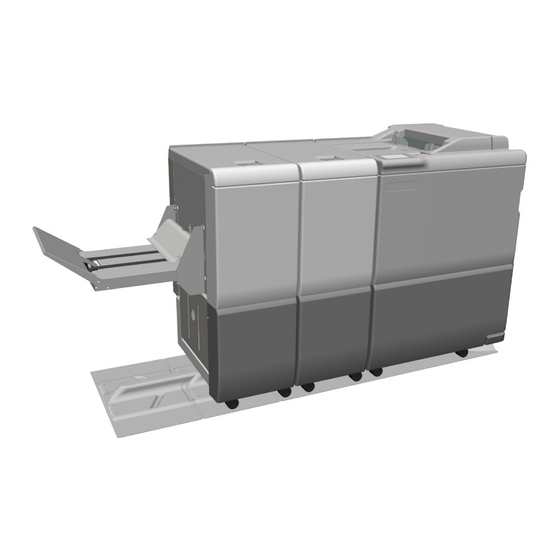

Guide To Components Booklet Maker Top cover Base Control panel Docking assembly Main power switch Belt Stacker Infeed assembly Belt Stacker Cover Exit tray storing shelf... - Page 12 Booklet Maker, continues Connections Fold stop gate POW BF5030 COM Copier Terminator/ Stacker Terminator COM TR5030 Main Power Interlock jumper/ POW TR5030...

- Page 13 Booklet Maker, continues Staple cartridges (incl. stapler heads) Hand feeding paper guides...

-

Page 14: Options

Options Cover Feeder Loading capacity mark Front side guide Paper orientation indicator Rear side guide Air nozzle (2x) Feed roller assembly Jam clearance baffle Paper separator pad (also see page 52) -

Page 15: Trimmer

Trimmer Top cover Trim bin Base Connections Stacker COM BK5030 Power from Terminator/ BK5030 Com BF5030... - Page 16 Trimmer, continues The Trimmer interior has parts that you will come in contact with if a misfeed occurs. Trimmer, top view Set counter Transport belt Trimmer stop Infeed roller shaft Outfeed drive release Trimmer fan Pre-trimming compressing Upper knife brackets Infeed drive release...

-

Page 17: Book Folder

Book Folder Top cover Trim bin location Base Connections Terminator COM BF5030 Stacker POW BF5030... - Page 18 Book Folder, continues The Book Folder interior has parts that you will come in contact with if a misfeed occur. Book Folder, top view, Upper feed belts in lifted up Lower feed belts Upper feed belt release latch Upper feed belts...

-

Page 19: Control Panel

Here you will find information showing the actual set up. From this screen you can also access other screens that will help you operate the complete BK5030 Booklet making system. Changing settings To change or adjust settings just point at an item in the Ready screen. - Page 20 The Processing screen This screen is shown when the machine is busy working. If the machine is used in off-line mode you do not have to wait for the Ready screen before handfeeding the next set. The Please wait screen While the machine sometimes needs time to perform changes in settings, the Please wait screen will be shown.

-

Page 21: Basics

1. Basics Docking / Undocking Docking the Booklet Maker Turn the Copier off. Lift up the Exit arm catcher and set the Exit paper arm in the upper position. Remove the Exit tray from the Finisher and put it on the shelf on the Booklet Maker Move the Booklet Maker up to the copier and dock it. -

Page 22: Undocking The Booklet Maker

Undocking the Booklet Maker Turn the Copier off. Note Keep the Booklet Maker powered on. Push in the latch on the docking assembly and move the Booklet Maker away from the Copier. Note Be careful not to damage the communication cable Take the Exit tray from the shelf on the Booklet Maker, and install it on the Finisher. -

Page 23: Turning On / Off The Main Power

Turning On / Off the Main Power Booklet Maker, Cover Feeder, Trimmer and Book Folder Plug the Booklet Maker power cord into the wall outlet. Cover Feeder (optional), Trimmer (optional) and Book Folder (optional) are powered from the Booklet Maker. Open the Top cover (1). -

Page 24: Change Staple Cartridges And Check Stapler

Change staple cartridges and Check stapler The staple cartridges contains approximately 5000 staples each. Each cartridge includes all wear-out and service parts (i.e. the stapler head). The cartridges may be removed ei- ther for renewal or for jam clearance. Change left/right staple cartridge(s) The booklet maker will indicate “Change left/right/ left and right staple cartridges”... -

Page 25: Check Left/Right Stapler

Check left/right stapler If the booklet maker indicates “Check left/right/left and right stapler”, it means that there is a jam in the indicated stapler. Remove the stapler cartridge as described above. Open the booklet maker top cover. Pull out the staple cartridge. Remove any sheets left in the booklet maker and look for jammed staples stuck in the sheets. -

Page 26: Emptying The Trim Bin

Emptying the trim bin Remove the trim bin by lifting it and pulling it out. trim bin, no Book Folder installed trim bin, with Book Folder installed... -

Page 27: Making Booklets

2. Making Booklets Changing settings General procedure Changing of settings can be performed in two ways. Temporary, which means that the changes will remain until a new job is loaded or permanent, which means that the changes will be stored as a job. This job can later be recalled. Procedure for temporary changes: From the Ready screen, select the option you wish to change and press the [Change] button. -

Page 28: Custom Paper Size

Custom paper size From the Paper size screen, select any of the present custom size formats and press the [Edit] button. Note The asterisk (star) indicates that the Auto shrink function is activated. See page 35. Select Length or Width and key in the desired value. Save the custom size format by pressing the [OK] button. -

Page 29: Staple Position

Staple position Adjusting staple position The position of the staples can be changed up to 3 mm (0.12”) on either side of the fold. Press the [-] or [+] button to change position of the staples and save setting by pressing the [OK] button. Note This change can be performed during run. -

Page 30: Cover

Cover If a Cover Feeder is present, the [Cover] button will be visible in the control panel. Set to On, the cover feeder will automatically feed one cover to each set from the copier, or if you are manually feeding a set. The cover feeder can be used in either for feeding regular covers or for feeding protection sheets. -

Page 31: Air Separation

Air Separation You might want to increase the Air flow when running thick, heavy covers. From the Cover screen, press the [Air separation] button to go to the Air separation screen. Set the desired amount of air flow by pressing the corresponding button and save setting by pressing the [OK] button. -

Page 32: Book Fold Unit

Book fold unit General The Book Folder has seven different settings. It can be set to [Auto], [Off] , [Mode 1], [Mode 2], [Mode 3], [Mode 4] or [Mode 5]. In [Auto] mode, the Booklet Maker automatically sets the Book Folder to the correct mode based on the information about paper weight and number of sheets in the set. -

Page 33: On-Line/Off-Line

On-line/Off-line The Booklet maker can be operated in two modes. On-line mode, when used together with the copier, or off-line mode, working as a stand-alone unit. Off-line mode Follow “Undocking the Booklet maker” in section 1. Basics. Adjust the hand feeding paper guides to the correct paper size. Turn on the Booklet maker. -

Page 34: Begin On-Line Production

Begin On-line Production Make sure that the [staple icon] is present on the copier control panel. If not, turn off the Copier and Booklet Maker. First turn the Booklet Maker ON and then turn the Copier ON. Make sure that the Booklet maker system is set according to your job specification. Select [Paper tray] (A). -

Page 35: Tools

3. Tools The Tools Screen The Tools screen. From the Ready screen, press the [Tools] button to get to the Settings screen. Select the setting you want to change and press the corresponding button. Stacker full detection Based on the information about paper weight, paper size and number of sheets in each booklet, the system calculates how many booklets the stacker can hold. -

Page 36: Language

Language Select desired language by pressing the corresponding button and save by pressing the [OK] button. Software version Select machine by pressing the corresponding button to display the software version. Press [Exit] button to go back to the Settings screen. Service access This function is for authorized service personnel only and is password protected. -

Page 37: Jobs

4. Jobs Handling jobs The Booklet Maker has a maximum storage capacity of 20 different jobs. To make temporary changes in the actual job settings or temporary changes of a stored job, see section 2. Making Booklets. From the Ready screen, press the [Jobs] button to be able to store, change or delete jobs. Saving a Job To store a new job, press the [Save as new job] button. -

Page 38: Handling Stored Jobs

Handling stored Jobs To access already stored jobs, press the [Saved jobs] button. Rename, open (load) or delete any stored job by pressing the job button and choose action. -

Page 39: Clearing Misfeed(S)

5. Clearing Misfeed(s) Clearing misfeed(s) General If a misfeed condition should occur, it is indicated on the Booklet Maker display. The message “Clear Misfeed(s)”, an error code and the location of the misfeed is displayed. See examples below. Misfeeds in the Booklet Maker are indicated as area A, B or C and by the error code BK-XXX. -

Page 40: Booklet Maker

Booklet Maker Clearing misfeed(s) Inside the Booklet Maker To clear a misfeed indicated in Area A or B Open the top cover. Remove misfed sheets. Close the top cover. To clear a misfeed indicated in Area C Open the top cover. Close top cover. -

Page 41: Trimmer

Trimmer Clearing misfeed(s) The upper trimmer blade on the trimmer is protected by a knife protection plate that moves away during the cutting stroke. WARNING: Never put fingers or other parts of the body between the upper and lower trimmer knives. Clearing misfeed in input area Raise the infeed roller shaft (A) by lifting latch (B). -

Page 42: Clearing Misfeed In Exit Area

Clearing misfeed(s), continues Clearing misfeed in exit area Lift the pre-trimming compressing brackets (A). Secure them under the latch (B). Remove the misfed sheets from the exit area. After the misfed sheets are removed, lift up the latch (B) and place the compressing brackets in operating position. -

Page 43: Cover Feeder

Cover Feeder Clearing misfeed(s) in vertical transport area Open the Top Cover. Lift the jam clearance baffle (A). Remove the misfed cover. Put the jam clearance baffle back in normal position. -

Page 44: Book Folder

Book Folder Clearing misfeed(s) Inside the Book Folder Open the top cover. Lift up both upper feed belts (A). Note Press the green dots (B) on the latches to release. Remove the misfeeds. Place the upper feed belts in normal position. Close the top cover. -

Page 45: Troubleshooting

6. Troubleshooting Fault codes General When there is a misfeed or fault condition in the booklet maker system, a message will be displayed on the Booklet Maker. In case there is a problem that can be rectified by the operator, a fault code and an explanation will be displayed. Fault codes that can be rectified by the operator: Booklet Maker: BK-201 to BK-210, BK-401 to 403 and BK-501 to BK-504... -

Page 46: General Fault Codes

General fault codes Clear Misfeed(s) In general, fault codes indicate a misfeed condition. When a misfeed occurs, the message “Clear Misfeed(s)”, a code and the jam area will be displayed. See section 5. Clearing Misfeeds, for how to clear a misfeed. Close cover(s) When the message “Close Cover(s)”... -

Page 47: Booklet Maker Fault Codes

Booklet maker fault codes Check stapler or Change staple cartridge These messages will be displayed when a staple cartridge is empty or when stapling could not be performed. Check in the following order: – If a staple cartridge is empty, replace according to section 1. Basics. –... -

Page 48: Load Covers

Cover feeder fault codes, continues Load covers Code “CF-501 Load covers” is displayed when covers run low. There are two ways to continue operation. Loading more cover sheets: Load more cover sheets according to section 2. Making Booklets and press the [Done] button. -

Page 49: Trimmer Fault Codes

Trimmer fault codes Note During poor environmental conditions waste from the trimming operation may be transported through the system. To improve the situation the trim margin may be increased and thereby ensuring that The waste is transported into the waste bin. Trim bin full This message will be displayed when the trim bin is full or when a trim strip, due to static electricity, is prevented from falling down into the trim bin. - Page 50 Page intentionally blank.

-

Page 51: Remarks

7. REMARKS Do’s And Don’ts • Always follow all warnings marked on, or supplied with, the equipment. • Always exercise care in moving or relocating the equipment. Caution: • Unplug the power cord from the wall outlet and machine before you move or relocate the equipment. -

Page 52: Where To Put Your Machine

Where to put Your Machine Machine environment • Always locate the equipment on a solid support surface with adequate strength for the weight of the machine. • Always keep magnets and all devices with strong magnetic fields away from the machine. -

Page 53: Access To Machine

Access to machine Place the machine near the power source, providing clearance as shown. 1. Left: more than 400 mm / 15.8”. 2. Front: more than 555 mm / 21.8” 3. Right: more than 400 mm / 15.8” (off-line use). -

Page 54: Maintaining Your Machines

Maintaining Your Machines Never attempt any maintenance function that is not specifically described in this documentation. Book Folder Cleaning feed belts The Feed belts need to be cleaned regularly when in use, and if the unit has not been used for a period of time. -

Page 55: Limitations In The Bk5030 System

The Plockmatic BK5030 Production Booklet Maker is suited for customers whose book- let making needs will not exceed an average 20,000 booklets per month. • If sheets entering the BK5030 is not uniform and square the booklet quality will vary accordingly. •... -

Page 56: Best Practice For The Bk5030 System

• If the set is not properly registered (side jogged and back jogged) changing to a smaller custom size of paper in the BK5030 may improve the situation. • If staples have problems penetrating thicker sets of heavy media changing staple car- tridge may improve the situation. -

Page 57: Specification

8. Specification Machine Specifications Booklet Maker BK5030 Major Specifications Specifications Remarks Speed (Online usage) Maintains engine speed (actual depends Actual speed in number of book- of engine speed). lets (per min / hour) depends on number of sheets per booklet. -

Page 58: Cover Feeder Cf5030 (Option)

Cover Feeder CF5030 (option) Specifications Remarks Maximum Speed Same as BK5030 A3/11x17” or bigger paper sizes, need two sheet sets as inlet at least Standard Paper Sizes Same as BK5030 Paper Weight (Minimum) 70 gsm / 18 lb Bond Paper Weight (Maximum) -

Page 59: Book Folder Bf5030 (Option)

Book Folder BF5030 (option) Specifications Remarks Speed Same as BK5030 Appr. 6 - 30 sheet booklet (80 gsm / 20 lb Bond) Standard Paper Sizes Same as BK5030 Custom sizes are available Paper Weight (Minimum) Same as BK5030 Paper Weight (Maximum) -

Page 60: Bk5030 System Set Size Guide

BK5030 System Set Size Guide Paper size <A3 (small sizes) >A3 (large sizes) Grain direction Grain direction Short Long Short Long Area coverage Area coverage Area coverage Area coverage Paper weight High Full High Full High Full High Full Bond Offset Cover Tag... - Page 61 Directives stated above. Name: Bengt Olenfalk Quality & Compliance Manager Date: See top of page PLOCKMATIC International AB – Box 10025, SE-121 26 Stockholm-Globen – Phone +46 8 602 50 00 – Fax +46 8 722 99 70...

- Page 62 Page intentionally blank.

-

Page 63: Index

Making Booklets 27 Undocking the Booklet Maker 22 Misfeed(s) Basics 21 clearing 39 Begin On-line Production 34 Best practice for the BK5030 system 56 BK5030 System Set Size Guide 60 Book Folder 17 On-line/Off-line 33 cleaning feed belts 54 Options 14...

Need help?

Do you have a question about the BK5030 and is the answer not in the manual?

Questions and answers