Summary of Contents for Woodward TecJet 50 Plus

- Page 1 Released Product Manual 26219 (Revision K, 07/2019) Original Instructions TecJet™ 50 Plus / TecJet 50 Plus Precision Flow Gas Regulation and Metering Valve/Actuator System Installation and Operation Manual...

- Page 2 Revisions—Changes in this publication since the last revision are indicated by a black line alongside the text. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

-

Page 3: Table Of Contents

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Contents ................3 ARNINGS AND OTICES ..........4 LECTROSTATIC ISCHARGE WARENESS ............... 5 EGULATORY OMPLIANCE 1. G ............7 HAPTER ENERAL NFORMATION Introduction ......................7 Connections to the TecJet ..................7 2. - Page 4 Figure 2-2. TecJet Wiring Diagram...............13 Figure 3-1. Address Claimed State Chart ............27 Figure 4-1. Maximum Specialty Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 ............33 Figure 4-2. Minimum Specialty Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 ............34...

-

Page 5: Warnings And Notices

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Warnings and Notices Important Definitions This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. -

Page 6: Electrostatic Discharge Awareness

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 To prevent damage to a control system that uses an alternator or battery-charging device, make sure the charging device is turned off before disconnecting the battery from the system. -

Page 7: Regulatory Compliance

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Regulatory Compliance European Compliance for CE Marking EMC Directive: Declared to Directive 2014/30/EU of the European Parliament and of the Council of 26 February 2014 on the harmonization of the laws of the Member States relating to electromagnetic compatibility (EMC). - Page 8 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 This product is certified as a component for use in other equipment. The final combination is subject to acceptance by CSA International or local inspection. The TecJet™ is suitable for use in Class I, Division 2, Groups A, B, C, and D per CSA for Canada and US, or non-hazardous location only.

-

Page 9: Chapter 1. General Information

This manual covers the TecJet 50 Plus (TJ50P) and the TecJet 50 Plus Precision Flow (TJ50PPF) Fuel Metering Valves. -

Page 10: Chapter 2. Installation

Be especially careful not to rest the TecJet on the valve position pointer or the actuator electrical connectors. Notify the shipper and Woodward if damage is found. If the TecJet is to be painted, appropriate means must be used to mask the following items/areas: ... -

Page 11: Electrical Connections

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator The inlet and outlet piping of the TecJet must be in accordance with ANSI/ISA- S75.02 to ensure the flow metering accuracy specified elsewhere in this manual. However, an inlet piping length as short as 6 diameters and an outlet piping length as short as 2 diameters can typically be used with a negligible loss in valve metering accuracy. -

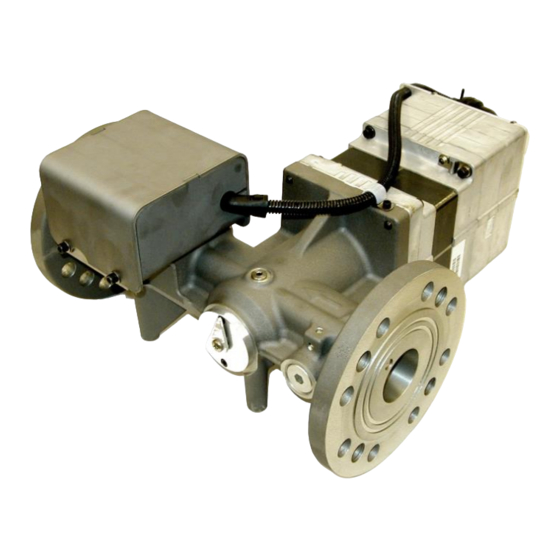

Page 12: Figure 2-1A. Tecjet 50 Plus Outline Drawing

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Figure 2-1a. TecJet 50 Plus Outline Drawing (TecJet 50 Plus Precision Flow is externally the same) Woodward... -

Page 13: Figure 2-1B. Tecjet 50 Plus Outline Drawing

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Figure 2-1b. TecJet 50 Plus Outline Drawing (TecJet 50 Plus Precision Flow is externally the same) Woodward... -

Page 14: Shielded Wiring

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Shielded Wiring All shielded cable must be twisted conductor pairs. Do not attempt to tin (solder) the braided shield. All signal lines should be shielded to prevent picking up stray signals from adjacent equipment. -

Page 15: Figure 2-2. Tecjet Wiring Diagram

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator From Previous CAN Device Do Not Connect TecJet 50 CAN Gnd Plus CAN Hi In CAN Lo In CAN Shield CAN Hi Out CAN Lo Out Jumper for CAN Termination... -

Page 16: Keyswitch

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Keyswitch F = Keyswitch The keyswitch is not active in all TecJet configurations. The keyswitch is used to switch the TecJet in and out of a low power state (less than 200 mA input current). -

Page 17: Can Termination

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator CAN Termination P = Termination resistor Q = Termination resistor The internal termination resistor (120 Ω) is used to terminate the CANbus. According to the CAN specification, every CANbus must be terminated at both ends of the bus. -

Page 18: Can Shield

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 CAN Shield X = CAN Shield The CAN Shield can be used to terminate the shield of the CAN wiring. Internally, this pin is connected to the TecJet case through a capacitor. -

Page 19: Chapter 3. Description Of Operation

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Chapter 3. Description of Operation External fire protection is not provided in the scope of this product. It is the responsibility of the user to satisfy any applicable requirements for their system. -

Page 20: Diagnostics

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Diagnostics The TecJet may not return to minimum fuel for all faults. The engine, turbine, or other type of prime mover should be equipped with an overspeed, misfire, detonation detection shutdown device(s), that... -

Page 21: Position Limiter

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Position Limiter After the TecJet is powered up and receives a flow command, the valve remains in a closed position until the delta-p sensor senses a non-zero valve delta-p. This non-zero delta-p is established when the fuel source is turned on. - Page 22 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 TecJet PDO Support All data in CANopen is formatted as “Little Endian” also known as “Intel Format”. This section lists the PDOs that will be sent from the TecJet.

- Page 23 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Transmit PDO 2 - Gaseous Fuel Flow Transmission rate: 99ms Message type = “ASYNC” (does not require SYNC message) COB Id: 658 (0x292) default for Node Id = 18. All others 640+Node Id.

- Page 24 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Byte 5 Bit 0: BATTERY_VOLT_LOW_ERR Bit 1: FGT_LOW_LIMIT_ERR Bit 2: DELTA_P_LOW_LIMIT_ERR Bit 3: FGP_LOW_LIMIT_ERR Bit 4: BATTERY_VOLT_HIGH_ERR Bit 5: FGT_HIGH_LIMIT_ERR Bit 6: DELTA_P_HIGH_LIMIT_ERR Bit 7: FGP_HIGH_LIMIT_ERR Byte 6 Bit 0: RESERVED...

-

Page 25: Sae J1939 Communications

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Bytes: 5-8 Fuel Flow Rate Data length: 4 bytes, unsigned Resolution: 0.0002778 L/sec/bit, 0 offset (Divide by 3600 to recover L/sec value) Range: 0 to 1169744.78194 L/sec If the received flow demand is 0.00 or greater than 1169.74478194 L/sec, the valve will be closed. - Page 26 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Gaseous Fuel Command 5 ms (Engine Control TecJet 50 Plus) Transmission rep rate: Data length: 8 bytes Data page: PDU format: Note that this is the only Proprietary PDU Format 1 message allowed in J1939.

- Page 27 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Gaseous Fuel Flow Transmission repetition rate: 100 ms (TecJet 50 Plus Engine Control) Data length: 8 bytes Data Page: PDU format: PDU specific: Default priority: Parameter Group Number:...

- Page 28 TecJet 2, 126 for TecJet 3, 127 for TecJet 4. Addresses are not re- programmable. The Address Claimed Message will also be sent out if the TecJet 50 Plus receives an Address Claimed message from the same Address as the receiving node and a lower priority (higher value) NAME.

-

Page 29: Figure 3-1. Address Claimed State Chart

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Start executing Power On Self Test POST Complete- Random Delay before Send Address Claim sending Address Delay Complete- Claimed Send Address Claim “Bus-off Error occurred or collision detected Check for Message... -

Page 30: Position Hold Feature

Cannot Claim Address message. If the TecJet 50 Plus cannot claim an Address a status bit will be set and the valve will shut down. TecJet 50 Plus NAME Arbitrary Address Capable Field = No = 0 (See J1939-81 Section 4.1.1.2) -

Page 31: General Specifications

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator The Position Hold feature requires a valid flow command for position hold to function. The command is not used for positioning, but in order to control the position, the flow command must be valid. The position limiter function is also active so it may not be possible to achieve the desired position without increasing the flow demand. - Page 32 Fuel Type The TecJet 50 Plus operates on gases ranging from pipeline quality natural gas to specialty gas (such as landfill, digester, or other biogases). The TecJet 50 Plus Precision Flow operates on gases ranging from pipeline quality natural gas to propane.

- Page 33 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Minimum proof pressure for the TecJet is 0.52 bar gauge. Minimum burst pressure for the TecJet is 1.72 bar gauge. Temperature The following are the temperature specifications for the TecJet: ...

-

Page 34: Chapter 4. Valve Sizing

Figures 4-1 through 4-4 show the maximum and minimum amounts of gas that the TecJet™ 50 Plus and TecJet 50 Plus Precision Flow will flow as a function of pressure differential in kPa(d). Figures 4-1 and 4-2 indicate flow values for specialty gas, while Figures 4-3 and 4-4 indicate flow values for natural gas. -

Page 35: Figure 4-1. Maximum Specialty Gas Flow Capacity Of Tecjet 50 Plus, 50 Plus Precision Flow, 50, And 110

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Figure 4-1. Maximum Specialty Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 (Specialty Gas, SG=1, Sea Level) Woodward... -

Page 36: Figure 4-2. Minimum Specialty Gas Flow Capacity Of Tecjet 50 Plus, 50 Plus

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Figure 4-2. Minimum Specialty Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 (Specialty Gas, SG=1, Sea Level) Woodward... -

Page 37: Figure 4-3. Maximum Natural Gas Flow Capacity Of Tecjet 50 Plus, 50 Plus Precision Flow, 50, And 110

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Figure 4-3. Maximum Natural Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 (Natural Gas, SG=0.6, Sea Level) Woodward... -

Page 38: Figure 4-4. Minimum Natural Gas Flow Capacity Of Tecjet 50 Plus, 50 Plus Precision Flow, 50, And 110

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Figure 4-4. Minimum Natural Gas Flow Capacity of TecJet 50 Plus, 50 Plus Precision Flow, 50, and 110 (Natural Gas, SG=0.6, Sea Level) Woodward... -

Page 39: Chapter 5. Troubleshooting

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Chapter 5. Troubleshooting The tables in this chapter refer to status indications, warnings, and errors that can be viewed on the service tool. See Chapter 6 for information on installing the service tool. - Page 40 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 STATUS INDICATIONS Status Description Possible Cause Possible Actions Zero Flow If the PWM flow demand ECM is requesting zero flow. Status indication, no action Detected high/low warnings are not required.

- Page 41 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator WARNINGS Warning Description Possible Cause Possible Actions CAN Flow The CAN flow demand is Incorrect TecJet Number. Check the CAN ID inputs to Demand Failed not being received. The the valve.

- Page 42 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 WARNINGS Warning Description Possible Cause Possible Actions Delta P Low The Delta Pressure value Warning threshold improperly Configure warning threshold is below the delta pressure configured. for value appropriate to the low warning threshold.

- Page 43 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator WARNINGS Warning Description Possible Cause Possible Actions Fuel Gas The Fuel Gas Temperature Warning threshold improperly Configure warning threshold Temperature value is below the fuel gas configured. for value appropriate to the temperature low warning application.

- Page 44 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 ERRORS When an error occurs, the valve closes, if possible. It will not attempt to operate again until power to the valve is cycled. If the error persists, the valve must be replaced.

-

Page 45: Chapter 6. Service Tool Installation

Chapter 6. Service Tool Installation Detailed information on the TecJet™ is contained in the TecJet Service Tool, which can be found on the web at: www.woodward.com/software. Select software product “TecJet Tools”. Follow the installation instructions given on that page. TecJet Users Guide... -

Page 46: Chapter 7. Maintenance

This build-up can affect the performance of the TecJet and may appear as degradation of actual flow vs command flow accuracy, or as flow control instability. This procedure does not apply to the TecJet 50 Plus Precision Flow version. Limits of Applicability Periodic cleaning may be performed and needed to ensure the best operation of the TecJet. - Page 47 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Remove the cap/seal on the outlet flange of the TecJet. Dump the soap solution out of TecJet. Fill the TecJet with fresh 60 °C tap water and move the water around in the valve bore with a long plastic rod or equivalent.

-

Page 48: Chapter 8. Product Support And Service Options

A current list of Woodward Business Partners is available at www.woodward.com/directory. Product Service Options Depending on the type of product, the following options for servicing Woodward products may be available through your local Full-Service Distributor or the OEM or Packager of the equipment system. -

Page 49: Returning Equipment For Repair

Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Replacement/Exchange: Replacement/Exchange is a premium program designed for the user who is in need of immediate service. It allows you to request and receive a like-new replacement unit in minimum time (usually within 24 hours of the request), providing a suitable unit is available at the time of the request, thereby minimizing costly downtime. -

Page 50: Engineering Services

Field Service engineering on-site support is available, depending on the product and location, from one of our Full-Service Distributors. The field engineers are experienced both on Woodward products as well as on much of the non- Woodward equipment with which our products interface. -

Page 51: Technical Assistance

TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Technical Assistance If you need to contact technical assistance, you will need to provide the following information. Please write it down here before contacting the Engine OEM, the Packager, a Woodward Business Partner, or the Woodward factory: General... -

Page 52: Revision History

Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Revision History Changes in Revision J— Updated Regulatory Compliance section Added new Declaration of Conformity and Declaration of Incorporation Changes in Revision H— Revision advanced to coordinate with new installation sheet, and to update manual to latest formats and safety warnings. - Page 53 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Declarations Woodward...

- Page 54 Released TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator Manual 26219 Woodward...

- Page 55 Released Manual 26219 TecJet 50 Plus/TecJet 50 Plus Precision Flow Valve/Actuator THIS PAGE INTENTIONALLY LEFT BLANK Woodward...

- Page 56 26219 Please reference publication ËB26219è:K´ º µ ¹ ´ ¹ Î PO Box 1519, Fort Collins CO 80522-1519, USA 1041 Woodward Way, Fort Collins CO 80524, USA Phone +1 (970) 482-5811 Fax +1 (970) 498-3058 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world.

Need help?

Do you have a question about the TecJet 50 Plus and is the answer not in the manual?

Questions and answers