Summary of Contents for Woodward VariStroke-DX

- Page 1 Released Product Manual 35132 (Revision -, 3/2020) Original Instructions VariStroke-DX Duplex Hydraulic Servo Skid Installation and Operation Manual...

- Page 2 Revisions— A bold, black line alongside the text identifies changes in this publication since the last revision. Woodward reserves the right to update any portion of this publication at any time. Information provided by Woodward is believed to be correct and reliable. However, no responsibility is assumed by Woodward unless otherwise expressly undertaken.

-

Page 3: Table Of Contents

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Contents ......................3 ARNINGS AND OTICES ..................4 LECTROSTATIC ISCHARGE WARENESS ......................5 EGULATORY OMPLIANCE 1. G ..................... 7 HAPTER ENERAL NFORMATION System Description ............................8 Design Characteristics ..........................9 Construction ..............................10 2. - Page 4 Figure 2-1. VariStroke-DX, Hydraulic Schematic ..................18 Figure 3-1. VS-DX Lifting Bracket Locations ....................20 Figure 3-2. VariStroke-DX, Junction Box Version, Main Terminal Box, Wiring Points Access ....22 Figure 3-3. VariStroke-DX, Junction Box Version, Main Terminal Block Connections Chart ..... 23 Figure 3-4.

-

Page 5: Warnings And Notices

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Warnings and Notices Important Definitions This is the safety alert symbol used to alert you to potential personal injury hazards. Obey all safety messages that follow this symbol to avoid possible injury or death. -

Page 6: Electrostatic Discharge Awareness

Do not touch the components or conductors on a printed circuit board with your hands or with conductive devices. To prevent damage to electronic components caused by improper handling, read and observe the precautions in Woodward manual 82715 , Guide for Handling and Protection of Electronic Controls, Printed Circuit Boards, and Modules. -

Page 7: Regulatory Compliance

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Regulatory Compliance European Compliance for CE Marking: PENDING Other International Compliance: -IECEX: PENDING North American Compliance: These listings are limited only to those units bearing the appropriate marking. Review the Compliance Code table for more information. - Page 8 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Risque d’explosion—Ne pas raccorder ni débrancher tant que l’installation est sous tension, sauf en cas l’ambiance est décidément non dangereuse. La substitution de composants peut rendre ce matériel inacceptable pour les emplacements de Classe I, applications Division 2 ou Zone 2.

-

Page 9: Chapter 1. General Information

Manual 25071: Oils for Hydraulic Controls Manual 25075: Commercial Preservation Packaging for Storage of Mechanical-Hydraulic Controls Manual 26455: Woodward Energy Segment Customer Publications: Cross-Reference by Application Revision Status & Distribution Restrictions Manual 35119: VS-I G1 VariStroke-I (VS-I) Electro-hydraulic Actuator Manual 35133:... -

Page 10: System Description

As a result of this servo’s integrated redundancy and when used within the VariStroke-DX skid these servos can be repaired or replaced while the turbine is on-line operating normally ensuring a high level of system reliability and availability. -

Page 11: Design Characteristics

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-1. Basic VS-DX Application and Configuration Designed as a stand-alone skid, servo-to-servo communication and automatic failover logic is included within each servo forcing automatic transfers to the healthy servo with no external control logic or interface required. -

Page 12: Construction

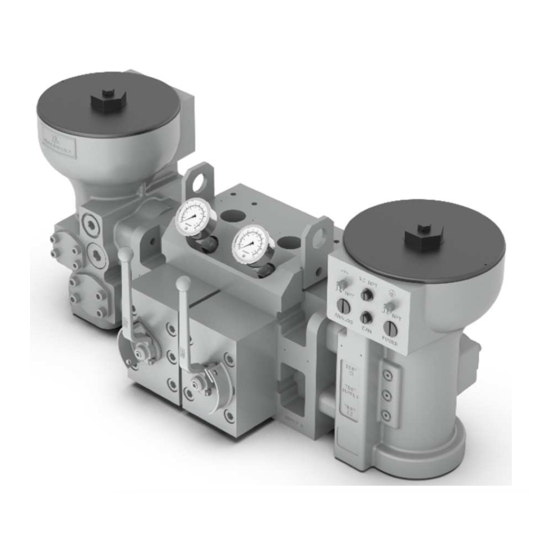

VariStroke-DX Duplex Hydraulic Servo Skid Construction The VS-DX is a complete packaged and tested assembly which consists of two Woodward VariStroke-I servos (VS-GI’s) connected together to a single manifold with all interconnect piping, gauges and wiring included and factory tested. -

Page 13: Figure 1-3. Varistroke-Dx, Junction Box Version, Front View

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-3. VariStroke-DX, Junction Box Version, front view Figure 1-4. VariStroke-DX, Junction Box Version, Top View Woodward... -

Page 14: Figure 1-5. Varistroke-Dx, Junction Box Version, Bottom View

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-5. VariStroke-DX, Junction Box Version, Bottom View Figure 1-6. VariStroke-DX, Junction Box Version, Back View Woodward... -

Page 15: Figure 1-7. Varistroke-Dx, Junction Box Version, Side View

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-7. VariStroke-DX, Junction Box Version, Side View Woodward... -

Page 16: Figure 1-8. Varistroke-Dx, Without Junction Box Version, Front View

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-8. VariStroke-DX, Without Junction Box Version, Front View Figure 1-9. VariStroke-DX, Without Junction Box Version, Rear View Woodward... -

Page 17: Figure 1-10. Varistroke-Dx, Without Junction Box Version, Bottom View

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 1-10. VariStroke-DX, Without Junction Box Version, Bottom View Woodward... -

Page 18: Chapter 2. System Specifications

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Chapter 2. System Specifications Table 2-1. Environmental Ambient Temperature: Without Junction Box –40 to +85°C (-40 to + 185⁰F) With Junction Box –30 to +85°C (-22 to + 185⁰F) Oil Temperature: +15 to +70°C (+59 to 158⁰F) continuous... - Page 19 It is for this reason that Woodward does NOT recommend using a combination of LVDTs and Signal Conditioners. This combination will typically result in unacceptable delays in the position sensor update rate.

-

Page 20: Figure 2-1. Varistroke-Dx, Hydraulic Schematic

Tank Pressure: Drain pressure must not exceed 10% of supply pressure or 3.4 bar (50 psig), whichever is less, under any condition. Recommended Fluid: Mineral or synthetic based oils may be used. Woodward oil recommendations per manual 25071. Oil Cleanliness: ISO 4406:99 code 20/18/16 max fluid cleanliness or better is recommended for optimum reliability. -

Page 21: Chapter 3. Installation

However careless handling may result in damage to the unit. If any damage to the VS-DX is discovered, notify both the shipping agent and Woodward. When unpacking the VS-DX, do not remove the hydraulic blanking plugs until you are ready to mount the unit to hydraulic lines. -

Page 22: Mounting Instructions

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 3-1. VS-DX Lifting Bracket Locations Mounting Instructions The VS-DX assembly is designed to be attached to a horizontal structure via the four threaded holes. The VS-DX should be mounted as close as possible to the controlled system (hydraulic power actuator) to minimize the hydraulic control line length and oil volume to achieve optimum system response. -

Page 23: Hydraulic Connections

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Hydraulic Connections There are two hydraulic ports on the back side of the VS-DX manifold. These are clearly marked DRAIN for the drain oil port and CONTROL for the control oil connection to actuation system. -

Page 24: Figure 3-2. Varistroke-Dx, Junction Box Version, Main Terminal Box, Wiring Points Access

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid It is important that during operation, the setpoint signals to both servos are nearly identical. Figure 3-2. VariStroke-DX, Junction Box Version, Main Terminal Box, Wiring Points Access Woodward... -

Page 25: Figure 3-3. Varistroke-Dx, Junction Box Version, Main Terminal Block Connections Chart

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 3-3. VariStroke-DX, Junction Box Version, Main Terminal Block Connections Chart Woodward... -

Page 26: Figure 3-4. Varistroke-Dx, Junction Box Version, Wiring Diagram

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 3-4. VariStroke-DX, Junction Box Version, Wiring Diagram Woodward... -

Page 27: Figure 3-5. Varistroke-Dx, Varistroke-Dx, Without Junction Box Version, Wiring Diagram

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 3-5. VariStroke-DX, VariStroke-DX, Without Junction Box Version, Wiring Diagram Woodward... -

Page 28: Input Power

Figure 3-6. Cylinder Position Sensor Connection Scheme All bare shield wires of the field wiring cable must be isolated from the Power Cylinder chassis or any conduit used. Woodward recommends using suitably rated heat shrink tubing on the shield RISK OF SHOCK AND... - Page 29 Steady State 24 V (dc) nominal Current For more electric requirements see Woodward manual 26615. Discrete Inputs The VS-GI has four (4) discrete inputs. External power is not necessary for these inputs as the isolation is provided internally. The discrete inputs have an internal pull-up resistor and are inverted at the processor, such that an open circuit is the passive low state.

-

Page 30: Figure 3-7. Pe Ground Connection Localization And Details, Junction Box Version

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Unit Grounding The junction box must be grounded using the designated PE ground connection point. PE ground connection point is located on the sidewall of the junction box. Figure 3-7. PE Ground Connection Localization and Details, Junction Box Version In VS-DX with Junction Box version for the PE connection, use the required type wire (typically green/yellow, 3 to 6 mm²... -

Page 31: Shielded Wiring

3. Install the PE ground and EMC ground straps to the lugs provided. Tighten to 5.1 Nm (45 lb-in). VS-DX Configuration and Calibration VS-DX Skid assembly consist of two Woodward VariStroke servos. When commissioning VS-DX skid, it is required to configure and calibrate each VS-I servo (Unit “A” and Unit “B”) separately. Please follow procedure steps according to Woodward manual 35148 (VS-I Customer Service Tool User Manual). - Page 32 2. Open VariStroke Cover (using Wrench: Type: Open End; Size: 2 1/4 in, CCW direction ) 3. Connect Communication Cable to VariStroke communication port. To perform VS unit calibration please follow procedure steps according to Woodward manual 35148 (VS-GI Customer Service Tool User Manual).

- Page 33 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 3-9. VS-DX Skid Pressure Gauges Location Woodward...

-

Page 34: Chapter 4. Initial Operation

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Chapter 4. Initial Operation The following procedure should be performed in the order as stated while commissioning and tuning the VS-DX skid: Only trained personnel should be allowed to work on this device during operation. -

Page 35: Figure 4-1. Isolation Valve Lever Positions

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Sudden Movement Stay clear of the actuator output shaft and all equipment that may be actuated by the Discrete or Analog Output, as sudden movement can occur at any time. Failure to comply with this recommendation can cause personal injury and/or property damage. -

Page 36: Figure 4-2. Vs-Dx Unit Components Topology

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Figure 4-2. VS-DX Unit Components Topology SERVO " A" SERVO " B" I SOLATED I SOLATED Figure 4-3. VS-DX Unit with Both Servos Control Port Paths Isolated 2. Open the supply isolation valves (not provided) and control isolation valve to both VS-GI units and drain isolation valves (not provided) if necessary. -

Page 37: Figure 4-4. Vs-Dx Unit Vs-Gi Unit "A" With Control Isolation Valves In Open Position

15. Slowly open the Supply isolation valve on one side of the VS-DX skid (VS-GI unit “A”). 16. Use the Customer Service Tool to initiate automatic VS-GI unit “A” trapped air flashing procedure please refer Woodward Manual 35148 for instructions). Repeat flashing procedure till stable unit operation is achieved (stable controlled actuator potion) -

Page 38: Figure 4-5. Vs-Dx Unit With All Isolation Valves In Open (Not Isolating) Position

27. Slowly open the Supply isolation valve to VS-GI Unit “B”. 28. Use the Customer Service Tool to initiate automatic VS-GI unit “A” trapped air flashing (please refer Woodward Manual 35148 for instructions) . Repeat flashing procedure till stable unit operation is achieved (stable controlled actuator potion). - Page 39 VS-DX electrical terminal box using dedicated knife disconnect type terminals. For a complete procedure of the individual VS-I replacement, see Woodward manual 35133. When replacing a failed VS-GI Servo, always use the following order to ensure there are no interactions with the operating servo.

-

Page 40: Vs-Dx Performance

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid VS-DX performance The VS-DX skid characterize very short transfer time and stable pressure during unit to unit control switchover or in case of unit in control fault or shutdown. Special shuttle valve design provide “position bumpless”... -

Page 41: Vsc-Dx Unit Trapped Air Releasing Procedure

– Please see Woodward manual 35148. VSC-DX Unit Tuning To prepare to operation and tune each individual VS-1 G1servo, follow Woodward manual 35148 (VS-I Customer Service Tool User Manual). Woodward... -

Page 42: Chapter 5. Repair And Troubleshooting

Repair and Troubleshooting General Repairs and servicing of the VS-DX must be performed by Woodward or its authorized service facilities or trained personnel. Use of a cable gland or stopping plug that does not meet the hazardous area certification requirements or thread form or thread size will invalidate the suitability for hazardous locations. -

Page 43: Troubleshooting

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Troubleshooting General The following troubleshooting guide will help you isolate trouble with the control circuit board, actuator, wiring, and system problems. Troubleshooting beyond this level is recommended ONLY when a complete facility for control testing is available. - Page 44 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Table 5-2. Trouble Shooting Data Symptom Cause Recommended Action Faulty power, check for green LED. Check power connections, 24 V (dc) pins. Error condition, check red LED (alarm or If on: Check actuator wire connection.

- Page 45 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Symptom Cause Recommended Action Replace VS-I and Adjust Control System: - Check for control signal instability. If control signal is highly active reduce dynamic settings at main control. Check wiring for proper shielding or ground loops. Correct these issues until the demand signal is stable.

-

Page 46: Chapter 6. Product Support And Service Options

• An Authorized Independent Service Facility (AISF) provides authorized service that includes repairs, repair parts, and warranty service on Woodward's behalf. Service (not new unit sales) is an AISF's primary mission. A current list of Woodward Business Partners is available at www.woodward.com/directory. -

Page 47: Returning Equipment For Repair

All repair work carries the standard Woodward service warranty (Woodward Product and Service Warranty 5-01-1205) on replaced parts and labor. -

Page 48: Replacement Parts

• The unit serial number, which is also on the nameplate Engineering Services Woodward offers various Engineering Services for our products. For these services, you can contact us by telephone, by email, or through the Woodward website. • Technical Support •... -

Page 49: Technical Assistance

VariStroke-DX Duplex Hydraulic Servo Skid Technical Assistance If you need to contact technical assistance, you will need to provide the following information. Please write it down here before contacting the Engine OEM, the Packager, a Woodward Business Partner, or the Woodward factory: General... -

Page 50: Chapter 7. Asset Management And Refurbishment Scheduling Period

Woodward’s overhaul services will return the unit to “like new” condition ready for another full operating cycle, lasting until the next planned maintenance outage. Upon reaching the recommended maintenance cycle of the auxiliary component, please contact either the sites turbine OEM service representative, local Woodward Distributor or Woodward Authorized Independent Service Facility to facilitate services. -

Page 51: Chapter 8. Long-Term Storage Requirements

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Chapter 8. Long-Term Storage Requirements Units that will not be put into service within twelve months should be packaged for long-term storage as described in Woodward manual 25075. Woodward... -

Page 52: Revision History

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Revision History New Manual— • Woodward... -

Page 53: Declarations

Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Declarations PENDING Woodward... - Page 54 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Woodward...

- Page 55 Released Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid Woodward...

- Page 56 Email and Website—www.woodward.com Woodward has company-owned plants, subsidiaries, and branches, as well as authorized distributors and other authorized service and sales facilities throughout the world. Complete address / phone / fax / email information for all locations is available on our website.

Need help?

Do you have a question about the VariStroke-DX and is the answer not in the manual?

Questions and answers