Dell EMC PowerEdge C6420 Manual

Hide thumbs

Also See for EMC PowerEdge C6420:

- Installation and service manual (92 pages) ,

- Reference manual (26 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Dell EMC PowerEdge C6420

- Page 1 Dell EMC PowerEdge C6420 Regulatory Model: E43S Series Regulatory Type: E43S001...

- Page 2 A WARNING indicates a potential for property damage, personal injury, or death. Copyright © 2017 Dell Inc. or its subsidiaries. All rights reserved. Dell, EMC, and other trademarks are trademarks of Dell Inc. or its subsidiaries. Other trademarks may be trademarks of their respective owners.

-

Page 3: Table Of Contents

Contents 1 PowerEdge C6420 overview...........................7 Supported configurations..............................7 Back view of the PowerEdge C6420 sled........................9 Network ports indicator codes............................10 Sled to hard drive mapping..............................12 Locating the Service Tag of your system........................13 2 Documentation resources..........................14 3 Technical specifications..........................16 Dimensions of the PowerEdge C6420 sled........................16 Chassis weight.................................. - Page 4 Viewing System Setup...............................37 System Setup details..............................37 System BIOS................................38 iDRAC Settings utility..............................58 Device Settings................................58 Dell Lifecycle Controller..............................58 Embedded system management..........................59 Boot Manager.................................. 59 Viewing Boot Manager..............................59 Boot Manager main menu............................59 One-shot BIOS boot menu............................60 System Utilities................................60...

- Page 5 7 Using system diagnostics..........................121 Dell Embedded System Diagnostics..........................121 Running the Embedded System Diagnostics from Boot Manager..............121 Running the Embedded System Diagnostics from the Dell Lifecycle Controller..........121 System diagnostic controls............................. 122 8 Jumpers and connectors ........................... 123 System board jumper settings............................123 System board connectors..............................124...

- Page 6 Receiving automated support with SupportAssist ....................126 Contacting Dell................................126 Documentation feedback...............................127 Accessing system information by using QRL......................127 Quick Resource Locator for C6400 and C6420 systems..................127 Contents...

-

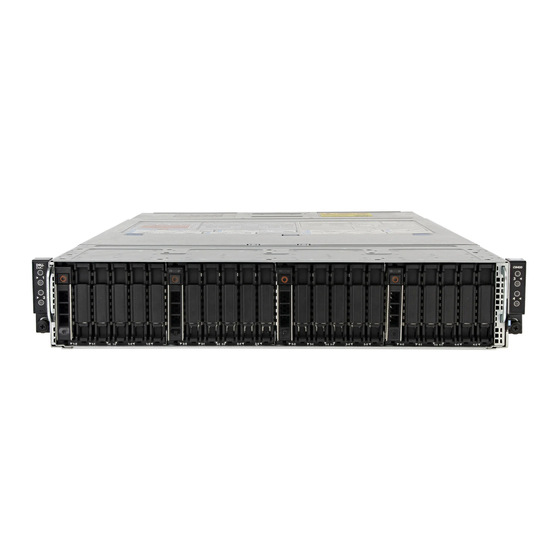

Page 7: Poweredge C6420 Overview

PowerEdge C6420 overview The PowerEdge C6420 sled supports up to two Intel Xeon Scalable E5- 2600 or E5- 2600 Fabric product family processors with 28 cores per processor. The sled also supports 16 memory modules, dedicated mezzanine, PCIe and Open Compute Project (OCP) adapters for expansion and connectivity. - Page 8 Figure 1. Supported configurations for PowerEdge C6420 PowerEdge C6420 overview...

-

Page 9: Back View Of The Poweredge C6420 Sled

Enables you to remotely access iDRAC or NIC port iDRAC. For more information, see the iDRAC User’s Guide at Dell.com/idracmanuals. mini display port Enables you to connect a display device to the system. For more information, see the Technical specifications section. -

Page 10: Network Ports Indicator Codes

Item Indicator, button, or connector Icon Description Omni-Path Architecture (OPA) expansion cards. For more information, see the Technical specifications section. EST pull out tab This tab has the unique Express Service Code, Service Tag, and MAC address labels. system id indicator The System Identification(ID) LED is available on the back of the system. - Page 11 Figure 4. LAN indicators on the QSFP mezzanine card Link indicator Activity indicator Table 2. QSFP port on mezzanine card indicator codes Connection State QSFP Upper green LED QSFP Lower green LED No link/Not Connected InfiniBand Physical Link - No Logical Link Green InfiniBand Logical Link - No Traffic Green...

-

Page 12: Sled To Hard Drive Mapping

Figure 5. Ethernet port indicator codes speed indicator link and activity indicator Table 3. Ethernet port indicator codes Convention Status Condition Link and activity indicators are off The NIC is not connected to the network. Link indicator is green The NIC is connected to a valid network at its maximum port speed. -

Page 13: Locating The Service Tag Of Your System

Your system is identified by a unique Express Service Code and Service Tag number. The Express Service Code and Service Tag are found on the back of the sled by pulling out the EST tag. This information is used by Dell to route support calls to the appropriate personnel. -

Page 14: Documentation Resources

Managing your system For information about systems management Dell.com/openmanagemanuals software offered by Dell, see the Dell OpenManage Systems Management Overview Guide. For information about setting up, using, and Dell.com/openmanagemanuals troubleshooting OpenManage, see the Dell OpenManage Server Administrator User’s Guide. - Page 15 Working with the Dell For information about understanding the features Dell.com/storagecontrollermanuals PowerEdge RAID controllers of the Dell PowerEdge RAID controllers (PERC), Software RAID controllers, or BOSS card and deploying the cards, see the Storage controller documentation. Understanding event and error For information about checking the event and error Dell.com/openmanagemanuals...

-

Page 16: Technical Specifications

Technical specifications The technical and environmental specifications of your system are outlined in this section. Topics: • Dimensions of the PowerEdge C6420 sled • Chassis weight • Processor specifications • System battery • Expansion bus specifications • Memory specifications • Hard drives and storage specifications •... -

Page 17: Chassis Weight

Chassis weight Table 6. Chassis weight of the PowerEdge C6400 enclosure with PowerEdge C6420 sleds System Maximum weight (with all sleds and drives) 12 x 3.5-inch hard drive systems 43.62 Kg (96.16 lb) 24 x 2.5-inch hard drive systems 41.46 Kg (91.40 lb) No backplane systems 34.56 Kg (76.19 lb) Processor specifications... -

Page 18: Hard Drives And Storage Specifications

Memory module sockets Architecture Memory capacity and Minimum RAM Maximum RAM ranking with support for • Dual rank - 64 GB • 16 GB with dual • 1024 GB with dual advanced ECC or processor processor memory optimized operation Hard drives and storage specifications The PowerEdge C6420 sled supports SAS and SATA hard drives and Solid State Drives (SSDs). -

Page 19: Environmental Specifications

Resolution Refresh rate (Hz) Color depth (bits) 1440 x 900 up to 24 Environmental specifications Temperature specifications Table 12. Temperature specifications Temperature Specifications Storage –40°C to 65°C (–40°F to 149°F) Continuous operation (for altitude less than 950 m or 3117 ft) 10°C to 35°C (50°F to 95°F) with no direct sunlight on the equipment. -

Page 20: Maximum Shock Specifications

Maximum shock specifications Table 15. Maximum shock specifications Maximum shock Specifications Operating 24 executed shock pulses 6 G in the positive and negative x, y, z axis for up to 11 ms (four pulses on each side of the system). Storage Six consecutively executed shock pulses of 71 G in the positive and negative x, y, z axes for up to 2 ms (one pulse on each side of the... -

Page 21: Particulate And Gaseous Contamination Specifications

Maximum corrosive contaminant levels measured at ≤50% relative humidity. Standard operating temperature specifications NOTE: Not available: Indicates that the configuration is not offered by Dell EMC. Not supported: Indicates that the configuration is not thermally supported. NOTE: All components including the DIMMs, communication cards, M.2 SATA, and PERC cards can be supported with sufficient thermal margin if the ambient temperature is equal to or below to the maximum continuous operating temperature listed in these tables with the exception of the Mellanox DP LP card. - Page 22 Table 20. Standard operating temperature specifications Standard operating temperature Specifications Temperature ranges (for altitude less than 950 m or 3117 ft) 10°C to 35°C (50°F to 95°F) with no direct sunlight on the equipment. NOTE: Some configurations require a lower ambient temperature. For more information see the following tables.

- Page 23 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks 8176M...

- Page 24 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks CPU2:...

- Page 25 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks CPU2:...

- Page 26 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks 4108...

- Page 27 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks 6142F...

- Page 28 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks 8176...

- Page 29 Proces Suppor 8x 3.5” 4x 3.5” 8x 2.5” 4x 2.5” DIMM 3.5” 2.5” 2.5” 2.5” 2.5” back HDDs HDDs HDDs HDDs count HDDs HDDs HDDs HDDs HDDs plane model heat enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu enclosu number sinks 6138...

- Page 30 Table 24. Maximum continuous operating temperature for fabric single processor configuration Process 12x 3.5” 8x 3.5” 4x 3.5” 24x 2.5” 20x 2.5” 16x 2.5” 12x 2.5” 8x 2.5” 4x 2.5” No back DIMM HDDs HDDs HDDs HDDs HDDs HDDs HDDs HDDs HDDs plane...

-

Page 31: Expanded Operating Temperature Specifications

Expanded operating temperature specifications Table 26. Expanded operating temperature Expanded operating temperature Specifications Continuous operation 5°C to 40°C at 5% to 85% RH with 29°C dew point. NOTE: Outside the standard operating temperature (10°C to 35°C), the system can operate continuously in temperatures as low as 5°C and as high as 40°C. - Page 32 • PCIe cards with power rating greater than 25 W are not supported. • AEP DIMM and LRDIMM are not supported. • Support only for CPU’s with wattages up to 105 W without the PERC H330 and H730. Technical specifications...

-

Page 33: Initial System Setup And Configuration

The Integrated Dell Remote Access Controller (iDRAC) is designed to make system administrators more productive and improve the overall availability of Dell systems. iDRAC alerts administrators to system issues, helps them perform remote system management, and reduces the need for physical access to the system. -

Page 34: Log In To Idrac

Ensure that you change the default user name and password after setting up the iDRAC IP address. For more information about logging in to the iDRAC and iDRAC licenses, see the latest Integrated Dell Remote Access Controller User's Guide at Dell.com/idracmanuals. -

Page 35: Downloading Drivers And Firmware

Using Dell OpenManage Deployment Toolkit (DTK) Dell.com/openmanagemanuals Downloading drivers and firmware Dell recommends that you download and install the latest BIOS, drivers, and systems management firmware on your system. Prerequisite Ensure that you clear the web browser cache before downloading the drivers and firmware. -

Page 36: Pre-Operating System Management Applications

You can manage basic settings and features of a system without booting to the operating system by using the system firmware. Topics: • Options to manage the pre-operating system applications • System Setup • Dell Lifecycle Controller • Boot Manager • PXE boot Options to manage the pre-operating system applications Your system has the following options to manage the pre-operating system applications: •... -

Page 37: Viewing System Setup

The iDRAC settings utility is an interface to set up and configure the iDRAC parameters by using UEFI (Unified Extensible Firmware Interface). You can enable or disable various iDRAC parameters by using the iDRAC settings utility. For more information about this utility, see Integrated Dell Remote Access Controller User’s Guide at Dell.com/idracmanuals. -

Page 38: System Bios

System BIOS You can use the System BIOS screen to edit specific functions such as boot order, system password, setup password, set the SATA and PCIe NVMe RAID mode, and enable or disable USB ports. Related link System BIOS Settings details Boot Settings Network Settings System Information... - Page 39 Option Description Network Settings Specifies options to manage the UEFI network settings and boot protocols. Legacy network settings are managed from the Device Settings menu. Integrated Devices Specifies options to manage integrated device controllers and ports, specifies related features and options. System Profile Specifies options to change the processor power management settings, memory frequency.

- Page 40 Specifies the memory operating mode. The options available are Optimizer Mode, Single Rank Spare Mode, Multi Mode Rank Spare Mode, Mirror Mode, and Dell Fault Resilient Mode. This option is set to Optimizer Mode by default. NOTE: The Memory Operating Mode option can have different default and available options based on the memory configuration of your system.

- Page 41 Description NOTE: The Dell Fault Resilient Mode option establishes an area of memory that is fault resilient. This mode can be used by an operating system that supports the feature to load critical applications or enables the operating system kernel to maximize system availability.

- Page 42 This option is only available on certain stock keeping units (SKUs) of the processors. X2APIC Mode Enables or disables the X2APIC mode. This option is set to Disabled by default. Dell Controlled Controls the turbo engagement. Enable this option only when System Profile is set to Performance. Turbo NOTE: Depending on the number of installed CPUs, there might be up to two processor listings.

- Page 43 NOTE: If your operating system begins to load before you press F2, wait for the system to finish booting, and then restart your system and try again. On the System Setup Main Menu screen, click System BIOS. On the System BIOS screen, click SATA Settings. SATA Settings details The SATA Settings screen details are explained as follows: Option...

- Page 44 Option Description For AHCI or RAID mode, BIOS support is always enabled. Option Description Model Specifies the drive model of the selected device. Drive Type Specifies the type of drive attached to the SATA port. Capacity Specifies the total capacity of the hard drive. This field is undefined for removable media devices such as optical drives.

- Page 45 Option Description Option Description Capacity Specifies the total capacity of the hard drive. This field is undefined for removable media devices such as optical drives. NVMe Settings The NVMe settings enable you to set the NVMe drives to either RAID mode or Non-RAID mode. NOTE: To configure these drives as RAID drives, you must set the NVMe drives and the Embedded SATA option in the SATA Settings menu to RAID mode.

- Page 46 Viewing Boot Settings To view the Boot Settings screen, perform the following steps: Turn on, or restart your system. Press F2 immediately after you see the following message: F2 = System Setup NOTE: If your operating system begins to load before you press F2, wait for the system to finish booting, and then restart your system and try again.

- Page 47 Operating systems must be UEFI-compatible to be installed from the UEFI boot mode. DOS and 32-bit operating systems do not support UEFI and can only be installed from the BIOS boot mode. NOTE: For the latest information about supported operating systems, go to Dell.com/ossupport. Changing boot order About this task You may have to change the boot order if you want to boot from a USB key.

- Page 48 On the System BIOS screen, click Integrated Devices. Integrated Devices details The Integrated Devices screen details are explained as follows: Option Description User Accessible Enables or disables the USB ports. Selecting All Ports Off disables all USB ports. The USB keyboard and mouse USB Ports operate during boot process in certain operating systems.

- Page 49 Option Description Memory Mapped When set to 12 TB, the system will map MMIO base to 12 TB. Enable this option for an OS that requires 44 bit I/O above Base PCIe addressing. When set to 512 GB, the system will map MMIO base to 512 GB, and reduce the maximum support for memory to less than 512 GB.

- Page 50 Serial Communication You can use the Serial Communication screen to view the properties of the serial communication port. Viewing Serial Communication To view the Serial Communication screen, perform the following steps: Turn on, or restart your system. Press F2 immediately after you see the following message: F2 = System Setup NOTE: If your operating system begins to load before you press F2, wait for the system to finish booting, and then...

- Page 51 You can only change the rest of the options if the mode is set to Custom.This option is set to Performance Per Watt Optimized (DAPC) by default. DAPC is Dell Active Power Controller., other options include Performance Per Watt (OS), Performance Per Watt (HWPM), Performance, and Workstation Performance.

- Page 52 Option Description Memory Refresh Sets the memory refresh rate to either 1x or 2x. This option is set to 1x by default. Rate Uncore Frequency Enables you to select the Processor Uncore Frequency option. Dynamic mode enables the processor to optimize power resources across the cores and uncore during runtime. The optimization of the uncore frequency to either save power or optimize performance is influenced by the setting of the Energy Efficiency Policy option.

- Page 53 System Security Settings details The System Security Settings screen details are explained as follows: Option Description Intel AES-NI Improves the speed of applications by performing encryption and decryption by using the Advanced Encryption Standard Instruction Set (AES-NI). This option is set to Enabled by default. System Password Sets the system password.

- Page 54 Option Description If the current mode is set to Deployed Mode, the available options are User Mode and Deployed Mode. If the current mode is set to User Mode, the available options are User Mode, Audit Mode, and Deployed Mode. Options Description User Mode...

- Page 55 • Only the following special characters are allowed: space, (”), (+), (,), (-), (.), (/), (;), ([), (\), (]), (`). A message prompts you to reenter the system password. Reenter the system password, and click OK. In the Setup Password field, type your setup password and press Enter or Tab. A message prompts you to reenter the setup password.

- Page 56 Operating with setup password enabled If Setup Password is set to Enabled, type the correct setup password before modifying the system setup options. If you do not type the correct password in three attempts, the system displays the following message: Invalid Password! Number of unsuccessful password attempts: <x>...

- Page 57 Option Description NOTE: RAID configurations and NVMe cards not are included as BIOS does not have the ability to distinguish between individual drives in those configurations. Redundant OS NOTE: This option is disabled if Redundant OS Location is set to None. State When set to Visible, the backup disk is visible to the boot list and OS.

-

Page 58: Idrac Settings Utility

Dell Lifecycle Controller Dell Lifecycle Controller (LC) provides advanced embedded systems management capabilities including system deployment, configuration, update, maintenance, and diagnosis. LC is delivered as part of the iDRAC out-of-band solution and Dell system embedded Unified Extensible Firmware Interface (UEFI) applications. -

Page 59: Embedded System Management

Certain platform configurations may not support the full set of features provided by the Dell Lifecycle Controller. For more information about setting up the Dell Lifecycle Controller, configuring hardware and firmware, and deploying the operating system, see the Dell Lifecycle Controller documentation at Dell.com/idracmanuals. -

Page 60: One-Shot Bios Boot Menu

Launch System Enables you to access System Setup. Setup Launch Lifecycle Exits the Boot Manager and invokes the Dell Lifecycle Controller program. Controller System Utilities Enables you to launch System Utilities menu such as System Diagnostics and UEFI shell. Related link... -

Page 61: Installing And Removing System Components

Damage due to servicing that is not authorized by Dell is not covered by your warranty. Read and follow the safety instructions that are shipped with your product. -

Page 62: Inside The Enclosure

• #4 nut driver • Torx #T30 screwdriver • Wrist grounding strap • ESD mat Inside the enclosure CAUTION: This system must be operated with the system cover installed to ensure proper cooling. Figure 10. Inside the C6400 enclosure sled (4) right midplane fan cage (2) fan (4) -

Page 63: Poweredge C6420 Sled

Figure 11. Inside the C6420 sled sled pull handle mezzanine card SATA connector memory slot (4) CPU1 processor heat sink module CPU2 processor heat sink module socket supporting bracket M.2 SATA riser memory slot (4) PCIe expansion card riser assembly PowerEdge C6420 sled The PowerEdge C6420 sled is a server unit that is installed into the PowerEdge C6400 enclosure. - Page 64 Figure 12. Removing a sled Installing and removing system components...

-

Page 65: Installing A Sled

Figure 13. Removing a sled blank Next step Install the sled into the enclosure. NOTE: If the sled is not being replaced immediately, a sled blank must be installed to ensure proper cooling of the system. Related link Installing a sled Installing a sled Prerequisites Follow the safety guidelines listed in... - Page 66 Figure 14. Installing a sled Installing and removing system components...

-

Page 67: Perc Battery

Follow the procedure listed in After working inside your system. NOTE: To add the Service Tag of the system board to match the Service Tag of the physical node, contact Dell Technical Support. PERC battery Removing the PERC battery Prerequisites... -

Page 68: Installing The Perc Battery

Figure 16. Removing the PERC battery Next step Install the PERC battery. Related link Removing a sled Installing the PERC battery Installing the PERC battery Prerequisite Follow the safety guidelines listed in Safety instructions. Steps Align and insert the non cable end of the PERC battery into the battery slot on the air shroud. Press the battery until it locks into place. -

Page 69: Air Shroud

Figure 17. Installing the PERC battery Next steps If disconnected, reconnect the battery cable to the PERC card. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a sled Air shroud The air shroud aerodynamically directs the airflow across the sled. -

Page 70: Installing The Air Shroud

Figure 18. Removing the air shroud Next step Install the air shroud. Related link Removing a sled Installing the air shroud Installing the air shroud Prerequisite Follow the safety guidelines listed in Safety instructions. Steps Insert the air shroud into the sled, aligning the shroud hinge with slot on the sled chassis. NOTE: Ensure that both the SATA cables are routed through the air shroud cable guide slot behind the air shroud latches. -

Page 71: System Memory

Figure 19. Installing the air shroud Next steps If disconnected, reconnect the battery cable to the PERC card. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a sled System memory The system supports DDR4 registered DIMMs (RDIMMs) and load reduced DIMMs (LRDIMMs). -

Page 72: General Memory Module Installation Guidelines

Figure 20. Memory socket locations Memory channels are organized as follows: Table 31. Memory channels Proces Channel 0 Channel 1 Channel 2 Channel 3 Channel 4 Channel 5 Proces Slots A1 and A7 Slots A2 Slots A3 Slots A8 and A4 Slots A5 Slots A6 sor 1... -

Page 73: Mode-Specific Guidelines

Mode-specific guidelines Five memory channels are allocated to each processor. The allowable configurations depend on the memory mode selected. It is recommended to set the memory to Memory Optimized mode. NOTE: You can mix x4 and x8 DRAM based DIMMs to support RAS features. However, all guidelines for specific RAS features must be followed. -

Page 74: Installing A Memory Module

Related link Installing a memory module Installing a memory module Prerequisite Follow the safety guidelines listed in Safety instructions. Steps Locate the appropriate memory module socket. CAUTION: Handle each memory module only by the edges, ensuring not to touch the middle of the memory module or metallic contacts. -

Page 75: Support Bracket

Run the system memory test in system diagnostics. Support bracket Removing the support bracket Prerequisites Follow the safety guidelines listed in Safety instructions. Follow the procedure listed in Before working inside your system. Remove the sled from the enclosure. Step Using the Phillips #1 screwdriver, remove the screws that secure the support bracket and lift the bracket away from the sled. -

Page 76: Linking Board And Sata Cable

Figure 24. Installing the support bracket Next steps Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a sled Linking board and SATA cable Each C6420 sled has one linking SATA signal cable connected to the onboard controller. The SATA cable is used to connect the onboard controller to the hard drive backplane through the midplane. -

Page 77: Installing The Linking Board And Sata Cable

Steps Pressing the release clip on the SATA_A connector, disconnect the connector from the system board. Pressing the release clip on the SATA_B connector, disconnect the connector from the system board. If connected, disconnect the SATA cable from the x16 M.2 riser. Using the Phillips #1 screwdriver, loosen the captive screws on the linking board and lift the board up along with the cables. -

Page 78: Processor And Heat Sink Module

Installing a sled Processor and heat sink module CAUTION: This is a Field Replaceable Unit (FRU). Removal and installation procedures must be performed only by Dell certified service technicians. NOTE: In a sled which has been configured with mixed CPUs – a fabric processor installed in the CPU2 socket and a non-fabric processor installed in the CPU1 socket, you must connect the external Omnipath link cables to Port 2 on the OCP carrier card. -

Page 79: Removing A Processor And Heat Sink Module

Table 32. Supported heat sinks Heat sink Dimensions Design CPU 1, standard heat sink Length =108 mm (4.25 inches), Width =88 2 heat pipes mm (3.46 inches), Height =24.8 mm (0.97 inches) CPU 1, extended heat sink Length =108 mm (4.25 inches), Width =96 2 heat pipes mm (3.77 inches), Height =24.8 mm (0.97 inches) -

Page 80: Installing A Processor And Heat Sink Module

Figure 27. Removing the processor and heat sink module Next step Install the PHM. Related link Installing a processor and heat sink module Installing a processor and heat sink module Prerequisites CAUTION: Never remove the heat sink from a processor unless you intend to replace the processor. The heat sink is necessary to maintain proper thermal conditions. - Page 81 CAUTION: To avoid damaging the fins on the heat sink, do not press down on the heat sink fins. NOTE: Ensure that the PHM is held parallel to the system board to prevent damaging the components. Push the blue retention clips inward to allow the heat sink to drop into place. Supporting the heat sink with one hand.

-

Page 82: Removing The Fabric Processor From The Processor Heat Sink Module

Figure 28. Installing a processor and heat sink module Next steps Install the air shroud. Connect the fabric cable to the fabric processor. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Removing the fabric processor from the processor heat sink module Prerequisites WARNING:... - Page 83 NOTE: This procedure is only for replacing a heat sink or a processor. This procedure should not be followed while replacing a system board. Follow the safety guidelines listed in Safety instructions. Follow the procedure listed in Before working inside your system.

-

Page 84: Installing The Fabric Processor Into The Processor Heat Sink Module

Figure 30. Removing the processor bracket Next step Install the fabric processor into the processor heat sink module. Related link Removing a sled Removing the air shroud Removing a processor and heat sink module Installing the fabric processor into the processor heat sink module Installing the fabric processor into the processor heat sink module Prerequisite... - Page 85 Figure 31. Installing the processor bracket If you are using an existing heat sink, remove the thermal grease from the heat sink by using a clean lint-free cloth. Use the thermal grease syringe included with your processor kit to apply the grease in a quadrilateral design on the top of the processor.

- Page 86 Figure 32. Applying thermal grease on top of the processor Place the heat sink on the processor and push down until the bracket locks onto the heat sink. NOTE: • Ensure that the two guide pin holes on the bracket match the guide holes on the heat sink. •...

-

Page 87: Removing The Non-Fabric Processor From The Processor And Heat Sink Module

Next steps Install the processor and heat sink module. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a processor and heat sink module Installing a sled Removing the non-fabric processor from the processor and heat sink module Prerequisites NOTE:... -

Page 88: Installing The Non-Fabric Processor Into A Processor And Heat Sink Module

NOTE: Ensure that the processor and the bracket are placed in the tray after you remove the heat sink. Figure 35. Removing the processor bracket Next step Install the non-fabric processor into the processor and heat sink module. Related link Removing a sled Removing the air shroud Removing a processor and heat sink module... - Page 89 Figure 36. Installing the processor bracket If you are using an existing heat sink, remove the thermal grease from the heat sink by using a clean lint-free cloth. Use the thermal grease syringe included with your processor kit to apply the grease in a quadrilateral design on the top of the processor.

-

Page 90: Removing The Fabric And Sideband Cables

Place the heat sink on the processor and push down on the base of the heat sink until the bracket locks onto the heat sink. NOTE: • Ensure that the two guide pin holes on the bracket match the guide holes on the heat sink. •... -

Page 91: Installing The Fabric And Sideband Cables

Follow the procedure listed in Before working inside your system. Remove the sled from the enclosure. Remove the air shroud. Steps Pull the blue pull tab on the locking bar up to release the connector from the lock on the processor base plate. To disengage and release the fabric connector, pull the connector away from the processor. -

Page 92: Expansion Cards

Steps Align the notches on the fabric connector with the guide pins on the processor base plate. Push the connector toward the processor, until the connector is engaged with the edge connector on the processor. Push the locking bar down to secure the fabric connector in place. Insert the side band cable into the respective connector, and press down to lock the connector. -

Page 93: Pcie Slot Priority

Mezzanine (slot 1) Dell PERC9 H330 Mezzanine Adapter Mezzanine (slot 1) Dell HBA H330 mini Mezzanine Adapter Slot 4 Dell SAS 12 GB HBA Low profile external Adapter Slot 5 SATA M.2 Low profile Slot 4 Mellanox Low profile ConnectX-4 Dual... - Page 94 Location Card type Form factor Link width Slot priority Maximum number of cards Port VPI FDR QSFP+ Adapter Slot 4 Mellanox Low profile ConnectX-4 Single Port VPI EDR QSFP+ Adapter Slot 4 Mellanox Low profile ConnectX-3 Single Port VPI FDR QSFP+ Adapter Slot 4 Intel OPA 100 Series...

-

Page 95: Removing The Expansion Card Riser Assembly

Location Card type Form factor Link width Slot priority Maximum number of cards Slot 4 SolarFlare Flareon Low profile SFN8522 10GE SFP Dual Port Adapter Slot 4 Intel 10GbE Quad Low profile Port X710-t Adapter Slot 4 Intel Gigabit Dual Low profile Port I350-t Adapter, Slot 4... -

Page 96: Installing The Expansion Card Riser Assembly

Related link Removing a sled Installing the expansion card riser assembly Installing the expansion card riser assembly Prerequisite NOTE: You must install an expansion card filler bracket over an empty expansion slot to maintain Federal Communications Commission (FCC) certification of the system. The brackets also keep dust and dirt out of the system and aid in proper cooling and airflow inside the system. - Page 97 Steps Remove the screw that secures the expansion card to the assembly. Hold the expansion card by its edges, and carefully remove it from the riser card. NOTE: You must install an expansion card filler bracket over an empty expansion slot to maintain Federal Communications Commission (FCC) certification of the system.

-

Page 98: Installing An Expansion Card

Figure 44. Installing the expansion card filler bracket Next step Install the expansion card or the expansion card filler bracket. Related link Removing a sled Removing the expansion card riser assembly Installing an expansion card Installing an expansion card Prerequisites CAUTION: Expansion cards can only be installed in the slots on the expansion card riser. - Page 99 Figure 45. Removing the expansion card filler bracket Installing and removing system components...

-

Page 100: Removing The Riser Card

Figure 46. Installing an expansion card Next steps Install the expansion card riser assembly. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing the expansion card riser assembly Installing a sled Removing the riser card Prerequisites Follow the safety guidelines listed in... -

Page 101: Installing The Riser Card

Steps Using the Phillips #2 screwdriver, remove the screws that secure the riser card to the expansion card bracket. Lift the riser card away from the expansion card bracket. Figure 47. Removing the riser card Next step Install the riser card. Related link Removing a sled Removing the expansion card riser assembly... -

Page 102: Removing The M.2 Sata X16 Riser

Figure 48. Installing the riser card Next steps If removed, install the expansion card. Install the expansion card riser assembly. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing an expansion card Installing the expansion card riser assembly Installing a sled Removing the M.2 SATA x16 riser... -

Page 103: Installing The M.2 Sata X16 Riser

Figure 49. Removing the M.2 SATA x16 riser Next step Install the M.2 SATA x16 riser. Related link Removing a sled Installing the M.2 SATA x16 riser Installing the M.2 SATA x16 riser Prerequisite Follow the safety guidelines listed in Safety instructions. -

Page 104: Removing The M.2 Sata Card

Figure 50. Installing the M.2 SATA x16 riser Next steps Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a sled Removing the M.2 SATA card Prerequisites Follow the safety guidelines listed in Safety instructions. -

Page 105: Installing The M.2 Sata Card

Figure 51. Removing the M.2 SATA card from the M.2 SATA x16 riser Next step Install the M.2 SATA card. Related link Removing a sled Removing the expansion card riser assembly Removing the M.2 SATA x16 riser Installing the M.2 SATA card Installing the M.2 SATA card Prerequisite Follow the safety guidelines listed in... -

Page 106: Mezzanine And Ocp Cards

Figure 52. Installing the M.2 SATA card on the SATA x16 riser Next steps If removed, install the expansion card riser assembly. Install the M.2 x16 riser. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. - Page 107 NOTE: You must install an expansion card filler bracket over an empty expansion slot to maintain Federal Communications Commission (FCC) certification of the system. The brackets also keep dust and dirt out of the system and aid in proper cooling and airflow inside the system. Figure 53.

-

Page 108: Installing A Mezzanine Card

Installing a mezzanine card Prerequisite NOTE: The procedure to install the mezzanine blank is similar to the removal of a mezzanine card. Follow the safety guidelines listed in Safety instructions. Steps Attach and secure the mezzanine card bracket to the mezzanine card. Holding the card by its edges, position the card so that the card edge connector aligns with the connector of the bridge board on the system board. - Page 109 Figure 54. Installing a mezzanine card Next steps Install the mezzanine card or the mezzanine card filler bracket. Install the expansion card riser assembly. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing the expansion card riser assembly Installing a sled...

-

Page 110: Removing The Mezzanine Card Bridge Board

Removing the mezzanine card bridge board Prerequisites Follow the safety guidelines listed in Safety instructions. Follow the procedure listed in Before working inside your system. Remove the sled from the enclosure. Remove the expansion card riser assembly. Remove the mezzanine card. Step Pull the mezzanine card bridge board away from the mezzanine card slot on the system board. -

Page 111: Removing The Ocp Card

Figure 56. Installing the mezzanine card bridge board Next steps Install the mezzanine card. Install the expansion card riser assembly. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. Related link Installing a mezzanine card Installing the expansion card riser assembly Installing a sled Removing the OCP card... -

Page 112: Installing The Ocp Card

Figure 57. Removing the OCP card Next step Install the OCP card. Related link Removing a sled Removing a mezzanine card Installing the OCP card Installing the OCP card Prerequisite Follow the safety guidelines listed in Safety instructions. Steps Insert the Open Compute Project (OCP) card into the sled, aligning the connector on the card with the connector in the system board. -

Page 113: Trusted Platform Module

Figure 58. Installing the OCP card Next steps Install the mezzanine card. Install the sled into the enclosure Follow the procedure listed in After working inside your system. Related link Installing a mezzanine card Installing a sled Trusted Platform Module Trusted Platform Module (TPM) is a dedicated microprocessor designed to secure hardware by integrating cryptographic keys into devices. -

Page 114: Initializing Tpm For Bitlocker Users

NOTE: To locate the TPM connector on the system board, see the System board jumpers and connectors section. Press to hold the module down and remove the screw using the security Torx 8-bit shipped with the TPM module. Slide the TPM module out from its connector. Push the plastic rivet away from the TPM connector and rotate it 90°... -

Page 115: Initializing The Tpm 2.0 For Txt Users

For more information, see the safety information that shipped with your system. NOTE: Battery is a Field Replaceable Unit (FRU). Only Dell certified service technicians must remove or install system battery. Follow the safety guidelines listed in Safety instructions. -

Page 116: Installing The System Battery

For more information, see the safety information that shipped with your system. NOTE: Battery is a Field Replaceable Unit (FRU). Removal and installation procedures are to be performed only by Dell certified service technicians. Follow the safety guidelines listed in Safety instructions. -

Page 117: System Board

Figure 61. Installing the system battery Next steps If removed, install the expansion card riser. Install the sled into the enclosure. Follow the procedure listed in After working inside your system. While booting, press F2 to enter System Setup and ensure that the battery is operating properly. Enter the correct time and date in the System Setup Time and Date fields. -

Page 118: Installing System Board

Disconnect all the cables from the system board. Keep the Phillips #1 screwdriver and #4 nut-driver ready. Steps Remove the screws that secure the system board to the sled assembly. CAUTION: Do not lift the system board by holding a memory module slot, any other connector, or component. Hold the system board by the edges, and lift the system board away from the sled. - Page 119 Follow the procedure listed in After working inside your system. Import your new or existing iDRAC Enterprise license. For more information, see Integrated Dell Remote Access Controller User's Guide, at Dell.com/esmmanuals. Ensure that you: Use the Easy Restore feature to restore the Service Tag. For more information, see the Easy restore section.

- Page 120 • Press Y to restore the Service Tag, license, and diagnostics information. • Press N to navigate to the Dell Lifecycle Controller based restore options. • Press F10 to restore data from a previously created Hardware Server Profile. After the restore process is complete, BIOS prompts to restore the system configuration data.

-

Page 121: Using System Diagnostics

Using system diagnostics If you experience a problem with your system, run the system diagnostics before contacting Dell for technical assistance. The purpose of running system diagnostics is to test your system hardware without using additional equipment or risking data loss. If you are unable to fix the problem yourself, service and support personnel can use the diagnostics results to help you solve the problem. -

Page 122: System Diagnostic Controls

System diagnostic controls Menu Description Configuration Displays the configuration and status information of all detected devices. Results Displays the results of all tests that are run. System health Provides the current overview of the system performance. Event log Displays a time-stamped log of the results of all tests run on the system. This is displayed if at least one event description is recorded. -

Page 123: Jumpers And Connectors

Jumpers and connectors This topic provides specific information about the jumpers. It also provides some basic information about jumpers and switches and describes the connectors on the various boards in the system. Jumpers on the system board help to disable the system and setup passwords. -

Page 124: System Board Connectors

System board connectors Figure 64. PowerEdge C6420 system board connectors Table 36. System Board Connectors and Description Item Connector Description PCIe B NVMe B connector PCIe A NVMe A connector PCIe Slot 5 Slot 5: x16 PCIe Gen3 from CPU 2 DIMM sockets (4) DIMM B8, DIMM B4, DIMM B5, DIMM B6 DIMM sockets (4) -

Page 125: Disabling Forgotten Password

Damage due to servicing that is not authorized by Dell is not covered by your warranty. Read and follow the safety instructions that are shipped with your product. -

Page 126: Getting Help

Contacting Dell Dell provides several online and telephone based support and service options. If you do not have an active internet connection, you can find contact information about your purchase invoice, packing slip, bill, or Dell product catalog. Availability varies by country and product, and some services may not be available in your area. - Page 127 Documentation feedback You can rate the documentation or write your feedback on any of our Dell documentation pages and click Send Feedback to send your feedback. Accessing system information by using QRL You can use the Quick Resource Locator (QRL) to get immediate access to the information about your system. The QRL is located on the top of the system cover and provides access to generic information about your system.