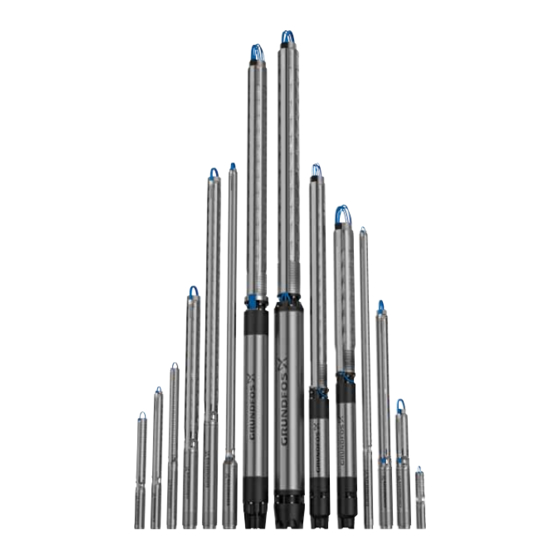

Grundfos SP Series Installation And Operating Instructions Manual

Hide thumbs

Also See for SP Series:

- Installation and operating instructions manual (586 pages) ,

- Installation and operation manual (24 pages) ,

- Installation and operating instructions manual (48 pages)

Summary of Contents for Grundfos SP Series

- Page 1 GRUNDFOS INSTRUCTIONS Installation and operating instructions Other languages http://net.grundfos.com/qr/i/98074911...

-

Page 2: Table Of Contents

Checking the motor liquid 1.1 Hazard statements Positional requirements The symbols and hazard statements below may appear in Pump/motor diameter Grundfos installation and operating instructions, safety Liquid temperatures and motor cooling instructions and service instructions. Pipe connection Electrical connection DANGER... -

Page 3: Notes

SP and SPA, with submersible motors, types Grundfos MS/MMS. Storage temperature If the pump is fitted with a motor of another brand than Grundfos MS or MMS, note that the motor data may differ from the data Pump: -20 - +60 °C. -

Page 4: Applications

If liquids with a viscosity higher than that of water are to be Sound pressure level of motors pumped, contact Grundfos. The sound pressure level of Grundfos MS and MMS motors is N EN 1.4401 and R EN 1.4539 grade stainless steel pump sets lower than 70 dB(A). -

Page 5: Installation Requirements

- Wear personal protective equipment. The use of a sine-wave filter is mandatory when operating an SPE pump set. Grundfos recommends to fit a 30 cm long pipe to the Fig. 3 Motor position during filling - MS4000 and MS402 pump to facilitate handling of the pump during installation. -

Page 6: Positional Requirements

5.1.3 Grundfos MMS6, MMS8000, MMS10000 and MMS12000 5.2 Positional requirements motors WARNING Filling procedure: Crushing of hands Place the motor at a 45 ° angle with the top of the motor upwards. Death or serious personal injury See fig. 5. -

Page 7: Liquid Temperatures And Motor Cooling

The maximum liquid temperature and the minimum flow velocity Q x 353 past the motor appear from the following table. [m/s] Grundfos recommends installing the motor above the well screen in order to achieve proper motor cooling via liquid passing the Flow rate motor. -

Page 8: Motor Protection

MP 204 motor protection unit and contactor(s). 6.1.3 Required settings of motor-protective circuit breaker For motors with an MP 204 motor protection unit, Grundfos recommends using a special trip curve with P-characteristics at a setting of Un times 5 for 1 second. -

Page 9: Lightning Protection

I × 1.73 × 100 × Grundfos supplies submersible drop cables for a wide range of installations. A cable sizing tool is available on Grundfos Insite at: Length of submersible drop cable [m] https://www.grundfos.com/sp-system/download-sp-app-html. Rated voltage [V] ΔU... -

Page 10: Control Of Single-Phase Ms402 Motors

Grundfos control box SA-SPM 50 Hz or 60 Hz without motor protection. MS4000, MS6000 3-wire single-phase motors must be connected to the mains via a Grundfos SA-SPM 50 Hz or 60 Hz control box incorporating motor protection. Fig. 10 2-wire motors When a conventional motor-protective circuit breaker is used, the electrical connection must be carried out as described below. -

Page 11: Connection Of Three-Phase Motors

16. 6.6 Connection of three-phase motors. W2 U2 PE U1 Fig. 16 Grundfos motors wound for star-delta starting - Fig. 14 Grundfos motors - direct-on-line starting direct-on-line starting 6.6.2 Motors wound for star-delta starting 6.6.3 MS6000P Synchronous motors requiring double... -

Page 12: Setting Up The Cue Frequency Converter In An Spe System

(and consequently the speed) to such a level that the necessary flow of cooling liquid past the http://net.grundfos.com/qr/i/98870684 motor is no longer ensured. enable the monitoring of the motor temperature, Grundfos recommend that Pt100 or Pt1000 sensor is installed. -

Page 13: Mechanical Installation

8. Mechanical installation 8.3 Lifting the product Grundfos recommends to fit a maximum 30 cm long pipe to the WARNING pump to facilitate handling of the pump during installation. Sharp element Death or serious personal injury - When mounting the facilitating pipe, wear personal protective equipment to avoid cutting on sharp edges on the pump. -

Page 14: Riser Pipe

When flanged pipes are used, the flanges must be slotted to take Grundfos recommends checking the borehole by means of an the submersible drop cable and a water indicator hose, if fitted. inside calliper before lowering the pump to ensure unobstructed passage. -

Page 15: Startup And Operation

If the pump can pump more than yielded by the well, we • Maximum 15 per day. MMS12000 recommend that you install the Grundfos MP 204 motor protector • Grundfos recommends or some other type of dry-running protection. minimum 1 per year. -

Page 16: Service

The pumps can be serviced at a Grundfos service centre. Death or serious personal injury If Grundfos is requested to service the pump, Grundfos must be - Switch off the power supply before starting any contacted with details about the pumped liquid, etc. before the work on the product. - Page 17 Fault Cause Remedy 1. The pump does not a) The fuses are blown. Replace the blown fuses. If the new ones blow too, run. check the electric installation and the submersible drop cable. b) The ELCB or the voltage-operated ELCB has Cut in the circuit breaker.

-

Page 18: Checking Motor And Cable

12. Checking motor and cable 12.1 SPE The following is only valid for SPE pump sets. DANGER DANGER Electric shock Electric shock Death or serious personal injury - Switch off the power supply before starting any Death or serious personal injury work on the product. -

Page 19: Disposing Of Hazardous Or Toxic Materials

This product or parts of it must be disposed of in an environmentally sound way: 1. Use the public or private waste collection service. 2. If this is not possible, contact the nearest Grundfos company or service workshop. The crossed-out wheelie bin symbol on a product means that it must be disposed of separately from household waste. - Page 20 Appendix U = 3 x 400 V Example: I = 40 A U = 2 % U = 3 x 400 V = 40 A L = 140 m L = 140 m U = 2 % ------- - --------- - 70 m 25 mm...

- Page 21 U = 3 x 380 V Example: I = 10 A U = 2 % U = 3 x 380 V L = 120 m = 10 A L = 120 m U = 2 % ------- - --------- - 60 m 6 mm U...

- Page 22 U = 3 x 220 V Example: I = 5 A U = 3 % U = 3 x 220 V = 5 A L = 105 m L = 105 m U = 3 % ------- - --------- - 35 m 2,5 mm U...

- Page 23 U = 3 x 415 V Example: I = 100 A U = 3 % U = 3 x 415 V = 100 A L = 150 m L = 150 m U = 3 % ------- - --------- - 50 m 50 mm U...

- Page 24 Appendix SP1 - SP 2 - SP 3 - SP 5 Fig. 1 Fig. 2 Fig. 3 Fig. 1 Fig. 2 Fig. 3 SP 7 - SP 9 - SP 11 - SP 14 - SP 17 - SP 30 - SP 46 - SP 60 Fig.

- Page 25 SP 77 - SP 95 - SP 125 - SP 160 - SP 215 Fig. 1 Fig. 2 Fig. 3 Fig. 1 Fig. 2 Fig. 3...

- Page 26 YETKİLİ GRUNDFOS SERVİSLERİ Telefon İlgili Kişi Firma Adres Cep telefonu Eposta Faks GEBZE ORGANİZE SANAYİ BÖLGESİ. İHSAN 0262 679 79 79 GRUNDFOS POMPA EMRAH ŞİMŞEK DEDE CADDESİ.2.YOL 200.SOKAK.NO:204 0553 259 51 63 KOCAELİ esimsek@grundfos.com GEBZE KOCAELİ 0262 679 79 05 0322 428 50 14 SUNPO ELEKTRİK...

- Page 27 GRUNDFOS Pumps (Hong Kong) Ltd. Turkey Brazil Norway Unit 1, Ground floor GRUNDFOS POMPA San. ve Tic. Ltd. Sti. BOMBAS GRUNDFOS DO BRASIL Siu Wai Industrial Centre GRUNDFOS Pumper A/S Gebze Organize Sanayi Bölgesi Av. Humberto de Alencar Castelo Branco, 29-33 Wing Hong Street &...

- Page 28 98074911 08.2020 ECM: 1290512 www.grundfos.com...

Need help?

Do you have a question about the SP Series and is the answer not in the manual?

Questions and answers