Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Valtra 6000

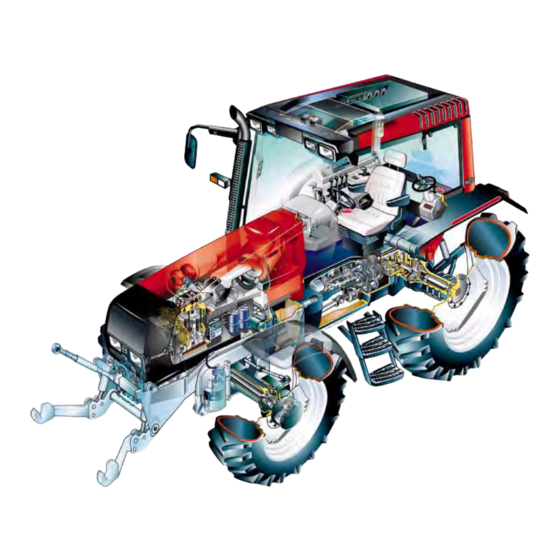

- Page 1 VALTRA – VALMET MEGA MEZZO HI-TEC WORKSHOP MANUAL...

-

Page 2: Electrical System

General Engine Electrical 6000, 6100, 6200 system 6250, 6300, 6350 6400, 6550, 6600 Power transmission 6650, 6800, 6850 6900, 8000, 8100 8200, 8400, 8050 Brake system 8150, 8450, 8550 8750, 8950 Steering sys- tem and Front 6600E---8750E axle Frame and... - Page 3 Order no 39 210 211 ENGLISH...

- Page 4 11. Layout 10. General 12. Repairs 13. Maintenance...

- Page 6 To the reader The Service Manual for the Valmet tractors is intended to be a practical reference source to be used in work- shop. The repair instructions in the manual are based on methods which have been worked out in practice during normal workshop conditions and which are based on the use of special tools from the manufacturer when stated in the instructions.

- Page 8 Model Code Page 1. 8. 2000 11. General 6000-- 8950 1. 9. 2002 The following supplements have been published for the Valmet 6000---8950 Service Manual: Ordering number Date Notes 39 256 211 15. 6. 1992 39 256 212 1. 9. 1992 39 256 213 15.

- Page 10 Model Code Page 11. Layout 6000-- 8750 8. 11. 1990 Layout of Service Manual 1. Division into groups The manual is divided into groups (10 ---100) which are based on the make ---up of the tractor. The groups are listed on the first index leaf.

- Page 11 Model Code Page 11. Layout 6000-- 8750 8. 11. 1990 3. Code designation Three ---digit code designations are used to distinguish the different document groups for the respective components. The same code is also used in the Time List as a reference to the text in this Manual. The code designation numbers appear both in the box at the top of the page and also in the headings.

- Page 12 Model Code Page 8. 11. 1990 11. Layout 6000-- 8750 1. 4. 1997 Code designation in the Service Manual 10. General 110 Layout 120 Repairs 130 Maintenance 20 Engine 21. Engine 210 Technical data, tools, description 211 Cylinder block and flywheel housing...

- Page 13 Model Code Page 8. 11. 1990 11. Layout 6000-- 8750 1. 4. 1997 50. Brakes 510 Technical data, description 511. Service brakes 520 Parking brake 60. Steering system and front axle 61. Steering system 610 Technical data, tools, description 611 Steering valve...

- Page 14 Model Code Page 12. Repairs 6000-- 8750 8. 11. 1990 General instructions for repairs Outer oil seals The Service Manual contains instructions for changing all outer oil seals, (e.g. oil seals on the PTO shaft end, on the output shaft to the front wheel drive and on the pinion shaft on the powered front axle, and so on).

- Page 15 Model Code Page 12. Repairs 6000-- 8750 8. 11. 1990 Handling of heavy components Cleanliness Unless otherwise specified, all removals should be accom- To ensure long life of a machine, it is important to keep dirt and plished using adjustable lifting equipment. All supporting foreign material out of its vital working components.

- Page 16 Model Code Page 12. Repairs 6000-- 8750 8. 11. 1990 Correct and incorrect method of fitting and bending locking The main parts of lip ---type seal: tabs. 1. Case 2. Sealing element 3. Ring spring Slackening of nuts and bolts is prevented by mechanical...

- Page 17 Model Code Page 12. Repairs 6000-- 8750 8. 11. 1990 Table Table 1. Tightening torques, metric standard thread (ISO) Tightening torques Nm Dim. Quality, surface treatment, material and so on 10.9 12.9 lubr. tol.± tol± tol. ± lubr. tol. ±...

- Page 18 Model Code Page 12. Repairs 6000-- 8750 8. 11. 1990 Conversion table for common units Quantities and units Conversion factors Overall and detail dimensions millimetres (mm) 100 mm=3,94 inches 1 inch=25,4 mm Short distances e.g. turning circles metres (m) 1 m=3,28 ft...

- Page 20 Model Code Page 1. 1. 1994 13. Maintenance 6000-- 8750 15. 5. 1996 Maintenance Valmet 6000---8750 Greasing lubricating points fitted with N.B. Detailed maintenance instructions, see Operator’s Man- grease nipples ual. Always clean the grease nipples before applying the General grease gun.

-

Page 21: Maintenance Schedule

Model Code Page 15. 5. 1996 13. Maintenance 6000-- 8750 1. 4. 1997 Maintenance schedule 11 12 16 17 6084--- 67 Every 250 hours Daily/every 10 hours 1. Check engine oil level 12. Clean engine air filter 2. Check coolant level and radiator fins 13. - Page 22 Model Code Page 1. 4. 1997 13. Maintenance 6000-- 8750 1. 11. 1998 27 29 31 36 28 33 42 40 43 33 25 38 37 20 6084--- 68 Every 500 hours Every 2000 hours/every other year Clean water trap (fuel system) (on 6 ---cylinder engines.

-

Page 23: Recommended Fuel And Lubricants

--- hubs, Dana 80W/90 GL ---5 (LS) --- hubs, ind. front axle Dana+Carraro 2x1,5 Fuel tank: --- 6000---8000 Hi Trol, 6250Hi ---6650Hi HiTrol --- other models diesel fuel --- extra fuel reservoir, metallic / plastic +82 / +121 Cooling system:... - Page 24 21. Engine 20. Engine 22. Fuel system 23. Cooling system...

- Page 26 Model Code Page 15. 6. 1992 21. Engine 6000-- 8750 1. 9. 1992 Contents General (Op. no. 210): Specifications ..............

- Page 27 Page 15. 6. 1992 21. Engine 6000-- 8750 1. 9. 1992 D. Connecting rods, weight classes ..........

- Page 28 Model Code Page 1. 8. 2000 21. Engine 6000-- 6800 1. 9. 2002 Specifications Engine designations 1. Basic markings: 320, 420, 620 and 634. The first digit indicates the number of cylinders and the two last digits the stroke (---20=120 mm, ---34=134 mm).

- Page 29 Model Code Page 1. 8. 2000 21. Engine 6800-- 8400 1. 9. 2002 Specifications Tractor 6800 6850 Hi 6900 8000 8050 8050 (L23517--- ) (--- L23317) (L23318--- ) Designation 420 DWRIE 420 DWRIE 620 DRE 620 D 620 DSR 620DSRE Turbocharger yes (+interc..) yes (+interc..)

- Page 30 Model Code Page 1. 8. 2000 21. Engine 8450-- 8950 1. 9. 2002 Specifications Tractor 8450 8450E 8450 8450 Hi 8550 8550E 8550 (--- L24134) (L24135--- ) (--- L24115) (L24116--- ) Designation 620 DWR 620 DWR 620 DWRE 620DWRE 634 DSR 634 DSR 634DSRE Turbocharger...

- Page 31 Page 1. 1. 1994 21. Engine 6000-- 8750 1. 8. 1998 Inside diameter of valve guide before fitting ......... .

-

Page 32: Connecting Rod

............. . 39,991...40,000 mm Width of ring grooves: --- 1st groove (right---angled ring; 6000, 6200, 6300, 8000R, 8000, 8100, 8050, 8150) ..2,560...2,580 mm --- 2nd grove . - Page 33 Page 8. 11. 1990 21. Engine 6000-- 8750 1. 9. 1992 --- 3. undersize 1,00 mm ............

- Page 34 Model Code Page 1. 1. 1994 21. Engine 6000-- 8750 1. 8. 1998 Timing marks: Timing marks on gears are in alignment when the 1st cylinder piston is at its top dead centre between compression and power strokes. On crankshaft gear .

- Page 35 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 Lubricating system Oil pressure at normal running temperature: --- at idling speed (min.) ............

- Page 36 Model Code Page 1. 6. 1999 21. Engine 6000-- 8950 1. 10. 1999 Balancing unit (420 engines) Tooth backlash: --- crankshaft ring gear ---balancer weight gear wheel ........

- Page 37 Model Code Page 1. 1. 1994 21. Engine 6000-- 8750 1. 11. 1998 Special tools Order no Description 1 9051 73100 Puller for cylinder liner 2 9101 65600 Milling cutter for cylinder liner seat 3 9052 46400 Centring tool for flywheel housing...

- Page 38 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 11. 1998...

- Page 39 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Engine, description The lower face of the flywheel housing functions as a sealing surface for the oil sump gasket. This means that the lower face of the cylinder block must be level with the flywheel housing.

- Page 40 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Crank mechanism The crankshaft is forged from chrome alloy special steel and is induction hardened at the bearing and sealing surfaces. This makes it possible to grind bearings four times without a new heat treatment.

- Page 41 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 15. 5. 1993 Timing gears The timing gear train consists of hardened, helically cut gear wheels. The gears are encased by the timing gear casing which is fitted to the front of the engine. The timing gear drives the camshaft, fuel injection pump and oil pump.

- Page 42 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Lubricating system (620-- engines) 1. Lubricating oil pump 2. Pressure ---relief valve 3. Oil filter 4. Turbocharger (not 8000 and 8100 tractors) 5. Main oil gallery 6. Oil pressure sensor...

- Page 43 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Induction and exhaust sys- The filter system for the engine inlet air comprises a cyclone An electric service indicator is located in the filter body. This type precleaner, and a paper filter which acts as the main filter.

- Page 44 Code Page 1. 4. 1997 21. Engine 6000-- 8950 1. 6. 1999 The picture above shows the air intake system of the 8400 tractor. 8400 has a turbocharged, 6---cylinder engine with an output of 140 hp (103 kW). The turbocharger type is Schwitzer S2B.

- Page 45 Model Code Page 1. 8. 2000 21. Engine 6250-- 8950 1. 9. 2002...

- Page 46 Model Code Page 1. 8. 2000 21. Engine 6200-- 8400 1. 9. 2002...

- Page 48 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Repair instructions 9051 73100 Cylinder block and flywheel housing (Op no 211) 1. Cylinder block and cylinder liners A. Measuring cylinder liner wear Note! Cylinder liner wear can be measured when the engine is attached to the tractor.

- Page 49 Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 0,1 ---0,4 mm 3. Press in a new bushing. Note the position of the oil hole. It is unnecessary to ream the bushing because it has a correct inner diameter when it is fitted in place.

- Page 50 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 134 mm 272 mm 6---7 mm Order no Hole diameter 1. 8363 24661 56,02...56,05 2. 8368 52460 55,42...55,45 Camshaft oversize bearing bushings for 420---engines. 3. 8368 52460 55,42...55,45...

- Page 51 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 G. Fitting pipe for oil dipstick 9101 65600 1. Clean the seat for the pipe. 2. Apply locking fluid Loctite 601 to the lower end of the pipe. 3. Tap the pipe in to the correct fitting height with tool 9025 95900.

- Page 52 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 6. If the cylinder liner height is too low, a liner with a higher flange is fitted. Order no Marking grooves +0,02 8266 47420 9,03 --- (norm) +0,02 8366 47933 9,08 9.

- Page 53 Model Code Page 1. 4. 1997 21. Engine 6000-- 8950 1. 10. 1999 2. Flywheel housing 8360 20054 A. Fitting flywheel housing The flywheel housing is centred on the cylinder block by two tension pins. Even the flywheel housings which are delivered as spare parts have ready ---made holes for the pins.

- Page 54 Code Page 1. 8. 1998 21. Engine 6000-- 8750 1. 11. 1998 C. Changing starter ring gear on flywheel Note! If a flywheel must be changed on the E ---engines, an If the ring gear is worn, change it with a new one. The ring gear...

- Page 56 Model Code Page 8. 11. 1990 21. Engine 6000-- 8750 1. 9. 1992 Cylinder head and valve 2. Compress the valve springs using lever 9101 66200. Re- mechanism (Op no 212) move the valve cotters, spring guide and spring. Remove the valves.

- Page 57 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 9101 65900 5. Measure the clearance between the valve stem and the 21 mm valve guide with a dial gauge. Lift the valve so that the valve head is 15 mm from the face of the cylinder head, and measure the clearance.

- Page 58 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 4. 1997 G. Grinding valves F. Changing valve seat inserts In order to ensure that there is a proper seal around the valves, Exhaust valves are fitted with separate valve seat inserts. If the there is a difference in the sealing surface angles.

- Page 59 Model Code Page 1. 8. 1998 21. Engine 6000-- 8750 1. 6. 1999 I. Fitting cylinder head 1. Measure the length of the cylinder head bolts. Compare with dimensions shown in figure below. Change too long bolts. max. 142 320, 620, 634 max.

- Page 60 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 2. Valve mechanism 60˚ A. Reconditioning rocker arm mechanism 1. Check the valve tappets, especially the contact surface against the camshaft. Worn or damaged tappets should be discarded. 5. Fit the plug to the other end of the rocker arm shaft. Lubri- cate the shaft and fit various parts in a correct order.

- Page 61 Model Code Page 1. 1. 1995 21. Engine 6000-- 8750 15. 5. 1996 6. Crank the engine until the aligning marks on the idler gear 320 ---engines and camshaft gear are facing each other. Extract the cam- Check the valve clearances in the injection order of the en- shaft.

- Page 62 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 4. 1997 Crank mechanism (Op. no 3. Refit the bearing caps with new bearing shells and tighten them to the correct torque. Measure the I.D. with a dial gauge 213) which has been zeroed to the dimensions obtained in point 2.

- Page 63 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 2. Fit the bearing shells into the cylinder block and the bearing 2. Clean the seat on the crankshaft with, for example, a wire caps. Ensure that the bearing shell clamping claws fit into their brush.

- Page 64 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 2. Connecting rods and pistons 3. If the piston pin bushing is worn, it should be driven out using a suitable drift. A. Removing pistons together with con- necting rods Note! Pistons and connecting rods can be removed from the 40,025...

- Page 65 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 3. Check that the connecting rod is not twisted by positioning 5. Also check the S ---bending of the connecting rod by using the measuring tool with the horizontally placed measuring sliding calipers to measure the distance between the edge of points against the face of the fixture.

- Page 66 Change worn parts. Note! The uppermost ring is square on tractors 6000, 6200, 6300, 8000R, 8000, 8100, 8050 and 8150. The uppermost ring is wedge ---shaped on tractors 6100, 6400, 6600, 6800, 8200,...

- Page 67 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 F. Checking pistons H. Fitting piston together with connecting rod. Check the condition of the pistons and piston pins. Pay special attention to possible cracks on the edge of the com- bustion chamber and on the upper edge of the piston pin 1.

- Page 68 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 . Balancer unit, 420---engines 4. Place the weights in the body, observing the notch mark- ings. The gear wheel with the punch mark runs against the crankshaft and should therefore be placed highest. Insert the A.

- Page 69 Model Code Page 15. 5. 1996 21. Engine 6000-- 8750 1. 4. 1997 C. Fitting balancer unit A. Checking element of the rubber damper 1. Fit the tension pins in the balancer unit body. 1. Check the alignment marks (A) on both sides of the rubber 2.

- Page 70 Model Code Page 1. 1. 1994 21. Engine 6000-- 8950 1. 8. 2000 Timing gears (Op no 214) 6. Unscrew the idler gear bolts (17 and 22 mm). Remove the A. Removing timing gear casing flange, gear wheel and bearing journal.

- Page 71 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 C. Fitting timing gear casing 4. Fit the idler gear with shaft stud and ensure that the mark- ings are in the correct position. Fit the washer and tighten the The position of the timing gear casing and cover is deter- bolts to the correct torque.

- Page 72 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 1. 1. 1994 9025 98700 9025 98800 9025 98900 6. Fit the oil deflector ring on the crankshaft and fit the timing gear casing cover using a new gasket. Drive in the tension pins with drifts 9025 98700 and 9025 98800 respectively (the tubular pin round the screw stud).

- Page 74 Model Code Page 1. 10. 1999 21. Engine 6000-- 8950 1. 8. 2000 Lubricating system (Op no B. Removing and dismantling lubricating 215) oil pump A. Reconditioning of oil relief valve for Note! Concerning the latest type oil pump in 6---cyl. engines lubricating oil pressure from engine no.

- Page 75 Model Code Page 1. 6. 1999 21. Engine 6000-- 8950 1. 8. 2000 C. Assembling and fitting lubricating oil Note! When measuring the tooth backlash, the engine should be the correct way up as the crankshaft bearing clearance af- pump fects the tooth backlash.

- Page 76 API CD ACEA E2 ---96/E3 ---96 --- turbocharged engines CCMC D4/D5 ) API ---CD can also be used in conventionally aspirated engines. NOTE! “Valtra Engine” oil 10W30 or 15W40 is recommended for engines (see page 130/4). TEMPERATURE ˚C ---30 ---10...

- Page 77 G. Latest lubricating oil pressure relief val- 8550, 8750 and 8950 The cooling nozzles can be removed after removing the oil J7595 --- (6000---8150), without piston cooling nozzles. sump. The nozzles have a ball valve with an opening pressure J14016 --- (8400---8950), with piston cooling nozzles of 3±0,25 bar.

- Page 78 Model Code Page 21. Engine 6900-- 8950 1. 8. 2000 F. Lubricating oil pump from engine no. J7034 incl. in 6---cyl. engines From engine no. J7034 incl. the lubricating oil pump in 620--- and 634--- engines has been replaced with 645---engine’s pump.

- Page 80 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Inlet and exhaust system, 4. Check that the exhaust manifold is air tight. Tighten the turbocharger (Op no 216) bolts to 50 Nm and inspect for any damage (cracks, deforma- tion, corrosion etc.).

- Page 81 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 4. Check the shaft end float. Place the stylus of the dial gauge against the end of the shaft and move the shaft axially. Refer to the clearance given in the specifications on page 210/9.

- Page 82 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 15. 5. 1993 D. Reconditioning turbocharger (Schwitzer S1A, S1B, S2B) N.B! The same degree of cleanliness should be observed when removing the turbocharger as with repairing the fuel system. Only remove the compressor and turbine covers if the requisite special tools, e.g.

- Page 83 Model Code Page 1. 9. 1992 21. Engine 6000-- 8750 15. 5. 1993 Cleaning parts of the turbocharger Assembling the turbocharger N.B. Use conventional cleaning agents. Do not clean with cor- It is recommended to use a repair kit when assembling the rosive substances as parts of the turbocharger may be dam- turbocharger.

- Page 84 Model Code Page 1. 11. 1998 21. Engine 6000-- 8750 1. 9. 2002 E. Fitting turbocharger F. Adjusting by ---pass turbo (S1BG) Locate the cause of the defects on the turbocharger. Remedy The by ---pass turbo is fitted on 6400DW, 6400 DWRE, the fault before fitting the new turbocharger.

- Page 85 Model Code Page 1. 11. 1998 21. Engine 6800 1. 9. 2002 G. Intercooler on 6800 tractor Valmet 6800 tractor has an intercooler, which cools the engine Note! On tractor 8400 (model 2001) and on HiTech ---tractors 6750 and 6850 (420 DWRIE) and on 8350 and 8950 (634 intake air.

- Page 86 Model Code Page 21. Engine 6800 15. 5. 1996 H. Exhaust pipe on 6800 trac- IMPORTANT! On 6800 tractor there is as standard an exhaust pipe which has been drawn up along the cab LH side front pillar. Near the Concerning tractors with the ejector pipe: cab there is a protective outer jacket round the exhaust pipe.

- Page 88 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 Working orders D. Lubricating oil pump A. Crankshaft seals (Lubricating oil pump, see page 215/1) (Rear seal, see page 211/6). --- Drain the engine coolant and the engine oil. Detach the (Front seal, see page 214/3).

- Page 89 Model Code Page 21. Engine 6000-- 8750 1. 9. 1992 I. Camshaft H. Timing gears (Camshaft, see page 212/5) (Timing gears, see page 214/1) As the timing gear casing forms a seal against the oil sump, Before removing the camshaft the following steps should be...

- Page 90 Model Code Page 1. 11. 1998 22. Fuel system 6000-- 8950 1. 6. 1999 Contents General (Op no 220) Specifications ..............

- Page 91 Bosch fuel injection pump Type (pump/governor), 6000 ---8750 ..........

- Page 92 Model Code Page 1. 4. 1997 22. Fuel system 6000-- 8950 1. 11. 1998 Special tools 9052 47800 Pressure gauge for checking delivery valve 9052 48900 Puller for injection pump drive gear 9025 99100 Locator for timing mark on the flywheel...

- Page 93 Model Code Page 1. 1. 1994 22. Fuel system 6000-- 8750 1. 6. 1999 1. Fuel tank 2. Water trap (not 8200/8400, 8750 and 8950) 3. Fuel feed pump 4. Fuel filter (+ water trap, 8200/8400, 8750, 8950: double filter with water traps) 5.

-

Page 94: Fuel Injection Pump

6000-- 8750 1. 6. 1999 Fuel injection pump Valmet 6000---8400 , 8750 and 8950 tractors have a Bosch ---make injection pump which is an in ---line pump and its basic construction is similar on engines with the different number of cylinders. - Page 95 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 The pump element consists of one plunger and one cylinder which are a matched pair and because of the fine tolerances the whole element should be changed as a complete unit.

- Page 96 Model Code Page 1. 6. 1999 22. Fuel system 8950 1. 8. 2000 Fuel injection pump (Bosch P-- pump) on 8950 tractor. 1. Boost control (for SigmaPower system) Function is similar to the boost control on 6800 and 8750 tractors, see page 223/9. 2.

- Page 98 This letter should always be quoted when ordering a replacement pump or when looking for setting values. The letters for different pumps on 6000---8950 tractors can be found in the tables on pages 220/8, 8B. 1. Governor weight 2.

- Page 99 1. 8. 2000 22. Fuel system 6000-- 6800 1. 9. 2002 Table of the fuel metering 6000---6800 (3 and 4 cyl.) Test equipment ISO 4008, Fluid ISO 4113 Nozzle ISO 7440 207 bar/0,60 orifice plate Pipe diam. ø6x2x600 ISO 4093...

- Page 100 Model Code Seite 1. 8. 2000 22. Fuel system 8000-- 8950 1. 9. 2002 Table of the fuel metering, 8000---8950 (6 cyl.) Test equipment ISO 4008. Fluid ISO 4113. Nozzle ISO 7440 207 bar/0,60 orifice plate. Pipe diam. ø6x2x600 ISO 4093. Engine Tractor Injection...

- Page 102 Model Code Page 1. 8. 2000 22. Fuel system 6000-- 8950 1. 9. 2002 Table of fuel equipment parts 6000---8950 Engine/Tractor Injection Element Delivery Governor Injector Nozzle Nozzle hol- pump valve spring compl. 420 D 8367 8353 8353 8353 8366...

- Page 103 Model Code Page 1. 8. 2000 22. Fuel system 6200-- 8550 1. 9. 2002 Specifications with Stanadyne distributor pump Note! 6200, 8000R, 8050, 8150, 8450 and 8550 (also latest 6300 and 6400 from week 24/01 incl.) tractors have Stanadyne distributor pump. Also 6250Hi ---8550 Hi tractors have this pump.The pump is equipped with an electric running solenoid (ignition switch stop) and with an automatic bleeding system.

- Page 104 Model Code Page 1. 6. 1999 22. Fuel system 6200-- 8550 1. 9. 2002 Fuel system with distributor pump 6200, 6900, 8000R, 6300---6400 from week 24/01 incl. All HiTech models. All latest Mezzo/Mega 1. Fuel tank 2. Water trap. 6200, 6900, 6300, 6400, 8000R and HiTech tractors have a diffe- rent water trap.

- Page 105 Model Code Page 22. Fuel system 8050-- 8550 15. 5. 1996 Stanadyne distributor pump 1. Drive shaft 2. Governor weights 3. Governor spring 4. Stop solenoid 5. Overflow valve 6. Metering valve 7. Cam ring rollers 8. Hydraulic head 9. Pressure regulator valve 10.

- Page 106 Model Code Page 1. 10. 1999 22. Fuel system 6200-- 8550 1. 8. 2000 Stanadyne distributor pump 1. Type plate with ordering number 2. Timing marks under the cover 3. Fuel inlet 4. Fuel return flow/overflow valve 5. Revolution lever 6.

- Page 107 Model Code Page 22. Fuel system 8350 1. 8. 2000 Electric advancing of the injection (CCA), wiring diagram...

- Page 108 Model Code Page 22. Fuel system 8050-- 8550 15. 5. 1996 Stanadyne distributor pump Housing pressure Transfer pump pressure Injection pressure 1. Fuel tank 10. Regulator spring 2. Water trap 11. Centrifugal weights 3. Fuel feed pump 12. Overflow valve 4.

- Page 109 Model Code Page 1. 8. 2000 22. Fuel system 6200-- 8550 1. 9. 2002...

- Page 110 Model Code Page 1. 8. 2000 22. Fuel system 6000-- 8950 1. 9. 2002...

- Page 112 Model Code Page 1. 4. 1997 22. Fuel system 6000-- 8750 1. 6. 1999 Repair instructions B. Bleeding thermostart system Always remove air from the glow plug fuel pipe when the pipe Fuel feed pump and fuel filter (Op no 222) or reservoir has been emptied during repair work etc.

- Page 113 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 D. Checking overflow valve E. Changing fuel feed pump valves If the fuel feed pressure deviates from the prescribed value, 1. Clean the feed pump. Disconnect fuel pipes to the feed check the opening pressure of the overflow valve.

- Page 114 Model Code Page 1. 8. 1998 22. Fuel system 6000-- 8750 1. 6. 1999 Fuel injection pump and injectors (Op no 223) (Bosch in ---line pump) Note! Concerning fuel injection pumps with a new type gov- ernor, see page 223/8.

- Page 115 Model Code Page 8. 11. 1990 22. Fuel system 6000-- 8750 1. 9. 1992 9052 48900 5. Use puller 9052 48900 and loosen the gear from the injec- tion pump camshaft front end. 6. Remove the injection pump attaching nuts (17 mm).

- Page 116 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 E. Checking/changing delivery valve 5. Bleed the fuel system (Op no 222 A). 6. Adjust the injection timing (Op B). 1. Clean the injection pump, injectors and surrounding parts.

- Page 117 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 2. Ensure that the throttle lever is in the idling position and that the engine is at normal operating temperature. 3. Start the engine and loosen the adjusting screw of the addi- tional spring so that it does not affect the idling speed.

- Page 118 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 G. Removing injectors 1. Clean the injectors and the area around them. Disconnect the delivery pipes and the leak ---off pipes. 9051 71300 2. Secure the injector in a test bench and check the follow-...

- Page 119 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 Tightness of nozzle Press down the tester pump lever until the pressure rises to approx. 20 bar below the adjusting value. Maintain this pres- sure for approximately 10 seconds and check whether drops of fuel are formed on the point of the nozzle.

- Page 120 Model Code Page 22. Fuel system 6000-- 8750 1. 9. 1992 K. Fitting delivery pipes J. Fitting injector in engine 1. Check the state of the pipes. If there are kinks, damage by chafing, or if the tapered sealing end is damaged, the pipes 1.

- Page 121 Model Code Page 1. 8. 1998 22. Fuel system 6800, 8750 1. 6. 1999 8950 L. Adjusting injection timing on 6800, 8750 and 8950 tractors Important! Adjusting fuel injection timing on 6800, 8750 and 8950 tractors and later on all tractors which have Bosch in --- line pump (G4720 --- (320), G2358 --- (420) and G5294 --- (620, 634), the injection timing is adjusted according to this instruc- tion.

- Page 122 Model Code Page 15. 5. 1996 22. Fuel system 6800 1. 6. 1999 Manifold pressure compensator on 6800 tractor (Bosch LDA) Note! Boost control is fitted also on 8750 and 8950 tractors which have SigmaPower system. The boost control unit on the governor housing has been connected via a hose to the engine inlet manifold.

- Page 123 Model Code Page 1. 4. 1997 22. Fuel system 8050-- 8550 1. 11. 1998 2. Stanadyne distributor pump. A. Removing pump 1. Clean the pump and the surrounding parts carefully. Remove the delivery pipes, the throttle cable wire from the rev- olution lever and the stop solenoid wire from the pump.

- Page 124 Model Code Page 1. 4. 1997 22. Fuel system 8050-- 8550 1. 8. 1998 C. Bleeding fuel system D. Fuel feed pump Note! This fuel system removes automatically small amounts For the membrane type fuel feed pump no spare parts are of air bubbles from the filter and the pump when the engine supplied.

- Page 125 Model Code Page 1. 8. 1998 22. Fuel system 8050-- 8550 1. 6. 1999 F. Adjusting low idling speed Fitting new fuel feed pump Revolution lever Max. revs Low idling speed --- Remove the old feed pump and fuel pipes The low idling speed can be adjusted with a limiting screw in --- Clean the sealing surface on the cylinder block front of the revolution lever.

- Page 126 Model Code Page 1. 11. 1998 22. Fuel system 6200-- 8550 1. 9. 2002 I. Dynamic adjustment of injection timing 1. Let the engine run to a normal working temperature before Note! Ensure before engine start that the wires do not to- adjustment.

- Page 127 Model Code Page 22. Fuel system 6200, 6900 1. 11. 1998 Possible disturbances If the injection timing deviates much from the specified value, check the following points: 1. Vibrating delivery pipe, hold to the pipe with one hand. 2. The distance between the magnetic sensor and the flyw- heel is incorrect, reposition the sensor.

- Page 128 Model Code Page 15. 5. 1996 23. Cooling system 6000-- 8950 1. 8. 2000 Contents General (Op no 230): Specifications ..............

- Page 129 8200, 8050 and 8150 has 8 cooling fan blades, other models 6 blades. Thermostat Spare part number Type Opening Fully Max stroke begins at open at 8361 15646 (6000---8400) ø67/79˚C 79˚±2˚C 94˚C 8361 15718 (6000---8400) ø67/83˚C 83˚±2˚C 97˚C 8360 15156 (8050---8750) ø54/79˚C...

- Page 130 Model Code Page 1. 1. 1994 23. Coolant pump 6000-- 8950 1. 8. 2000 Special tools Order no Description 9101 93200 Puller for coolant pump impeller, 620---engines 9022 03500 Puller for coolant pump impeller, 320--- and 420---engines (earlier no 8360 85499) 9104 27700 Puller for coolant pump impeller, new coolant pump (420, K6491---), see page 230/8.

- Page 131 Model Code Page 1. 9. 1992 23. Cooling system 6000-- 8750 1. 6. 1999 Cooling system 1. Coolant pump 2. Thermostat 3. By ---pass passage 4. Radiator Caution! Open the radiator cap carefully, if the coolant is hot Description as there will be pressure in the system. Carefully turn the radi- ator cap to the first stop.

- Page 132 Model Code Page 1. 8. 2000 23. Cooling system 6200-- 8950 1. 9. 2002 Expansion tank 6200---6800 (K41106---) 6250---6850 Picture 2. Cooling system on 8200 ---8400 tractors from ser. The level of hot coolant is upper. Before filling the expan- no.

- Page 133 Model Code Page 15. 5. 1996 23. Cooling system 8400-- 8950 1. 9. 2002 Viscous fan (Ø 600, 8 pcs blades) Picture 3. Viscous fan on 8350, 8400 (model 2001), 8450, 8550, 8750 and 8950. 1. Reservoir (filled with silicone fluid). 2.

- Page 134 Model Code Page 1. 6. 1999 23. Cooling system 6000-- 8950 1. 9. 2002 Temperature sensor, engine coolant temperature: The sensor is placed on the engine beside the thermostat housing: Temperature gauge pin Warning light Resistance value, temperature gauge side: 60˚C=134±...

- Page 135 Code Page 1. 8. 2000 23. Cooling system 6250-- 6850 1. 9. 2002 Coolant pump Valtra 6250Hi--6850Hi (K16108--). From engine number K6491 incl. Valtra 6200--6400 (K41106--). 8367 64215 Expansion tank Note! left hand thread Heating unit 25 Nm Oil cooler...

- Page 136 Model Code Page 15. 5. 1996 23. Coolant system 6000-- 8950 1. 8. 2000 Repair instructions (Op no 231) B. Reconditioning coolant pump (320---, and 420---engines), ---K6490. A. Thermostat 1. Drain the engine coolant. Disconnect the water hoses from the thermostat housing and from the coolant pump. Remove the thermostat housing and the by ---pass hose.

- Page 137 Model Code Page 1. 1. 1995 23. Cooling system 6000-- 8750 15. 5. 1996 178,5 mm 6. Tap out the shaft seal in the body using a suitable drift. Clean all parts and inspect their condition. Replace damaged 174,5 mm parts with new ones.

- Page 138 Code Page 1. 9. 1992 23. Cooling system 6000-- 8750 1. 1. 1995 5. Remove the circlip in the pump body. Press the shaft together with bearings in the direction of the fan. Use e.g. a hydraulic press. Support the pump body so that the bearings have enough space for releasing.

- Page 139 Model Code Page 15. 5. 1996 23. Cooling system 8050, 8150 1. 9. 2002 E. Coolant pump and thermostat housing on 8050 and 8150 The coolant pump is the same as on 8000 ---8400 tractors, see instr. C on page 231/2. 8050 and 8150 tractors have two thermostats.

- Page 140 Model Code Page 15. 5. 1996 23. Cooling system 8450-- 8750 1. 9. 2002 F. Coolant pump on 8450---8750 tractors 0,8---1,2 mm On 8450, 8550 and 8750 tractors the coolant pump pulley bearing is different compared with other 6---cylinder en- gines.

- Page 142 Page Model PRE---CLEANER, FITTING INSTRUCTION 17.05.1994 29.1 08.04.1998 8100, 8400 Pre-- cleaner ..32938500 (8400, vertical air filter) Pre-- cleaner ..33267100 (8100, vertical air filter) --- The self---cleaning precleaner of a cyclone type is intended to be used in very dusty conditions.

- Page 143 Page 17.05.1994 Model PRE---CLEANER, FITTING INSTRUCTION 29.1 08.04.1998 8100, 8400 Tee lovi Skär skåra Cut notch...

- Page 144 Tractor electrical system Autocontrol II (662343 ---) Autocontrol 2.1 (668103 ---) 30. Electrical system Σ---power Autocontrol 2.2 / 2.3 (J05133---) AC power lift ACD power lift ACB power lift Agrodata Agrodata---instrument FieldMaster Agroline ---instrument Autocontrol III (6600E, 8100E) Autocontrol IV (6600E---8750E) CareTel Autocontrol 5...

- Page 146 Autocontrol---III, see section 34, Autocontrol IV, see section 35. CareTel is described in section 36 and AC V in section 37. Valmet 6000---8750 tractors have 12 V electrical system (negative earthing). Battery (12 V, 160 Ah) is fitted in the engine com- partment in front of the cab.

- Page 147 Model Code Page 1. 6. 1999 31. Tractor electrical system 6000-- 8950 1. 9. 2002 Fuses and relays K14 relay, starter motor (in engine compartment) Relays K11, K12, K13, K15 and K16, see Autocontrol II under code 311 or Autocontrol 2.2 under code 314.

- Page 148 Model Code Page 8. 11. 1990 31. Tractor electrical system 6000-- 8750 1. 8. 1998 Headlight adjustment Standard trailer socket 1. Brake light (red) 2. LH side direction indicator (yellow) 3. Earthing (white) 4. RH side direction indicator (violet) 5. RH side parking light (brown) 6.

- Page 149 38 mm Note! Tractors 8050---8750 have starter motor ISKRA 12 V 3,6 kW (F2858---). Mezzo---tractors which have Bosch in---line fuel injection pump, have a new starter motor ISKRA 12 V 3,1 kW (6000---6800: F3792---), (8000---8400: F3818---). Alternator Magneti Marelli (Lucas) A127---65...

- Page 150 111 A --- 6000 r/min ..............

- Page 151 Model Code Page 31. Tractor electrical system 6000-- 8750 1. 8. 1998 Starter motor Iskra AZJ3234 12 V 3,1 kW (Sisu Diesel no. 8366 40949) Test values, unloaded: Rotation speed .............

- Page 152 4,8 meter (Dickey ---john) or from 60 cm to 1,2 meter (see picture above). (Vansco). The recommended height of the radar in Valtra tractors is about 60 cm. The ground figure C must be situated so that in this area there are no moveable points e.g.

- Page 153 Model Code Page 31. Tractor electrical system 6000-- 8950 1. 6. 1999 Radar fastening parts (e.g. ACD ---power lift) (these parts can be ordered from the Spare Part Center): 62=radar=31702100 63=bracket=32912800 64=plate=32891600 65=bolt=HA8351 (2 pcs) 66=washer=JD0412 (2 pcs) 67=nut=JB8906 (2 pcs)

- Page 154 Model Code Page 15. 5. 1993 31. Tractor electrical system 6000-- 8750 1. 1. 1994 Position of electric components on frame Note! Symbols, see component lists on pages 310/7 ---8, 310/11 ---12 and 310/16 ---17.

- Page 155 Model Code Page 8. 11. 1990 31. Tractor electrical system 6000-- 8750 15. 5. 1993...

- Page 156 Model Code Page 15. 4. 1995 31. Tractor electrical system 6000-- 8750 1. 4. 1997...

- Page 157 Model Code Page 1. 4. 1997 31. Tractor electrical system 6000-- 8750 1. 10. 1999...

- Page 158 Model Code Page 1. 10. 1999 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Not HiTech...

- Page 159 Model Code Page 1. 10. 1999 31. Tractor electrical system 6250-- 8950 1. 8. 2000...

- Page 160 Model Code Page 1. 10. 1999 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech...

- Page 161 Model Code Page 1. 10. 1999 31. Tractor electrical system 6200-- 8750 1. 9. 2002 Not HiTech...

- Page 162 Model Code Page 1. 10. 1999 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech...

- Page 164 Model Code Page 1. 9. 1992 31. Tractor electrical system 6100-- 8400 15. 5. 1993 Wiring diagram up to serial no 660070 Sym--- (E -- models, see section 34) . Diagram no. 318 716 10 Component Code 32E. Battery See diagrams on pages 310/9 ---10 Alternator Sym--- Ind.

- Page 165 Model Code Page 8. 11. 1990 31. Tractor electrical system 6100-- 8400 1. 9. 1992 Sym--- Earth lead, rear lights Component Earth lead, roof Code Earth lead, Autocontrol Safety circuit breaker Earth lead, cable harness instr. panel Brake light contact, right Earth lead, battery Earth lead, headlights Fuel gauge sender unit...

- Page 166 Model Code Page 8. 11. 1990 31. Tractor electrical system 6100-- 8400 1. 9. 1992...

- Page 167 Model Code Page 8. 11. 1990 31. Tractor electrical system 6100-- 8400 1. 9. 1992...

- Page 168 Model Code Page 15. 5. 1993 31. Tractor electrical system 6000-- 8400 1. 1. 1994 Wiring diagram from tractor serial no 660071 up to ser. no 662342 (E-- models, section Diagram Alternator 31871620---32. See diagrams on pages 310/13---15. Pilot light, direction indicator III...

- Page 169 Model Code Page 31. Tractor electrical system 6100-- 8400 15. 5. 1993 Sym--- Code Solenoid valve, diff lock Component Solenoid valve pto Solenoid valve 4WD (S19) Air cond. compressor press. switch (Y 4) Solenoid valve, quick ---shift gear, lower range, Brake light contact, left 2 ---step Switch, differential lock...

- Page 170 Model Code Page 31. Tractor electrical system 6100-- 8400 15. 5. 1993 318 716 20--- 32 6184--- 127 6184--- 128...

- Page 171 Model Code Page 31. Tractor electrical system 6100-- 8400 15. 5. 1993 6184--- 130...

- Page 172 Model Code Page 31. Tractor electrical system 6100-- 8400 15. 5. 1993 6184--- 132...

- Page 173 Model Code Page 1. 1. 1994 31. Tractor electrical system 6000-- 8400 15. 4. 1995 Wiring diagram from tractor serial number 662343 up to no 668102. Sym--- Code Component (E-- models, see section 35) . Diagram no 318 716 30B.

- Page 174 Model Code Page 31. Tractor electrical system 6000-- 8400 1. 1. 1994 Sym--- Code Sym--- Code Component Component Combination control Solenoid valve, diff lock 25, 34, 52 Switch, front working lights Solenoid valve pto (S 6) Switch, rot. warning light...

- Page 175 Model Code Page 31. Tractor electric system 6000-- 8400 1. 1. 1994 318 716 30 B...

- Page 176 Model Code Page 31. Tractor electric system 6000-- 8400 1. 1. 1994...

- Page 177 Model Code Page 31. Tractor electric system 6000-- 8400 1. 1. 1994 Autocontrol...

- Page 178 Model Code Page 31. Tractor electrical system 6000-- 8400 15. 4. 1995 Wiring diagram from ser. no 668103. Sym--- Code Diagram Component no 318 716 40A. See diagrams on pages 310/23 ---25. 10 A Brake lights, diff. lock., trailer brakes This diagram includes also Autocontrol 2.1 system, Agro-...

- Page 179 Model Code Page 31. Tractor electrical system 6000-- 8400 15. 4. 1995 Sym--- Code Sym--- Code Componenet Component (X29) Connector, 2 pin., STOP---alarm (max. 2 W) Switch, head lights Socket, 2 pin, PTO ---emerg. stop Switch, rear working lights (X32) Connector, 1 pin, electric stop...

- Page 180 Model Code Page 31. Tractor electrical system 6000-- 8400 15. 4. 1995 AC2.1--- 1/6 318 716 40 A AC2.1--- 2/6...

- Page 181 Model Code Page 31. Tractor electrical system 6000-- 8400 15. 4. 1995 AC2.1--- 3/6 AC2.1--- 4/6...

- Page 182 Model Code Page 31. Tractor electrical system 6000-- 8400 15. 4. 1995 AC2.1--- 5/6 AC2.1--- 6/6...

- Page 184 Model Code Page 15. 5. 1996 31. Tractor electrical system 6000-- 8750 1. 4. 1997 Wiring diagram, F17107---. Sym--- Code Component 10 A Brake lights, diff. lock., trailer brakes Diagram no 318 716 40D. Diagrams on pages 310/29---31. 10 A Telephone...

- Page 185 Model Code Page 15. 5. 1996 31. Tractor electrical system 6000-- 8750 1. 4. 1997 Sym--- Code Sym--- Code Componenet Component Connector, 9 pin., upwards Switch, head lights (X25) Connector, 9---pin. Agrodata ---instrument Switch, rear working lights Connector, 26 pin., instr. left, white.

- Page 186 Model Code Page 31. Tractor electrical system 6000-- 8750 15. 5. 1996 318 716 40D ACD2.1--- 1/8 ACD2.1--- 1/ ACD2.1--- 2/8 ACD2.1--- 2/8...

- Page 187 Model Code Page 31. Tractor electrical system 6000-- 8750 15. 5. 1996 ACD2.1--- 3/8 ACD2.1--- 4/8...

- Page 188 Model Code Page 15. 5. 1996 31. Tractor electrical system 6000-- 8750 1. 4. 1997 ACD2.1--- 7/8 ACD2.1--- 8/8...

- Page 190 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 Wiring diagram F 50112--- Sym--- Code Component Diagram no 318 716 40F. Diagrams on pages 310/35 ---38. 10 A Brake lights, diff. lock. 10 A Telephone Sym--- Code 10 A Cigarette lighter, power socket...

- Page 191 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 Sym--- Code Componenet Sym--- Code Component Connector, 9 pin., upwards (X25) Connector, 9---pin. Agrodata ---instrument Switch, head lights Connector, 26 pin., instr. left, white. Switch, rear working lights Connector, 26 pin., instr. right, blue Switch, fan (X29) Connector, 2 pin., STOP---alarm (max.

- Page 192 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 PT97, 1/9 318 716 40 F PT97, 2/9...

- Page 193 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 PT97, 3/9 PT97, 4/9...

- Page 194 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 PT97, 7/9 PT97, 8/9...

- Page 195 Model Code Page 31. Electrical system 6000-- 8750 1. 4. 1997 PT97, 9/9...

- Page 196 Model Code Page 1. 6. 1999 31. Tractor electric system 6250-- 8950 1. 10. 1999 Wiring diagram, HiTech models Sym--- Code bole Component H49112---J38342. Fuses The diagrams on pages 310/43---47. Diagram no 33563500. Incl. also FieldMaster, CareTel and AC V--- system. F 1 15/20A Hazard warning flashers, water pump 31, 97 5/16A Radio, clock, tachograph, CareTel...

- Page 197 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 11. 1998 Sym--- Code bole Component Sym--- Code bole Component (S32) Switch, rear window washer/wiper (S33) Toggle switch, headlights up Relay, fan III ---speed (S34) Switch, water pump Relay, four wheel braking (S35) Switch, reverse drive control lock Relay, interval wiper (S36) Switch, control stop...

- Page 198 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 11. 1998 CareTel Sym--- Code bole Component Sym--- Code (X33) 3 pins, rear fog light bole Component (X35) 9 pins, SIGMA supply X39 9 pins, shuttle lever A1L CareTel, data gathering unit (X41) 2 pins, front PTO (X42) 4 pins, front PTO, supply B1L Pressure sensor, CareTel, 18 Bar...

- Page 199 Model Code Page 31. Tractor electric system 6250-- 8950 1. 11. 1998...

- Page 200 Model Code Page 1. 11. 1998 31. Tractor electric system 6250-- 8950 1. 9. 2002 HiTech, H49112---J38342 33563500...

- Page 201 Model Code Page 1. 11. 1998 31. Tractor electric system 6250-- 8950 1. 9. 2002 HiTech, H49112---J38342...

- Page 202 Model Code Page 1. 11. 1998 31. Tractor electric system 6250-- 8950 1. 9. 2002 HiTech, H49112---J38342...

- Page 203 Model Code Page 1. 11. 1998 31. Tractor electric system 6250-- 8950 1. 9. 2002 HiTech, H49112---J38342...

- Page 204 Model Code Page 1. 11. 1998 31. Tractor electric system 6250-- 8950 1. 9. 2002 HiTech, H49112---J38342...

- Page 206 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 Wiring diagram 6200---8750 (AC 2.2), Sym--- Code bol Component J05133--- . Diagram no. 31871650A (not HiTech) F20 10A Rear window wiper/washer F21 15A Fan (I, II), air conditioner, floor fan Sym--- Code F22 10A 4WD, PTO, DPS...

- Page 207 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 Sym--- Code Sym--- Code bol Component bol Component M1 Starter motor Diodes Y1, Y2, Y3, Y4, Y6 M2 Fan Diodes, AC---2 M3 Windscreen wiper Diodes, 4WD M4 Windscreen washer Diodes, Y11, Y12, (Y17) (M5) Rear window wiper (V5) Diodes, HiShift...

- Page 208 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 Sym--- Code bol Component CareTel, information collecting system A1L CareTel, data logger B1L Pressure sensor, CareTel, 18 Bar (B2L) Pressure sensor, CareTel, 190 Bar B3L Sensor, gearbox temperature B4L Temperature sensor, engine H1L Indicator light, CareTel X1L Connector housing, 9 pin, CareTel,...

- Page 210 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 31871650A AC 2.2.1 AC 2.2.2...

- Page 211 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 AC 2.2.3 AC 2.2.4...

- Page 212 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 AC 2.2.5 AC 2.2.6...

- Page 213 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 6. 1999 AC 2.2.7 AC 2.2.8...

- Page 214 Model Code Page 1. 10. 1999 31. Tractor eletrical system 6250-- 8950 1. 8. 2000 Wiring diagram, HiTech, Sym--- Haku bol Component J38343---K41106. Fuses Diagram no. 33563500A on pages 310/61---66. New wire 15A Hazard blinkers, water pump 31, 97 loom 33412510 and Twin Trac. 5A Radio, clock, tachograph, CareTel 2, 120 Code...

- Page 215 Model Code Page 31. Tractor eletrical system 6250-- 8950 1. 10. 1999 Sym--- Code bol Component Sym--- Code bol Component S31 Switch, floor fan (S32) Switch, rear window wiper and washer Auxiliary relay, starter switch (S33) Change over switch, head lights up Relay, fan III (S34) Switch, water pump Control relay, 4---wheel brake...

- Page 216 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 10. 1999 CareTel, information collecting system Sym--- Code bol Component A1L CareTel, data logger B1L Pressure sensor, CareTel, 18 Bar (X32) 1 pin, electric stop (B2L) Pressure sensor, 190 Bar (X33) 3 pin, fog light, rear B3L Sensor, gearbox temperature (X35) 9 pin, SIGMA supply...

- Page 218 Model Code Page 31. Tractor eletrical system 6250-- 8950 1. 10. 1999 33563500A ACV I ACV II...

- Page 219 Modell Code Page 1. 10. 1999 31. Tractor electrical system 6250-- 8950 1. 9. 2002 ACV III ACV IV...

- Page 220 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 10. 1999 ACV V ACV VI...

- Page 221 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 10. 1999 ACV VII ACV VIII...

- Page 222 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 10. 1999 ACV IX ACV X...

- Page 223 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 10. 1999 ACV XI...

- Page 224 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 Wiring diagram HiTech, K41107--- Sym--- Code bole Component Diagram no. 33563510C. Incl. e.g. AC 5.2 unit. Diagrams on pages 310/71---77. Fuses 15A Hazard blinkers, water pump 31, 97 Sym--- Code 5A Radio, clock, tachograph, CareTel...

- Page 225 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 Sym--- Code bole Component Sym--- Code bole Component (S33) Change over switch, head lights up (S34) Switch, water pump Control relay, 4---wheel brake (S35) Switch, rear steering prevention Relay, interval wiper (S36) Switch, control stop K10 Direction indicator relay...

- Page 226 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 Sym--- Code bole Component Sym--- Code bole Component S7E Switch, lowering speed 85B, 85D S8E Switch, transport height 85B, 85D X43 8 pin, RS ---232 bus S9E Switch, draft control 85B, 85D (X45) 9 pin, Fieldmaster, extra equipment (X46) 7 pin, Fieldmaster, current socket...

- Page 228 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 33563510C AC 5.2 1 AC 5.2 2...

- Page 229 Model Code Page 31. Trcator electrical system 6250-- 8950 1. 8. 2000 AC 5.2 3 AC 5.2 4...

- Page 230 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 AC 5.2 5 AC 5.2 6...

- Page 231 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 AC 5.2 7 AC 5.2 8...

- Page 232 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 AC 5.2 9 AC 5.2 10...

- Page 233 Model Code Page 1. 8. 2000 31. Tractor electrical system 6250-- 8950 1. 9. 2002 AC 5.2 11 AC 5.2 12...

- Page 234 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 8. 2000 AC 5.2 13 AC 5.2 14...

- Page 236 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 Wiring diagram 6200---8750 (AC 2.3), Sym--- Code bol Component K44242---, (not HiTech). Diagram no. 318 716 60A. Diag- rams on pages 310/83 ---88. F17 10A Direction indicators, Fieldmaster 32, 153 F18 5A Instruments, warning lights, Autocontrol 17, 166...

- Page 237 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 Sym--- Code bol Component Sym--- Code bol Component Diodes Y1, Y2, Y3, Y4, Y6 Diodes, AC---2 M1 Starter motor 3, 167 Diodes Y1, Y2, Y3, Y4, Y6 M2 Fan (V5) Diodes, HiShift M3 Windscreen wiper M4 Windscreen washer...

- Page 238 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 Sym--- Code bole Component Sym--- Code bol Component S7E Switch, lowering speed 83B, 83D S8E Switch, transport height 83B, 83D CareTel, information collecting system S9E Switch, draft control 83B, 83D A1L CareTel, data logger S10E Autocontrol---Switch, lift/stop/lower...

- Page 240 Model Code Page 1. 8. 2000 31. Tractor electrical system 6200-- 8750 1. 9. 2002 31871660A AC 2.3 1 AC 2.3 2...

- Page 241 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 AC 2.3 3 AC 2.3 4...

- Page 242 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 AC 2.3 5 AC 2.3 6...

- Page 243 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 AC 2.3 7 AC 2.3 8...

- Page 244 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 AC 2.3 9 AC 2.3 10...

- Page 245 Model Code Page 31. Tractor electrical system 6200-- 8750 1. 8. 2000 AC 2.3 11...

- Page 246 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 Wiring diagram, HiTech, L18105---. Sym--- Code bol Component Diagram no. 33563520A. Diagram incl. e.g. Agroline ---instru- ment. Diagrams on pages 310/93---100. Fuses Sym--- Code 15A Hazard blinkers, water pump 31, 97 bol Component 5A Radio, clock, tachograph, CareTel...

- Page 247 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 Sym--- Code bol Component Sym--- Code bol Component S18 Engine temperature sender unit (stop) (S19) Switch, compressor pressure Relay, front working lights S20 Switch braking lights, left Relay, rear working lights S22 Switch, differential lock (K3) Relay, fog light, rear S23 Extra switch, Delta Power Shift, selector...

- Page 248 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 Sym--- Code bol Component Sym--- Code bol Component ACB/ACD Autocontrol power lift: (X18) 2 pin, rear window washer A1E Autocontrol electronic unit 82B, 82D X19 37 pin, engine X20 9 pin, front direction indicator A2E Autocontrol, switch panel 85B, 85D...

- Page 249 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002...

- Page 250 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105--- 33563520A...

- Page 251 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 252 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 253 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 254 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 255 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 256 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 257 Model Code Page 31. Tractor electrical system 6250-- 8950 1. 9. 2002 HiTech, L18105---...

- Page 258 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Wiring diagram, 6200---8550 Sym--- Code (AC 2.3), bol Component L17307---, Diagram no. 318 716 70A (not HiTech). Dia- gram incl. e.g. Agroline ---instrument. Diagrams on pages Fuses 310/105 ---109. 15A Hazard blinkers, water pump 31, 97 5A Radio, clock, tachograph, CareTel...

- Page 259 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Sym--- Code bol Component Sym--- Code bol Component Switch, head lights Switch, rear working lights Relay, front working lights Switch, fan Relay, rear working lights Combined switch 25, 34, 52 (K3) Relay, fog light, rear Switch, front working lights Auxiliary relay, starter switch...

- Page 260 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Sym--- Code bol Component Sym--- Code bol Component ACB/ACD Autocontrol power lift Ground leads A1E Autocontrol electronic unit 82B, 82D A2E Autocontrol, switch panel 83B, 83D GR1 Rear lights, solenoid valves GR2 Roof B1E Position sensor 81B, 81D...

- Page 261 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002...

- Page 262 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Mezzo/Mega, L17307--- 31871670A...

- Page 263 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Mezzo/Mega, L17307---...

- Page 264 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Mezzo/Mega, L17307---...

- Page 265 Model Code Page 31. Tractor electrical system 6200-- 8550 1. 9. 2002 Mezzo/Mega, L17307---...

- Page 266 Model Code Page 31. Tractor electrical system 1. 9. 2002 6200-- 8550 Mezzo/Mega, L17307---...

- Page 267 Model Code Page 31. Tractor electrical system 1. 9. 2002 6200-- 8550...

- Page 268 31. Autocontrol II 6000-- 8750 1. 8. 1998 From the beginning of 1994 (662343---) all 6000---8400 trac- In addition, Autocontrol II has a three ---position lift/lower tors (except E ---models) have Autocontrol II as standard switch for the hydraulic power lift. Autocontrol II also controls equipment.

- Page 269 Model Code Page 1. 1. 1994 31. Autocontrol II 6000-- 8750 1. 8. 1998 3. Power take ---off The PTO is controlled with a lever and a three ---position rocking switch on the driver’s right. PTO 540 or 1000 (or 540E) is selected mechanically with the lever at which time a pilot light comes on in the instrument panel.

- Page 270 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994 Picture 1. Components of the Autocontrol II A. Differential lock rocking switch on the right hand side of the seat. B. PTO rocking switch on the right hand side of the seat.

- Page 271 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994...

- Page 272 Model Code Page 1. 1. 1994 31. Autocontrol II 6000-- 8750 1. 4. 1997 A. Delta Powershift Picture 2. Delta Powershift control. 1. Powershift control buttons: S23A=change down S23B=change up 2. Electronic control unit A10. 3. The circuit card A9 of the buzzer and the pilot lights. The...

- Page 273 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994 Circuit card of buzzer and ind. lights A. Buzzer test: --- Ground connector pin 5 and feed voltage of 12 V to pin 7. --- Ground pin 9 and feed voltage of 12 V to pin 8 at which time the buzzer should alarm continuously.

- Page 274 Model Code Page 35. Autocontrol II 6000-- 8750 1. 1. 1994 B. Differential lock control Picture 5. Differential lock components on tractor K12: Switches on voltage to the solenoid valve, when the Y1: Differential lock solenoid valve rocking switch rear edge is depressed. Ind. light comes K11, K12 and K13: control relays on.

- Page 275 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994 Checking function of the differential lock control (engine at idling speed) --- Depress the rocking switch front edge at which time the lock indicator light comes on. --- Turn the switch to the middle position at which time the indicator light goes out.

- Page 276 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994 C. 4WD control Checking function (engine at low idling speed) --- Move the switch in the range gear lever knob to the front position at which time the 4WD ind. light comes on.

- Page 277 Model Code Page 31. Autocontrol II 6000-- 8750 1. 1. 1994 D. PTO control Checking function: Make sure that the plug is fitted in the rear emergency socket. Move the control lever in the middle position. Check that the PTO rocking switch front edge is depressed (OFF). Switch off tractor current.

- Page 278 Model Code Page 15. 4. 1995 31. Autocontrol 2.1 6000-- 8750 1. 9. 2002 1. Differences between AC II and AC D. Power lift Compared with AC II system, the power lift has one rocker Autocontroll 2.1 replaces under code 311 shown Autocontrol switch more.

- Page 279 Model Code Page 15. 5. 1996 31. Autocontrol 2.1 6000-- 8750 1. 4. 1997 Picture 1. AC 2.1, control of Delta Powershift E. PTO emergency stop socket at the rear of the tractor (as on AC II system) A. Differential lock switch (as on AC II).

- Page 280 Model Code Page 15. 4. 1995 31. Autocontrol 2.1 6000-- 8750 1. 4. 1997 DPS circuit card INPUT signals Pin 3: Permanent earthing Pin 4: 12 V via starter switch and fuse F22. Pin 5: 12 V, when the foremost push button is pressed.

-

Page 281: Control Stop

Modell Code Page 15. 4. 1995 31. Autocontrol 2.1 6000-- 8750 1. 8. 1998 Control stop Picture 3. Wiring diagram of control stop (optional) Note! Stop ---light wire must be equipped with a diod. Other- Q1=starter switch (number 32553200) wise, when driver uses the direction indicator lever S4 or... - Page 282 Engine (634 DS/634DSBIE) on Valtra 8750 and 8950 trac- tors has as a standard equipment Σ ---power system The torque of the PTO unit is measured by two sensors.

- Page 283 Model Code Page 1. 6. 1999 31. Σ---power system 8750, 8950 1. 10. 1999 337 450 00 34008010 34008110 Picture 1. Components for Σ ---power system 5. Solenoid valve Y13. 6. ETB ---light and output % display 1. Engine speed sensor B4 7.

- Page 284 Model Code Page 1. 10. 1999 31. Σ---power 8750, 8950 1. 9. 2002 Version markings of SigmaPower (see picture on page 313/2) Sigma ---ver- Tractor Used in pro- Sigma control unit A13, Sensors B4 Wire loom Modificati- sion duction part number and B5 In producti- As a spare...

- Page 286 Model Code Page 1. 10. 1999 31. Σ---power system 8750, 8950 1. 8. 2000 B. Control unit A13 IMPORTANT! If on 8750 tractor is fitted the control unit of version 2.0 in place of the versions’ 1.0 or 1.1 units, con- nector A13 wires to pins 4, 7 and 12 (on tractor wire loom Marking side) must be disconnected and the ends of the wires must...

- Page 287 Model Code Page 1. 6. 1999 31. Σ---power system 8750, 8950 1. 10. 1999 D. Sensors B4 and B5, versions 1.0, 1.1 and 2.0 Version 1.0 ---G22506 1=+12 V (Brown)=A 2= Earth (Green)=B 3=Sign (White)=C Versions 1.1 an 2.0 G22507 --- H02431--- A, C and D In connection with sensor...

- Page 288 Model Code Page 1. 10. 1999 31. Σ---Power system 8950Hi 1. 9. 2002...

- Page 290 Model Code Page 1. 10. 1999 31. Σ---power system 8750 1. 8. 2000 2. Electric connections, versions 1.0, 1.1 and 2.0 *) 8750 with has ver- sions 1.0 or 1.1: These wires must be discon- nected from connector A13 on the tractor wire loom side, if version 2.0 control unit is fitted (if not disconnected...

- Page 292 Model Code Page 1. 8. 2000 31. Σ---power system 1. 9. 2002...

- Page 293 Model Code Page 1. 6. 1999 31. Σ---power system 8750, 8950 1. 10. 1999 3. Fault tracing, adjustments and repairs If the Sigma Power - system has malfunctions, the function is checked in the following order:A. Checking function with the aid of the ETB ---light B.

- Page 294 Model Code Page 1. 10. 1999 31. Σ---power system 8750, 8950 1. 9. 2002 C. Fault tracing by measuring voltages The latest connectors (G22507 ---) are tight, and connector rubber seals must not be opened, but the voltage measurements are done by connecting ETV 894 310 into the wire loom. On the earlier connectors (---G22506) the measurements can be done through the holes in connector A13 and/or through the holes in connectors B4 and B5.

- Page 295 Model Code Page 1. 10. 1999 31. Σ---power system 8750, 8950 1. 9. 2002 Incorrect voltage readings may be caused by: Pins +<> ---: battery cable shoes, bad battery or faulty alternator. 1<>5: fuse F26, connectors X35, A13, or X4 or earth point GR9 in the cab front wall. 1<>7: Versions 1.0 and 1.1: connector A13 or earth point GR9.

- Page 296 Model Code Page 31. Σ---power system 8750 1. 8. 1998 D. Checking and adjusting sensors with Fluke123 ---oscilloscope (if necessary) 1. Connect the measuring cable ETV 894310 (requires later connectors, G22507---) to the connector (A13) of the control unit. Connect the oscilloscope (FLUKE 123 Scopemeter) to the measuring cable connector with cables ETV 894 400. A red wire to connector pin 6 (foremost sensor channel A) and blue wire to connector pin 3 (rear sensor channel B).

- Page 297 Model Code Page 1. 8. 1998 31. Σ---power system 8750 1. 10. 1999 INTERPRETATION OF OSCILLOSCOPE WAVES AND SPECIFIED VALUES 2. Select oscilloscope settings; channel A DUTY (pulse The phase difference indicates the time difference of ratio %) and channel B PHASE (phase difference B>A the waves in channels A and B as degrees within (deg)) and DUTY (pulse ratio %).

- Page 298 Model Code Page 1. 8. 1998 31. Σ---power system 8750 1. 10. 1999 Figures below show two different measuring results from 3. Start the engine and let it run about 20 s at the low idling two different tractors with different PTO units (widths of speed, PTO disengaged and the hydraulic pump in unload- waves).

- Page 299 Model Code Page 31. Σ---power system 8750 1. 8. 1998 More detailed instruction on how to carry out the oscilloscope settings: 2x ”PEEP” (=RESET)

- Page 300 Model Code Page 1. 8. 1998 31. Σ---power system 8750, 8950 1. 6. 1999 5 V/d 5 V/d 5 V/d 5 V/d 2 ms/d...

- Page 302 Model Code Page 1. 6. 1999 31. Autocontrol 2.2/2.3 6200-- 8150 1. 8. 2000 Autocontrol 2.2 replaces under code 312 presented Autocontol 2.1 from ser. no. J05133 incl. on tractors 6200 ---8150 (not Hi- Tech). Autocontrol 2.2 includes also ACB power lift which is a standard equipment on these tractors, see code 321. Note! AC 2.3 replaces AC 2.2.

- Page 303 Model Code Page 31. Autocontrol 2.2 / 2.3 6200-- 8150 1. 6. 1999 3. Power take ---off The PTO is controlled with a lever and a three ---position rocker switch on the driver’s right. PTO 540 or 1000 (or 540E) is selected mechanically with the lever at which time a pilot light comes on in the instrument panel.

- Page 304 Model Code Page 1. 6. 1999 31. Autocontrol 2.2 / 2.3 6200-- 8150 1. 8. 2000 Picture 1. AC 2.2 / 2.3, components A. Diff. lock rocker switch Relays K11 ---K13: Diff. lock control relays (relay K12 is not fitted in AC 2.3). B.

- Page 305 Model Code Page 31. Autocontrol 2.2 / 2.3 6200-- 8150 1. 6. 1999 1. Fault tracing B. Buzzer functions A. General The buzzer notifies, when parking, that the parking brake must be applied (engine stopped) or that a driver does not Note! In connection with malfunctions fuses F6, F8, F11, drive with applied parking brake (engine running).

- Page 306 Model Code Page 31. Autocontrol 2.2 / 2.3 6000-- 8750 1. 6. 1999 C. DPS---circuit card A10 Pins 1 and 2: Current to DPS solenoid valves (Y4, Y6), battery voltage (12 V) Pin 3: Continuous ground Pin 4: voltage of 12 V via ignition switch and fuse F22.

- Page 307 Model Code Page 1. 6. 1999 31. Autocontrol 2.2 / 2.3 6000-- 8750 1. 8. 2000 D. 4WD control Checking function (engine is run- ning) --- Depress the 4WD rocker switch rear edge, at which time the 4WD pilot light must light...

- Page 308 Model Code Page 1. 6. 1999 31. Autocontrol 2.2 / 2.3 6000-- 8750 1. 8. 2000 E. Differential lock control Picture 3. Differential lock component K12: Switches on voltage to the solenoid valve, when the Y1: Diff. lock solenoid rocker switch rear edge is depressed. Ind. light K11, K12 (not in AC 2.3) and K13: control relays...

- Page 309 Model Code Page 1. 6. 1999 31. Autocontrol 2.2 6000-- 8750 1. 8. 2000 Checking function of the differential lock control (engine at idling speed). Concerning AC 2.3, see page 314/10. --- Depress the rocker switch front edge at which time the lock indicator light comes on.

- Page 310 Model Code Page 31. Autocontrol 2.2 / 2.3 6000-- 8750 1. 6. 1999 F. PTO control Checking function: Make sure that the plug is fitted in the rear emergency socket. Move the control lever in the middle position. Check that the PTO rocker switch front edge is depressed (OFF).

- Page 311 Model Code Page 31. Autocontrol 2.3 6000-- 8750 1. 8. 2000 The function of the differential lock has been changed in the latest tractors (AC 2.3): (concerns also HiTech models 6250Hi ---8950Hi). Note! Manufacturing of AC 2.3, K44242 ---. In connection with modification of the differential lock function, relay K12 has been removed and diodes V3 are for solenoid valves.

- Page 312 Model Code Page 32. Electro---hydraulic power lift 6000-- 8400 8. 11. 1990 Fig. 1 Autocontrol power lift system 1. Hydraulic pump 2. Control valve 3. Lifting cylinder 4. Electronic unit 5. Draft sensor 6. Position sensor 7. Switch panel 1. Autocontrol --- hydraulic lift, elec-...

- Page 313 Model Code Page 1. 9. 1992 32. Electro---hydraulic power lift 6000-- 8400 1. 1. 1994 Wiring diagram, electro---hydraulic power lift, ---662342...

-

Page 314: Wiring Diagram

32. Electro---hydraulic power lift 6000-- 8400 1. 1. 1994 Wiring diagram, ---662342 (E-- models, see section34) Note! See also picture on page 310/6. This diagram concerns 6000---8400 tractors up till the end of the year 1993. Sym--- Component Code Autocontrol electronic unit 70---73... - Page 315 Model Code Page 32. Electro---hydraulic power lift 6000-- 8400 1. 1. 1994 Wiring diagram,662343---...

- Page 316 6000-- 8400 15. 4. 1995 Wiring diagram 662343---F17106 Note! On 6000---8400 models the diff. lock is disengaged when the lift/lower switch is turned to the transport position, see Autocontrol II under code 311. In addition, the lift/lower switch has a middle position which stops the movement of the lower links.

- Page 317 Model Code Page 15. 5. 1996 32. Autocontrol power lift 6000-- 8400 1. 4. 1997 AC power lift, F17107---.

- Page 318 Model Code Page 32. Autocontrol power lift 6000-- 8400 15. 5. 1996 AC power lift, F17107---. Sym--- Code Component Autocontrol electronic unit Autocontrol, switch panel Compensator Position sensor Draft sensor, right Draft sensor, left Illumination, switch panel Illumination, position control knob...

- Page 319 Model Code Page 1. 4. 1997 32. Electro---hydraulic power lift 6000-- 8750 1. 8. 2000 0.2 MPa Fig. 2. Electro ---hydraulic power lift AC/ACD Connectors (B1E, B2E and B3E) for position sensor and draft 1. Control valve sensors are placed in the lever console in the cab and they are 2.

- Page 320 Model Code Page 15. 4. 1995 32. Electro---hydraulic power lift 6000-- 8400 15. 5. 1996 Fig. 3. Control switches for power lift 5. Position control/draft control: Note! For detailed instructions on how to use Autocontrol--- --- position P is position control power lift, see Operator’s Manual.

- Page 321 Model Code Page 15. 6. 1992 32. Electro---hydraulic power lift 6000-- 8750 1. 8. 1998 SIGNAL Supply SIGNAL 10 mm Supply (max. 13 View A Fig. 4. Position sensor 1. Locking nut 2. On threads sealant Permatex Super 300 3. Eccentric on lifting arm shaft 4.

- Page 322 Model Code Page 1. 1. 1994 32. Electro---hydraulic power lift 6000-- 8400 1. 8. 1998 View A SIGNAL SUPPLY 45 Nm Figure 5. Draft sensor 1. Pressure resistant grease Draft sensors Measuring the draft sensor internal volt- ages See page 320/13.

- Page 323 Model Code Page 8. 11. 1990 32. Electro---hydraulic power lift 6000-- 8400 15. 6. 1992 Functional checks c) If the lower links e.g. lift but will not lower: If a malfunction should occur, the reasons may be either in the...

- Page 324 Model Code Page 8. 11. 1990 32. Electro---hydraulic power lift 6000-- 8400 15. 4. 1995 D. Checking the indicator lights on switch G. Checking the draft control operation panel When the draft control is in use (Eg. during ploughing), the lift --- Check that the position control indicator light (7) is lit when and lower indicator lights will flash.

- Page 325 Model Code Page 8. 11. 1990 32. Electro---hydraulic power lift 6000-- 8400 15. 4. 1995 1. Checking switch panel A2E sharp ends so that they can be pricked through protective lac- quer. If lowering speed (S7E), transport height (S8E) or draft control...

- Page 326 Model Code Page 32. Electro---hydraulic power lift 6000-- 8400 8. 11. 1990 B. Voltage measurements Checking transport height selector Turn the current on with the ignition switch and activate the control system with the lift/lower switch (do not detach the connector from the switch panel).

- Page 327 Model Code Page 32. Electro---hydraulic power lift 6000-- 8400 8. 11. 1990 C. Changing switch panel N.B: If the voltage measurements show that the switch panel is defective the panel must be replaced as a complete unit as follows: 1. Detach the switch panel from the bracket by removing se- lector knobs and by unscrewing ring nuts.

- Page 328 Code Page 15. 5. 1996 32. Electro---hydraulic power lift 6000-- 8400 1. 9. 2002 2. Measuring internal voltages of position sensor and draft sensors The condition of the sensors can be checked by measuring the sensor supply and signal voltages with the aid of a spe- cial tool.

- Page 329 Model Code Page 1. 6. 1999 32. Electro---hydraulic power lift 6000-- 8400 1. 9. 2002 3. Checking the position control potentio- 4. Checking control valve and its solenoid meter valves If the lifting or lowering speeds do not function correctly, it is necessary to clear up whether the fault lies in the electric sys- tem or in the control valve (valve spools can get trapped etc.).

- Page 330 Model Code Page 15. 5. 1996 32. Electro---hydraulic power lift 6000-- 8400 1. 8. 1998 Forced ---lowering switch, 668103---. Picture 2. Forced ---lowering switch 1. Without switch 2. With switch S11E=forced lowering switch S10E=lift/lower switch A1E=control unit A2E=switch panel R1E=position control potentiometer...

- Page 331 This new wire loom can be fitted as a spare --- Unit 31287215: 6000---8750 up to 7.96 part in place of the earlier loom. --- Unit 31287220: 6000---8750 *) from 8.96 incl (also earlier tractors, which have AD ---instrument). When using this wire loom, the forced lowering function can be fitted as an option also on all earlier manufactured trac- *) Modification in instrument, instrument no.

- Page 332 1. 6. 1999 Valtra ---Valmet 8450, 8550, 8750 and 8950 tractors have as standard ACD power lift. Basic functions of the ACD are the same as described under code 320 showing Autocontrol power lift. ACD power lift is available as an alternative equipment also for other Mezzo---tractors.

- Page 333 Model Code Page 1. 8. 1998 32. ACB / ACD electro---hydraulic power lift 8450-- 8750 1. 11. 1998 B. Position sensor, ACB and ACD SIGNAL SUPPLY Picture 2. Position sensor on ACB/ACD power lift 4. Permatex Super 300 to threads 5.

- Page 334 Model Code Page 15. 5. 1996 32. ACB / ACD electro---hydraulic power lift 8450-- 8750 1. 11. 1998 C. Function of diagnostic light and fault codes (ACB and ACD) When the current is switched on with an ignition switch, the diagnostic light is lit for a while (book symbol). This is the self --- testing of the ACD system.

- Page 335 Model Code Page 15. 5. 1996 32. ACD electro---hydraulic power lift 8450-- 8750 1. 6. 1999 2. Medium serious faults Fault code Fault Control Description number unit con- nector pin Position sensor Signal from sensor faulty --- Poor contact or position sensor disconnected --- Possible short circuit or earthing --- Position sensor faulty adjusted Position control...

- Page 336 Model Code Page 32. ACB power lift 6250-- 8150 1. 11. 1996 Fault codes of ACB power lift 1. Serious fault Fault code Fault Control Description number unit con- nector pin Output/lifting Output signal to lifting solenoid faulty or poor contacts in solenoid wire to pin 6.

- Page 338 Model Code Page 15. 5. 1996 32. ACB / ACD electro---hydraulic power lift 8450-- 8750 1. 11. 1998 D. Drive Balance Control (DBC) The switch ---on driving speed can be changed as follows: a) Adjust with the lowering speed selector to the minimum Not slip contr.

- Page 339 Model Code Page 15. 5. 1996 32. ACD electro---hydraulic power lift 8450-- 8750 1. 11. 1998 E. Clip control (option) (not on ACB) Functional check (on E ---models as standard) --- disengage the diff. lock and the 4WD --- raise the RH side rear wheel --- activate the ACD and adjust the lower links to the work- ing position, in which they follow accurately the position control potentiometer.

- Page 340 Model Code Page 1. 4. 1997 32. ACD electro---hydraulic power lift 8450-- 8750 1. 11. 1998 F. 1. Checking switch panel of ACD 3. Checking transport height selector S8E Remove the switch panel from the lever console (do not disconnect the connector). Switch on currrent and activate the ACD power lift.

- Page 341 Model Code Page 1. 11. 1998 32. ACD electro---hydraulic power lift 8450-- 8750 1. 9. 2002 5. Checking DBC/slip control selector S12E Picture e) Measure voltage between pin 8 and pins 1 (DBC) and 2 (slip control) with all selector positions: Position Pin 1 Pin 2...

- Page 342 Model Code Page 32. ACB power lift 8250-- 8150 1. 11. 1998 F.2. Checking switch panel of ACB 3. Checking transport height selector S8E Remove the switch panel from the lever console (do not dis- connect the connector). Switch on currrent and activate the ACB power lift.

- Page 343 Model Code Page 1. 11. 1998 32. ACB / ACD power lift 8250-- 8150 1. 9. 2002 G. Changing switch panel, ACB/ACD 5. Checking DBC selector S12E Note! If the voltage measurements show that the switch panel is defective the panel must be replaced as a complete unit as follows: 1.

- Page 344 Model Code Page 1. 10. 1999 32. ACB / ACD power lift 8250-- 8750 1. 9. 2002 H. Checking switch panel indicator lights Lowering speed positions: ... . . approx 0,90 A approx 1,25 A If the ACB/ACD functions properly, but the indicator lights .

- Page 345 Model Code Page 1. 8. 1998 32. ACD power lift 8450-- 8750 1. 11. 1998 Wiring diagram, ACD ACD2.1--- 6/7...

- Page 346 Model Code Page 1. 11. 1998 32. ACD power lift 8450-- 8750 1. 6. 1999 ACD: List of components Connectors: Connector X1E for the radar (B10), for the gearbox speed sensor (B6) and for the possible position sensor on imple- Sym--- Code ment (B4E) are placed in the cab lever console.

- Page 347 Model Code Page 32. ACB power lift 8450-- 8750 1. 11. 1998 Circuit diagram, ACB...

- Page 348 Model Code Page 1. 11. 1998 32. ACB power lift 6200-- 8750 1. 6. 1999 ACB: List of components Connector X2E for supply and for the rear push buttons is placed in the lever console. If the ACD does not respond when the push buttons are used, check then fuse F11.

- Page 349 Model Code Page 1. 11. 1998 32. ACD Power lift 8450-- 8750 1. 6. 1999 ACD Power lift...

- Page 350 Model Code Page 1. 6. 1999 32. ACB Power lift 6200-- 8150 1. 9. 2002 ACB Power lift...

- Page 351 Model Code Page 32. ACB/ACD Power lift 6200-- 8950 1. 6. 1999 K. Checking function of ACB and ACD Power lifts Note! The slip control is an optio- nal equipment on ACD Power lift. ACB Power lift has not a pilot light (7) for the draft control mo- de.

- Page 352 Model Code Page 32. ACB/ACD power lift 6200-- 8950 1. 10. 1999 0.2 MPa Fig. 3. Electro ---hydraulic power lift ACB/ACD, J05133 ---. 1. Control valve 2. Draft sensors 3. Lower links 4. Electronic unit (different on ACB and ACD) 5.

- Page 354 Model Code Page 33. Valmet Agrodata 6000-- 8400 8. 11. 1990 Valmet Agrodata performance monitor N.B. ! These instructions deal with trouble shooting on the Agrodata unit. For detailed instructions concerning the use of the Agrodata system, please see the Operator’s Manual.

- Page 355 Model Code Page 33. Valmet Agrodata 6000-- 8400 8. 11. 1990 (F17) 5 mm X55=supply voltage connector X54=connector for sensors and implement socket Fig. 2. Agrodata monitor and sensors B8=wheel sensor 1. Agrodata unit X7C=connector to lift/lower switch of power lift 2.

-

Page 356: Trouble Shooting

Model Code Page 33. Valmet Agrodata 6000-- 8400 8. 11. 1990 sign. sign. sign. Earth Supply Implement sensor Wheel Lift/lower voltage RPM sensor sensor switch Figure 3. Cable terminal panel (monitor unit rear panel) Terminal 1; earth (no lead) Terminal 2; Signal from lift/lower switch of power lift Terminal 3 and 4;... - Page 357 Model Code Page 33. Valmet Agrodata 6000-- 8400 8. 11. 1990 B. Checking the sensors and signal from 8. Set the lift/lower switch to the lifting position and measure the voltage between terminals 1 (---) and 2 (+); this voltage lift/lower switch should be close to zero.

- Page 358 Model Code Page 33. Valmet Agrodata 6000-- 8400 8. 11. 1990 Spare part numbers for sensors and plug Wheel sensor/sensor for detecting movement of part of imple- ment: 31703200 (2 ---pole sensor) Piece counter/flow meter: 31703000 (3---pole sensor) Plug: 31702900 C.

- Page 360 Model Code Page 15. 4. 1995 33. Agrodata---instrument 6000-- 8950 1. 8. 2000 Agrodata---instrument Note! This is a different device as Agrodata performance monitor shown under code 330. Agrodata is a factory --- mounted option. Standard equipment in HiTech tractors.

- Page 361 Model Code Page 15. 4. 1995 33. Agrodata---instrument 6000-- 8950 1. 8. 2000 Agrodata---instrument, sensors and wiring...

- Page 362 Model Code Page 15. 4. 1995 33. Agrodata---instrument 6000-- 8950 1. 8. 2000 Agrodata---instrument, sensors and wiring Zeroing the travelling distance (See picture on previous page) --- select travelling distance into the display by pressing the switch rear edge. Agrodata ---instrument P5 (upper display) --- press the switch front edge until the display is zeroed.