Table of Contents

Summary of Contents for Ditch Witch 1030

-

Page 1: Service

1030/1230 - SERVICE SERIAL NUMBER RECORD SERVICE SERIAL NUMBER RECORD Record serial numbers and date of purchase in spaces provided. Serial number plate is mounted to frame behind right wheel. Date of purchase Serial number Engine serial number... -

Page 2: Support Procedure

Return damaged parts to dealer for inspection and warranty consideration. Order genuine Ditch Witch replacement parts from your authorized Ditch Witch dealer. Use of another manufacturer’s parts may void warranty. RESOURCES... -

Page 3: Foreword

If you sell your equipment, be sure to give this manual to the new owner. If you need a replacement copy, contact your Ditch Witch dealer. If you need assistance in locating a dealer, visit our website at www.ditchwitch.com or write to the following address:... - Page 4 Copyright 1997, 1999, 2001, 2003, 2004 by The Charles Machine Works, Inc., Perry, Oklahoma , Ditch Witch, CMW, AutoCrowd, Modularmatic, Jet Trac, Roto Witch, Subsite, Fluid Miser, Perma- Soil, Power Pipe, Super Witch, Super Witch II, Pierce Airrow, The Underground, and The Underground Authority Worldwide are...

-

Page 5: Table Of Contents

1030/1230 - CONTENTS CONTENTS SERVICE ........1 Serial Number Record . - Page 6 SPECIFICATIONS ......61 1030 ........61...

-

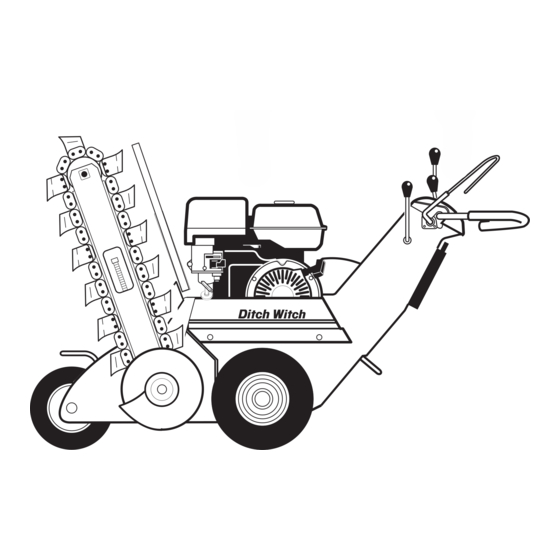

Page 7: Overview

1030/1230 - OVERVIEW OVERVIEW The Ditch Witch 1030 and 1230 pedestrian trenchers are designed for easy, efficient use. Color-coded controls are within easy reach of the operator. These compact units fit through most standard yard gates, and the machines are balanced for easy jobsite maneuvering. A choice of a 24”, 30”, or 36”... - Page 8 1030/1230 - OVERVIEW...

-

Page 9: Controls

1030/1230 - CONTROLS CONTROL CONSOLE OVERVIEW CONTROLS CONTROL CONSOLE OVERVIEW 1. Bail 2. Digging boom control (green) 3. Axle lock (blue) 4. Speed/direction control (orange) 5. Throttle (black) 6. Digging chain control (yellow) 7. Power switch... -

Page 10: Control Console Descriptions

1030/1230 - CONTROLS CONTROL CONSOLE DESCRIPTIONS CONTROL CONSOLE DESCRIPTIONS Bail This start interlock control engages and disengages hydraulic system. • Move down into handlebar to engage. • Release to disengage. Axle Lock (Blue) This lever locks or unlocks axle. •... - Page 11 1030/1230 - CONTROLS CONTROL CONSOLE DESCRIPTIONS Digging Chain Control (Yellow) This lever starts digging chain when bail is engaged. • Push to start digging chain. • Returns to neutral and digging chain stops when bail is released. ic0014c.tif Speed/Direction Control...

- Page 12 1030/1230 - CONTROLS CONTROL CONSOLE DESCRIPTIONS Throttle (Black) This lever controls engine speed. Increasing engine speed also increases digging chain speed. • Push down to speed engine. • Pull up to slow engine. ic0128h.eps Power Switch This two-position switch controls power to the machine.

-

Page 13: Engine Controls Overview

1030/1230 - CONTROLS ENGINE CONTROLS OVERVIEW ENGINE CONTROLS OVERVIEW 1. Fuel shut-off valves 2. Choke 3. Pull start... -

Page 14: Engine Controls Descriptions

1030/1230 - CONTROLS ENGINE CONTROLS DESCRIPTIONS ENGINE CONTROLS DESCRIPTIONS Fuel Shut-off Valves Two valves separate fuel reservoir from engine. • Close when transporting unit to or from jobsite. • Open before starting engine. Choke This valve regulates air/fuel mixture. Close valve to help start cold engine. -

Page 15: Safety

Use equipment carefully. Stop operation and investigate anything that does not look or feel right. • Do not operate unit where flammable gas is present. • Contact your Ditch Witch dealer if you have any question about operation, maintenance, or equipment use. -

Page 16: Accessories

It should meet legal and regulatory requirements. Lighting Kit If you need additional light, plug lighting kit into provided outlet. Contact your Ditch Witch dealer for further information. UNDERGROUND HAZARDS Striking underground hazards can cause explosion, electrocution, fire, and exposure to hazardous materials. -

Page 17: Emergency Procedures

1030/1230 - SAFETY EMERGENCY PROCEDURES EMERGENCY PROCEDURES Before operating any equipment, review emergency procedures and check that all safety precautions have been taken. EMERGENCY SHUTDOWN - Turn ignition switch to stop position or push remote engine stop button. Electric Strike Description When working near electric cables, remember the following: •... - Page 18 1030/1230 - SAFETY EMERGENCY PROCEDURES If an Electric Line is Damaged If you suspect an electric line has been damaged and you are on tractor, DO NOT MOVE. Remain on tractor and take the following actions. The order and degree of action will depend upon the situation.

- Page 19 1030/1230 - SAFETY EMERGENCY PROCEDURES If a Gas Line is Damaged If you suspect a gas line has been damaged, take the following actions. The order and degree of action will depend on the situation. • Immediately shut off engine(s), if this can be done safely and quickly.

-

Page 20: Jobsite Classification

1030/1230 - SAFETY JOBSITE CLASSIFICATION JOBSITE CLASSIFICATION Inspecting Jobsite • Follow U.S. Department of Labor regulations on excavating and trenching (Part 1926, Subpart P) and other similar regulations. • Contact One-Call (888-258-0808) and any utility companies which do not subscribe to One-Call. - Page 21 1030/1230 - SAFETY JOBSITE CLASSIFICATION Selecting a Classification Jobsites are classified according to underground hazards present. If working . . . then classify jobsite as . . . within 10’ (3 m) of a buried electric electric line within 10’ (3 m) of a natural...

- Page 22 1030/1230 - SAFETY JOBSITE CLASSIFICATION Applying Precautions Once classified, precautions appropriate for jobsite must be taken. Electric Jobsite Precautions Use one or both of these methods. • Expose line by careful hand digging or soft excavation. • Have service shut down while work is in progress. Have electric company test lines before returning them to service.

- Page 23 1030/1230 - SAFETY JOBSITE CLASSIFICATION Crystalline Silica (Quartz) Dust Precautions Follow OSHA or other guidelines for exposure to crystalline silica when trenching, sawing or drilling through material that might produce dust containing crystalline silica (quartz). Other Jobsite Precautions You may need to use different methods to safely avoid other underground hazards.

-

Page 24: Safety Alert Classifications

1030/1230 - SAFETY SAFETY ALERT CLASSIFICATIONS SAFETY ALERT CLASSIFICATIONS These classifications and the icons defined on the following pages work together to alert you to situations which could be harmful to you, jobsite bystanders or your equipment. When you see these words and icons in the book or on the machine, carefully read and follow all instructions. -

Page 25: Safety Alerts

1030/1230 - SAFETY SAFETY ALERTS SAFETY ALERTS Moving digging teeth will kill you or cut off arm or leg. Stay away. Turning shaft will kill you or crush arm or leg. Stay away. Electric shock. Contacting electric lines will cause death or serious injury. Know location of lines and stay away. - Page 26 1030/1230 - SAFETY SAFETY ALERTS Jobsite hazards could cause death or serious injury. Use correct equipment and work methods. Use and maintain proper safety equipment. Crushing weight could cause death or serious injury. Use proper procedures and equipment or stay away.

- Page 27 1030/1230 - SAFETY SAFETY ALERTS Explosion possible. Serious injury or equipment damage could occur. Follow directions carefully. Incorrect procedures could result in death, injury, or property damage. Learn to use equipment correctly. Looking into fiber optic cable could result in permanent vision damage. Do not look into ends of fiber optic or unidentified cable.

- Page 28 1030/1230 - SAFETY SAFETY ALERTS Fire or explosion possible. Fumes could ignite and cause burns. No smoking, no flame, no spark. Moving traffic - hazardous situation. Death or serious injury could result. Avoid moving vehicles, wear high visibility clothing, post appropriate warning signs.

- Page 29 1030/1230 - SAFETY SAFETY ALERTS Flying objects may cause injury. Wear hard hat and safety glasses. Hot parts may cause burns. Do not touch until cool. Exposure to high noise levels may cause hearing loss. Wear hearing protection. Fall possible. Slips or trips may result in injury.

- Page 30 1030/1230 - SAFETY SAFETY ALERTS...

-

Page 31: Transportation

1030/1230 - TRANSPORTATION LIFT TRANSPORTATION LIFT Lifting Points Lifting points are identified by lifting decals. Lifting at any other point can be unsafe and can damage machinery. om1362.pcx... - Page 32 1030/1230 - TRANSPORTATION LIFT Lifting Unit Crushing weight could cause death or serious injury. Use proper procedures and equipment or stay away. Before lifting, check SPECIFICATIONS. Use a hoist capable of supporting equipment’s size and weight. Lift trencher by running a sling through the front guide, under...

-

Page 33: Tiedown

1030/1230 - TRANSPORTATION TIEDOWN TIEDOWN Tiedown Points Tiedown points are identified by tiedown decals. Securing unit to truck or trailer at any other points may be unsafe and can damage machinery. om1363.pcx Tieing Down Unit Attach tiedowns at front and rear tiedown points. Make sure... - Page 34 1030/1230 - TRANSPORTATION HAUL HAUL Crushing weight could cause death or serious injury. Use proper procedures and equipment or stay away. NOTICES: • Read trailer operator’s manual, if applicable, before loading or transporting your machine. Incorrectly loaded machine can slip or cause trailer sway.

-

Page 35: Haul

1030/1230 - TRANSPORTATION HAUL Loading The 1030 and 1230 trenchers can be hauled in the bed of a light truck or by trailer. To load: 1. Start engine. See OPERATION for start-up procedures. 2. Raise digging boom, but keep it low. - Page 36 1030/1230 - TRANSPORTATION HAUL Unloading 1. Remove tiedowns. 2. Open fuel shut-off valves and start engine. 3. Move throttle to about 1/4 open. 4. Ensure that axle is locked and speed/direction control is in the BAIL RELEASE (neutral) position. 5. Engage bail.

-

Page 37: Freewheel

1030/1230 - TRANSPORTATION FREEWHEEL FREEWHEEL If trencher must be moved without engine running, this feature allows the 1030 or 1230 to be wheeled manually. Crushing weight could cause death or serious injury. Use proper procedures and equipment or stay away. -

Page 38: Tow

1030/1230 - TRANSPORTATION Under normal conditions, unit should not be towed. If unit becomes disabled and towing is necessary: • tow for short distances at less than 1 mph (1.6 km/h) • do not tow for more than 100’ (30 m) •... -

Page 39: Operation

1030/1230 - OPERATION DAILY INSPECTION OPERATION DAILY INSPECTION For safe and efficient use of your machine, do the following before each day’s work. • Check general appearance of tractor and digging attachment. Look for loose, worn, or damaged parts and fluid leaks. -

Page 40: Startup

1030/1230 - OPERATION STARTUP STARTUP Before operating trencher, read engine manufacturer’s starting and operating instructions. Follow instructions for new engine break-in. Incorrect procedures could result in death, injury, or property damage. Learn to use equipment correctly. EMERGENCY SHUTDOWN: Turn power switch off. - Page 41 NOTICES: • If interlock system does not work, contact your Ditch Witch dealer. Improper repair might allow machine to start or operate with controls in gear. • Do not wire or tape bail to handlebar or defeat interlock system in any manner.

-

Page 42: Driving

1030/1230 - OPERATION DRIVING DRIVING Incorrect procedures could result in death, injury, or property damage. Learn to use equipment correctly. NOTICE: Keep attachment low when operating on a slope. Drive slowly and cautiously at all times. 1. Ensure that speed/direction control is in the BAIL RELEASE (neutral) position. -

Page 43: Trenching

1030/1230 - OPERATION TRENCHING TRENCHING Jobsite hazards could cause death or serious injury. Use correct equipment and work methods. Use and maintain proper safety equipment. NOTICE: Know and comply with regulations covering One-Call service and utility notification before digging. Jobsite hazards could cause death or serious injury. - Page 44 1030/1230 - OPERATION TRENCHING 1. Drive trencher to starting point. Move in line with planned trench. 2. For a straighter trench, lock axle. 3. Move throttle to half open. 4. Ensure that speed/direction control and digging chain control are in neutral.

- Page 45 1030/1230 - OPERATION TRENCHING 7. Slowly lower digging boom to desired trench depth. Incorrect procedures can result in death, injury, or property damage. Learn to use equipment correctly. NOTICES: • Machine may move when chain starts to dig. Allow 3’ (1 m) between end of chain and obstacle.

- Page 46 1030/1230 - OPERATION TRENCHING 10. When trench is complete, move speed direction control to neutral. 11. Move throttle to half open. 12. Raise digging boom to top of trench. 13. Release bail to stop digging chain. 14. Engage bail and raise digging boom completely.

-

Page 47: Lubrication And Maintenance

1030/1230 - LUBRICATION AND MAINTENANCE TRENCHING LUBRICATION AND MAINTENANCE Proper lubrication and maintenance protects Ditch Witch equipment from damage and failure. In extreme conditions, lubricate more frequently. Use only recommended lubricants. Fill to capacities listed in SPECIFICATIONS. Recommended Lubricants Gasoline engine oil (see chart for appropriate SAE viscosity rating) meeting API engine... -

Page 48: Lubrication Overview

1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION OVERVIEW LUBRICATION OVERVIEW (GEO) Gasoline engine oil (THF) Tractor hydraulic fluid AGMA-7 (MPG) Multipurpose grease Filter Check level Pivot gearbox on opposite side of machine not shown. Check oil every 50 hours. Change gearbox oil every 1000 hours with... -

Page 49: Lubrication Schedule

1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE LUBRICATION SCHEDULE Interval Task Page Each use Check engine oil Check hydraulic oil 10 hours Lube attachment pivot Lube pivot stub 25 hours Lube trail wheel Lube axle lock 50 hours Check pivot gearbox oil... - Page 50 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Engine Oil Check Check engine oil at dipstick (A) before each operation. Add GEO at fill neck (A) as necessary to keep oil level at highest line on dipstick. Change • Change oil every 100 hours with GEO.

- Page 51 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Hydraulic Oil and Filter Check With digging boom fully raised, check hydraulic oil at dipstick (A) before each operation. Add THF at fill neck (A) as necessary to keep oil level at highest line on dipstick.

- Page 52 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Tires Lube trail wheel (A) every 25 hours with MPG. Pivot Lube Pivot (B) every 10 hours with MPG. Axle Lock Lube axle lock every 25 hours with MPG.

- Page 53 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Pivot Gearbox Check Check gearbox oil every 50 hours at fill plug (A). Refill with THF as necessary to keep oil level with fill plug. Change Change gearbox oil every 1000 hours. •...

- Page 54 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Worm Drive Check Check worm drive oil every 50 hours at fill plug (A). Refill with AGMA-7 as necessary to keep oil level with fill plug. om0049c Change Change worm drive oil every 500 hours.

- Page 55 1030/1230 - LUBRICATION AND MAINTENANCE LUBRICATION SCHEDULE Digging Boom Boom with Adjustment Screw Lube adjustment screw (A) every 50 hours with MPG. Lube pivot stub (B) every 10 hours with MPG. om0056c Greaseable Boom Lube boom stub every 50 hours...

-

Page 56: Maintenance Schedule

1030/1230 - LUBRICATION AND MAINTENANCE MAINTENANCE SCHEDULE MAINTENANCE SCHEDULE Interval Task Page Each use Check tire pressure Check lug nut torque 100 hours Change air filter paper element As needed Change remote air cleaner paper element Adjust digging chain tension... - Page 57 1030/1230 - LUBRICATION AND MAINTENANCE MAINTENANCE SCHEDULE Remote Air Cleaner Change optional air cleaner paper element as needed. • Remove air cleaner cover. • Remove paper element and replace. NOTICE: Use of this option does not eliminate the need for proper maintenance of standard air filter.

- Page 58 1030/1230 - LUBRICATION AND MAINTENANCE MAINTENANCE SCHEDULE Grease Cylinder: To tighten digging chain, pump MPG into cylinder at check valve zerk. NOTICE: Do not overtighten chain. Overtightening will cause chain stretch, loss of machine performance, and possible premature chain failure.

- Page 59 1030/1230 - LUBRICATION AND MAINTENANCE MAINTENANCE SCHEDULE Drive Belts Check drive belts regularly and adjust tension as needed. • Turn engine off. • Move bail down into handlebar and clamp in place. • Engage digging chain control rg0020c.eps until locked in place.

- Page 60 1030/1230 - LUBRICATION AND MAINTENANCE...

-

Page 61: Specifications

1030/1230 - SPECIFICATIONS 1030 SPECIFICATIONS 1030 om0050c.eps DIMENSIONS U.S. METRIC Trench depth, maximum 30 in 760 mm Trench width 4.3 - 6 in 110-150 mm Boom travel down 60° 60° Boom travel up 47° 47° Headshaft height--digging chain 8.60 in... - Page 62 Angle of approach 35° 35° Dimensions based on 16x6.50x8 tires and 24” (610-mm) boom in transport position GENERAL Ditch Witch model 1030, self-propelled, pedestrian, manually steered, two- wheel drive rigid frame, chain type trencher OPERATIONAL U.S. METRIC Vehicle speeds Maximum transit forward...

- Page 63 1030/1230 - SPECIFICATIONS 1030 POWER U.S. METRIC Maximum governed speed installed (no load) 3400 rpm 3400 rpm Flywheel power @ 3200 rpm (full load) 10.2 hp 7.5 kW Fuel consumption @3600 rpm .89 gph 3.4 L/h Maximum tilt angle 20°...

- Page 64 1030/1230 - SPECIFICATIONS 1230 1230 DIMENSIONS U.S. METRIC Trench depth, maximum 36 in 915 mm Trench width 4.3-6 in 110-150 mm Boom travel down 60° 60° Boom travel up 47° 47° Headshaft height--digging chain 8.60 in 220 mm Length 88 in 2.2 m...

- Page 65 Angle of approach 35° 35° Dimensions based on 16x6.50x8 tires and 24” (610-mm) boom in transport position GENERAL Ditch Witch model 1230, self-propelled, pedestrian, manually steered, two- wheel drive rigid frame, chain type trencher OPERATIONAL U.S. METRIC Vehicle speeds Maximum transit forward...

- Page 66 1030/1230 - SPECIFICATIONS 1230 POWER U.S. METRIC Maximum governed speed installed (no load) 3600 rpm 3600 rpm Flywheel power @ 3200 rpm (full load) 12 hp 8.9 kW Fuel consumption @3600 rpm .89 gph 3.4 L/h Maximum tilt angle 20°...

- Page 67 CMW reserves the right to supply remanufactured replacement parts as it deems appropriate. * Equipment owners in countries other than U.S., Canada, Mexico, and Puerto Rico should refer to Ditch Witch International Warranty Policy.

- Page 68 1030/1230 - WARRANTY Product Limited Warranty Products are warranted for 90 days from date of delivery of any new product. Free replacement parts and labor will be provided at any authorized dealership for any product which has a defect in material or workmanship within warranty period.

- Page 69 COMMERCIAL BUYER. ALL OTHER PROVISIONS OF THIS LIMITED WARRANTY APPLY INCLUDING THE DUTIES IMPOSED. Ditch Witch products have been tested to deliver acceptable performance in most conditions. This does not imply they will deliver acceptable performance in all conditions. Therefore, to assure suitability, products should be operated under anticipated working conditions prior to purchase.

- Page 70 1030/1230 - WARRANTY For information regarding this limited warranty, contact CMW’s Product Support department, P.O. Box 66, Perry, OK 73077-0066, or contact your local Ditch Witch dealer. First version: 1/91; Latest revision: 4/99...

Need help?

Do you have a question about the 1030 and is the answer not in the manual?

Questions and answers