Rockwell Automation Allen-Bradley FLEX 5000 User Manual

Standard and safety digital i/o modules

Hide thumbs

Also See for Allen-Bradley FLEX 5000:

- User manual (78 pages) ,

- Installation instructions manual (16 pages) ,

- Installation instructions manual (20 pages)

Summary of Contents for Rockwell Automation Allen-Bradley FLEX 5000

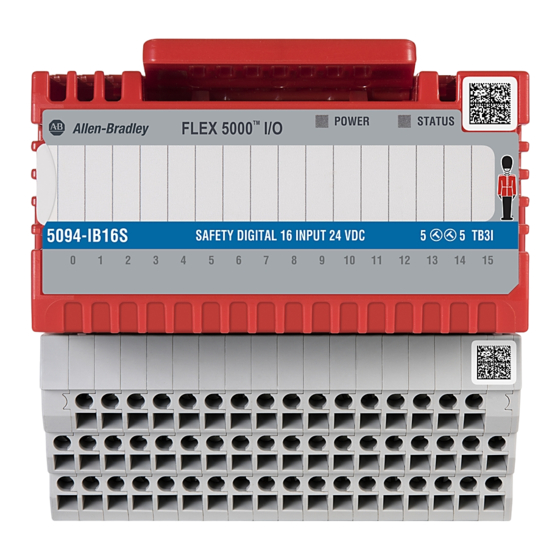

- Page 1 User Manual Original Instructions FLEX 5000 Standard and Safety Digital I/O Modules Catalog Numbers 5094-IB16, 5094-IB16XT, 5094-IB16S, 5094-IB16SXT, 5094-OB16, 5094-OB16XT, 5094-OB16S, 5094-OB16SXT, 5094-OW8I, 5094-OW8IXT...

- Page 2 If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired. In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

-

Page 3: Table Of Contents

Safety Precautions ......... 39 Safety Application Requirements ......40 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 4 5094-OB16XT Modules........66 Time-scheduled Output Control ......66 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 5 View the Module Tags........105 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 6 Test Output Tags ........148 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 7 FLEX 5000 I/O Safety Input Module Safety Data ....164 Safety Data for I/O Modules FLEX 5000 I/O Safety Output Module Safety Data... . . 164 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 8 Table of Contents Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 9: Preface

(catalog numbers ending in “S” or “SXT”). Further, we use FLEX 5000 I/O module to indicate when a concept or task applies to both the standard and safety digital I/O modules. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 10: Graphics Indicate Feature Support

If both standard and safety modules support a feature, you see icons for both types. If only one type of module, standard or safety, supports a feature, you see only one type of icon. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 11: Terminology

A ladder logic instruction that sets controller system data. — Standard (devices) Devices or portions of devices that do not have functional safety capability. — Unicast The transmission of information from one sender to one receiver. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 12: Additional Resources

Provides more information on event tasks and event Programming Manual, publication 1756-PM005 task configuration. Position-based Output Control with the MAOC Describes how to configure time-scheduled output Instruction, publication 1756-AT017 control with the MAOC instruction. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 13 Provides declarations of conformity, certificates, and other certification details. http://www.rockwellautomation.com/ rockwellautomation/certification/overview.page SISTEMA software utility, The Rockwell Automation SISTEMA data library is available for download, together with a link to the http://marketing.rockwellautomation.com/safety/en/ SISTEMA download site. Sistema_Download You can view or download publications at http://www.rockwellautomation.com/global/literature-library/overview.page.

- Page 14 Preface Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 15: Digital I/O Module Operation In A Logix 5000 Control System

The term does not refer to all Logix 5000 controllers. For the most current information on the Logix 5000 controllers with which you can use FLEX 5000 I/O modules, see the product description at http://www.ab.com. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 16 DIGITAL 16 INPUT 24 VDC 1 TB3 5094-OB16 DIGITAL 16 OUTPUT 24 VDC 2 TB3 5094-OW8I RELAY 8 OUTPUT ISOLATED 2 TB3W LINK 1 IP ADDRESS LINK 2 5094-AENTR POWER 5069-L340ERM EtherNet/IP Network 5094-AENTR 5094 Standard I/O Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 17: Controller And Software Compatibility

While you must pair safety I/O with a safety controller, you can also pair standard I/O with a safety controller. For example, ControlLogix 5580 controllers are compatible with FLEX 5000 standard I/O modules. GuardLogix® 5580 controllers are compatible with FLEX 5000 standard and safety I/O modules. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 18: Firmware And Software Compatibility

Compact GuardLogix 5380 5069-L306ERMS2, 5069-L306ERS2, 5069-L310ERS2, 5069-L310ERMS2, 32.00.00 or later 5069-L320ERS2, 5069-L320ERMS2, 5069-L330ERS2, 5069-L330ERMS2, 5094-IB16S, 5094-IB16SXT, 5069-L340ERS2, 5069-L340ERMS2, 5069-L350ERS2, 5069-L350ERMS2, 5094-OB16S, 5094-OB16SXT 5069-L380ERS2, 5069-L380ERMS2, 5069-L3100ERS2, 5069-L3100ERMS2 GuardLogix 5580 1756-L81ES, 1756-L82ES, 1756-L83ES, 1756-L84ES 32.00.00 or later Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 19: Secure Access To The System

• Locate control system networks and devices behind firewalls and isolate them from the business network. • Subscribe to the Rockwell Automation Security Advisory Index, Knowledgebase article KB54102, so you have access to information about security matters that affect Rockwell Automation products. -

Page 20: Module Overview

Terminal base - Indicates the type of terminal base assembly to use with the module Latching hooks - Securely installs FLEX 5000 modules on the terminal base assembly Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 21 Module keying - Indicates the keying position the terminal base assembly must be configured to before installing the module Terminal base - Indicates the type of terminal base assembly to use with the module Latching hooks - Securely installs FLEX 5000 modules on the terminal base assembly Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 22: Ownership

Multicast or Unicast connection over the EtherNet/IP network. For more information on Listen-only controllers, see Listen Only Mode on page Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 23: Configuration Changes In An Input Module

Logix Designer to change the configuration, see Chapter 3. Repeat step 1 step 2 for all owner-controllers, making the exact same changes in each. 4. Clear the Inhibit checkbox in each owner-controller configuration. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 24: Construct A 5094 Flex 5000 I/O System

5 A, you can use a module power supply that is limited to 5 A. • You must use SELV-listed power supplies for module power if there are functional safety modules that are connected to the FLEX 5000 I/O system. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 25: Before You Begin

The Logix Designer application transfers the project to the owner-controller during the program download. Data is then transferred to the FLEX 5000 I/O modules over the EtherNet/IP network. The FLEX 5000 I/O modules can operate immediately after receiving the configuration data. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 26: Connections For Standard I/O Modules

• You change the RPI value. In this case, the connection is closed and reopened immediately after you apply the change to the module configuration. For more information on guidelines for specifying RPI rates, see the Logix 5000 Controllers Design Considerations Reference Manual, publication 1756-RM094. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 27: Standard I/O Modules

Data with Events include Data, Packed Data, or Timestamped Data. For more information on the Connection and Data parameter choices available with FLEX 5000 I/O modules, see the Logix Designer application. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 28: Connections For Safety I/O Modules

FLEX 5000 I/O system, causes a fault. The Logix Designer application monitors the fault status tags to indicate when a fault occurs on a module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 29: Configured By' Options For Safety I/O Modules

When the External Means option is chosen, another controller owns the module. A controller that chosen this option does not write configuration for the module. It merely listens to the data exchanged with the owner-controller. That is, it receives Safety input data. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 30: Data Types Available With Flex 5000 Safety I/O Modules

You set the RPI value during initial module configuration and can adjust it as necessary after module operation has begun. The valid RPI values for FLEX 5000 I/O safety modules are 2…500 ms. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 31 For more information on specifying RPI rates, see the following: • FLEX 5000 I/O safety I/O modules - page • Logix 5000 Controllers Design Considerations Reference Manual, publication 1756-RM094 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 32: Connection Over An Ethernet/Ip Network

• If the controller is directly connected to the EtherNet/IP network, it receives the input data immediately. • If the controller is connected to the EtherNet/IP network through another communication module, the module sends the data to its backplane and the controller receives it. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 33: Trigger Events

RPI timer. Based on the RPI rate and the length of the controller program scan, the output module can receive and echo data multiple times during one program scan. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 34 • If the controller is connected to the EtherNet/IP network through another communication module, the module transmits the data to its backplane and the controller receives it. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 35: Listen Only Mode

• If the connection between an owner-controller and the module is broken, the module stops sending data and connections to all ‘listening controllers’ are also broken. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 36: Protected Operations

For more information on the maximum ambient operating temperature specification for FLEX 5000 I/O safety modules, see the FLEX 5000 Modules Specifications Technical Data, publication 5094-TD001. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 37: Single-Channel Or Dual-Channel Mode

SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I Table 2 on page 18 safety modules, see You must use the Logix Designer application, version 32 or later, to configure the FLEX 5000 I/O safety modules. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 38: Determine Conformity

Only download firmware and access product release notes from the Rockwell Automation PCDC. Do not download firmware from non-Rockwell Automation sites. Safety Function During Firmware Update The FLEX 5000 I/O safety modules are not safety capable when a firmware update is in process. -

Page 39: Safety Precautions

• Configure the replacement device properly and confirm that it operates correctly. • After installation of the module, a safety administrator must confirm the installation and conduct trial operation and maintenance. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 40: Safety Application Requirements

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference Manual, publication 1756-RM012. You must read, understand, and fulfill the requirements that are described in this publication before you operate a safety system that uses FLEX 5000 I/O safety modules. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 41: Safe State

I/O connection is lost, you accept responsibility for any consequences that result from your decision to inhibit. We recommend that you use other means to maintain the safe state if you inhibit the safety module from transitioning to a safe state. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 42: Configuration Signature And Ownership

• Path from the controller to the FLEX 5000 I/O safety module • Configuration signature If any differences are detected, the connection between the owner-controller and the FLEX 5000 I/O safety module is lost, the yellow yield icon appears in the controller project tree. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 43: Reset Flex 5000 I/O Safety Modules To Out-Of-Box State

You cannot reset the module to its out-of-box configuration if either of the following conditions is true: • Pending edits to the module properties exist • Safety signature exists in the controller project Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 44 Chapter 1 Digital I/O Module Operation in a Logix 5000 Control System Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 45 Module Firmware Module Data Quality Reporting Software Configurable Fault and Status Reporting Module Firmware Module Inhibiting Electronic Keying This chapter describes module features that are available on all FLEX 5000™ digital I/O modules. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 46: Input Module Compatibility

Listen Only connection to the module can consume it. When an input module produces data, the controllers can consume the data simultaneously. Simultaneous data consumption mitigates the need for one controller to send the data to other controllers. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 47: Module Data Quality Reporting

– Data is under manual or override control TIP We strongly recommend that you monitor the tags in your program to make sure that the application is operating as expected with accurate channel input data. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 48: Software Configurable

DIGITAL 16 INPUT 24 VDC 1 TB3 to correct an anomaly that existed in previous module firmware revisions. Safety Modules Firmware information for I/O devices is available at the Rockwell Automation Product Compatibility and Download Center (PCDC). The PCDC is available FLEX 5000 POWER STATUS https://compatibility.rockwellautomation.com/Pages/home.aspx... -

Page 49: Module Inhibiting

In this case, you can inhibit the module in your program until it physically resides in the proper slot. page 120 To see where to inhibit a FLEX 5000 digital I/O module, see Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 50: Electronic Keying

If an I/O connection to a device is interrupted, the result can be a loss of data. For more detailed information on Electronic Keying, see Electronic Keying in Logix5000 Control Systems Application Technique, publication LOGIX-AT001. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 51: Module Firmware

DIGITAL 16 INPUT 24 VDC 1 TB3 to correct an anomaly that existed in previous module firmware revisions. Safety Modules Firmware information for I/O devices is available at the Rockwell Automation Product Compatibility and Download Center (PCDC). The PCDC is available FLEX 5000 POWER... - Page 52 Chapter 2 Common Digital I/O Module Features Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 53: Chapter 3 Data Transfer At Rpi

26, and for safety FLEX 5000 POWER STATUS modules, see page 114. 5094-IB16 DIGITAL 16 INPUT 24 VDC 1 TB3 Safety Modules FLEX 5000 POWER STATUS 5094-IB16S SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 54: Software Configurable Input Filters And Delays

Module Tag Definitions on page 137 Safety Modules To see where to enable or disable field power detection, see page FLEX 5000 POWER STATUS 5094-IB16S SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 55: Fault And Status Reporting

The module is operating outside its designed operating range if data is under manual or override control. (1) Not all tag names apply to all FLEX 5000 digital input modules. (2) This tag provides module-wide data and affects all points simultaneously. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 56 Chapter 3 Input Module Features Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 57: Features Specific To All Flex 5000 Output Modules

4.5 ms 5094-IB16S SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I 5094-OW8I, 5094-OW8IXT 10 ms (1) The times that are listed in Table 10 are from the time the module receives the message. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 58: Configurable Point-Level Output State In Program Mode Or

• In standard modules only – Length of time that the output behaves as defined – Output behavior if the connection remains broken when the length of time that is defined previously expires Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 59: Output Behavior Immediately After A Connection Fault

• Temporarily maintain normal system operations when an input device has failed. Use forces only as a temporary measure. They are not intended to be a permanent part of your application. Make sure that you understand the following before using forces. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 60: Enable Forces

ATTENTION: Changes to forces can cause unexpected machine motion that could injure personnel. Before you disable or remove forces, determine how the change affects your machine or process and keep personnel away from the machine area. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 61: Check Force Status

No forces of this type exist in the project. GSV Instruction This example shows how to use a GSV instruction to get the status of forces. For the purposes of this example, Force_Status is a DINT tag. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 62: Data Echo

1 ms. For more information on fault reporting, see Appendix A, Troubleshoot Your Module on page 123. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 63: Features Specific To Only Standard And Safety Solid-State

IMPORTANT These FLEX 5000 output modules are the only ones to support No Load Detection: • 5094-OB16 • 5094-OB16XT • 5094-OB16S • 5094-OB16SXT The standard output modules support the following minimum load currents: • No load detection current, max = 0.5 mA Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 64: Short-Circuit Protection

• 5094-OB16XT • 5094-OB16S • 5094-OB16SXT In standard modules, when a short-circuit condition is detected, the following occurs: • The output turns off. • The I/O status indicator for the output becomes steady red. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 65: Thermal Shutoff

• The I/O status indicator for the output becomes solid red. • The I.Ptxx.ShortCircuit tag is set to 1. For more information on how to use the modules, see Appendix Module Tag Definitions on page 137. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 66: Features Specific To Only 5094-Ob16 And 5094-Ob16Xt Modules

On and Off times of an output is completed through the MAOC instruction. The instruction then updates values in the output s of the module that define the scheduled output behavior. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 67: Use A Maoc Instruction With A 5094-Ob16 Or 5094-Ob16Xt Standard Output Module

Logix Designer application and configure the module, Chapter Configure the Standard Module on page 2. From the Module Properties dialog box, click Change to access the Module Definition parameters. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 68 For more information on how to use an MAOC instruction in general, see the following: • Logix5000 Controllers Motion Instructions Reference Manual, publication MOTION-RM002 • Position-based Output Control with the MAOC Instruction Application Technique, publication 1756-AT017 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 69: Feature Specific To Only 5094-Ow8I And 5094-Ow8Ixt Modules

DIGITAL 16 INPUT 24 VDC 1 TB3 • 5094-OW8IXT IMPORTANT Although some FLEX 5000 digital I/O modules do not provide wiring isolation, all FLEX 5000 modules maintain internal electrical isolation between the system-side and field-side power buses. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 70 Chapter 4 Output Module Features Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 71: Safety I/O Module Features

Point mode be Safety Pulse Test. – Point mode is Safety Pulse Test only To achieve the specific Safety Integrity Level, see Appendix C, Application/Wiring Examples for Safety I/O Modules on page 155. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 72: Input Modules In Cip Safety Systems

• Separate test outputs are provided for short-circuit detection of a safety input (or inputs). • Can supply 24V DC power to devices, such as safety sensors. • Test output rating (TO) 200 mA @ 18…32V DC Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 73: Use Test Output With A Safety Input

• A 2-wire sensor is connected to safety input 0, with test output 0 configured as Test Pulse/Power Supply. • A 3-wire sensor is connected to safety input 15, with test output 7 configured as Power Supply. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 74 Test Output. For example, Test Output 0 associates to Safety Input 0 and 8. If these two channels short circuit, it cannot be detected. Figure 9 - Short Circuit Between Input Signal Lines Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 75: Single-Channel Mode

Safety Input 0 Status Test Output 0 Fau lt Detec tion External Device Input Terminal 0 Fault D etected Safety Safety Input 0 Data Network Data Sent to the Safety Input 0 Controller Status Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 76: Safety Input Fault Reset

1 second until it checks if the fault is removed. If the fault is removed, the channel clears the fault status only upon detecting the safety input is low on the screw. If not, the channel continues to check if the fault is removed. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 77: Safety Input Delay

• 1 ms • 2 ms • 5 ms • 10 ms • 20 ms • 50 ms Figure 11 - Off to On Delay Input Signal Safety Input Network Data On-delay 440 94 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 78 • 1 ms • 2 ms • 5 ms • 10 ms • 20 ms • 50 ms Figure 12 - On to Off Delay Input Signal Safety Input Network Data Off-delay 44 095 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 79: Safety Output Module Features

• Solid-state outputs • Safety outputs can be pulse-tested to detect field wiring short circuits to 24V DC • Supports field-power loss detection and configurable channel-level output state in Fault and Program modes Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 80: Output Module In Cip Safety Systems

• Safety output points are configured as the following: – Not Used – Safety – Safety Pulse Test • Safety output point shall connect to a load that draws a minimum current of 10 mA while in the “ON” state. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 81: Safety And Safety Pulse Test Mode

Refer to 5094-OB16S and 5094-OB16SXT Module Wiring Diagrams page 161 for more details about applying Safety Mode and Safety Pulse Test Mode in your application. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 82: Single-Channel Mode

Figure 13 - 5094-OB16S/5094-OB16SXT Single-channel Mode (Not to Scale) Output 0 Normal Operation Safety Output 0 Safety Network Data Status Sent to the Controller Output 0 Fault Detection Error Detected Safety Network Data Safety Output 0 Sent to the Controller Status Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 83: Dual-Channel Mode

Safety Network Data Safety Outputs 0 Sent to the Controller and 1 Status Output 0 Fault Detection Output 1 Error Detected Safety Network Data Safety Outputs 0 Sent to the Controller and 1 Status Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 84: Surge Capability Of Safety Output

= Surge time, maximum 150 msec t2 = ON time t3 - t2 = OFF time, 2 seconds Surge Current per channel = 1.8 Amperes IMPORTANT: The module current rating cannot exceed 10 Amperes at any time. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 85: Safety Output Fault Reset

After the channel clears the fault, the I/O indicator (red) turns off. The output data can now be controlled. IMPORTANT If the module outputs experience persistent high faults, consider cycling power to the module to clear the error. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 86: Fault And Status Reporting

• 5094-IB16S and 5094-IB16SXT modules - Table 32 on page 147 Table 34 on page 148 • 5094-OB16S and 5094-OB16SXT modules - • Appendix Troubleshoot Your Module on page 123. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 87: Configure The Standard Module

For detailed information about module features, see the following: Chapter Common Digital I/O Module Features on page 45 Chapter 3 Input Module Features on page 53 Chapter Output Module Features on page 57 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 88: Before You Begin

After you create a Logix Designer application project and add a FLEX 5000 Create a New Module EtherNet/IP adapter to the project, you can use the following methods to add modules to the project. • Discover Modules • New Module Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 89: Discover Modules

2. Right-click the FLEX 5000 EtherNet/IP adapter and choose Discover Modules. The Logix Designer application automatically detects available modules that are connected to the backplane. 3. At the Select Module Type window, click Create to add the discovered module to your project. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 90 • If you cleared the Close on Create check box when you created the first I/O module, repeat steps 3…6. • If you did not clear the Close on Create checkbox when you created the first I/O module, repeat steps 2…6. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 91: New Module

Discover Modules on page One exception is that, in step 1, you choose New Module instead of Discover Modules. 1. Right-click the FLEX 5000 EtherNet/IP adapter and choose New Module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 92 • If you cleared the Close on Create checkbox when you created the first I/O module, repeat steps 2…3. • If you did not clear the Close on Create checkbox when you created the first I/O module, repeat steps 1…3. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 93: Edit The Module Configuration Common Categories

FLEX 5000 digital I/O modules. You use this category to complete the following tasks: • Name the module. • Assign a slot number. (required) • Describe the module. • Access the Module Definition. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 94 (2) Controller and module establish communication without the controller sending any configuration or output data to the module. A full input data connection is established but depends on the connection between the owner-controller and the module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 95: Connection Category

• Configure whether a connection failure while the controller is in Run module causes a major or minor fault. TIP The Module Fault area of the Connection category is useful during module troubleshooting. For more information on the Module Fault area, see page 131. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 96: Module Info Category

You can use this category to complete the following: • Determine the identity of the module. • Access module diagnostics. • Refresh the data on the screen. • Reset the module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 97: Edit 5094-Ib16 Module Configuration Categories

For example, if you configure a 5094-IB16 module to use four counters, the first four terminals are not available to use as points. The number of points available on the module in this case is 12. That is, points 4…15. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 98: Points Category

Points Category The Points category shows the available input filter time values for the module points. If you choose Timestamped Data for Input Data in the Module Definition dialog box, the Points category expands. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 99 IMPORTANT You must choose the Input Data option Timestamp Data on the Module Definition dialog box to see this category in the Module Properties dialog box. Click each Ptxx to configure it as necessary for your application. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 100: Events Category

You must use the Event Output tags to configure an event. For more information, see Configure an Event in the Event Output Tags on page 101. The Events subcategories show the configuration parameters for events. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 101 Module Properties are updated automatically. For more information on module tags, see the following: • View the Module Tags on page 105 • Appendix Module Tag Definitions on page 137 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 102: Time Sync Category

The Time Sync category displays and status information about the module when the project is online. The Time Sync category displays the following information: • CIP Sync™ Time Synchronization • UTC System Time • Grandmaster Clock information • Local Clock information Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 103: Edit 5094-Ob16 Module Configuration Categories

• Output State During Fault Mode • Fault Mode Output State Duration • Fault Mode Output State Final State • Output State When Communications Fail in Program Mode • Enable No Load Diagnostics Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 104: Edit 5094-Ow8I Module Configuration Categories

• Output State During Program Mode • Output State During Fault Mode • Fault Mode Output State Duration • Fault Mode Output State Final State • Output State When Communications Fail in Program Mode Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 105: View The Module Tags

Monitor Tags. The Controller Tags dialog box appears with data. 2. To view the tags, click the symbols as shown. For more information on module tags, see Appendix Module Tag Definitions on page 137. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 106 Chapter 6 Configure the Standard Module Notes: Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 107 Safety I/O Module Features on page 71 IMPORTANT By default, all safety input and output channels on FLEX 5000 safety I/O modules are disabled. You must configure each point that is used in a safety application. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 108: Chapter 7 Before You Begin

To create a new FLEX 5000 safety I/O module, complete these steps. 1. Add a FLEX 5000 I/O EtherNet/IP adapter to the project. This example uses a 5094-AENTR or 5094-AEN2TR adapter. 2. Right-click the FLEX 5000 I/O EtherNet/IP adapter and choose New Module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 109 • If you cleared the Close on Create checkbox when you created the first I/O module, repeat steps 3…4. • If you did not clear the Close on Create checkbox when you created the first I/O module, repeat steps 2…4. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 110: Edit The Module Configuration Common Categories

You must configure each point that is used in a Safety application. The following categories apply to all FLEX 5000 digital safety I/O modules and are described in these sections: • General Category • Connection Category • Safety Category • Module Info Category Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 111: General Category

The application assigns the same SNN to additional safety modules that are added to this remote I/O system. For more information on Safety Network Numbers, see the GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference Manual, publication 1756-RM012. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 112 (1) Controller and module establish communication without the controller sending any configuration or output data to the module. A full input data connection is established but depends on the connection between the owner-controller and the module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 113: Connection Category

• With safety input data, you can choose Unicast or Multicast. • With safety output data, you must choose Unicast. For more information on unicast and multicast connections, see the EtherNet/IP Communication Modules in 5000 Series Systems User Manual, publication ENET-UM004. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 114: Safety Category

IMPORTANT Remember, the Safety Task period determines the 5094-OB16S module RPI. Need to add artwork. For more information on the RPI and the Connection Reaction Time Limit parameters, see Requested Packet Interval on page Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 115: Module Info Category

Configuration Categories • Test Output Points Category Input Points Category The Input Points category is only available if you choose This Controller for the Configured By parameter on the Module Definition dialog box. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 116: Test Output Points Category

Configured By parameter on the Module Definition dialog box. You must configure each point to use it in a safety application. The outputs are disabled by default. Need to add artwork. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 117: Edit The 5094-Ob16S Or 5094-Ob16Sxt Module

Complete the following steps to access the tags for a module. 1. In the Controller Organizer, right-click Controller Tags and choose Monitor Tags. The Controller Tags dialog box appears with data. 2. To view the tags, click the triangle symbols. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 118: Replace A Module

However, each FLEX 5000 safety I/O modules require a unique identifier within the same subnet. A DeviceID is used to uniquely identify each safety module. The SNN and module slot number make up the DeviceID of the safety module. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 119: Set The Snn Manually

Safety Network Number. 2. On the Safety Network Number dialog box, click Manual. 3. Type the SNN in the Number field and click OK. 4. On the Module Properties dialog box, click OK. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 120: Reset To Out-Of-Box Configuration

1. Right-click the module and choose Properties. 2. On the Safety tab, click Reset Ownership. 3. When a dialog box appears asking if you want to continue with the reset, read it and click Yes. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 121: Replace A Module In A Logix 5000 System

Set the SNN Manually on page 119. Reset to Out-of-Box Configuration on page 120. 2. Follow your company-prescribed procedures to functionally test the replaced I/O device and system and to authorize the system for use. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 122 3. Click the Safety tab. 4. Click Reset Ownership. 5. Click OK. 6. Follow your company-prescribed procedures to functionally test the replaced I/O module and system and to authorize the system for use. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 123 • SA Power Indicator - This indicator operates the same for all FLEX 5000 I/O modules. • Module Status Indicator - This indicator operates the same for all FLEX 5000 I/O modules. • I/O Status Indicator - This indicator operates differently based on the module type. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 124: Sa Power Indicator

– If an external power supply is used, confirm that the power supply is turned on. – If power is daisychained from the previous terminal base, confirm that the wiring on the previous terminal base is installed properly. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 125: Module Status Indicator

If a connection has timed out, determine the cause and correct it. For example, a cable failure can cause a connection timeout. Red/green (railroad) None For safety modules only - This pattern indicates that a UNID for the safety device needs to be configured. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 126: Flex 5000 Digital Input Modules Status Indicators

FLEX 5000 EtherNet/IP adapter. Steady yellow The input point is operating normally. None Flashing red A Field Power Loss condition exists. Locate and correct the cause of field power loss condition. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 127: Flex 5000 Output Modules Status Indicators

• A No Load or Short Circuit condition is • Locate and correct the cause of No Load detected. or Short Circuit condition. • A Field Power Loss condition exists. • Locate and correct the cause of Field Power Loss condition. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 128 FLEX 5000 EtherNet/IP adapter. Steady yellow The output point is operating normally. None Flashing red A Field Power Loss condition exists. Locate and correct the cause of field power loss condition. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 129: Flex 5000 Safety Input Modules Status Indicators

FLEX 5000 EtherNet/IP adapter. Steady yellow The input point is operating normally. None Flashing red • Recoverable faults. Locate and correct the cause of field power loss condition. • A Field Power Loss condition exists. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 130: Flex 5000 Safety Output Modules Status Indicators

• Locate and correct the cause of No Load or Short condition is detected. Circuit condition. • A Field Power Loss condition • Locate and correct the cause of Field Power Loss exists. condition. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 131: Use The Logix Designer Application For Troubleshooting

SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I As shown in Figure 21, a warning icon appears in the I/O Configuration tree when a fault occurs. Figure 21 - Warning Icon in Controller Organizer Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 132: Properties Categories

Module Status on General Category As shown in Figure 22, the status of a module is indicated on the General category of the Modules Properties. Figure 22 - Fault Message in Status Line Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 133 Figure 23 - Fault Description with Error Code Module Fault Descriptions on Module Info Category As shown in Figure 24, major and minor fault information is listed on the Module Info category. Figure 24 - Major and Minor Fault Information Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 134 Module diagnostics provide information on a module-wide basis. For example, the Module Diagnostics dialog box indicates the mode within which a module is operating, that is, Run, Remote Run, Remote Program, or Program. Figure 25 - Module Diagnostics Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 135 Module Properties dialog box category from which you can access point diagnostics is Points. Figure 26 shows how to access output point diagnostics on the 5094-OB16S module and the diagnostics dialog box. Figure 26 - Point Diagnostics Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 136: Logix Designer Application Tag Editor

Appendix A Troubleshoot Your Module Logix Designer Application Tag Editor Figure 27 show how fault conditions are indicated in the controller tags for the module. Figure 27 - Fault Indication in Controller Tags Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 137 The tables contained in this section list all of the tags available with a module. Not all tags in the list are used when that module type is added to a project. Tag use varies by module configuration. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 138: Appendix B Tag Name Conventions

5094-IB16 DIGITAL 16 INPUT 24 VDC 1 TB3 Safety Modules FLEX 5000 POWER STATUS 5094-IB16S SAFETY DIGITAL 16 INPUT 24 VDC 5 TB3I 3. Open the tags as necessary to view specific tags. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 139: 5094-Ib16 Module Tags

• 14 = 2 ms • 15 = 5 ms • 16 = 10 ms • 17 = 20 ms • 18 = 50 ms Ptxx.ChatterTime A value from 1…10000 ms in whole ms increments. 1…10000 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 140: Input Tags

Set to zero by product reset or power cycle. Wraps from 255 (-1) to 1 skipping zero. Counterxx.Data BOOL Indicates the current digital input value. • 0 = Off • 1 = On Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 141 If the tag is set to 1, you must troubleshoot the on page module to correct the cause of the inaccuracy. IMPORTANT : Once the condition that causes the tag to change to 1 is removed, the tag automatically resets to 0. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 142 All values. state Off to On was recorded at the input. Ptxx.TimestampOnOff LINT 64 bit Timestamp corresponding to when a change of All values. state On to Off was recorded at the input. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 143: Output Tags

When Latching is enabled and the Timestamp Number that is received from the controller matches the most recent timestamp that is produced, the module is then allowed to produce a new timestamp. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 144: Event Input Tags

Eventx.EventsPending SINT The number of events currently queued in the modules. A All positive values. value greater than 0 indicates that the controller is not currently keeping up with the rate of events. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 145: Event Output Tags

When set, events are latched until acknowledged. A new • 0 = Not latched (default) event is lost if the previous event has not been • 1 = Latched acknowledged. When not set, new events overwrite old events. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 146 Eventxx.PtxxDataValue BOOL Indicates the input value of the event point data. • 0 = Input inactive • 1 = Input active Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 147: 5094-Ib16S And 5094-Ib16Sxt Module Tags

Indicates a short circuit. • 0 = No short circuit • 1 = Short circuit Ptxx.Status BOOL Indicates the status of the channel. • 0 = Bad, causing a fault • 1 = Good Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 148: Test Output Tags

If the fault is removed, it will clear only the fault status upon detecting that the ResetFault bit in its channel sees a rising edge. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 149: 5094-Ob16 Module Tags

Ptxx.FaultValueStateDuration SINT This value determines the length of time the Fault Mode • 0 = Hold forever (default). state is held before the FaultFinalState being applied. • 1, 2, 5, or 10 seconds Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 150: Input Tags

RTB has been removed. Used • 1 = Fault with Output points. Ptxx.ShortCircuit BOOL Indicates an output short circuit or overcurrent. • 0 = No short circuit • 1 = Short circuit or overcurrent Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 151: Output Tags

Output data to be applied at time that is specified in 0 or 1 schedule. Schedulex.TimeOffset DINT Offset from schedule base time. Used for scheduled output All values. consumed tags. Base/Offset scheme that is used to fit enough schedules in the assembly. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 152: 5094-Ob16S And 5094-Ob16Sxt Module Tags

Indicates an output short circuit or overcurrent. • 0 = No short circuit • 1 = Short circuit or overcurrent Ptxx.Status BOOL Indicates the status of the channel. • 0 = Bad, causing a fault • 1 = Good Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 153: Safety Output Tags

Ptxx.FaultValueStateDuration SINT This value determines the length of time the Fault Mode • 0 = Hold forever (default). state is held before the FaultFinalState being applied. • 1, 2, 5, or 10 seconds Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... -

Page 154: Input Tags

5094-OW8I module outputs tags. Table 42 - Relay Output High Current Module Output Tags Name Data Type Definition Valid Values Ptxx.Data Indicates the current digital input value. • 0 = Off • 1 = On Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 155 The wiring configuration affects the safety application level to which a FLEX 5000 I/O safety module is suitable. IMPORTANT Conformity to requirements of the safety category and safety integrity level must be determined for the entire system. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 156: 5094-Ib16S And 5094-Ib16Sxt Module Wiring Diagrams

SIL level and Category: SIL 3, PLc, Cat. 2 SI_n(n = 0...15) Fault Exclusion: None TO_n(n = 0...7) Other: External connected device must be SIL 3 rated. Point Mode: Safety Mode TO_n SI_n Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 157 SI_n(n = 0...15) SIL level and Category: SIL 3, PLe, Cat. 4 TO_n(n = 0...7) Fault Exclusion: External Wiring fault Other: Use SIL 3/CAT 4/PLe qualified sensor. Point Mode: Safety mode TO_n SI_n or SI_n+8 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 158 SIL level and Category: SIL 3, PLe, Cat. 4 Fault Exclusion: External Wiring fault SI_n(n = 0...15) Point Mode: Safety Mode TO_n(n = 0...7) TO_n SI_n The second SI channel can be any TO_n+1 channel other than SI_n+8. SI_n+1 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 159 SIL level and Category: SIL 3, PLe, Cat. 4 Fault Exclusion: External Wiring fault SI_n(n = 0...15) Point Mode: Safety Mode TO_n(n = 0...7) TO_n SI_n Equivalent Sensor The second SI channel can be any TO_n+1 channel other than SI_n+8. SI_n+1 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 160 SIL level and Category: SIL 3, PLe, Cat. 4 Fault Exclusion: External Wiring fault SI_n(n = 0...15) Point Mode: Safety Mode TO_n(n = 0...7) TO_n SI_n Non-Equivalent Sensor The second SI channel can be any TO_n+1 channel other than SI_n+8. SI_n+1 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 161: 5094-Ob16S And 5094-Ob16Sxt Module Wiring Diagrams

Channel 0, 1 pair Channel 2, 3 pair Channel 4, 5 pair SO_n+1_RETURN Channel 6, 7 pair Channel 8, 9 pair Channel 10, 11 pair Channel 12, 13 pair Channel 14, 15 pair Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 162 SIL level and Category: SIL 3, PLe, Cat. 4 n = 0 Fault Exclusion: External Wiring fault … Other: Use IEC 60947 Safety Contactor. Channel_n Point Mode: Safety Pulse mode, Safety mode SO_n SO_n_RETURN Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 163 (SRT). Additionally, you must individually toggle each output point by the controller and user-verify that the output point changes state. For more information, refer to the safety controller manuals listed in Additional Resources on page Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

-

Page 164: Flex 5000 I/O Safety Input Module Safety Data

Spurious Trip Rate (STR) 5.68E-06 — Mean Time to Failure, Spurious (MTTF-spurious), (hours) 176037 — PFH (1/hours) 4.6523E-10 4.3173E-10 , at Mission Time of 20 years 4.0754E-05 3.7819E-05 Safety Reaction Time (SRT), (millisecond) Rockwell Automation Publication 5094-UM001C-EN-P - April 2019... - Page 165 5094-OW8I module 153 name module tag 138 Points category 98 tag editor 138 See electronic data sheet Time Sync category 102 electronic data sheet 11 troubleshooting 131 view module tag 105 electronic keying 36 Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 166 22 unicast multiple owners of input modules 22 data broadcast method 32 PCDC obtain firmware 48 PFD 11 See probability of failure on demand. PFH 11 See probability of failure per hour. Rockwell Automation Publication 5094-UM001C-EN-P - April 2019...

- Page 168 Rockwell Automation maintains current product environmental information on its website at http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page. Allen-Bradley, CompactLogix, ControlLogix, FLEX 5000, GuardLogix, Integrated Architecture, Logix 5000, Rockwell Automation, Rockwell Software, RSNetWorx, Studio 5000, and Studio 5000 Logix Designer are trademarks of Rockwell Automation, Inc.

- Page 169 FLEX 5000 Standard and Safety Digital I/O Modules User Manual...

Need help?

Do you have a question about the Allen-Bradley FLEX 5000 and is the answer not in the manual?

Questions and answers