York YVAA Installation, Operation & Maintenance Instructions Manual

Air-cooled screw liquid chillers with variable speed drive

Hide thumbs

Also See for YVAA:

- Service information (3 pages) ,

- Installation operation & maintenance (192 pages)

Table of Contents

Advertisement

Quick Links

AIR-COOLED SCREW

LIQUID CHILLERS

Supersedes: 201.28-NM1.1 (1117)

Form 201.28-NM1.1 (118)

INSTALLATION, OPERATION, MAINTENANCE

035-23219-100

MODEL YVAA STYLE A

AIR-COOLED SCREW LIQUID CHILLERS WITH

VARIABLE SPEED DRIVE

FRAME SIZES 015 - 052

150 - 500 TONS

525 - 1750 KW

2 COMPRESSOR

50 AND 60 HZ

LD15045

HFC-134A OR R-513A

Issue Date:

January 31, 2018

Advertisement

Table of Contents

Summary of Contents for York YVAA

- Page 1 AIR-COOLED SCREW LIQUID CHILLERS Supersedes: 201.28-NM1.1 (1117) Form 201.28-NM1.1 (118) INSTALLATION, OPERATION, MAINTENANCE 035-23219-100 MODEL YVAA STYLE A AIR-COOLED SCREW LIQUID CHILLERS WITH VARIABLE SPEED DRIVE FRAME SIZES 015 - 052 150 - 500 TONS 525 - 1750 KW 2 COMPRESSOR...

- Page 2 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 IMPORTANT! READ BEFORE PROCEEDING! GENERAL SAFETY GUIDELINES This equipment is a relatively complicated apparatus. which it is situated, as well as severe personal injury or During rigging, installation, operation, maintenance, death to themselves and people at the site. or service, individuals may be exposed to certain com- This document is intended for use by owner-authorized ponents or conditions including, but not limited to:...

- Page 3 YVAA Style A Frame Size 015 - 027, 2 Compressor 60 Hz (150-350 Tons) 201.28-RP1 YVAA Style A Frame Size 054 - 098, 2 Compressor 50 Hz (525-950 KW) Manufactured before April 2012 YVAA Style A Frame Size 015 - 052, 2 Compressor 50 & 60 Hz (150-500 Tons) 201.28-RP2...

- Page 4 FORM 201.28-NM1.1 ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 5: Table Of Contents

High Temperature and Pressure Cleaning .................... 16 Emergency Shutdown ...........................16 Safety Labels ............................16 SECTION 2 - PRODUCT DESCRIPTION .......................17 General System Description ........................... 17 Semi-Hermetic YORK Twin-Screw Compressors ...................19 Evaporator ..............................19 Condenser ..............................19 Refrigerant Circuit ............................19 Electrical ................................. 19 Building Automation System Capabilities ....................... - Page 6 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 TABLE OF CONTENTS (CONT'D) SECTION 4 - INSTALLATION ..........................37 Location Requirements ..........................37 Outdoor Installations ............................37 Location Clearances ............................37 Recommended Minimum Clearances ....................38 Vibration Isolators ............................39 Installation .............................39 Shipping Braces ............................. 39 Chilled Liquid Piping ............................

- Page 7 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 TABLE OF CONTENTS (CONT'D) Two Inch Deflection Isolator Installation And Adjustment ................94 Two Inch Deflection, Restrained Spring Isolator Specifications ..............95 Y2RSI-xx-xxx ............................95 SECTION 6 - COMMISSIONING ..........................97 Preparation ..............................97 Inspection .............................97 Refrigerant Charge ..........................97 Correct System Refrigerant Charge ......................

- Page 8 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 TABLE OF CONTENTS (CONT'D) Basic Operating Sequence ........................... 103 Start Sequence and Loading ....................... 103 Unit Warning ..............................103 Unit Warning Operation ........................103 Low Battery Warning ...........................103 Microboard (331-03478-xxx) ........................104 Power Supplies and LEDs ........................104 Power Supply Test Points ........................104 Configuration Jumpers ........................104 Building Automation System (BAS) Communications ..................

- Page 9 Operating Conditions ...........................161 Compressor Oil Level ..........................161 Refrigerant Charge ..........................161 Adding Charge to a System ........................ 161 Refrigerant Removal, Evacuation and Charging a YVAA Chiller ..............162 Refrigerant Removal ...........................162 Evacuating a System ...........................162 Charging Refrigerant into a System ....................163 Microchannel Coil Cleaning ..........................

- Page 10 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 LIST OF FIGURES FIGURE 1 - YVAA Air-Cooled Screw Liquid Chiller with Variable Speed Drive ............17 FIGURE 2 - Chiller Control System .........................18 FIGURE 3 - View of York Control Center User Interface ..................20 FIGURE 4 - Acceptable Minimum Clearances Around/Between Unit(s) ..............

- Page 11 TABLE 12 - Real Time Error Numbers For BAS, SC-EQ or E-Link Communications Card ........109 TABLE 13 - YVAA Native Communications Data Map ..................111 TABLE 14 - YVAA Operational and Fault / Inhibit Codes ..................114 TABLE 15 - YVAA E-Link Communications Data Map ..................115 TABLE 16 - Flash Card Update Error XXXXX ......................

- Page 12 FORM 201.28-NM1.1 ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 13: Section 1 - General Chiller Information And Safety

SECTION 1 - GENERAL CHILLER INFORMATION AND SAFETY INTRODUCTION WARRANTY YORK YVAA chillers are manufactured to the high- Johnson Controls warrants YVAA chillers in accor- est design and construction standards to ensure high dance with the "Limited Warranty Engineered Systems performance, reliability and adaptability to all types of Equipment"... -

Page 14: Quality Assurance And Safety

SECTION 1 - GENERAL CHILLER INFORMATION AND SAFETY ISSUE DATE: 1/31/2018 QUALITY ASSURANCE AND SAFETY FLUORINATED GREENHOUSE GASES YVAA chillers are designed within EN ISO 9001 and • This equipment contains fluorinated greenhouse built within an EN ISO 9002 accredited manufacturing gases covered by the Kyoto Protocol. -

Page 15: Structural Support

FORM 201.28-NM1.1 SECTION 1 - GENERAL CHILLER INFORMATION AND SAFETY ISSUE DATE: 1/31/2018 Structural Support This equipment equipped with VSD, may generate conducted and radiated disturbances, which may inter- Structural support of the unit must be provided as in- fere with or damage susceptible connected apparatus. dicated in these instructions. -

Page 16: Refrigerants And Oils

FORM 201.28-NM1.1 SECTION 1 - GENERAL CHILLER INFORMATION AND SAFETY ISSUE DATE: 1/31/2018 Refrigerants and Oils Emergency Shutdown Refrigerants and oils used in the unit are generally non- In case of emergency , the control panel is fitted with toxic, non-flammable and non-corrosive, and pose no an incoming supply circuit breaker with a red and yel- special safety hazards. -

Page 17: Section 2 - Product Description

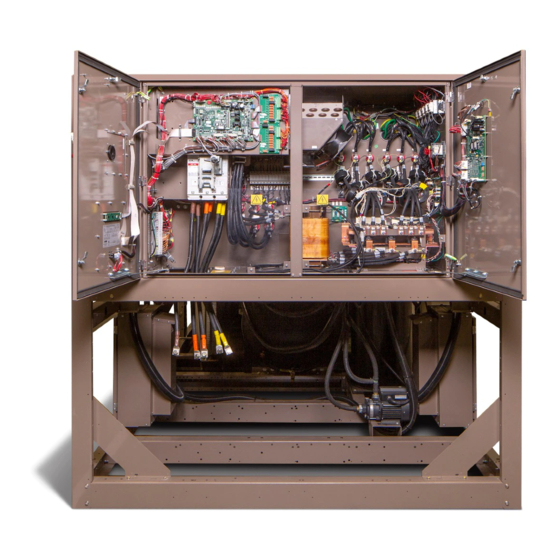

LD15045 FIGURE 1 - YVAA AIR-COOLED SCREW LIQUID CHILLER WITH VARIABLE SPEED DRIVE JOHNSON CONTROLS... -

Page 18: Figure 2 - Chiller Control System

FORM 201.28-NM1.1 SECTION 2 - PRODUCT DESCRIPTION ISSUE DATE: 1/31/2018 INPUTS OUTPUTS Pressure Transducers Relay Output Board) Temperature Sensors Switches Solenoids Liquid Flow Contactors CONTROL High Pressure Alarm PANEL Start/Stop Pump Chiller Control Level Compressor Heater Board) Run Status Customer Supplied Evaporator Heater Contacts Microprocessor... -

Page 19: Semi-Hermetic York Twin-Screw Compressors

ELECTRICAL CONDENSER Johnson Controls has over 25 years of experience de- The YVAA introduces micro-channel coil to the York signing variable -speed drives specifically for chiller screw compressor chiller line. The micro-channel max- applications. The result is an extremely reliable air-... -

Page 20: Building Automation System Capabilities

• History Data for Last Ten Shutdown Faults fined fashion. The E-Link Gateway is available as a field-installed option on YVAA. A simple switch se- Programmable Setpoints lection allows configuration of the required equipment •... -

Page 21: Accessories And Options

• Flow switch operation Condenser Coil Protection ACCESSORIES AND OPTIONS The aluminum alloys used in the YVAA micro-chan- nel condenser have been carefully selected and tested All options factory mounted unless otherwise noted. for high corrosion resistance. However, all metals can Sound Attenuation corrode in harsh conditions. -

Page 22: Evaporator Options

FORM 201.28-NM1.1 SECTION 2 - PRODUCT DESCRIPTION ISSUE DATE: 1/31/2018 End Hail Guard – Louvered panels, painted with the Building Automation System Interface (Load same color as the unit, are installed on the rear of the Limit) – Factory installed option to accept a 4 to 20mA unit (opposite end of the control panel) to protect the or a 0 to 10VDC input to allow remote reset of the Load exposed condenser from flying debris or hail. -

Page 23: Vibration Isolation

FORM 201.28-NM1.1 SECTION 2 - PRODUCT DESCRIPTION ISSUE DATE: 1/31/2018 Circuit Breaker – A unit-mounted circuit breaker with Vibration Isolation external lockable handle will be supplied to isolate the Elastomeric Isolation – This option is recommended single point power voltage for servicing. The circuit for normal installations. - Page 24 FORM 201.28-NM1.1 ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 25: Section 3 - Rigging, Handling And Storage

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 SECTION 3 - RIGGING, HANDLING AND STORAGE LD19197 Rigging and lifting should only be done by a professional rigger in accordance with a written rigging and lifting plan. The most appropriate rigging and lifting method will depend on job specific factors, such as the rigging equipment available and site needs. -

Page 26: Inspection

FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 INSPECTION Remove any transit packing and inspect the unit to ensure that all components have been delivered and that no damage has occurred during transit. If any damage is evident, it should be noted on the carrier’s freight bill and a claim entered in accordance with the instructions given on the advice note. - Page 27 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 28: Table 1 - Unit Rigging

FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1512 2937 4866 inches Rigging Hole Location 1533 3482... - Page 29 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1511 2937 4866 inches Rigging Hole Location 1533...

- Page 30 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1533 3485 5456 6919 inches Rigging Hole Location...

- Page 31 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1533 3485 5456 6919 inches Rigging Hole Location...

- Page 32 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1845 4092 6443 7763 9941 inches Rigging Hole...

- Page 33 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1845 4092 6443 7763 9941 inches Rigging Hole...

- Page 34 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1845 4602 6039 7358 11059 12135 13835 inches...

- Page 35 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 1/31/2018 LD18582 TABLE 1 - UNIT RIGGING (CONT'D) YVAA MODEL RIGGING HOLES DESCRIPTION UNITS FRAME COND EVAP inches Rigging Hole Location 1845 4602 6039 7358 11059 12135 13835 inches...

- Page 36 FORM 201.28-NM1.1 SECTION 3 - RIGGING, HANDLING AND STORAGE ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 37: Section 4 - Installation

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 SECTION 4 - INSTALLATION LOCATION REQUIREMENTS Any ductwork or attenuators fitted to the unit must not have a total static pressure resistance, at full unit air- For optimum performance and trouble-free service, it flow, exceeding the capability of the fans installed in is essential that the installation site meet the location the unit. -

Page 38: Recommended Minimum Clearances

SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 Recommended Minimum Clearances TABLE 2 - MINIMUM EVAPORATOR TUBE REMOVAL CLEARANCE Recommended clearances for the YVAA units are: TUBE REMOVAL • Side to wall – 6' (1.8 m) MODEL YVAA CLEARANCE DIMENSIONS • Rear to wall – 6' (1.8 m) FRAME COND EVAP IN. -

Page 39: Vibration Isolators

"Maximum Tube Side heat exchanger without disrupting flow to other units. Pressure" of Pressure Vessel Name Plate for YVAA and YVFA with Falling Film Thermometer and pressure gauge connections should Evaporator. be provided on the inlet and outlet connections of each The liquid must enter the evaporator at evaporator. -

Page 40: Evaporator Pressure Drop

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 The liquid pump(s) may also be used to ensure liquid The installer/user must also ensure that the quality of the water in circulation is is circulated when the ambient temperature approaches adequate, without any dissolved gases, freezing point. -

Page 41: Water Treatment

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 Evaporator C Evaporator B Evaporator E Evaporator A Water Flow Rate (l/s) LD15147 FIGURE 6 - TWO PASS WATER PRESSURE DROP, SI UNITS PIPEWORK ARRANGEMENT WATER TREATMENT The following is a suggested piping arrangement for The unit performance provided in the Design Guide single unit installations. -

Page 42: Minimum Water Volume

SUPPLY TO LOAD LEAVING WATER TEMPERATURE OUT OF RETURN FROM LOAD RANGE The YVAA chiller line has a maximum leaving water LOAD temperature of 15.6°C (60°F). Where process applica- LD15049 tions require a chilled water temperature higher than what the chiller provides, a simple piping change can remove the problem. -

Page 43: Thermal Storage

The YVAA has special control logic to be able to pro- duce chilled leaving brine temperatures below 4.4°C (40°F) so as to supply a storage tank with chilled liquid during times of low demand. -

Page 44: Table 3 - Evaporator Connections Dimensions

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 3 - EVAPORATOR CONNECTIONS DIMENSIONS FLANGE DIMENSIONS (GB ONLY) IN MM* VICTAULIC NOMINAL FRAME COND. EVAP. CONNECTIONS DIAMETER SIZE 6" DN150 170.5 241.5 6" DN150 170.5 241.5 6" DN150 170.5 241.5 6"... -

Page 45: Option Flanges

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 4" / 6" / 8" FLANGE 10" FLANGE LD16185a FIGURE 12 - FLANGE FOR GB VESSELS The size of any piping attached to a relief valve must Option Flanges be of sufficient diameter so as not to cause resistance to One of two types of flanges may be fitted depending the operation of the valve. -

Page 46: Power Wiring

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 After power wiring connection, do not POWER SUPPLY WIRING switch on mains power to the unit. Some • Units require only one 3-phase supply, plus earth. internal components are live when the mains are switched on and this must •... -

Page 47: Volts Free Contacts

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 VOLTS FREE CONTACTS Remote Run / Stop A Remote Run/Stop input is available for each systems. Chilled Liquid Pump Starter These inputs require a dry contact to start and stop the Terminals 23 and 24 on 1TB close to start the chilled system. -

Page 48: Power Supply Wiring

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 POWER SUPPLY WIRING Single Point Wiring LD18588 Voltage Utilization Range Minimum Circuit Ampacity (MCA), Minimum/Maximum Fuse Size and RATED UTILIZATION RANGE Minimum/Maximum Circuit Breaker size VOLTAGE varies on chillers based upon model and 200/60/3 180-220 options ordered. -

Page 49: Dual Point Wiring

FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 Dual Point Wiring LD18589 FIGURE 15 - DUAL POINT POWER WIRING JOHNSON CONTROLS... -

Page 50: Customer Control Wiring

+ SIGNAL INPUT CONTACTS - SIGNAL INPUT (GND) CHILLER LEGEND TERMINAL BLOCK FOR CUSTOMER CONNECTIONS TERMINAL BLOCK FOR YORK CONNECTIONS WIRING AND COMPONENTS BY YORK OPTIONAL EQUIPMENT WIRING AND/OR COMPONENTS BY OTHERS FIGURE 16 - CUSTOMER CONTROL CONNECTIONS JOHNSON CONTROLS... - Page 51 FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 52: Table 4 - Electrical Lug Data

SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA STANDARD & ULTRA QUIET CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRES WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ... - Page 53 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) HIGH AIRFLOW/HIGH STATIC CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ...

- Page 54 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) STANDARD & ULTRA QUIET CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRES WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ...

- Page 55 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) HIGH AIRFLOW/HIGH STATIC CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE FRAME COND EVAP VOLTS...

- Page 56 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) STANDARD & ULTRA QUIET CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRES WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ...

- Page 57 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) HIGH AIRFLOW/HIGH STATIC CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE FRAME COND EVAP VOLTS...

- Page 58 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) STANDARD & ULTRA QUIET CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRES WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ...

- Page 59 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) HIGH AIRFLOW/HIGH STATIC CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE FRAME COND EVAP VOLTS...

- Page 60 ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) STANDARD & ULTRA QUIET CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE FRAME COND EVAP VOLTS...

- Page 61 SECTION 4 - INSTALLATION ISSUE DATE: 1/31/2018 TABLE 4 - ELECTRICAL LUG DATA (CONT'D) HIGH AIRFLOW/HIGH STATIC CONDENSER FANS FIELD WIRING LUGS TERMINAL CIRCUIT NON-FUSED BLOCK BREAKER DISCONNECT SWITCH YVAA MODEL WIRE WIRES WIRES INPUT INPUT WIRE WIRE WIRE VOLTS FREQ...

- Page 62 FORM 201.28-NM1.1 SECTION 4 - INSTALLATION ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 63: Section 5 - Technical Data

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 SECTION 5 - TECHNICAL DATA NOMENCLATURE YVAA 021 3AXX 46 AA : York : Condenser code : 200 / 3 / 60 : Development Level A : Refrigerant R134a : Variable Speed : Evaporator code... -

Page 64: Table 5 - Physical Data - Microchannel Coil

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 The data shown in this table is applicable to select- Please contact your nearest Johnson Controls Sales ed typical configurations. Other configurations are Office for the chiller configuration that best matches available through our configuration/selection software. - Page 65 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 5 - PHYSICAL DATA - MICROCHANNEL COIL (CONT'D) UNIT FRAME CONDENSER CODE EVAPORATOR CODE GENERAL UNIT DATA Number of Independent Refrigerant Circuits Refrigerant Charge, 210/190 250/225 250/250 210/210 250/250 265/265 265/265 270/270...

- Page 66 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 5 - PHYSICAL DATA - MICROCHANNEL COIL (CONT'D) UNIT FRAME CONDENSER CODE EVAPORATOR CODE GENERAL UNIT DATA Number of Independent Refrigerant Circuits Refrigerant Charge, R-134a, 295/250 315/275 315/295 295/295 290/290 310/310 315/315...

- Page 67 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 5 - PHYSICAL DATA - MICROCHANNEL COIL (CONT'D) UNIT FRAME CONDENSER CODE EVAPORATOR CODE GENERAL UNIT DATA Number of Independent Refrigerant Circuits Refrigerant Charge, R-134a, 470/310 475/360 460/345 480/365 475/385 370/370 445/445...

-

Page 68: Table 6 - Physical Data - Round Tube Coil

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 6 - PHYSICAL DATA - ROUND TUBE COIL UNIT FRAME CONDENSER CODE EVAPORATOR CODE GENERAL UNIT DATA Number of Independent Refrigerant Circuits Refrigerant Charge, R-134a, 211/211 229/191 241/241 229/229 273/235 273/273 304/304... - Page 69 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 6 - PHYSICAL DATA - ROUND TUBE COIL (CONT'D) UNIT FRAME CONDENSER CODE EVAPORATOR CODE GENERAL UNIT DATA Number of Independent Refrigerant Circuits Refrigerant Charge, R-134a, 367/367 371/371 391/391 537/308 568/417 478/478...

-

Page 70: Table 7 - Optional One-Pass Evaporator

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 7 - OPTIONAL ONE-PASS EVAPORATOR ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME. WATER FLOW WATER FLOW SIZE GALLONS RATE RATE (LITERS) GPM (L/S) GPM (L/S) 20.8... - Page 71 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 7 - OPTIONAL ONE-PASS EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME. WATER FLOW WATER FLOW SIZE GALLONS RATE RATE (LITERS) GPM (L/S) GPM (L/S) 20.8...

- Page 72 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 7 - OPTIONAL ONE-PASS EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME. WATER FLOW WATER FLOW SIZE GALLONS RATE RATE (LITERS) GPM (L/S) GPM (L/S) 166.9...

- Page 73 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 7 - OPTIONAL ONE-PASS EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME. WATER FLOW WATER FLOW SIZE GALLONS RATE RATE (LITERS) GPM (L/S) GPM (L/S) 23.3...

-

Page 74: Table 8 - Standard Two-Pass, Rear Inlet/Outlet Evaporator

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 8 - STANDARD TWO-PASS, REAR INLET/OUTLET EVAPORATOR ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME WATER WATER SIZE GALLONS FLOW RATE FLOW RATE (LITERS) - Page 75 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 8 - STANDARD TWO-PASS, REAR INLET/OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME WATER WATER SIZE GALLONS FLOW RATE FLOW RATE...

- Page 76 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 8 - STANDARD TWO-PASS, REAR INLET/OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MAXIMUM MINIMUM WATER CHILLED CHILLED E- NOZZLE VOLUME WATER WATER SIZE GALLONS FLOW FLOW RATE...

- Page 77 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 8 - STANDARD TWO-PASS, REAR INLET/OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MAXIMUM MINIMUM WATER CHILLED CHILLED E- NOZZLE VOLUME WATER WATER SIZE GALLONS FLOW FLOW RATE...

-

Page 78: Table 9 - Optional Three-Pass Rear Inlet/Front Outlet Evaporator

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 9 - OPTIONAL THREE-PASS REAR INLET/FRONT OUTLET EVAPORATOR ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E- NOZZLE VOLUME WATER FLOW WATER SIZE GALLONS RATE FLOW RATE... - Page 79 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 9 - OPTIONAL THREE-PASS REAR INLET/FRONT OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E- NOZZLE VOLUME WATER FLOW WATER SIZE GALLONS RATE...

- Page 80 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 9 - OPTIONAL THREE-PASS REAR INLET/FRONT OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME WATER FLOW WATER SIZE GALLONS RATE FLOW RATE...

- Page 81 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 9 - OPTIONAL THREE-PASS REAR INLET/FRONT OUTLET EVAPORATOR (CONT'D) ALL DIMENSIONS - INCHES (MM) YVAA MINIMUM MAXIMUM WATER CHILLED CHILLED E-NOZZLE VOLUME WATER FLOW WATER SIZE GALLONS RATE FLOW RATE...

-

Page 82: Figure 17 - Yvaa Dimensions

11.5" (292 mm) HIGH 13" (330 mm) HIGH 1.5" 3.0" 120" (38 mm) (305 mm) (75 mm) VSD / CONTROL PANEL VIEW B-B VIEW A-A 60.0" (1524 mm) 14.1" (359 mm) 47.4" (1204 mm) FIGURE 17 - YVAA DIMENSIONS JOHNSON CONTROLS... - Page 83 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 84: Table 10 - Isolator Selection And Mounting Locations

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 LD18587 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (1852) (3662) (4900) Isolator Y-Dimension 1 (34) Isolator X-Dimension (263) (1943) (3000) - Page 85 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 LD18587 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS (CONT'D) YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (1852) (3662) (4900) Isolator Y-Dimension 87 (2206) Isolator X-Dimension (263) (1943)

- Page 86 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS (CONT'D) YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (1943) (2999) (3984) (5298) (7823) Isolator Y-Dimension 1 (34) Isolator X-Dimension (263)

- Page 87 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS (CONT'D) YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (1943) (2999) (3984) (5298) (7823) Isolator Y-Dimension 87 (2206) Isolator X-Dimension (263)

- Page 88 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS (CONT'D) YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (2057) (3680) (5219) (7218) (10842) Isolator Y-Dimension 1 (34) Isolator X-Dimension (263)

- Page 89 FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TABLE 10 - ISOLATOR SELECTION AND MOUNTING LOCATIONS (CONT'D) YVAA CONFIGURATION DESCRIPTION FRAME COND EVAP Isolator X-Dimension (263) (2057) (3680) (5219) (7218) (10842) Isolator Y-Dimension 87 (2206) Isolator X-Dimension (263)

-

Page 90: Elastomeric Isolator Installation

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 ELASTOMERIC ISOLATOR INSTALLATION TOP BOLT TOP WASHER SECTION D-D SECTION D-D LD13762C Read the following instructions before beginning 3. Bolt or anchor all isolators to supporting structure installation. utilizing base thru holes (B). 1. -

Page 91: Elastomeric Isolator Specifications

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 ELASTOMERIC ISOLATOR SPECIFICATIONS MOLDED DURULENE MOLDED DURULENE Ø = AD Thru Typ 2 Places R = 0.280 Slot Typ 2 Places LD17304 DIMENSION DATA (INCHES) MOUNT TYPE RD1-WR 3.13 1.75 1.25 2.38 0.34... -

Page 92: One Inch Deflection Isolator Installation

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 ONE INCH DEFLECTION ISOLATOR INSTALLATION EQUIPMENT POSITIONING BASE UPPER PIN (H) HOUSING 0.25” min - 0.5” max LOWER HOUSING NON-SKID ELASTOMERIC 4. Place equipment on top of isolators making sure Read the following instructions before beginning that mounting holes of the equipment line up with installation. -

Page 93: One Inch Deflection Spring Isolator Specifications

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 ONE INCH DEFLECTION SPRING ISOLATOR SPECIFICATIONS CPX-xx-xxx 5/8" H" C" T" B" L" D" W" DIMENSION DATA (INCHES) MOUNT TYPE 7-3/4 6-1/2 4-3/4 5-5/8 10-1/2 9-1/4 7-3/4 9/16 RATED CAPACITY (FOR UNITS WITH ALL LOAD POINTS LESS THAN 1785 LBS (810 KG) MODEL NUMBER COLOR CODE... -

Page 94: Two Inch Deflection Isolator Installation And Adjustment

FORM 201.28-NM1.1 SECTION 5 - TECHNICAL DATA ISSUE DATE: 1/31/2018 TWO INCH DEFLECTION ISOLATOR INSTALLATION AND ADJUSTMENT ("G") ("E") ("A") ("E") ("A") GROMMET 1/4 - 3/8 GAP EQUIPMENT ("F") WASHER ("E") ("F") ("C") ("C") ("B") Read the following instructions before beginning 6. -

Page 95: Two Inch Deflection, Restrained Spring Isolator Specifications

8-3/8" OPER. HEIGHT 12-1/4" 14" 3-1/2" 3/8" 5" MODEL NUMBER WEIGHT RANGE (LBS) WEIGHT RANGE (KGS) YORK P/N Y2RSI-2D-460 Up thru 391 UP TO 177 029-25336-006 Y2RSI-2D-710 392 thru 604 178 - 274 029-25336-008 Y2RSI-2D-870 605 thru 740 275 - 336... - Page 96 FORM 201.28-NM1.1 ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 97: Section 6 - Commissioning

If no pressure is present, a Compressor Oil leak test must be undertaken, the leak(s) located and To add oil to a circuit - connect a YORK hand oil pump repaired. (Part No. 470-10654-000) to the 1/4" (6.35 mm) oil... -

Page 98: Fans

FORM 201.28-NM1.1 SECTION 6 - COMMISSIONING ISSUE DATE: 1/31/2018 High oil concentration in the system may cause Unit Maintenance Shutdown nuisance trips resulting from incorrect readings on the Sub-freezing Conditions on Page 100. Before placing level sensor and temperature sensors. Temperature the unit back in service, valves should be opened and power sensor errors may result in poor liquid control which must be switched on (if power is removed for more than... -

Page 99: Setpoint And Remote Offset

FORM 201.28-NM1.1 SECTION 6 - COMMISSIONING ISSUE DATE: 1/31/2018 Setpoint and Remote Offset Oil Pressure Set the required leaving chilled liquid temperature When a compressor starts, press the relevant “System setpoint and Control Range under the SETPOINTS key. Pressures” key and verify that oil differential pressure The chilled liquid temperature control settings need to (oil pressure-suction pressure) develops immediately. -

Page 100: General Operation

Sub-freezing Conditions After completion of the above checks for System 1, If the YVAA is maintained or shut down and will be switch OFF the SYS 1 switch on the keypad and repeat subjected to sub-freezing conditions, it is critical to the process for each subsequent system. -

Page 101: Section 7 - Operation

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 SECTION 7 - OPERATION OPERATING CONTROLS The keypad also contains keys in the center section for data entry in the various program modes. These keys DISPLAY are listed below: • 0-9 Keys NUMERIC KEYPAD • PERIOD/DECIMAL •... -

Page 102: Keypad Data Entry Mode

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 The ◄ ► (LEFT and RIGHT ARROW) keys allow XXXXXXXXXXX PRESS TO ACCEPT VALUE OR scrolling between non-numeric program choices under X TO CANCEL DATA ENTRY the OPTION, DATE/TIME, and SCHEDULE keys. If the ... -

Page 103: Evaporator Heater Control

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 Evaporator Heater Control Remote Run / Stop The evaporator heater is controlled by ambient A Remote Run/Stop input is available for each system. air temperature. If no systems are running and the BASIC OPERATING SEQUENCE ambient temperature drops below 4.4 °C (40°F), the heater is turned ON. -

Page 104: Microboard (331-03478-Xxx)

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 POWER – On solid indicates that the base board +12V UNIT WARNING: !! LOW BATTERY !! and +5V power supplies are operational. CHECK SETPOINTS/PROGRAM/OPTIONS/TIME TX1 – Red LED flashes when transmitting data out If a low battery condition exists, all programmed Port 1 TB3 (Future native communications BAS port). -

Page 105: Figure 19 - New 331-03478-Xxx Microboard

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 LD19331 DESC DESC DESC DESC Port 2 Port 1 TP3 +5V Power LED Native BAS RX2, TX2 PORT 2 RS-232 TP2 +3.3V Status LED TP1 GND Printer or Modbus VSD RX SD Card Power LED TP4+12V... -

Page 106: Building Automation System (Bas) Communications

To setup the BACNET MS/TP Port 1, follow the I/O Board as shown in Figure 19 on page 105. steps below: 2. Set up the YVAA Port 1 (P1) for N2 Communica- 1. Connect the BACnet MS/TP Network to Port 1 on tions. -

Page 107: E-Link Or Sc-Eq Interface

IPU II I/O Board as shown in Figure 19 on page 1. Press the PROGRAM key once. 105. 2. Enter the password 5255. 2. Set up the YVAA Port 2 (P2) for YorkTalk 2 3. Press the (ENTER) key to display the Port 1 Communications. (P1) settings. -

Page 108: Table 11 - Values Required For Bas Communication

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 The table below shows set-up requirements for each communication protocol. TABLE 11 - VALUES REQUIRED FOR BAS COMMUNICATION Protocol SETTING DESCRIPTION BACnet MS/TP Modbus RTU YorkTalk2 DE MODIFIER ADDRESS 0 to 41943 DE MODIFIER OFFSET 0 to 99 P1 PROTOCOL... -

Page 109: Table 12 - Real Time Error Numbers For Bas, Sc-Eq Or E-Link Communications Card

DE modifier address is set to -1. GET PACKET FAILED The most current data map information GET TYPE FAILED is listed on the Johnson Controls/York INVALID UNIT CONVERSION Chiller Equipment Integration website. A INVALID HARDWARE SELECTION... -

Page 110: Sc-Eq Or E-Link Bas Communications Card

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 SC-EQ OR E-LINK BAS COMMUNICATIONS Transmitted Data CARD After receiving a valid transmission from the SC-EQ or E-Link, the chiller will transmit either operational data Received Data (Control Data) or history buffer data depending on the History Buffer The chiller receives eight data values from the SC-EQ or Request, ENG PAGE 10, found in Table 13 on page E-Link. -

Page 111: Table 13 - Yvaa Native Communications Data Map

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 13 - YVAA NATIVE COMMUNICATIONS DATA MAP JOHNSON CONTROLS... - Page 112 FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 13 - YVAA NATIVE COMMUNICATIONS DATA MAP (CONT'D) JOHNSON CONTROLS...

- Page 113 FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 13 - YVAA NATIVE COMMUNICATIONS DATA MAP (CONT'D) JOHNSON CONTROLS...

-

Page 114: Table 14 - Yvaa Operational And Fault / Inhibit Codes

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 14 - YVAA OPERATIONAL AND FAULT / INHIBIT CODES Code Value Operational Code Code Value Fault/Inhibit Code Manual Override No Fault Code Daily Schedule Shutdown Low Ambient Temperature Unit Switch OFF... -

Page 115: Table 15 - Yvaa E-Link Communications Data Map

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 15 - YVAA E-LINK COMMUNICATIONS DATA MAP JOHNSON CONTROLS... - Page 116 FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 15 - YVAA E-LINK COMMUNICATIONS DATA MAP (CONT'D) JOHNSON CONTROLS...

- Page 117 FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 15 - YVAA E-LINK COMMUNICATIONS DATA MAP (CONT'D) JOHNSON CONTROLS...

-

Page 118: Vsd

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 9. After the update is completed and the controller reboots, the keypad and display will return to full- J2 VSD#1 and J1 VSD#2 connections headers for functionality. The SD card may be left in place for RS-485 communications to the Variable Speed datalogging or else replaced with another SD card Drive(s). -

Page 119: Invalid Number Of Compressors Warning

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 Follow all JCI Safety Directives when in- Once the file is read in to Excel, you can hide unrelated serting or removing the SD card since the columns or plot desired parameters to analyze the data. card is located inside the control cabinet. -

Page 120: Unit Safeties

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 UNIT SAFETIES Low Ambient Temp Fault If the ambient temperature falls below the program- Unit Safety Operation mable Low Ambient Temp Cutout the chiller will Unit faults are safeties that cause all running compres- shut down with a controlled ramped shutdown. -

Page 121: System Safeties (Faults)

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 and have been successfully initialized, the Chiller and these faults will be recorded as such under the Control Board will not request them again. If the com- HISTORY information stored at the instant of the pri- ms connection fails to occur and a reply from the VSD mary fault. -

Page 122: Low Suction Pressure Cutout (Software) Fault

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 The HPCO is wired in series with the VSD Run 30 seconds, the suction pressure does not stay above Signal and will only be checked by the Chiller the ramped cutout, which ramps between 10% of the Control Board when the system is running. -

Page 123: High Discharge Temperature Cutout Fault

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 push oil through the oil cooling circuit and through the SYS X YYYYYYYY HIGH DISCHARGE TEMP internal compressor lubrication system. The Status dis- play fault message for this safety is shown below: The X indicates the system and YYYYYYY indicates the system is in a “FAULT”... -

Page 124: Suction Pressure Load Limiting/Unloading

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 TABLE 19 - DISCHARGE PRESSURE LOAD TABLE 20 - SUCTION PRESSURE LOAD LIMITING/ LIMITING/UNLOADING UNLOADING DISCHARGE PRESSURE UN-LOADING SUCTION PRESSURE UN-LOADING Discharge Pressure Cutout- 20 Suction Pressure is between PSIG and Discharge Pres- 0 Hz Cutout +2 PSIG and Suc- 0 Hz... -

Page 125: High Motor Temperature Cutout Fault

FORM 201.28-NM1.1 SECTION 7 - OPERATION ISSUE DATE: 1/31/2018 The start inhibit thresholds for each sensor are shown The safety will “not” shut down a system if the UNIT in the following table. switch is OFF, which electrically removes the 115VAC to “all”... - Page 126 FORM 201.28-NM1.1 ISSUE DATE: 10/12/2017 THIS PAGE INTENTIONALLY LEFT BLANK JOHNSON CONTROLS...

-

Page 127: Section 8 - Micropanel

UNIT STATUS When power is first applied to the control panel, the MANUAL OVERRIDE following message displaying York International Cor- poration, the EPROM version, date, and time will be This message indicates the chiller is operating in displayed for 2 seconds, followed by the appropriate MANUAL OVERRIDE mode. - Page 128 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 message will be displayed on the lag system until the UNIT STATUS loading sequence is ready for the lag system to start. UNIT SWITCH OFF SHUTDOWN This message indicates the UNIT SWITCH is in the SYS X COOLING DEMAND SHUTDOWN OFF position and not allowing the unit to run.

- Page 129 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The VSD Internal Ambient Temp Limiting message SYS X PULLDOWN MOTOR CURRENT LIMITING indicates the VSD internal ambient temp is high and load limit or unloading is in effect. The pulldown motor current limiting message indicates the pulldown motor current load limit or pulldown SYS X SOUND LIMITING motor current unloading is in effect based on the...

- Page 130 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 UNIT DATA KEY UNIT DATA LD10605 General The UNIT DATA key provides the user with displays UNIT TEMP ERROR = XXX.X °F of unit temperatures, and unit related data. Displays RATE = XXX.X °F/M can be selected by repeatedly pressing the UNIT DATA key or the▲...

- Page 131 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The types of remote control are listed as follows: The next key press displays the sound limit values as set under the PROGRAM key by the Local, ISN, and the • NONE - No remote control is actively controlling Remote Sound Limit Inputs.

- Page 132 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 SYSTEM DATA KEYS 1 THROUGH 4 SYSTEM 1 DATA KEY SYSTEM 2 DATA KEY SYSTEM 3 DATA KEY SYSTEM 4 DATA KEY LD10605 General The next key press displays system oil and eductor temperatures.

- Page 133 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 If any motor temp sensor is being ignored, The next key press will indicate the state of the (selectable under Unit Set-up Mode), optional VI solenoids where XXX indicates ON or that sensor’s value will be displayed as OFF.

-

Page 134: Table 22 - Sensor Min/Max Outputs

FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 Sensor Displays Table 22 on page 134 lists all the sensors attached If values exceed the limits in the table, a < (less than) or > (more than) sign will be display along with the to the control board associated with system data keys. - Page 135 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 VSD DATA KEY DATA KEY LD10605 General The next key press displays DC Bus voltage. The VSD DATA key provides the user with displays of VSD temperatures, voltages, currents, and other oper- DC BUS VOLTAGE = XXX VDC ating data.

-

Page 136: Table 23 - Compressor Motor Overload Settings

FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 TABLE 23 - COMPRESSOR MOTOR OVERLOAD SETTINGS 380V-60HZ 400V-50HZ 460V-60HZ (see note 1) MODEL SYS # 1 SYS # 2 SYS # 1 SYS # 2 SYS # 1 SYS # 2 50/60 HZ TONS 50/60 HZ KW OL SETTING OL SETTING OL SETTING OL SETTING OL SETTING OL SETTING YVAA0153 YVAA0543... - Page 137 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 OPERATING HOURS / START COUNTER KEY OPERATING HOURS/ START COUNTER LD10605 Compressor operating hours and compressor starts are A single display is available under this key and is dis- displayed with a single key press. The maximum value played below.

- Page 138 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 HISTORY KEY HISTORY LD10605 History Key Operation XX is the normal shutdown number. The display will provide date and time of the shutdown and the reason The HISTORY key provides the user access to many for the cycling shutdown (YYY….).

- Page 139 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The operator can view any of the stored 10 fault history All Fault Data buffers. History buffer number 1 provides the most re- FAULT HIST XX ALL FAULTS ZZ OF WW cent safety shutdown information and buffer number YYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYYY 10 is the oldest safety shutdown information saved.

- Page 140 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 Load / Unload Timers VSD Data UNIT LOAD TIMER = XXX SEC VSD Actual and Command Frequency UNLOAD TIMER = XXX SEC VSD FREQUENCY ACTUAL = XXX.X HZ COMMAND = XXX.X HZ This message indicates remaining time on the load and unload timers at the time of the fault.

- Page 141 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 Precharge Signal Status and VSD Cooling Compressor Speed and Heater Status Status SYS 1 COMPRESSOR SPEED = XXX.X % HEATER = XXX.X °F PRECHARGE SIGNAL = XXX This message indicates the compressor speed in % and the heater status at the time of the fault.

- Page 142 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 Compressor #1 Run Time Maximum Remote Temperature Setpoint SYS 1 RUN TIME SETPOINTS XX DAYS XX HOURS XX MINUTES XX SECONDS MAXIMUM REMOTE TEMP RESET = XXX.X °F This message displays the system run time since the This message displays the maximum remote reset pro- last start in days, hours, minutes, and seconds at the grammed at the time of the fault.

- Page 143 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 System Lead/Lag Control Mode Low Ambient Cutout OPTIONS LEAD / LAG CONTROL MODE PROGRAM ◄ ► XXXXXXXXXXXXXXXXXXXXX LOW AMBIENT TEMP CUTOUT = XXX.X °F This message indicates the type of lead lag control se- This message displays the low ambient temp cutout lected at the time of the fault.

- Page 144 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 Sound Limit Setpoint Eductor Safety Time PROGRAM ◄DEF XXXXX LO XXXXX HI XXXXX PROGRAM EDUCTOR SAFETY TIME = XXX MIN SOUND LIMIT SETPOINT = XXX % This message indicates the eductor safety time pro- This indicates the sound limit setpoint programmed at grammed at the time of the fault.

- Page 145 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 SETPOINTS KEY SETPOINTS LD10605 Setpoints Key Operation SETPOINTS REMOTE SETPOINT = XXX.X °F Cooling setpoints and ranges may be programmed by REMOTE CONTROL RANGE = +/- X.X °F pressing the SETPOINTS key. The first setpoint en- If there is no remote setpoint being utilized, the remote try screen will be displayed as shown below.

-

Page 146: Table 24 - Setpoint Limits

FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The ▲ (ARROW) key allows scrolling back through The minimum, maximum, and default values the setpoints displays. allowed under the SETPOINTS key are provided in Table 24 on page 146. TABLE 24 - SETPOINT LIMITS PROGRAM VALUE MODE LOW LIMIT... - Page 147 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 PROGRAM KEY PROGRAM LD10605 Suction Pressure Cutout Program Key Operation Various operating parameters are programmable by the PROGRAM ◄DEF XXXXX LO XXXXX HI XXXXX user. These are modified by pressing the PROGRAM SUCTION PRESSURE CUTOUT = XXX.X PSIG key and then the ...

- Page 148 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 pulldown limiting for a defined period of time for the Low Ambient Cutout purpose of peak time energy savings. The pulldown PROGRAM ◄DEF XXXXX LO XXXXX HI XXXXX limit point is programmable from 0 to 255 with a LOW AMBIENT TEMP CUTOUT = XXX.X °F default of 0 Min.

-

Page 149: Table 25 - Programmable Operating Parameters

FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The programmed temperature assures the micro will Motor Temperature Unload sense a loss of educator oil flow, if the temperature dif- PROGRAM ◄DEF XXXXX LO XXXXX HI XXXXX ferential rises. A small differential of 2.8°C (5.0°F) is MOTOR TEMPERATURE UNLOAD = XXX °F recommended. - Page 150 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 OPTIONS KEY OPTIONS LD10605 Options Key Operation Chilled Liquid Cooling Mode Selection The OPTIONS key provides the user with a display of The Chilled liquid cooling mode can be selected for unit configuration and the capability to modify the con- Water Cooling or low temperature Glycol Cooling.

- Page 151 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 OPTIONS LEAD / LAG CONTROL MODE OPTIONS LOCAL / REMOTE CONTROL MODE ◄ ► AUTOMATIC ◄ ► XXXXXXXXXXXXXXXXXX When LOCAL CONTROL mode is selected, chilled The default mode will be AUTOMATIC. liquid control is from the keypad of the chiller.

- Page 152 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 OPTIONS REMOTE SOUND LIMIT INPUT OPTIONS REMOTE CURRENT LIMIT INPUT ◄ ► 0.0 TO 10.0 VOLTS DC ◄ ► 0.0 TO 10.0 VOLTS DC OPTIONS REMOTE SOUND LIMIT INPUT OPTIONS REMOTE CURRENT LIMIT INPUT ◄...

- Page 153 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 DATE/TIME AND SCHEDULE KEYS DATE/TIME SCHEDULE LD10605 Date/Time Key Operation CLOCK FRI 18-JUN-2011 10:15:33 AM When the DATE/TIME key is pressed, the chiller mi- DAY OF MONTH = XX croprocessor will display the date and the time. This Pressing the ▼...

- Page 154 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The month can be selected by scrolling through the Pressing the ▼ (DOWN ARROW) key again scrolls to months with the ◄ or ►arrow keys. After the month is the time format selection: selected, the ...

- Page 155 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 The HOLIDAY SCHEDULE is a tem- the (ENTER) key. The cursor will then move to the porary schedule. Once the schedule is AM/PM selection. The meridian (AM/PM) value may executed, the selected holidays will be be changed by the ◄...

- Page 156 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 MANUAL OVERRIDE KEY MANUAL OVERRIDE LD10605 Manual Override Key Operation the STATUS display mode. Therefore, do not expect to see any other STATUS messages when in the MANUAL If the MANUAL OVERRIDE key is pressed during a OVERRIDE mode.

-

Page 157: Table 26 - Printout Types

FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 PRINT KEY PRINT LD10605 Print Key Operation The following table shows the available printout types. The PRINT key is used to initiate a printout of cur- TABLE 26 - PRINTOUT TYPES rent operating data (real time data), a complete history printout of all history (fault) buffers, a printout of all PRINTOUT TYPES... - Page 158 OPERATING HOURS 1=XXXXX, 2=XXXXX START COUNTER 1=XXXXX, 2=XXXXX Operating Data Printout YORK INTERNATIONAL CORPORATION SOFTWARE VERSION C.ACS.XX.00 VSD DATA YVAA SCREW CHILLER ACTUAL FREQUENCY XXX.X HZ OPERATING DATA COMMAND FREQUENCY XXX.X HZ 2:04:14 PM 30 DEC 11 SYS 1 DC BUS VOLTAGE...

- Page 159 FLASH TANK LEVEL < 512 ADC COND DRAIN % OPEN XXX.X% YORK INTERNATIONAL CORPORATION ECONOMIZER % OPEN XXX.X% YVAA SCREW CHILLER CONDENSER FANS ON HISTORY NUMBER 1 CONDENSER FAN SPEED XXX% (vsd) 2:04:14 PM 30 APR 11 COMPRESSOR HEATER...

- Page 160 FORM 201.28-NM1.1 SECTION 8 - MICROPANEL ISSUE DATE: 1/31/2018 SYSTEM SWITCHES KEY SYSTEM SWITCHES LD10605 The ◄ (LEFT ARROW) or ► (RIGHT ARROW) System Switches Key Operation keys allow scrolling through the choices of: The SYSTEM SWITCHES key allows the operator to turn individual systems ON and OFF.

-

Page 161: Section 9 - Maintenance

If in any doubt, contact your lo- needs to be added, see Refrigerant Re- cal Johnson Controls Service Agent. moval, Evacuation and Charging a YVAA Unit Status Chiller on Page 162 in this section. Use the valve on the liquid line for adding the Press the ‘STATUS’... -

Page 162: Refrigerant Removal, Evacuation And Charging A Yvaa Chiller

Throttle the flow as needed with the Refrigerant Removal manifold gauge valves to prevent pressures from The YVAA utilizes a flooded evaporator. Extreme care dropping below the freeze point. must be taken when removing refrigerant to prevent 6. Continue to remove the liquid refrigerant while damage to the evaporator and the chiller. -

Page 163: Charging Refrigerant Into A System

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 Microchannel coils tend to accumulate more dirt on Charging Refrigerant into a System the surface, but less dirt inside the coils, which makes To charge the system with refrigerant, follow the pro- them easier to clean. -

Page 164: Maintenance Requirements For Yvaa Chillers

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 MAINTENANCE REQUIREMENTS FOR YVAA CHILLERS SEMI- EVERY 5 EVERY * PROCEDURE WEEKLY QUARTERLY ANNUALLY ANNUALLY YEARS HOURS Check Oil Level in Oil Separator Sight Glass. Check Liquid Line Sight Glass/ Moisture Indicator. -

Page 165: Table 27 - Troubleshooting Guide

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 27 - TROUBLESHOOTING GUIDE PROBLEM POSSIBLE CAUSE ACTION High Voltage to the Chiller is missing. Check 1FU, 2FU, 4FU, 5FU 17FU, or Supply to the Panel is missing. 19FU. NO DISPLAY ON CONTROL Check 2T or 10T Transformer. - Page 166 FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 27 - TROUBLESHOOTING GUIDE (CONT'D) PROBLEM POSSIBLE CAUSE ACTION Coils dirty. Check and clean coils. Coils are damaged. Comb out fins. SYSTEM FAULT: Check fan fuses. HIGH DISCHARGE Fans NOT operating. Check fan rotation.

- Page 167 FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 27 - TROUBLESHOOTING GUIDE (CONT'D) PROBLEM POSSIBLE CAUSE ACTION Ambient temperature is high, normal response from controller Remote or panel limiting is in effect, SYSTEM STATUS: A high motor current anticipatory control Normal response.

-

Page 168: R-513A Conversion Table

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 R-513A CONVERSION TABLE The table below can be used for conversion of refrigerant R-513A from pressure to saturated temperature. TABLE 28 - R-513A REFRIGERANT PRESSURE TO SATURATED TEMPERATURE PRESSURE TEMP. AVG. PRESSURE TEMP. -

Page 169: R-513A Conversion Table

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 R-513A CONVERSION TABLE The table below can be used for conversion of refrigerant R-513A from temperature to equivalent pressure. TABLE 29 - R-513A REFRIGERANT TEMPERATURE TO PRESSURE TEMP. (°F) PRESSURE TEMP. (°F) PRESSURE TEMP. -

Page 170: Table 30 - Temperature Input Voltage Sensor (Measured Signal To Shield At The Sensor)

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 CHILLED LIQUID AND SUCTION TEMPERATURE SENSOR INPUT VOLTAGE TABLE 30 - TEMPERATURE INPUT VOLTAGE SENSOR (MEASURED SIGNAL TO SHIELD AT THE SENSOR) TEMP. ºF (°C) VOLTAGE TEMP. °F (°C) VOLTAGE TEMP. °F (°C) VOLTAGE 16.1 (-8.8) 1.52... -

Page 171: Table 31 - Outside Air Temperature Sensor Input Voltage (Measured Signal To Shield At The Sensor)

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 31 - OUTSIDE AIR TEMPERATURE SENSOR INPUT VOLTAGE (MEASURED SIGNAL TO SHIELD AT THE SENSOR) TEMP. ºF (°C) VOLTAGE TEMP. ºF (°C) VOLTAGE TEMP. ºF (°C) VOLTAGE 0.24 (-17.6) 0.68 49.8 (9.9) 2.00 93.3 (34.1) -

Page 172: Table 32 - Pressure Transducer Output Voltage (Measured Signal To Return At The Transducer)

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 32 - PRESSURE TRANSDUCER OUTPUT VOLTAGE (MEASURED SIGNAL TO RETURN AT THE TRANSDUCER) DISCHARGE CONDENSER LIQUID PRESSURE AND SUCTION PRESSURE TRANSDUCER DISCHARGE PRESSURE TRANSDUCER (125 PSIG) (400 PSIG) PRESSURE VOLTAGE PRESSURE VOLTAGE 0.50... -

Page 173: Table 33 - Motor Temperature Sensor Resistance (Check At The Motor)

FORM 201.28-NM1.1 SECTION 9 - MAINTENANCE ISSUE DATE: 1/31/2018 TABLE 33 - MOTOR TEMPERATURE SENSOR RESISTANCE (CHECK AT THE MOTOR) TEMP. R NOMINAL R TOL RMIN RMAX ºF (ºC) (OHMS) (± %) (OHMS) (OHMS) -4 (-20) 97,062 5.00 92,209 101,915 5 (-15) 77,941 4.60... - Page 174 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 THIS PAGE INTENTIONALLY LEFT BLANK. JOHNSON CONTROLS...

-

Page 175: Section 10 - Decommissioning, Dismantling And Disposal

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 SECTION 10 - DECOMMISSIONING, DISMANTLING AND DISPOSAL Never release refrigerant to the atmo- If glycol or similar solutions have been sphere when emptying the refrigerating used in the water system, or chemical circuits. Suitable retrieval equipment additives are contained, the solution must be used. -

Page 176: Table 34 - Si Metric Conversion

FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 The following factors can be used to convert from English to the most common SI Metric values. TABLE 34 - SI METRIC CONVERSION MEASUREMENT MULTIPLY ENGLISH UNIT BY FACTOR TO OBTAIN METRIC UNIT Capacity Tons Refrigerant Effect (ton) 3.516 Kilowatts (kW) Power... - Page 177 FORM 201.28-NM1.1 ISSUE DATE: 1/31/2018 NOTES JOHNSON CONTROLS...

- Page 178 800-861-1001 5000 Renaissance Drive, New Freedom, Pennsylvania USA 17349 800-861-1001 Subject to change without notice. Printed in USA www.johnsoncontrols.com Copyright © by Johnson Controls 2018 ALL RIGHTS RESERVED Form 201.28-NM1.1 (118) Issue Date: January 31, 2018 Supersedes 201.28-NM1.1 (1117)

Need help?

Do you have a question about the YVAA and is the answer not in the manual?

Questions and answers

Where do I hook up the service gfci