Table of Contents

Advertisement

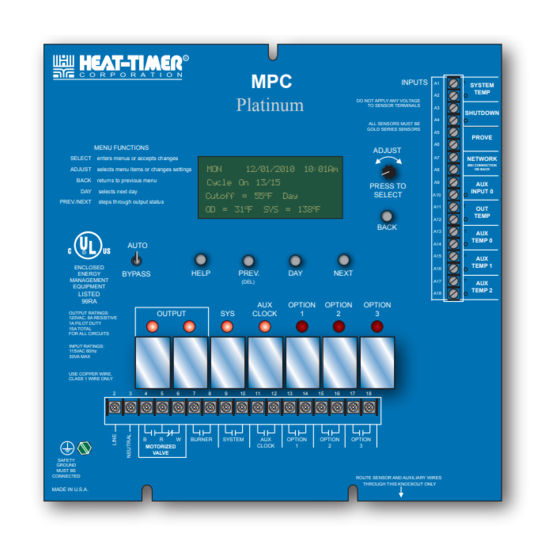

Installation and Operation Manual

Steam Outdoor Reset Boiler /Motorized

Valve Cycling Heating Control

SELECT

ADJUST

PREV./NEXT

MANAGEMENT

OUTPUT RATINGS:

120VAC, 6A RESISTIVE

1A PILOT DUTY

15A TOTAL

FOR ALL CIRCUITS

INPUT RATINGS:

115VAC 60Hz

30VA MAX

USE COPPER WIRE,

CLASS 1 WIRE ONLY

SAFETY

GROUND

MUST BE

CONNECTED

MADE IN U.S.A.

This Heat-Timer control is strictly an operating control; it should

never be used as a primary limit or safety control. All equipment

must have its own certified limit and safety controls required by local

codes. The installer must verify proper operation and correct any

safety problems prior to the installation of this Heat-Timer control.

MPC Platinum Installation and Operation Manual

R

C O R P O R A T I O N

MENU FUNCTIONS

enters menus or accepts changes

selects menu items or changes settings

MON

BACK

returns to previous menu

Cycle On 13/15

DAY

selects next day

Cutoff = 55

steps through output status

OD = 31

AUTO

ENCLOSED

HELP

BYPASS

ENERGY

EQUIPMENT

LISTED

99RA

OUTPUT

6

7

8

2

3

4

5

B

R

W

BURNER

MOTORIZED

VALVE

WARNING

MPC

Platinum

DO NOT APPLY ANY VOLTAGE

GOLD SERIES SENSORS

12/01/2010

10:01Am

o

F

Day

o

o

F

SYS = 138

F

PREV.

DAY

NEXT

(DEL)

AUX

OPTION

OPTION

OPTION

SYS

CLOCK

1

2

9

10

11

12

13

14

15

16

17

18

SYSTEM

AUX

OPTION

OPTION

OPTION

CLOCK

1

2

3

ROUTE SENSOR AND AUXILIARY WIRES

THROUGH THIS KNOCKOUT ONLY

MPC

Platinum

INPUTS

T

A1

SYSTEM

TEMP

A2

TO SENSOR TERMINALS

A3

SHUTDOWN

A4

ALL SENSORS MUST BE

A5

PROVE

A6

ADJUST

A7

NETWORK

MSI CONNECTION

A8

ON BACK

A9

AUX

PRESS TO

INPUT 0

SELECT

A10

T

A11

OUT

TEMP

A12

BACK

A13

T

AUX

TEMP 0

A14

A15

T

AUX

TEMP 1

A16

T

A17

AUX

TEMP 2

A18

3

1

Advertisement

Table of Contents

Summary of Contents for heat-timer MPC Platinum

- Page 1 THROUGH THIS KNOCKOUT ONLY MADE IN U.S.A. WARNING This Heat-Timer control is strictly an operating control; it should never be used as a primary limit or safety control. All equipment must have its own certified limit and safety controls required by local codes.

-

Page 2: Table Of Contents

MPC Platinum MODBUS Variable List Option Outputs Modes Troubleshooting Option relay 1 mode Diagrams Option 2 Relay Mode Warranty Option 3 relay mode Specifications: DHW Supply and return Defaults Setting the Date and Time MPC Platinum Installation and Operation Manual... -

Page 3: Mpc Platinum Function Chart

MPC requires steam BYPASS position runs Green Earth Operates additional equipment based the output. Ground screw on a separate Aux Schedule * DRY CONTACT ONLY ** Only available with the Remote Communications package MPC Platinum Installation and Operation Manual... -

Page 4: Understanding The Cycle Concept

(Two outdoor cutoffs are available. One is for the day and the other is for the night), the MPC Platinum will not call for any heat. When the outdoor temperature drops below the cutoff, the MPC Platinum will automatically begin controlling the heating cycle. -

Page 5: Sequence Of Operation

• Once the Cycle-ON part has ended, the Cycle-OFF part of the cycle will begin. The MPC Platinum will turn off the boiler or close the steam valve for the remainder of this cycle. -

Page 6: Typical Steam Heat Configuration

Day and Night Schedules • The MPC Platinum has 4 Day and 4 Night settings for each day of the week. By setting a Schedule, Day and Night Heat Adjustments, and Outdoor Cutoffs, you can save energy while providing comfortable heat to the building. The settings allow the MPC Platinum to reduce the length of the steam Cycle-ON portion during the night or when building is unoccupied. -

Page 7: Making Sure You Have The Right Control

MAkING SURE YOU HAVE THE RIGHT CONTROL If you need the MPC Platinum to do additional tasks that either are not listed or you do not know how to configure them, contact Heat-Timer Corp. Sales Department either by Phone (973)575-4004, Fax (973) 575-4052, or over the web (visit http://www.heat-timer.com). -

Page 8: Installation

Control Communication Upgrade • All non-communication MPC Platinum controls are upgradable to any of the available communication options. This, requires the • The Upgrade Kit consist of two boards, a CPU Board and a Communication Board. The CPU Board has the control operating software. -

Page 9: Sensor Installation

ALERT Immersion Heating System Sensor Determining the proper location for the Outdoor Sensor is very important The MPC Platinum will base the heat on the outdoor temperature information it receives from this location If the sensor is in Immersion Well... -

Page 10: Wiring The Power

• The MPC Platinum is capable of operating a boiler, a floating motorized valve, or both. 120VAC, 6A RESISTIVE 1A PILOT DUTY 15A TOTAL FOR ALL CIRCUITS • The MPC Platinum output terminal R (5) is the Common. Wire it to the 24 VAC power INPUT RATINGS: 115VAC 60Hz 30VA MAX source (transformer). -

Page 11: Wiring To System Output

• The contacts can switch a 6A resistive at 120VAC load. DO NOT APPLY ANY VOLTAGE TO SENSOR TERMINALS • A good practice is to use the MPC Platinum's Prove input terminals to connect to the ALL SENSORS MUST BE BURNER... -

Page 12: Input Wiring

DO NOT APPLY ANY VOLTAGE DO NOT APPLY ANY VOLTAGE INPUT RATINGS: 15A TOTAL • You can use this feature whenever it is desirable to deactivate the MPC Platinum from a TO SENSOR TERMINALS TO SENSOR TERMINALS 115VAC 60Hz FOR ALL CIRCUITS... -

Page 13: Testing The Sensors

ICMS website (http://www.htcontrols.com). TEMP 2 TEMP 2 Wireless LISTED LISTED Sensors Network 99RA 99RA • The MPC Platinum Network terminals can connect up to 64 or 128 network sensors, OPTION OPTION OPTION OPTION OPTION OPTION Manager OUTPUT OUTPUT CLOCK... -

Page 14: Remote Communication Wiring

• Use 18# AWG Twisted Pair cable. The cable length must not exceed B(-) 3500 feet. A(+) • The ground RS485 terminal (G) MUST be connected to the BMS B(-) CPU Board RS485 Ground. • Manual". Motherboard RS485 Cable Connect to BACnet MS/TP Network MPC Platinum Installation and Operation Manual... -

Page 15: Modbus Rtu Wiring

TO MODBUS NETWORK MODBUS RTU WIRING • A MODBUS communication board and a CPU board with the MODBUS software is required for proper MODBUS communication. MODBUS • Heat-Timer Platinum control MODBUS communication uses a Communication Board RS485 connection. A(+) • Connect the MODBUS RS485 cable to the Communication Board's B(-) RS485 socket. -

Page 16: Auto/Bypass Switch

AUTO/BYPASS SWITCH AUTO • The switch must be in the AUTO position for the MPC Platinum to control the heating system. • The BYPASS position overrides all automatic control of the MPC Platinum. • If the MPC Platinum has power and is operational, switching to BYPASS automatically activates the Motorized Valve, the Burner, and the System output. -

Page 17: Display Messages

DISPLAY MESSAGES The MPC Platinum normal display layout utilizes the second line for message indications. The following is a list of the most common Message Display Line information: • BYPASS: 0D 0H 15M The control is switched to Bypass for the amount of time indicated. See "AUTO/BYPASS Switch"... -

Page 18: Menu Settings

120 F Peak Diff 10 F --- SET YEAR --- Below Outdoor Cut Light Diff 20 F 2000 OPTION RELAY 2 MODE DHW SUPPLY DEFAULT DHW RETURN DEFAULT Inverse of Output Heat Established Summer MPC Platinum Installation and Operation Manual... -

Page 19: -- System Setpoint

75 F Switch to IP Night Target 65 F - DAY SPACE TARGET - 75 F INTERNET SETTINGS IP___,___,___,___ NIGHT SPACE TARGET Msk___,___,___,___ Internet 65 F Gwy___,___,___,___ DNS___,___,___,___ MODBUS SETTINGS MODBUS MAC Address Baud 9600 MPC Platinum Installation and Operation Manual... -

Page 20: Startup Settings

• If your steam source is of the later type, you may decide to select the District Steam option. • With the District Steam option, the HSS is not used. The MPC Platinum uses a timer to start the Cycle-ON. See "District Steam Delay" on page 25. -

Page 21: Day Light Saving Mode

SELECT Settings/System Startup/.../Sensor Fault/Day Light Saving Disable • If it is desirable for the MPC Platinum to automatically adjust the system clock for Day Light savings, select Enable. • If the control is located where Day Light Savings time is not observed, or if you wish to manually change the clock for Day Light Savings, select Disable. -

Page 22: Dhw Supply And Return Defaults

• If "Night" is selected, Option 3 Relay will energize whenever the MPC Platinum is holding the lower, or Night, heat settings and will be de-energize when the MPC Platinum is holding the Day settings. • If "Above Outdoor Cutoff" is selected, Option 3 Relay will energize whenever the Outdoor sensor temperature registers above the Outdoor Cutoff temperature and will de-energize whenever the Outdoor sensor temperature registers below the Outdoor Cutoff. -

Page 23: Operation

Cycle-On. -- DAY ADJUSTMENT -- • The MPC Platinum has two heat levels, Day and Night. The Day heat level is for when Higher = More heat the building is occupied and people are active. The Night heat level holds a lower ambient temperature, and is for when the building is unoccupied or people are sleeping. -

Page 24: Cycle Length Table

55 F SELECT Settings/<System Settings>/Day Outdoor Cutoff or Night Outdoor Cutoff • The Day and Night Outdoor Cutoffs determine when the MPC Platinum calls for heat. ---- NIGHT CUTOFF --- • When the outside temperature rises above the Cutoff by 2F°, the MPC Platinum stops 40 F providing steam to heat the building. - Page 25 District Steam as the Operating Mode. See "Operation Mode" on page 20. No Thermal Lockout is • The MPC Platinum uses this time setting to determine the beginning of the steam cycle. available with District Steam • No system sensor is required in the District Steam mode.

-

Page 26: Boost Mode

• The Boost quickly returns the building to comfortable ambient temperatures after the cooler Night period. • The MPC Platinum accomplishes this by either running the boiler on its limits or opening --- BOOST MODE--- the steam valve for a given Boost time based on the #1 Day schedule. See "Schedules" on Disabled page 29. -

Page 27: Early Shutdown Curves

• If space sensors are available and the Space Lockout is set to enable, the ESD message may end sooner if the Space Average reaches the Night Space Target. From that time,, the MPC Platinum will continue using the Night settings. -

Page 28: System Run-On

65 F See "Communication Options" on page 34. • The Vari-Boost also uses the Day Space Target. During the Vari Boost, the MPC Platinum may remain in Boost until the space average reaches the Day Space Target or exceeds the maximum Boost time limit. -

Page 29: Schedules

SELECT Settings/<Schedules> Day/Night Schedule Copy Schedule • The MPC Platinum has two levels of heat. The Day Time level is for an occupied building Set Date/Time where people are active. The Night Time (Setback) level is for an unoccupied building or Aux Schedule when people are asleep. -

Page 30: Copy Schedule

• The vacation Space Target and settings can only be set on the Internet ICMS website (http://www.htcontrols.com). • The MPC Platinum offers a Vacation Schedule with an adjustable lower space target that it • During that time, the MPC Platinum uses the Vacation Schedule Space Target. However, it also uses the Night Heat Adjustment and Night Outdoor Cutoff settings. -

Page 31: Maintenance

MPC Platinum will bring on the boiler or open the valve. to do so will result in under heating • Note that the Fast Cycle feature only works when the MPC Platinum is in a cycle. It does and boiler/steam valve short cycling. -

Page 32: Dhw Settings

DHW usage. It allows the boiler or pump relay to turn on for a slightly longer period. However, due to the reduced usage, the relay will remain off for a much longer period. Its value must be greater than the same sensor's Peak Differential. DHW RETURN LIGHT DIFF 40 F MPC Platinum Installation and Operation Manual... -

Page 33: Dhw Demand Schedule

Extend Day with a Shift option. Schedule • The Shift option will immediately change the status of the MPC Platinum from Day to Night, or Night to Day, without changing the program schedule. - EXTEND DAY TIME - • By selecting Night or Day, the shift is permanent until the clock advances to the next setting 90 Min on the schedule. -

Page 34: Communication Options

Day to Night (Setback) until the Night Target is reached. • Water Meter Inputs. The MPC Platinum is designed to connect to a variety of sensors including a water meter sensor. Thus providing water consumption monitoring. This can be used to detect boiler feed or building water leaks. -

Page 35: Internet Communication

65 F SELECT Settings/System Settings/More Settings/Remote Interface Internet ID Solo • The MPC Platinum can connect to the Internet for remote monitoring and setting changes. • It can communicate to a large number of sensors. INTERNET ID ---- INTERNET ID ---... - Page 36 ◦ (#3000) The Platinum control could not establish a dependable two way communication with the Heat-Timer Servers for over 24 hours. (#8000) Is an end alarm that can be set to indicate that the initial alarm status has terminated.

-

Page 37: Bacnet Communication Features

BACNET COMMUNICATION FEATURES The MPC Platinum BAC (with BACnet IP and BACnet MSTP connections) has many features and benefits. • Boiler and Sensor status, values, and settings. Provides “Live” status and editing capability of Platinum control settings and values from the BACnet network. -

Page 38: Ms/Tp Address/ Mac Address

0 - 60 2400 SYSSEN System Sensor °C(62), °F(64) -40 - +122°C, -40 - +250°F 2500 SYSTEM System Relay 0=Off, 1=On 2600 SYTRIM System Sensor Trim °C(62), °F(64) -3 - +3°C, -5 - +5°F MPC Platinum Installation and Operation Manual... - Page 39 BOOSTMODE is set to ManualBoost Note: The MPC Platinum has a schedule, which is 7-days, 4 day/night pairs per day For example: Instance 2000 is the first DAY schedule of Monday; Instance 2001 is the first NIGHT schedule of Monday; Instance 2008 is the first DAY schedule of Tuesday;...

-

Page 40: Bacnet Pics Statement

Address and Phone Heat-Timer Corporation 20 New Dutch Ln. Fairfield, NJ 07004 - (973)575-4004 Product Description MPC Platinum control for hot water heating applications (see http://www heat-timer com for more information) BACnet Standardized Device Profile (Annex L) Product Device Profile... -

Page 41: Modbus Communication Features

MODBUS COMMUNICATION FEATURES The MPC Platinum BUS (with MODBUS RTU connections) has many features and benefits. • Boiler and Sensor status, values, and settings. Provides “Live” status and editing capability of Platinum control settings and values from the MODBUS network. - Page 42 'Manual Boost Time' when 'Vari-Boost Adjustment' is set to Manual Boost Note: The MPC Platinum has a schedule, which is 7-days, 4 day/night pairs per day For example: Register 38 is the first DAY schedule of Monday; Register 39 is the first NIGHT schedule of Monday; Register 46 is the first DAY schedule of Tuesday;...

-

Page 43: Troubleshooting

Check if the control has any of the following conditions: 5941 • B ypass Mode - The MPC Platinum will only manage the boiler or valve if the Bypass switch is 4649 set to Auto. See "AUTO/BYPASS Switch" on page 16. 3667 •... - Page 44 If wires are connected to the Prove input, check the equipment activating the Prove. If no wires are connected, then you must place the factory installed jumper. See "Wiring The Prove" on page 12. See "Display Messages" on page 17. MPC Platinum Installation and Operation Manual...

-

Page 45: Diagrams

• System Run-On = 2 Minutes ALERT Since each installation is unique, Heat-Timer Corp is not responsible for any installation related to any electrical or piping diagram generated The provided illustrations are to demonstrate the control operating concept only MPC Platinum Installation and Operation Manual... - Page 46 MPC Platinum Installation and Operation Manual...

- Page 47 MPC Platinum Installation and Operation Manual...

- Page 48 Valve Actuator ALERT Since each installation is unique, Heat-Timer Corp is not responsible for any installation related to any electrical or piping diagram generated The provided illustrations are to demonstrate the control operating concept only MPC Platinum Installation and Operation Manual...

- Page 49 MPC Platinum Installation and Operation Manual...

- Page 50 MPC Platinum Installation and Operation Manual...

- Page 51 • Thermal Lockout = On ALERT Since each installation is unique, Heat-Timer Corp is not responsible for any installation related to any electrical or piping diagram generated The provided illustrations are to demonstrate the control operating concept only MPC Platinum Installation and Operation Manual...

- Page 52 MPC Platinum Installation and Operation Manual...

-

Page 53: Warranty

WARRANTIES AND LIMITATIONS OF LIABILITY AND DAMAGE: Heat-Timer Corporation warrants that it will replace, or at its option, repair any Heat-Timer Corporation manufactured product or part thereof which is found to be defective in material workmanship within one year from the date of installation only if the warranty registration has been properly filled out and returned within 30 days of the date of installation. - Page 54 MPC Platinum Installation and Operation Manual...

- Page 55 MPC Platinum Installation and Operation Manual...

-

Page 56: Specifications

... . Day Target (55 F/13°C to 85 F/29°C), Night Target (50 F/10°C to 80 F/27°C) ° ° ° ° 20 New Dutch Lane, Fairfield, NJ 07004 Ph: (973) 575-4004 • Fax: (973) 575-4052 http://www heat-timer com MPC Platinum Installation and Operation Manual...

Need help?

Do you have a question about the MPC Platinum and is the answer not in the manual?

Questions and answers