Table of Contents

Summary of Contents for Curtis Dyna-Fog TWISTER XL 3 4 Series

- Page 1 TWISTER XL 3 MODEL 3950 SERIES 4 MOTORIZED KNAPSACK ULV SPRAYER 17335 U.S. Highway 31 North Westfield, Indiana, U.S.A. www.dynafog.com Instruction Manual For Installation, Operation and Maintenance ® Manufactured by Curtis Dyna-Fog , Ltd.

-

Page 2: Table Of Contents

TABLE OF CONTENTS Forward Machine Specifications Main Components Diagram Working Principles Machine Operation Pre-Spray Checklist Engine Operation Instructions 9-10 Operator Safety On/Off Control Valve Measuring Liquid Flowability Flow Rate Chart Honda Engine Maintenance Speed Adjustment Air Filter Oil Level Check Oil Change Spark Plug 18-19... -

Page 3: Forward

To the New Owner Dear Valued Customer, Congratulations on selecting Dyna-Fog and one of the finest Ultra-Low-Volume (ULV), ® machines in the world. The TWISTER™XL 3 is the newest in the Dyna-Fog family of ® professional spraying equipment, and represents the latest in portable spray technology. -

Page 4: Machine Specifications

Machine Specifications TWISTER™XL, MODEL 3950 SERIES 4 Type: Aerosol Generator, Non Thermal, Insecticide, Ultra-Low-Volume (ULV). Using adequate orifice will produce larger droplets. Engine: Honda GX-35 4-stroke, overhead camshaft, single cylinder. Gasoline consumption: 25.7 oz/hour (760 ml/hour) approximate. Oil Type: 10 W-30. Oil Capacity: 100 cc (3.4 fl. -

Page 5: Main Components Diagram

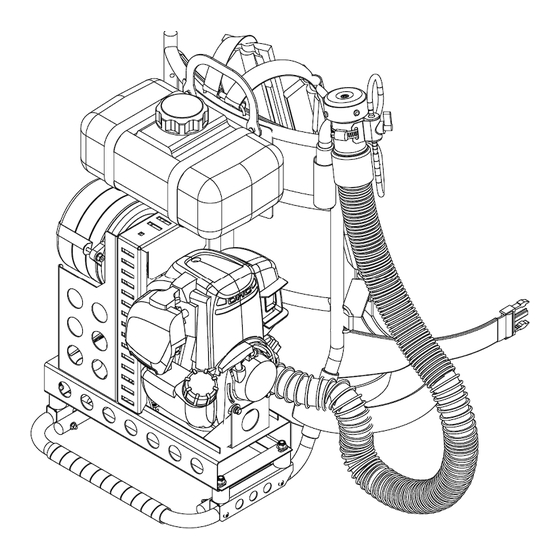

Twister XL-3 Main Components Diagram... -

Page 6: Working Principles

Working Principles The TWISTER™XL is powered by a 35cc 4-stroke GX-35 Honda or a 40cc 2-cycle Tanaka PF- 4000 gasoline engine. The TWISTER™XL is designed to take the weight and stress off the operators hand and wrist to ensure ease and comfort when working. The engine and blower assembly are mounted on a lightweight, padded INJECTION TUBE... -

Page 7: Machine Operation

Machine Operation CAUTION READ THIS COMPLETE OPERATION SECTION AND THE SECTION ON SAFETY PRECAUTIONS BEFORE STARTING THE MACHINE FOR THE FIRST TIME. When operating this machine for the first time, move to an uncongested and well-vented work area away from flammable materials. WARNING READ THE SECTION ON SAFETY PRECAUTIONS BEFORE PREPARING TO DISPENSE FORMULATION. -

Page 8: Pre-Spray Checklist

Pre-Spray Checklist 1. Verify that the operator came easily find and operate the engine kill switch, to stop the machine, or allow it run. 2. Verify that the steam of the formulation (spray) ON/OFF valve is easy to rotate, to open and close the valve, remaining in off position. -

Page 9: Engine Operation Instructions

Honda GX-35 Engine Operation Instructions FUEL Check the fuel level by looking through the translucent fuel tank. If the fuel level is low, refuel in a well-ventilated area with the engine stopped. If the engine has been running, allow it to cool. STARTING INSTRUCTIONS Read and understand operation manual before attempting to... - Page 10 Tanaka PF-4000 Engine Operation Instructions WARNING The Twister™ XL is equipped with a two-stroke engine. Always run the engine on gasoline, which is properly mixed with oil. FUEL Use unleaded gasoline with an 89 octane or higher rating. Use a quality two-cycle at mixing ratio of 50:1 (right diagram).

-

Page 11: Operator Safety

WARNING As recommended for any machine driven by an internal combustion engine, this equipment is intended to use outdoor and in a well ventilated area, in order to preventing Carbon Monoxide poisoning. CAUTION Keep the flexible air hose far away from the engine exhaust to avoid damage to the hose. -

Page 12: On/Off Control Valve

Using the Spray On/Off Control Valve The flow of formulation to the nozzle is controlled by the Spray ON/OFF Valve. The valve is located between the nozzle and the carrying handle. The upper drawing shows the Spray ON/OFF control valve in open (ON) position, allowing the flow of formulation from the formulation tank to the... -

Page 13: Measuring Liquid Flowability

Measuring Liquid Flowability (Viscosity) In order to achieve consistent results in generating aerosols with a mass median diameter (MMD) in the sub 20 micron range, several variables must be kept under control at the same time. The ability of an aerosol generator to consistently break up a liquid into appropriate sized droplets depends on 3 key elements: 1. -

Page 14: Flow Rate Chart

NOTE: Periodically calibrate the flowability meter using plain water. Water should flow ± through the orifice such that the time between the top line and the bottom line is 32 seconds. Once the flowability of the liquid has been measured, Tables 1 and 2 can be used as an approximate guide for setting the Flow Control Orifice size for your spray application. -

Page 15: Honda Engine Maintenance

Honda GX-35 Engine Maintenance Maintenance, replacement, or repair of the emission control devices and systems may be performed by any non-road engine repair establishment or individual. In the carburetor, fuel is mixed with air. When the engine is tested at the factory, the carburetor is pre-set. -

Page 16: Oil Level Check

4. Wipe dirt from the air cleaner body and cover, using a moist rag. Be careful to prevent dirt from entering the carburetor. Oil Level Check Check the engine oil level before each use, or every 10 hours if operated continuously. Check the engine oil level with the engine stopped and in a level position. -

Page 17: Oil Change

Oil Change Drain the used oil when the engine is warm. Warm oil drains quickly and completely. 1. Check that the fuel filler cap is tightened securely. 2. Place a suitable container below the engine to catch the used oil. 3. -

Page 18: Spark Plug

Spark Plug Recommended Spark Plug: CM5H (NGK), CMR5H (NGK). The recommended spark plug is the correct heat range for normal engine operating temperatures. For good performance, the spark plug must be properly gapped and free of deposits. 1. Remove the top cover. Loosen the 5 mm hex bolt with a hexagon wrench, then remove the top cover. -

Page 19: Engine Fins

6. Install the spark plug carefully, by hand, to avoid cross threading. 7. After the spark plug is seated, tighten with a 5/8- inch spark plug wrench to compress the sealing washer. 8. When installing a new spark plug, tighten 1/2 turn after the spark plug seats to compress the washer. -

Page 20: Fuel Filter And Fuel Tank

Fuel Filter and Fuel Tank CAUTION A loose spark plug can overheat and damage the engine. Overtightening the spark plug can damage the threads in the cylinder head. 1. Check that the engine oil filler cap is tightened securely. 2. Remove the fuel filler cap, and drain the fuel into an approved gasoline container by... -

Page 21: Spark Arrester

Spark Arrester The spark arrester may be standard or an optional part, depending on the engine type. In some areas, it is illegal to operate an engine without a spark arrester. Check local laws and regulations. A spark arrester is available from authorized Honda servicing dealers. -

Page 22: Tanaka Engine Maintenance

Tanaka PF-4000 Engine Maintenance Maintenance, replacement, or repair of the emission control devices and systems may be performed by any non-road engine repair establishment or individual. In the carburetor, fuel is mixed with air. When the engine is tested at the factory, the carburetor is pre-set. -

Page 23: Fuel Filter

Fuel Filter Drain all fuel from the fuel tank and pull fuel filter line from tank. Pull filter element out of holder assembly and rinse element in warm water with detergent. Rinse thoroughly until all traces of detergent are eliminated. Squeeze, do not wring away excess water and allow element to dry. -

Page 24: Blower Assembly

Blower Assembly The TWISTER™ XL is equipped with a high performance rotary blower, including special features as following: Three -stage, 5.7˝ (145 mm) diameter. Air delivery: 99 CFM Unrestricted. Steel shaft mounted on double ball bearing. Thermoset fan end bracket. Aluminum (anodized) bearing housing. - Page 25 the pulley side. Also try to move the shaft axially and transversely, looking for bearing play. If the rotation of the shaft is not smooth or if a considerable play is not found, a detailed inspection should be performed. Additionally, at this point, it is convenient to check the fan for high corrosion by using a flashlight and looking thru the air filter, the critical point is around the nut/washer, on the aluminum of the fan.

-

Page 26: Air Filter Assembly

Air Filter Assembly: The Intake Filter Assembly is mounted on the blower, and it is performing three main functions: • Dirt and other foreign particles are filtered from the incoming air by the reusable stainless steel element. • It works as a safety guard, avoiding the contact of body parts (as fingers) from rotary parts (fan/shaft end). - Page 27 Poly-V Belt and Sheave Drive For Honda GX-35 In order to obtain the appropriated blower speed and use low weight components, the Poly-V drive provide the best of all the power transmission , including the superior driving force of multiple V-belts without the matching problems associated with individual belts. To obtain the longer life of the belt transmission components, please follow the instructions indicated in this section.

-

Page 28: Poly-V Belt And Sheave Drive

Poly-V Belt and Sheave Drive For Tanaka PF-4000 In order to obtain the appropriated blower speed and use low weight components, the Poly-V drive provide the best of all the power transmission , including the superior driving force of multiple V-belts without the matching problems associated with individual belts. To obtain the longer life of the belt transmission components, please follow the instructions indicated in this section. -

Page 29: Belt Tension

BELT TENSION Belt tension is highly important. When in operation both tight and slack strands of the belt should be in a straight line from sheave to sheave; a very small sag or bow could be acceptable at the slack strand. Check belt tension after eight (8) hours operation, followed by periodic inspections to be sure belt is under sufficient tension and that belt is not slipping or DEFLECTION... -

Page 30: Flushing The System

Flushing the System In order to avoid accumulations of sediment, or premature degradation of hoses, valve and nozzle, it is recommended to flush the fluid system with flushing solution immediately after every use of the machine. To flush the system, locate the machine in an open and well ventilated place, and perform the following procedure: 1. - Page 31 Preventive Maintenance Schedule for Honda GX-35 Frequency Operation After Each 8 Hours 25 Hours or 50 Hours or 100 Hours or or Daily New Season New Season New Year Engine Clean Air Filter Clean Spark Plug Arrester Clean Gasoline Filter Change Engine Oil Check RPM Check or Replace Spark...

-

Page 32: Preventive Maintenance Schedule

Preventive Maintenance Schedule for Tanaka PF-4000 Frequency Operation After Each 8 Hours 25 Hours or 50 Hours or 100 Hours or or Daily New Season New Season New Year Engine Clean Air Filter Check Muffler Clean Gasoline Filter Clean Cooling Fins Check RPM Clean or Replace Spark Plug... -

Page 33: Flow Rate Verification

FLOW RATE VERIFICATION The flow Rate chart supplied with the machine (label and manual) has good accuracy. For verification purposes, this procedure could be performed. 1. Be sure liquid lines of the machine are filled with the liquid to be sprayed. Then disconnect the upper plastic nut to the union/orifice. -

Page 34: Trouble Shooting Guide

TROUBLE SHOOTING GUIDE SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION 1) Recoil Starter Fails a) Defective recoil starter a) Check recoil starter. Service it if to Crank the Engine required. b) Belt transmission with b) Check belt and pulleys for obstructions. obstructions. c) Engine locked up. - Page 35 7) Engine Does Not a) Carburetor choke valve a) Adjust choke. Deliver Full Power partially open. b) Air cleaner dirty. b) Service air cleaner. c) Carburetor defective. c) Clean, adjust, or replace. d) Exhaust restricted. d) Clean or replace muffler. e) Spark arrestor clogged.

- Page 37 TWISTER XL 3 EXPLODED VIEW DIAGRAM ITEM QTY. DESCRIPTION 39602 BAR, STRAP 39728 HANDLE, TWISTER XL 3 39751 FRAME AY, TWISTER 3 39756 PLATE, SUPPORT, TWISTER 39657-4 WIRE, KILL SWITCH (HONDA) 39791-3 TANK,FORMULATION, LOW PROFILE 39755-3 39809-4 INSULATOR, TANK STRAP 120391 WASHER, FLAT, #10, REG.

-

Page 38: Straps

STRAPS FOR TWISTER XL 3 MODEL #3950 ITEM DESCRIPTION 39728 HANDLE, TWISTER XL 39765-1 SHOULDER STRAP W/HOOK 39759 HARNESS/PAD AY. 39765 SHOULDER STRAP W/O HOOK... -

Page 39: Engine Blower Plate Assembly

PLATE AY., ENGINE/BLOWER (P/N: 39668) - Page 40 PLATE AY., ENGINE/BLOWER (P/N: 39668) ITEM DESCRIPTION 121887 BOLT HEX 1/4-20 X 3/4 120380 WASHER, LOCK 1/4 SPLIT 120392 WASHER, FLAT, 1/4 REG. 39651 BLOWER AY., TWISTER 120391 WASHER, FLAT, #10, REG. 157684 SCREW, 10-24 X 1/2, TRCR 63921 BRACKET, SUPPORT 30024 RING,LOCKING 62369...

-

Page 41: Blower Assembly - Exploded

CURTIS DYNA-FOG® Twister™ XL 3 BLOWER ASSEMBLY P/N: 39651 ITEM QTY. PART NUMBER ITEM DESCRIPTION A273746 SCREW, 10-24X3/4 TRCR B39663 FILTER ASSEMBLY A39651-11 NUT AMETEK NO. 7491 A39651-13 WASHER B39651-9 FAN SHELL B39651-5 FAN ROTATING B39651-8 FAN STATIONARY B39651-6 SPACER... -

Page 42: Engine Assembly

CURTIS DYNA-FOG® Twister™ XL 3 ENGINE ASSEMBLY, HONDA GX-35 (P/N: 39616) ITEM QTY. PART NUMBER ITEM DESCRIPTION 39597 ENGINE, 35CC, GX-35 HONDA 39614 PULLEY AY., HONDA GX-35 39720 BOLT, 6 MM., - 1.00 MM. HEX 121753 WASHER, LOCK, 1/4, EXTO 120392 WASHER, FLAT, 1/4, REG. - Page 43 CURTIS DYNA-FOG® Twister™ XL 3 TANAKA PF-4000 ENGINE ASSEMBLY P/N 39656-1 ITEM QTY. PART NUMBER ITEM DESCRIPTION 39656 ENGINE, 40 CC, TANAKA 39712 PULLEY/SHAFT ADAPTER AY 39658 BRACKET, L.H. 120391 FLAT WASHER, #10 39659 BRACKET, R.H. 39720 BOLT 6 MM – 1 MM...

-

Page 44: Remote Nozzle Assembly

REMOTE NOZZLE ASSEMBLY ITEM QTY. PART NUMBER ITEM DESCRIPTION 39726 NOZZLE/ADAPTER ASSEMBLY 20054-2 CLAMP, 1.5 DIA 62200 HANDLE 59962-1 FOAM GRIP 11719 D-RING 449623 SCREW 10-24 X ½ 39672 HOSE ASSEMBLY 39703-1 VALVE BRACKET, S.S. 39767 FITTING, BRASS, STRAIGHT, 1/4, MPT 22273 VALVE ASC-35... -

Page 45: Nozzle/Adaptor Assembly

HOSE ASSEMBLY P/N 39672 ITEM QTY. PART NUMBER ITEM DESCRIPTION 39732-51 HOSE AY, ORANGE 80447-8 TUBING, VINYL, .312 GRES. 80447-48 TUBING, VINYL, .312 GRES. 21158 CLAMP, 3/8, PLASTIC 62584-29 TUBING, 1/4 OD., POLY. 20054-8 CLAMP, HOSE, WORM DRIVE NOZZLE/ADAPTOR AY P/N: 39726 ITEM QTY. -

Page 46: Formulation Tank Assembly

NOTE: Your Twister XL 3 unit will use either P/N: 39791 or P/N: 39755 formulation tank. You can identify which tank you have by inspecting the formulation cap. If the cap has an outside diameter of 3.0”, your Twister XL 3 unit came with P/N: 39791 formulation tank. FORMULATION TANK AY (P/N: 39791) ITEM DESCRIPTION... -

Page 47: Control Assembly, Throttle

OPTIONAL NOTES: 1. Switch with slot in the direction shown. 2. Item (6) does not show ON/OFF. CONTROL ASSEMBLY, THROTTLE, TWISTER XL 3 P/N: 39699 ITEM DESCRIPTION 39680 BRACKET, THROTTLE CONTROL 120361 NUT, #10-24 39729 STOP 397679 CONTROL, THROTTLE, TWISTER XL 58707 NUT, #10-24 J-TYPE 157684... - Page 49 TANAKA PF-4000 ENGINE ONLY...

-

Page 50: Dual Nozzle Attachment Diagram And Parts List

TWISTER XL-3 DUAL NOZZLE ATTACHMENT P/N: 39716... -

Page 51: Labels

TWISTER XL-3 DUAL NOZZLE ATTACHMENT P/N: 39716 ITEM PART NO. DESCRIPTION 80447-4 TUBE, VINYL, .312 GRES 62313 NOZZLE AY. 63503-29 ADAPTOR, NOZZLE/HOSE 62163 SCREW, 8-32X3/8 TAP 62299-6 HOSE, 1.5 I.D., FLEX 449623 SCREW, 10-24X1/2 TAP 11719 CLAMP CARRY STRAP 59962-1 GRIP, HANDLE, MODIFIED 39713 “Y”... -

Page 52: Installation Instructions For Dual Nozzle

(OPTIONAL) -

Page 53: Tanaka Engine Information

3$576 ,1)250$7,21 &</,1'(5 3,6721 ,*1,7,21 ‡ ),*85( ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 &29(5 63$5. 3/8* 58%%(5 &$3 63$5. 3/8* $66 < 3/8* 63$5. 6(7 &</,1'(5 %2/7 +(; +2/( ; *$6.(7 &</,1'(5 5,1* 3,6721 6(7 3,6721 3,1 3,6721 &,5&/,3 3,6721 3,1 &5$1.6+$)7 %($5,1* 1(('/( ) .(<... - Page 54 3$576 ,1)250$7,21 &5$1.&$6( )/<:+((/ 67$57(5 38//(< ‡ ),*85( 3DJH ZZZ WDQDNDSRZHUHTXLSPHQW FRP FXVWVYF#WDQDND LVP FRP...

- Page 55 3$576 ,1)250$7,21 &5$1.&$6( )/<:+((/ 67$57(5 38//(< ‡ ),*85( ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 %2/7 +(; ; 3$:/ 67$57(5 5,1* 6723 635,1* 3$:/ 67$57(5 3$:/ 67$57(5 $66 < &$6( &5$1. %HIRUH 6 1 8 &$6( &5$1. 6 1 8 DQG DIWHU *$6.(7 &5$1.&$6( &UDQNFDVH DVV\ LQFOXGHV EHDULQJV VHDOV 6($/ 2,/ 9(...

- Page 56 3$576 ,1)250$7,21 08))/(5 08))/(5 &29(5 ‡ ),*85( &OLFN RQ WKH SLSH IRU PRUH LQIRUPDWLRQ ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 3527(&725 08))/(5 %2/7 +(; ; %2/7 +(; ; %HIRUH 6 1 8 6&5(: +(; ; :$6+(5 6(7 08))/(5 :$6+(5 %HIRUH 6 1 8 :$6+(5 6 1 8 DQG DIWHU...

- Page 57 3$576 ,1)250$7,21 )8(/ 6<67(0 $,5 ),/7(5 ‡ ),*85( 3DJH ZZZ WDQDNDSRZHUHTXLSPHQW FRP FXVWVYF#WDQDND LVP FRP...

- Page 58 3$576 ,1)250$7,21 )8(/ 6<67(0 $,5 ),/7(5 ‡ ),*85( ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 *$6.(7 ,1/(7 0$1,)2/' 6(7 &$5% ,168/$725 *$6.(7 &$5%85(725 & &2//$5 &2//$5 &/($1(5 %2'< &/($1(5 9$/9( &+2.( %2$5' %/2: 29(5 &+(&. (/(0(17 &/($1(5 :$6+(5 &29(5 &/($1(5 $66< &...

- Page 59 3$576 ,1)250$7,21 5(&2,/ 67$57(5 ‡ ),*85( ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 67$57(5 5(&2,/ $66 < %2'< 5(&2,/ 67$57(5 5((/ 67$57(5 523( 635,1* 5(&2,/ 523( 67$57(5 &$3 +$1'/( +$1'/( 67$57(5 6&5(: 6(7 3DJH ZZZ WDQDNDSRZHUHTXLSPHQW FRP FXVWVYF#WDQDND LVP FRP...

- Page 60 3$576 ,1)250$7,21 &$5%85(725 ‡ ),*85( ,7(0 3$57 180%(5 '(6&5,37,21 47< &200(176 6(7 &$5%85(725 ,QFOXGHV FDUEXUHWRU JDVNHW 6&5(: 7+5277/( 6(7 67$< $'-867 &$%/( 6:,9(/ :$6+(5 7+5867 a &RQWDLQHG LQ &DUE 5HSDLU .LW 5,1* 6723 $'-867(5 &$%/( 1RW DYDLODEOH LQGLYLGXDOO\ 2 5,1* -(7 0$,1 /21* a a a *$6.(7 3803...

- Page 61 Dyna-Fog Offers a Complete Assortment of Sprayers and Foggers PULSE-JET POWERED THERMAL FOGGERS: From 0-120 GPH (0-453 LPH) output. Our complete line include different models like the Superhawk, Golden Eagle, Trailblazer, Falcon, Patriot, Blackhawk, Mister III, SilverCloud and Model 1200. Portable or Truck mounted machines. Different models are available for Oil base or Water base formulations.

Need help?

Do you have a question about the TWISTER XL 3 4 Series and is the answer not in the manual?

Questions and answers