Champion R Series Operation & Service Manual

Engine drive compressors & units

Hide thumbs

Also See for R Series:

- Operation & service manual (32 pages) ,

- Operation maintenance manual & parts list (32 pages)

Table of Contents

Advertisement

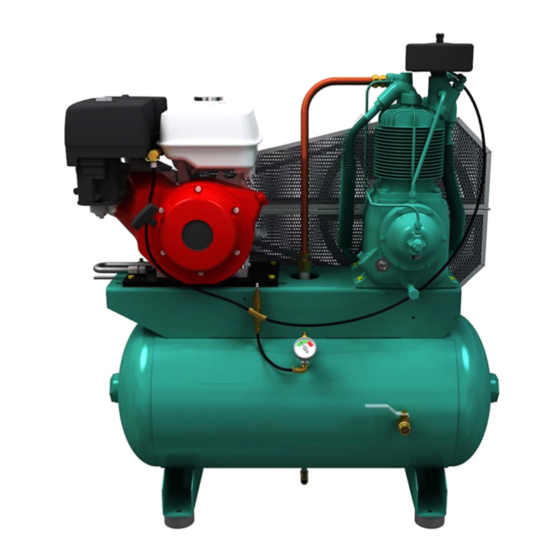

R-SERIES

Air Compressors and Units

OPERATION & SERVICE MANUAL

Engine Drive Compressors & Units

THIS MANUAL CONTAINS IMPORTANT SAFETY INFORMATION AND SHOULD ALWAYS

BE AVAILABLE TO THOSE PERSONNEL OPERATING THIS UNIT. READ, UNDERSTAND

AND RETAIN ALL INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT TO PREVENT

INJURY OR EQUIPMENT DAMAGE.

CQF3474 v.00

Jan.2018

Advertisement

Table of Contents

Summary of Contents for Champion R Series

- Page 1 R-SERIES Air Compressors and Units OPERATION & SERVICE MANUAL Engine Drive Compressors & Units THIS MANUAL CONTAINS IMPORTANT SAFETY INFORMATION AND SHOULD ALWAYS BE AVAILABLE TO THOSE PERSONNEL OPERATING THIS UNIT. READ, UNDERSTAND AND RETAIN ALL INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT TO PREVENT INJURY OR EQUIPMENT DAMAGE.

- Page 2 Reliability in materials and quality assurance are incorporated in our genuine replacement parts. Your authorized Champion Compressor distributor offers all the backup you’ll need. A worldwide network of authorized distributors provides the finest product support in the air compressor industry. Your authorized distributor can support your Champion air compressor with these services: 1.

-

Page 3: Table Of Contents

Table of Contents Introduction ............................4 Safety and Operation Precautions ......................5 Explanation of Safety Instructions, Symbols, and Decals ................6 Safety and Operation Precautions ......................6 Unit Hazard Decal List – See Page 8 ......................7 Pump Hazard Decal List – See Page 9 ....................... 7 Unit Hazard Decals .......................... -

Page 4: Introduction

Express Limited Warranty CHAMPION warrants each new air compressor unit manufactured by CHAMPION to be free from defects in material and workmanship under normal use and service for a period of twelve (12) months from date of installation or eighteen (18) months from date of shipment by CHAMPION or CHAMPION distributor, whichever may occur first. -

Page 5: Safety And Operation Precautions

Safety and Operation Precautions can result in injuries or equipment damage. However, Champion – A Gardner Denver Co., does not state as fact or does not mean to imply that the preceding list of Safety and Operating Precautions is all inclusive, and further that the observance of this list will prevent all injuries or equipment damage. -

Page 6: Explanation Of Safety Instructions, Symbols, And Decals

Indicates immediate hazards which will result in severe injury or death. Indicates hazards or unsafe practice which could result in severe injury or death. Indicates hazards or unsafe practice which could result in damage to the Champion compressor or minor injury. -

Page 7: Unit Hazard Decal List

Unit Hazard Decal List – See Page 8 PART NO. DESCRIPTION P10157A PRODUCT LIABILITY DECAL SHEET - MASTER Unit Pressure Setting WARNING – Tank Pressure DANGER – Breathing Air DANGER – Drain Tank Daily WARNING – Pressure/Safety Valve NOT USED DANGER –... -

Page 8: Unit Hazard Decals

Unit Hazard Decals R-Series Engine CQF3474 v.00 Operation & Service Jan.2018... -

Page 9: Pump Hazard Decals

Pump Hazard Decals R-Series Engine CQF3474 v.00 Operation & Service Jan.2018... -

Page 10: Installation

Tanks anchored directly to a floor without vibration isolator pads will not be warranted against cracking. Champion vibration isolator pads must be used for extended warranty to apply to ASME air receivers. See “Air Receiver Installation” section. - Page 11 Installation (continued) 7. Battery and Wiring Recommendations A. If engine is connected to a dedicated battery: 1) The battery should have a minimum capacity of 24 AH and at least 350 CCA rating. 2) The wire size must be a minimum of #4 AWG. If the positive cable is longer than 5 feet or the negative cable is longer than 7.5 feet the wire size should be increased so that the maximum voltage drop from the battery to the unit connection does not exceed 0.5 volts while cranking.

- Page 12 Installation (continued) B. HONDA GAS ENGINE ONLY: If engine is connected to the vehicle battery: 1) The vehicle battery should have a minimum capacity of 24 AH and at least 350 CCA rating. 2) The wire size must be a minimum of #4 AWG. If the positive cable is longer than 5 feet or the Negative cable is longer than 7.5 feet the wire size should be increased so that the maximum voltage drop from the battery to the unit connection does not exceed 0.5 volts while cranking.

- Page 13 Installation (continued) b) Remove the black plastic cover from the back of the key switch box. Locate the black rectangular rectifier diode. It is on the side closest to the engine. Gently pry back the white plastic retainer clip on top of the diode closest to the key switch end and remove the diode.

- Page 14 Installation (continued) Do not install isolating valves between compressor outlet and air receiver. This will cause excessive pressure if valve is closed, and cause injury and equipment damage. Always use an air pressure regulating device at the point of use. Failure to do so can result in injury or equipment damage.

-

Page 15: Air Receiver Installation

Air Receiver Installation Vibration isolator pads can be purchased from your local authorized distributor. Installation hardware items (studs, screws, nuts, shims) are not provided. It is the compressor owner’s responsibility to provide a suitable foundation and isolator installation. Do not tighten the anchor screws/nuts down completely – this will result in undesirable stress on the tank foot. -

Page 16: Operation

Operation This compressor has been inspected, thoroughly tested and approved at the factory. For this unit to give long satisfactory service it must be installed and operated properly. This compressor has been designed for an 80%/ON – 20%/OFF duty cycle. Engine Drive units are equipped with a pilot valve and head unloaders to provide continuous run capabilities. - Page 17 Operation (continued) 6. Start engine. Allow engine to warm up. 7. Flip toggle lever on pilot valve to the “Run” position. See Figure 5. 8. With receiver ball valve closed, let the machine pump up to operating pressure. 9. Check for proper operation of the head unloaders. a.

-

Page 18: Compressor Oil Specifications

Emulsification of oil (white milky substance) indicates unsafe accumulation of moisture and may be evidence compressor is oversized for application. Failure to promptly consult your local distributor, or Champion Customer Service, can be grounds to deny warranty. BREAK-IN PERIOD: 1. Compressor must run for a 100 hour break-in period using ChampLub ISO 100 lubricant. - Page 19 Compressor Oil Specifications (continued) LUBRICANTS CHAMPLUB ISO 100 DESCRIPTION PART NUMBER 1 – Quart Case (12/case) P09479A 1 – Gallon Case (4/case) P08909A 5 – Gallon Pail P08908A 55 – Gallon Drum P08907A CHAMPLUB SYNTHETIC DESCRIPTION PART NUMBER 1 – Quart Case (12/case) P13179A 1 –...

-

Page 20: Guide To Maintenance

Guide to Maintenance For Service contact an authorized Champion distributor. To obtain reliable and satisfactory service, this unit requires a consistent preventive maintenance schedule. Maintenance schedule pages are included in the back of this manual to aid in keeping the proper records. - Page 21 Guide to Maintenance (continued) PILOT VALVE: The pilot valve actuates the head unloader mechanism to provide a means of stopping or starting the compression of air by the compressor without stopping or starting the engine. The pilot valve is pre-set from the factory, according to the order specification. Only a certified field service technician should make adjustments to the pilot valve.

- Page 22 Guide to Maintenance (continued) COMPRESSOR VALVES: If compressor fails to pump air or seems slow in filling up tank, disconnect unit from power source and remove valves and clean thoroughly, using compressed air and a soft wire brush. After cleaning, exceptional care must be taken that all parts are replaced in exactly the same position.

- Page 23 Guide to Maintenance (continued) TORQUE VALUES: Component Fastener Size & Thread Model Torque Governor Housing 3/8-16 400 Inch-lb. Governor Housing 7/16-20 550 Inch-lb. Cylinder Flange 7/16-20 R15, R30 400 Inch-lb. Governor Spindle Screw 7/16-20 R15, R30 470 Inch-lb. Rod Bolt 5/16-18 R15, R30 230 Inch-lb.

- Page 24 Guide to Maintenance (continued) SETTING BELT TENSION 1. Proper setting of the belt tension requires a belt tension checker (part number TEN011452). 2. Measure the belt span. 3. On the belt tension checker, position the o-ring on the span scale at the measured belt span.

- Page 25 Guide to Maintenance (continued) BELT DEFLECTION FORCE MODEL H.P. MOTOR BELT BELT USED BELT NEW BELT PULLEY SECTION NUMBER DEFLECTION DEFLECTION O.D. BELTS FORCE FORCE (lbs. min) (lbs. max) R15 GAS 13, 14 1025 4.95 R15 DIESEL 9.1, 9.3 4.35 R30 GAS 20.5 4.35...

-

Page 26: Maintenance Checklist

Maintenance Checklist DAILY MAINTENANCE Check oil level of compressor. Add Champlub recip lubricant as required. See “Compressor Oil Specifications” Section. NOTE: Do not mix oil type, weight, or brands. Check oil level of engine. Consult engine manual for manufacturer’s recommended oil. Drain moisture from tank by opening tank drain valve located in bottom of tank. -

Page 27: Troubleshooting Chart

Troubleshooting Chart Always shut off unit and relieve all pressure from air tank before performing any maintenance. Failure to do so may result in equipment damage or injury. Never operate unit without belt guard in place. Troubleshooting Chart Symptom Possible Cause(s) Corrective Action Engine will not start. -

Page 28: Maintenance Log

Maintenance Log DAILY ● CHECK OIL LEVEL ● DRAIN MOISTURE FROM TANK WEEKLY MONTHLY EVERY 3 MONTHS ● CLEAN FILTER ● INSPECT AIR SYSTEM ● CHANGE OIL ● CLEAN COMPRESSOR ● INSPECT VALVE ASSEMBLIES ● TIGHTEN ALL FASTENERS ● TEST PRESSURE RELIEF VALVE R-Series Engine CQF3474 v.00 Operation &... - Page 29 Maintenance Log DAILY ● CHECK OIL LEVEL ● DRAIN MOISTURE FROM TANK WEEKLY MONTHLY EVERY 3 MONTHS ● CLEAN FILTER ● INSPECT AIR SYSTEM ● CHANGE OIL ● CLEAN COMPRESSOR ● INSPECT VALVE ASSEMBLIES ● TIGHTEN ALL FASTENERS ● TEST PRESSURE RELIEF VALVE R-Series Engine CQF3474 v.00 Operation &...

- Page 30 Maintenance Log DAILY ● CHECK OIL LEVEL ● DRAIN MOISTURE FROM TANK WEEKLY MONTHLY EVERY 3 MONTHS ● CLEAN FILTER ● INSPECT AIR SYSTEM ● CHANGE OIL ● CLEAN COMPRESSOR ● INSPECT VALVE ASSEMBLIES ● TIGHTEN ALL FASTENERS ● TEST PRESSURE RELIEF VALVE R-Series Engine CQF3474 v.00 Operation &...

-

Page 31: Notes

Notes R-Series Engine CQF3474 v.00 Operation & Service Jan.2018... - Page 32 *CQF3474VER00* *CQF3474VER00* For additional information, contact your local representative or visit: www.championpneumatic.com/contactus.aspx ©2018 Gardner Denver, Inc. Printed in U.S.A.

Need help?

Do you have a question about the R Series and is the answer not in the manual?

Questions and answers