Summary of Contents for FLENDER N-EUPEX

- Page 1 FLENDER COUPLINGS N-EUPEX / N-EUPEX DS Operating Instructions 3100en Edition 10/2017 A, B, ADS, BDS...

- Page 2 21.09.2017 14:39 V6.00...

- Page 3 Introduction Safety instructions Description FLENDER COUPLINGS Application planning N-EUPEX / N-EUPEX DS 3100en Assembly Commissioning Operating Instructions Operation Servicing Service and support Disposal Spare parts A, B, ADS, BDS Technical data Quality documents Edition 10/2017...

-

Page 4: Safety Instructions

Note the following: WARNING Flender products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Flender. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems. -

Page 5: Table Of Contents

Radial misalignment.......................33 Commissioning............................35 Operation..............................37 Normal operation of the coupling...................37 Faults - causes and rectification.....................37 7.2.1 Procedure in the event of malfunctions..................37 7.2.2 Identifying the fault cause......................37 7.2.2.1 Possible faults........................38 7.2.2.2 Possible causes........................39 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 6 Tightening procedure......................64 Flexible elements (12)......................64 A.5.1 Use and storage of flexible elements (12)................64 A.5.2 N-EUPEX flexible elements (12)....................65 A.5.3 N-EUPEX DS flexible elements (12)..................66 Quality documents............................67 Declaration of Conformity.......................67 Tables Table 2-1 General warnings........................11 Table 2-2 Temperature classes (TX) for explosive atmospheres as a result of gases, vapours or mists..16...

- Page 7 Spare parts drawing for types A and ADS...................54 Figure 11-2 Spare parts drawing for types B and BDS...................55 Figure A-1 Type A............................57 Figure A-2 Type B............................59 Figure A-3 Type ADS............................60 Figure A-4 Type BDS............................61 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

- Page 8 Table of contents N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 9: Introduction

The note provides you with help or further suggestions/ ideas. Copyright The copyright for these instructions is held by Flender. These instructions must not be used wholly or in parts without our authorisation or be given to third parties. -

Page 10: Operating Instructions

Introduction 1.3 Copyright N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 11: Safety Instructions

This coupling is state-of-the-art at the time of printing these instructions. In the interest of further development, Flender reserves the right to make such changes to the individual components and accessories that increase performance and safety whilst maintaining the essential features. - Page 12 This also applies to test runs and rotational direction checks. Work on the coupling Only carry out work on the coupling when it is not in operation and is not under load. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 13: Intended Use

● Do not make any modifications to the coupling that go beyond the permissible machining described in these instructions. This also applies to touch protection facilities. ● Only use original spare parts from Flender. Flender only accepts liability for original spare parts from Flender. - Page 14 -30 °C ≤ Ta ≤ +80 °C/+70 °C/+55 °C 46393 Bocholt - Germany II 2D c T 110 °C -30 °C ≤ Ta ≤ +80 °C FLENDER couplings N‑EUPEX <Year of man‐ I M2 c -30 °C ≤ Ta ≤ +80 °C ufacture>...

-

Page 15: Conditions Of Use

Coupling part 2 or 4 Coupling part 2 or coupling part 4 is stamped with Undrilled or predrilled coupling A coupling part with Ex marking, the letter "U" and the Flender order number has been delivered undrilled or predrilled. Note... -

Page 16: General Warning Notices

The coupling may burst if it is not used properly. There is a risk of fatal injury from flying fragments. Bursting of the coupling can lead to an explosion in potentially explosive atmospheres. ● Use the coupling for the purpose for which it is intended. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 17 ● Please observe the manufacturer's information on how to handle cleaning agents and solvents. ● Wear suitable protective equipment (gloves, safety goggles). CAUTION Physical injury Risk of injury due to falling coupling parts. ● Secure the coupling parts to prevent them from falling. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

- Page 18 Safety instructions 2.4 General warning notices N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 19: Description

These instructions describe the assembly and operation of an N‑EUPEX or N‑EUPEX DS coupling arranged horizontally with a shaft-hub connection made by a cylindrical or conical bore with parallel key. Please consult Flender if you want to use a different type of installation. Application N‑EUPEX couplings are designed for use in all kinds of machines. -

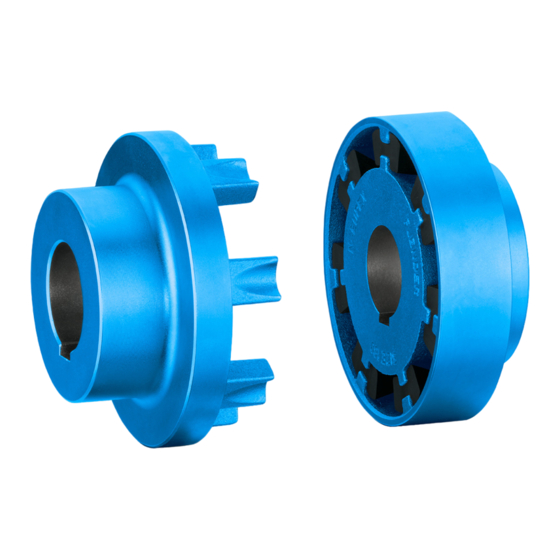

Page 20: Figure 3-2 Type B And Bds

Description Coupling part 1 Coupling part 4 Flexible element Figure 3-2 Type B and BDS N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 21: Application Planning

Storage of the coupling NOTICE Property damage due to improper storage Negative changes to the physical properties of the coupling and/or coupling damage. ● Please observe the information about storing the coupling. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 22: Table 4-1 Types Of Preservative Agents For Long-Term Storage

Tectyl 846 or similar Long-term preservative agent on Up to 36 months Up to 12 months wax basis Emulsion cleaner + VCI foil Active system, reusable Up to 5 years Up to 5 years N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 23: Assembly

Preparatory work Note Please consult Flender if you want to machine a conical finished bore. Carry out the following steps if the coupling does not have a finished bore: ● Milling the parallel keyway (Page 24) ●... -

Page 24: Milling The Parallel Keyway

Assembly 5.1 Preparatory work Note The customer is responsible for execution of the finishing work on the coupling. Flender shall have no liability whatsoever for claims under warranty arising from finishing work that has not been carried out adequately. 5.1.1 Milling the parallel keyway The diameter of the finished bore depends on the shaft used. -

Page 25: Milling The Parallel Keyway

Centred between the flexible element pockets N‑EUPEX Centred between the tapped holes N‑EUPEX DS Centred between the tapped holes and offset relative to the recesses for replacement of flexible elements N‑EUPEX Beneath a cam N‑EUPEX DS N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 26: Machining An Axial Locking Mechanism

Machining an axial locking mechanism The coupling part is secured by a set screw or an end plate to prevent axial movements. Please consult Flender if you want to use an end plate. Note the following when using a set screw: ●... - Page 27 315 / 340 350 / 380 400 / 430 440 / 472 480 / 514 520 / 556 Apply the recommended tightening torques in accordance with the stipulations in section Tightening procedure (Page 64). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 28: Balancing The Coupling

If you completely drill through the base of a flexible element pocket on coupling part 1 (1), then coupling part 1 (1) is no longer allowed to be used for operation. ● Please observe the stipulations about machining the balancing hole. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 29: Figure 5-3 Position Of The Balancing Bore For Single-Plane Balancing

A better balancing result can be achieved by balancing the coupling parts (2 and 3) when they are bolted together as an assembly. When balancing all parts together, mark the position of the components relative to one another. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 30: Assembling The Coupling

150 °C if required. Note when doing this the temperature range of the flexible elements (12) (see sections N-EUPEX flexible elements (12) (Page 65)and N-EUPEX DS flexible elements (12) (Page 66)). Remove the flexible elements (12) if necessary. -

Page 31: Aligning The Coupling

● Reduced restoring forces ● Misalignment reserves for operation of the coupling You can find the maximum permitted shaft misalignment values during operation in section Shaft misalignment values during operation (Page 62). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 32: Possible Misalignment

[deg] = (ΔS / DA) · (180 / π) perm perm DA in mm see section Speeds, geometry data and weights (Page 57) ΔS see section Shaft misalignment values during operation (Page 62) perm N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 33: Radial Misalignment

Determine the value ΔKr. The determined value ΔKr may not exceed the value ΔKr perm You can find the permissible radial misalignment ΔKr in section Shaft misalignment values perm during operation (Page 62). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 34 Assembly 5.3 Aligning the coupling N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 35: Commissioning

3. Check whether the enclosures (coupling guard, touch protection) have been installed and that the function of the coupling has not been adversely affected by the enclosure. This also applies to test runs and rotational direction checks. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 36 Commissioning N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 37: Operation

7.2.2 Identifying the fault cause Faults occur frequently due to application errors or they occur due to operational circumstances such as wear of wearing parts or changes to the system. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 38: Possible Faults

Please observe all the stipulations and requirements given in chapter Servic‐ Check the possible causes given in sec‐ ing (Page 43). tions Maintenance-related causes (Page 40) and Specific installation-rela‐ ted and maintenance-related causes (Page 40). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 39: Possible Causes

● Dynamic load conditions not taken into consideration. ● Coupling and the machine and/or drive train form a critical torsional, axial or bending vibration system. Assembly-related causes ● Damaged parts installed. ● Shaft diameter outside the stipulated tolerance range. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 40: Correcting Faults

Maintenance-related causes ● Stipulated maintenance intervals not adhered to. ● Spare parts that were used were not original spare parts from Flender. ● Flender spare parts that were used were old or damaged. ● Leak in the area of the coupling not detected so that chemically aggressive substances damage the coupling. -

Page 41: Correcting The Changed Alignment

1. Correct the cause for the change in alignment. 2. Check the wearing parts for wear and replace them as required. 3. Check the locking elements that prevent axial movements and correct these as required. 4. Realign the coupling. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 42 Operation 7.2 Faults - causes and rectification N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 43: Servicing

According to the ATEX Directive, need only be inspected if a failure of the flexible elements (12) and shutdown of the drive as a result of this failure could give rise to a risk of explosion. We recommend that the torsional backlash is checked regularly. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 44: Maximum Permissible Torsional Backlash

19.5 21.0 22.5 torsional backlash ΔS [mm] Table 8-4 Maximum permissible torsional backlash for the types ADS and BDS (sizes 66 to 218) Size Maximum permissible 10.5 11.5 torsional backlash ΔS [mm] N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 45: Replacing Wearing Parts

3 (3). ① Tapped jacking hole in coupling part 1 ② Tapped jacking hole in coupling part 3 Figure 8-2 Tapped jacking hole for loosening coupling part 3 (3) N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 46: Removing The Coupling

80 °C. Note when doing this the temperature range of the flexible elements (12) (see sections N- EUPEX flexible elements (12) (Page 65)and N-EUPEX DS flexible elements (12) (Page 66)). Remove the flexible elements if necessary. - Page 47 Servicing 8.4 Removing the coupling When reinstalling the coupling parts please observe the information in chapters Assembly (Page 23) and Commissioning (Page 35). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

- Page 48 Servicing 8.4 Removing the coupling N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 49: Service And Support

When ordering spare parts, requesting a customer service technician or in the case of technical queries, please contact our factory or one of our customer service addresses: Flender GmbH Schlavenhorst 100 46395 Bocholt Germany Tel.: +49 (0)2871/92-0 Fax.: +49 (0)2871/92-2596 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 50 Service and support 9.1 Contact N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 51: Disposal

Disposal Disposal of the coupling Dispose of the coupling parts according to applicable national regulations or recycle them. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 52 Disposal N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 53: Spare Parts

Flender will accept no liability or warranty whatsoever for damage occurring as a result of the use of non-approved spare parts. The same applies to any accessories that were not supplied by Flender. -

Page 54: Spare Parts Drawing And Spare Parts List

Spare parts list for types A and ADS Part number Designation Coupling part 1 Coupling part 2 Coupling part 3 Flexible element Cylinder-head screw Cylindrical pin only with type A sizes 560 to 710 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 55: Types B And Bds

Types B and BDS Figure 11-2 Spare parts drawing for types B and BDS Table 11-2 Spare parts list for types B and BDS Part number Designation Coupling part 1 Coupling part 4 Flexible element N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 56 Spare parts 11.2 Spare parts drawing and spare parts list N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 57: Technical Data

Speed Maximum bore Weight NL1 / NL2 5 300 2 … 4 5 100 2 … 4 4 900 2 … 4 4 250 2 … 6 3 800 2 … 6 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 58 1 100 6 … 12 1 000 6 … 12 1 000 6 … 12 Maximum bore for parallel keyway in accordance with DIN 6885/1. Weight applies to one coupling with maximum bore. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

-

Page 59: Type B

3 000 2 … 6 2 750 3 … 8 2 450 3 … 8 Maximum bore for parallel keyway in accordance with DIN 6885/1. Weight applies to one coupling with maximum bore. N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 60: Type Ads

2 … 6 2 750 3 … 8 2 450 3 … 8 2 150 3 … 8 2 000 3 … 8 1 700 3 … 8 1 550 5 … 10 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 61: Type Bds

2 … 4 5 500 2 … 4 5 300 2 … 4 5 100 2 … 4 4 900 2 … 4 4 250 2 … 6 3 800 2 … 6 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 62: Shaft Misalignment Values During Operation

0.15 0.15 0.25 0.15 0.15 0.35 0.25 0.25 0.15 0.35 0.25 0.15 0.25 0.25 0.15 0.15 0.35 0.25 0.15 0.35 0.25 0.15 0.35 0.25 0.55 0.45 0.55 0.35 0.25 0.35 0.35 0.35 N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 63: Tightening Torques And Widths A/F

Hexagon socket-head screws according to DIN EN ISO 4762 Size Size 17.5 67.5 1 450 1 450 1 450 Apply the recommended tightening torques in accordance with the stipulations in section Tightening procedure (Page 64). N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 64: Tightening Procedure

● Protect against direct sunlight, artificial light with a high UV‐content and extreme temperatures ● Avoid contact with aggressive media ● Only replace complete sets ● Only use flexible elements of the same type and age N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 65: N-Eupex Flexible Elements (12)

Black flexible elements -10 °C to +100 °C Not approved with high-temperature use red stripe 80 Shore A Special, Green flexible ele‐ -30 °C to +80 °C IIA, IIB ments electrically insulating N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... -

Page 66: N-Eupex Ds Flexible Elements (12)

Technical data A.5 Flexible elements (12) A.5.3 N-EUPEX DS flexible elements (12) Table A-9 N‑EUPEX DS flexible elements Material Hardness Comment Marking Ambient tempera‐ Approved for ture explosion group 80/90 Shore A Standard, Black flexible elements -30 °C to +80 °C... -

Page 67: Quality Documents

Quality documents Declaration of Conformity N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017... - Page 68 The notified body, DEKRA EXAM GmbH, code number 0158, has received the technical documentation. Signed for and on behalf of: Flender GmbH Bocholt, 2017-10-01 i.V. Felix Henseler, Head of PD MD AP Bocholt, 2017-10-01 i.V. Thomas Tebrügge, Head of PD MD AP COU BA N-EUPEX / N-EUPEX DS 3100en Operating Instructions 10/2017...

- Page 69 AA 3100_KE_en_FLE...

- Page 70 FLENDER COUPLINGS N-EUPEX / N-EUPEX DS Operating Instructions 3100en Edition 10/2017 Flender GmbH Alfred-Flender-Straße 77 46395 Bocholt GERMANY...

Need help?

Do you have a question about the N-EUPEX and is the answer not in the manual?

Questions and answers