Table of Contents

Advertisement

Quick Links

Download this manual

See also:

Manual

Tunnel Master®Jr.

User Manual - Version 3.0

Corporate Office: 1349 Jacobsburg Road, Wind Gap, PA 18091

Sales: 800.642.9396

|

Email: sales@icscarwashsystems.com

Copyright © 2016 Innovative Control Systems, Inc. Portions of this document may contain information that is ICS proprietary.

Innovative Control Systems is an industry leading provider of innovative business solutions in

the car wash industry. It is our mission to help car wash operators build successful businesses

through advanced control products and management solutions.

|

Production Facility: 3370 Fox Hill Road, Easton, PA 18045

|

icscarwashsystems.com

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for ICS Tunnel Master Jr

- Page 1 Corporate Office: 1349 Jacobsburg Road, Wind Gap, PA 18091 Production Facility: 3370 Fox Hill Road, Easton, PA 18045 Sales: 800.642.9396 Email: sales@icscarwashsystems.com icscarwashsystems.com Copyright © 2016 Innovative Control Systems, Inc. Portions of this document may contain information that is ICS proprietary.

- Page 2 Information in this manual is subject to change without notice. Companies, names and data used in examples within the manual are fictitious unless otherwise noted. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, for any purpose without the express written permission of Innovative Control Systems, Inc.

-

Page 3: Table Of Contents

User Manual—Version 3.0 Tunnel Master TABLE OF CONTENTS TABLE OF CONTENTS Chapter 1: Introduction ................11 Version Considerations . - Page 4 TABLE OF CONTENTS Tunnel Master User Manual—Version 3.0 Push Button Wiring ............34 Push Button Wiring 1 Row 8 Columns .

- Page 5 User Manual—Version 3.0 Tunnel Master TABLE OF CONTENTS Communication and Keypad Installation ..........75 Entrance Keypad Mounting and Installation .

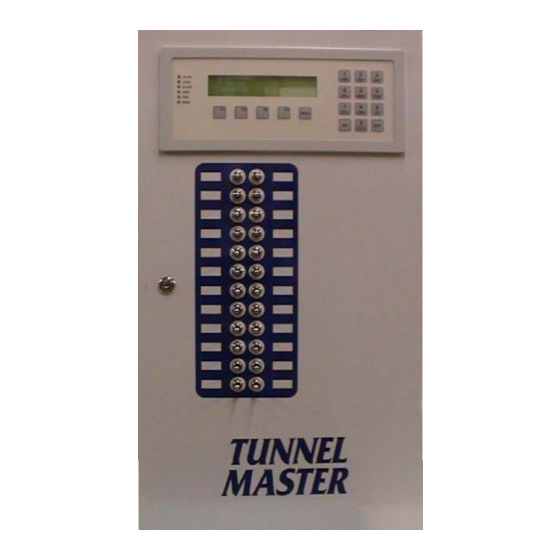

- Page 7 User Manual—Version 3.0 Tunnel Master List of Figures List of Figures Figure 1. Front Panel ............. . 15 Figure 2.

- Page 9 User Manual—Version 3.0 Tunnel Master List of Tables List of Tables Table 1. Relay Box Circuit Descriptions ..........39 Table 2.

-

Page 11: Introduction

(also known as the TMJ) from Innovative Control Systems, Inc. As an ICS customer, you benefit from a thoroughly researched and developed car wash controller system. This manual will enable the operator to have an active part in the control and operation of your car ... -

Page 12: Controller Features

Troubleshoot issues, if they occur Many of the features you will find in the ICS Controller system were integrated at the request of car wash operators. We welcome your feedback and want to assure you that ICS is committed to being the leader in the industry in car wash controller and management systems. -

Page 13: System Hardware And Installation

User Manual—Version 3.0 Tunnel Master System Hardware and Installation CHAPTER 2: SYSTEM HARDWARE AND INSTALLATION This chapter includes preliminary steps to take for a new Tunnel Master installation. This chapter provides a brief description of the hardware components and their function and the tunnel settings wiring diagrams. ... -

Page 14: Resetting Default Configuration Settings

The following procedure shows how to erase the current settings. NOTE: ICS recommends a complete, first-time erase using DIP switch 6, as described below. To erase all configuration settings, follow these steps: 1 Remove the battery from the Main CPU PCB. -

Page 15: Warning Marking

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Warning Marking WARNING: This warning on equipment or hardware indicates the need to consult accompanying documentation before proceeding. OUTPUT OVERVIEW 24 Outputs The Tunnel Master Jr. Relay Box is the control center for firing the various outputs or services in the wash tunnel: Soap foamer, Reclaim motor, etc. -

Page 16: Relay Box Installation

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Each toggle switch controls the operation of one output or service. The switch has three positions: UP = Manual Override. Manually turn on output. (This feature can be turned off if desired.) ... - Page 17 User Manual—Version 3.0 Tunnel Master System Hardware and Installation respectively, then loop the commons together to each relay. This power is to fire the solenoids and equipment. A separation of 120 VAC and 24 VAC shall be maintained for all field-wiring circuits.

-

Page 18: Relay Box Interior

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Figure 2. Low Voltage Layout Wiring Diagram RELAY BOX INTERIOR Each relay has circuits to control both 24 VAC and/or 120 VAC simultaneously so that a service sign as well as the service solenoid can be operated from the same relay. -

Page 19: Figure 3. Relay Box Interior Components

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Termination points for Pulse, Gate, Tire, and Panic Circuits. Plug in relays for ease of serviceability. Each relay has two fuses (24 VAC and 120 VAC). Built in spare fuses and fuse tester. -

Page 20: Pulse/Proximity Switch Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 PULSE/PROXIMITY SWITCH WIRING IMPORTANT: The pulse switch is a critical input for the Controller. It signals the system that the conveyor is moving and is the measuring device from which the system knows when to turn equipment devices on and off. -

Page 21: Pulse/Proximity Switch Wiring

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Pulse/Proximity Switch Wiring 2-Wire pulse 3-Wire (NPN) switch with Proximity N.O. contact switch - Sinking "Used when connecting a standard "Push Button" entry box. Terminals not used in this diagram Terminal strip on top of relay board Refer to Jumper settings Figure 4. -

Page 22: Gate Switch (Electric Eye) Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 GATE SWITCH (ELECTRIC EYE) WIRING IMPORTANT: The Gate switch is the second critical input device to the Relay Box. It is usually an electric eye system or some type of vehicle position detector located just before the first piece of wash equipment. -

Page 23: Gate Eye Switch Wiring

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Gate Eye Switch Wiring TMJ RELAY BOX TERMINAL STRIP (TOP) 24 VAC SUPPLY (BY OTHERS) COMMON NORMALLY OPEN ELECTRIC PHOTO EYE OR OTHER SENSING DEVICE CONTACTS Alternate symbol for N.O. Switch Figure 5. -

Page 24: Tire Switch Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 TIRE SWITCH WIRING IMPORTANT: This circuit is used if the customer has purchased a tire position switch from the equipment vendor. The switch enables the Controller software to turn equipment on and off as each of the vehicle's tires pass that piece of equipment. -

Page 25: Entrance Management System Wiring

User Manual—Version 3.0 Tunnel Master System Hardware and Installation ENTRANCE MANAGEMENT SYSTEM WIRING IMPORTANT: This circuit is used if the customer has purchased a treadle switch from the equipment vendor. The Entrance Management System in the Tunnel Master allows a roller to be fired automatically upon seeing a second 24V input on Input 10. -

Page 26: Entrance Management System Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Entrance Management System Wiring TMJ RELAY BOX TERMINAL STRIP (TOP) 24 VAC SUPPLY (BY OTHERS) COMMON NORMALLY OPEN TREADLE SWITCH N.O. CONTACTS Figure 7. Entrance Management Overview and Wiring Diagram ROLLER LOCATOR WIRING IMPORTANT: You can add a roller locator to the Tunnel ... -

Page 27: Conveyor Roller Locator Cross Section Diagram

User Manual—Version 3.0 Tunnel Master System Hardware and Installation A roller locator switch needs to be wired into Input 9, and installed on the conveyor. This switch should be positioned so that as soon as a roller passes the switch it will be in a position where it is safe for the roller forks to come up. -

Page 28: Roller Locator Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Roller Locator Wiring TMJ RELAY BOX TERMINAL STRIP (TOP) 24 VAC SUPPLY (BY OTHERS) NORMALLY COMMON OPEN ROLLER LOCATOR DEVICE CONTACTS Alternate symbol for N.O. Switch Figure 9. Roller Locator Wiring January 2016... -

Page 29: Panic Stop Circuit Wiring

User Manual—Version 3.0 Tunnel Master System Hardware and Installation PANIC STOP CIRCUIT WIRING IMPORTANT: This drawing shows the basic wiring of the panic circuit. The Panic circuit allows for certain software programming that could not be programmed without this circuit in place. -

Page 30: Panic Stop Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Panic Stop Wiring Figure 10. Panic Stop Circuit Wiring January 2016... -

Page 31: Anti-Collision Wiring

User Manual—Version 3.0 Tunnel Master System Hardware and Installation ANTI-COLLISION WIRING IMPORTANT: The anti-collision on the Tunnel Master Jr. is a function to help prevent cars from running into each other at the exit end of the tunnel. In order for this to work you need an anti-collision device mounted in the tunnel at the spot where you could have a potential collision. -

Page 32: Anti-Collision Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Anti-Collision Wiring TMJ RELAY BOX TERMINAL STRIP (TOP) 24 VAC SUPPLY (BY OTHERS) NORMALLY COMMON OPEN ANTI- COLLISION DEVICE CONTACTS Alternate symbol for N.O. Switch Figure 11. Anti-Collision Wiring January 2016... -

Page 33: Input Wiring Summary

User Manual—Version 3.0 Tunnel Master System Hardware and Installation INPUT WIRING SUMMARY Figure 12. Inputs January 2016... -

Page 34: Push Button Wiring

System Hardware and Installation Tunnel Master User Manual—Version 3.0 PUSH BUTTON WIRING IMPORTANT: Please be certain to install it exactly as it is shown in the diagram. Wiring it in any other way would conflict with the designated inputs causing the washes to run incorrectly or not at all. -

Page 35: Push Button Wiring 1 Row 8 Columns

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Push Button Wiring 1 Row 8 Columns PB 1 Input 1 Service 1 PB 2 Input 2 Service 2 PB 3 Input 3 Service 3 PB 4 Input 8 All Clear 24VAC Inputs 1-8 Common... -

Page 36: Push Button Wiring First 8 Buttons

System Hardware and Installation Tunnel Master User Manual—Version 3.0 Push Button Wiring First 8 Buttons Service 1 Service 5 Input 5 Service 2 Service 6 Input 6 Service 3 Service 7 Input 6 Service 4 Service 8 Input 6 24VAC Inputs 1-8 Common... -

Page 37: Push Button Wiring For Second 8 Buttons

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Push Button Wiring for Second 8 Buttons Service 9 Service 13 Input 5 Service 10 Service 14 Input 6 Service 11 Service 15 Input 6 Service 12 ALL CLEAR Input 6 24VAC Inputs 1-8 Common... -

Page 38: Relay Box Jumper Settings

System Hardware and Installation Tunnel Master User Manual—Version 3.0 RELAY BOX JUMPER SETTINGS The following figure and table will explain the location and purpose of the various jumpers on the Relay Box circuit board. This board is located on the inside of the Relay Box door. -

Page 39: Table 1. Relay Box Circuit Descriptions

User Manual—Version 3.0 Tunnel Master System Hardware and Installation Table 1: Relay Box Circuit Descriptions Jumper Setting Function Does not exist. BIAS High (+) set ON for the Main Relay box only. 3 position jumper should be on 2 pins to select 485 Communication (Up). 3 position jumper should be on 2 pins to select 485 Communication (Up). -

Page 40: Dip Switch Settings

System Hardware and Installation Tunnel Master User Manual—Version 3.0 DIP SWITCH SETTINGS The following picture and table will show the Relay Box DIP switch and the various settings that may be used. The ON position is marked with an arrow and is always up. A 24 Output Relay Box will ship as ADDR1. -

Page 41: Operating Procedures

User Manual—Version 3.0 Tunnel Master Operating Procedures CHAPTER 3: OPERATING PROCEDURES OPERATING PROCEDURES The Operating Procedures chapter will provide the user with an explanation of how to operate their Tunnel Controller, process customer vehicles and review operations through the reports available. As in the previous chapters, the instructions will follow a logical trail through a day’s operations beginning with the opening process. -

Page 42: Wet Down Wash

NOTE: If a password has been set, it will be necessary to enter the password before the main menu can be accessed. From the display panel numeric keypad, press the ICS Tunnel Controller 10:25:35 PM VER 1 REV numeric 2 key to select 5.1104/15/2002 Wet Down Wash. -

Page 43: Wash Configuration

Jr. Car Wash Controller. The Tunnel Master Jr. Controller contains unique features usually found only in the high-end full-service wash controller systems. Features like ICS copyrighted anti-theft software; integration with a Panic Stop circuit; and for quick morning wash checkouts, use Wet down. -

Page 44: Relay Box Display Keypad

Wash Configuration Tunnel Master User Manual—Version 3.0 RELAY BOX DISPLAY KEYPAD The Relay Box keypad is the primary place from which to program and configure the wash tunnel. If your facility has two relay boxes, one of them will serve as the primary input relay box. From this screen you can: ... -

Page 45: Set Password

User Manual—Version 3.0 Tunnel Master Wash Configuration Table 5: Relay Box Display and Keypad Indicator Light Descriptions Button Function Indicator Lights: +5V DC This light should be lit at all times indicating that the input terminal system has good power. -

Page 46: Table 6. Change The System Password Instructions

Enter in your password. New Password: _ Example: For the letter L, press the 4 key three times Press the ENT key to save your changes, and New Password: ICS _ return to the Configure Wash Menu. NOTE: Remember this password. January 2016... -

Page 47: Access A Password Protected Menu

Step Action Screen Displays From the main screen, press the Menu key. ICS Tunnel Controller 10:25:35 PM VER 1 REV 5.1104/15/2016 Password _ _ _ _ _ _ ADDR =1CARS 0000 Using the numeric keypad, type in the first letter of ICS Tunnel Controller 10:25:35 PM VER 1 REV the password. -

Page 48: Configure Wash Menu

Wash Configuration Tunnel Master User Manual—Version 3.0 CONFIGURE WASH MENU Before any washes can be processed, the user must configure the wash. There are many items to be configured including the actual tunnel setup all the way to setting up services. Each item must be configured accurately if the wash is to operate properly. -

Page 49: Table 9. Wash Settings Menu

User Manual—Version 3.0 Tunnel Master Wash Configuration The following is a list of menu items within the Wash Settings menu option and a brief explanation of their function. Table 9: Wash Settings Menu Wash Setting Field Description Auto Pulse Period This is the rate in which you want the conveyor to run when in Auto Pulse. - Page 50 If you do not have a push button station, this option is disregarded. Console Debug This is a debug utility that ICS may use to track system activity. This should be set to N if you are using the Tunnel Master Jr.

- Page 51 User Manual—Version 3.0 Tunnel Master Wash Configuration Table 9: Wash Settings Menu Wash Setting Field Description Footer 3 Enter information desired to display on the third line on the bottom of receipts. This is usually a message to the customer. Footer 4 Enter information desired to display on the fourth line on the bottom of receipts.

-

Page 52: Set Date Time

The number of times the Tunnel Master Jr. has been reset. For information purposes only. ExpireDays For ICS use only. EqptMeasurement If Y (Yes), the equipment distance measured in inches. If N (No) the equipment InInches distances is measured in pulses. -

Page 53: Table 10. Set Date And Time Instructions

User Manual—Version 3.0 Tunnel Master Wash Configuration Follow these procedures to set or change the correct date and time in the system. Table 10: Set Date and Time Instructions Step Action Screen Displays Press the numeric key 3 from the Main Menu to [1] Shift Break[4] View Counts select Configure Wash. -

Page 54: Configure Wash Settings

Wash Configuration Tunnel Master User Manual—Version 3.0 CONFIGURE WASH SETTINGS Before any washes can be processed, the user must configure the wash. Each item must be configured accurately if the wash is to operate properly. Table 11: Configure Wash Settings Step Action Screen Displays... -

Page 55: About Countdown Times

User Manual—Version 3.0 Tunnel Master Wash Configuration About Countdown Times Set the Wet Down Period in the panel to the exact wet down time (e.g., 100). This is the amount of time you want the actual wet down relays to fire and apply water to the equipment. -

Page 56: Outputs

Wash Configuration Tunnel Master User Manual—Version 3.0 OUTPUTS The Outputs menu option is where the user will initially setup and later, as needed, edit the wash relays that will be activate for the various was equipment. The basic Tunnel Master Jr. - Page 57 User Manual—Version 3.0 Tunnel Master Wash Configuration Table 12: Outputs (Continued)Descriptions Menu Item Function Part Use the “0” button to advance to the part of car selection that the piece of equipment turns on. AC = All of the Car FH = Front Half of the Vehicle FB = Front Bumper On RH = Rear Half of Vehicle...

-

Page 58: Output Settings

Wash Configuration Tunnel Master User Manual—Version 3.0 OUTPUT SETTINGS Follow these procedures to set or change the settings for the Outputs in the Tunnel Master Jr. Controller program. Table 13: Output Settings Step Action Screen Displays Press the MENU button from the main screen [1] Shift Break[4] View Counts display. - Page 59 User Manual—Version 3.0 Tunnel Master Wash Configuration Table 13: Output Settings Step Action Screen Displays Using the numeric buttons enter the Start time in Output 01 Name Roller inches or pulses depending on the wash setting Start 0084 Type _ Part _ _ Flash _ selection.

-

Page 60: Table 14. Services Menu Item Descriptions

Wash Configuration Tunnel Master User Manual—Version 3.0 Table 13: Output Settings Step Action Screen Displays From the numeric keypad, type the number of Output 01 Name Roller seconds of delay for this relay to turn on before Start 0084 Type R Part AC Flash N Extend 000 the convey Look 000 Wet N Panic N - 0 or will restart. -

Page 61: Table 15. Change Or Set Services Instructions

User Manual—Version 3.0 Tunnel Master Wash Configuration Table 14: Services Menu Item Descriptions Menu Item Function Price Use the numeric keys to enter the price for the service being programmed. NOTE: To enter a decimal point, press the number 0 key two times. Type Use the 0 button to advance to the type of service. - Page 62 Wash Configuration Tunnel Master User Manual—Version 3.0 Table 15: Change or Set Services Instructions Step Action Screen Displays Press the ENT button on the display pad to Service 01 Name _ _ _ _ _ _ _ _ _ _ PriceType advance to the next setting.

-

Page 63: Assign Outputs To Services

User Manual—Version 3.0 Tunnel Master Wash Configuration Table 15: Change or Set Services Instructions Step Action Screen Displays Using the numeric buttons enter the desired tax Service 01 Name GOLD WASH Price 9.99Type B rate option, 0, 1, 2, or 3. Rate 1 F1=PREV F2=NEXT F3=ERASE F4=SAVE Press the F4 button to save the service. - Page 64 Wash Configuration Tunnel Master User Manual—Version 3.0 Table 16: Assign Outputs to Services Instructions Step Action Screen Display Press the ENT button on the display pad to Service 03 advance to the next setting. Outputs 05, Repeat steps 6 & 7 until all desired outputs have Service 03 been programmed.

-

Page 65: Entrance Keypad

User Manual—Version 3.0 Tunnel Master Entrance Keypad CHAPTER 5: ENTRANCE KEYPAD The Entrance Keypad is the service/output station at the front of the car wash. Services sold to the customer are entered into the Entrance Keypad. Vehicles are processed at the front of the wash with Entrance Keypad. ... -

Page 66: Entrance Keypad Functions

Entrance Keypad Tunnel Master User Manual—Version 3.0 ENTRANCE KEYPAD FUNCTIONS NOTE: In order to utilize the full functionality of the Entrance Keypad, Tunnel Master Jr. it is very important that the electrician adhere to the wiring instructions provided with the Relay Box. Power indicator After selecting light. -

Page 67: Table 17. Entrance Keypad Buttons

The car is the Roller button and when selected will activate the roller relay. In ICS-POS mode, when the AC button is selected, the stack displays in blinking Led lights on the numeric buttons. Number one is the closest to the tunnel entrance. The stack blinks for 5 seconds. -

Page 68: Entrance Keypad To Process Vehicles (Non-Stacking)

Entrance Keypad Tunnel Master User Manual—Version 3.0 ENTRANCE KEYPAD TO PROCESS VEHICLES (NON-STACKING) These are the steps to follow for a non-stacking system. Table 18: Process Vehicles (Non-Stacking) Step Non-Stacking Action Keypad Response On the numeric keypad, press the button The red indicator light will light up indicating the associated with the service the customer has input has been accepted. -

Page 69: Entrance Keypad To Process Vehicles (Stack)

User Manual—Version 3.0 Tunnel Master Entrance Keypad ENTRANCE KEYPAD TO PROCESS VEHICLES (STACK) For Stack with Keypad Only, these are the steps to follow: Table 19: Process Vehicles Stack Instructions Status Step Stacking Action Keypad Response Ready Press the numeric button associated with The red indicator light will light up the service that the customer has indicating the input has been accepted. -

Page 70: Add A Car To Stack

Entrance Keypad Tunnel Master User Manual—Version 3.0 2 Press to select the numeric button that represents the car in the stack you would like to modify. The service that is selected for that car will light up on the keypad. 3 If necessary, press to select the numeric button of the service you wish to clear. -

Page 71: View Service Counts

User Manual—Version 3.0 Tunnel Master Entrance Keypad VIEW SERVICE COUNTS There will be times during the course of daily operations that management personnel will want to review sales counts. From the View Counts menu, this option allows the user to quickly determine how many of each service option have been processed during the current shift. -

Page 72: Shift Break

Entrance Keypad Tunnel Master User Manual—Version 3.0 Table 20: View Service Counts Instructions Step Action Screen Display Press the ENT button on the display keypad to EXTERIOR W 0052 05- POLISH WAX 0023 advance to additional services. SILVER WAS 0023 06-CLEAR COAT 0015 GOLD WASH 0015 07-[EMPTY]0000 PLATNUM W 0009 08-[EMPTY]0000 Repeat Step 3 to review up to... -

Page 73: Bump A Shift Or Manually Close Current Shift

User Manual—Version 3.0 Tunnel Master Entrance Keypad Bump a Shift or Manually Close Current Shift Follow these steps to manually break (close) the current shift. Table 21: Manually Close or Bump the Current Shift Instructions Step Action Screen Displays Access the Main Menu by pressing the “Menu”... -

Page 75: User Manual-Version

User Manual—Version 3.0 Tunnel Master Communication and Keypad Installation CHAPTER 6: COMMUNICATION AND KEYPAD INSTALLATION The following instructions will provide detailed information on proper mounting and installation of the entrance keypad and communication. ENTRANCE KEYPAD MOUNTING AND INSTALLATION Entrance Keypad Mounting ... -

Page 76: Figure 20. Keypad Connectors (Keypad Board)

Communication and Keypad Installation Tunnel Master User Manual—Version 3.0 The following picture shows the connection points for the various components. Communications wire Optional Pole Display termination points. screen termination You can use either points terminal block. In a second keypad, you would use serial. -

Page 77: Figure 21. Ac Power Terminations

User Manual—Version 3.0 Tunnel Master Communication and Keypad Installation Tunnel Master Jr. AC Power Terminations GROUND ELECTRICIAN 120 VAC FROM SUPPLIED 14/3 POWER DISTRIBUTION SHIELDED PANEL – 14/3 SHIELDED WIRE “E” SUPPLY FOR TMJ KEYPAD INSIDE TMJ RELAY BOX... - Page 78 User Manual—Version 3.0 Electrician must run a single-twisted pair, 24AWG shielded COM cable (can be purchased from ICS) through 3/4” conduit from the 485 terminal to the Entrance Keypad. There is a terminal block (NETWORK 485), located on the keypad circuit board labeled with DT+, DT-, and GND, for Data+, Data- and Ground, respectfully.

-

Page 79: Figure 22. Communication Cable Termination Diagram

User Manual—Version 3.0 Tunnel Master Communication and Keypad Installation Figure 22. Communication Cable Termination Diagram January 2016... -

Page 80: Second Entrance Keypad Mounting And Installation

Communication and Keypad Installation Tunnel Master User Manual—Version 3.0 SECOND ENTRANCE KEYPAD MOUNTING AND INSTALLATION The following instructions will provide detailed information on proper mounting and installation of the optional second Entrance Keypad. Second Entrance Keypad Mounting The second Entrance Keypad should be mounted securely to the wall of the car wash, directly next to the first Entrance Keypad in the entrance to the tunnel. - Page 81 Communication and Keypad Installation Electrician must run a single-twisted pair, 12AWG shielded Comm cable (can be purchased from ICS) through the above 3/4” conduit from the first Entrance Keypad to the second Entrance Keypad. There is a terminal block (NETWORK 485), located on each of the keypad circuit boards labeled with DT+, DT-, and GND, for Data+, Data- and Ground, respectfully.

-

Page 82: Entrance Keypad Jumper Settings

Communication and Keypad Installation Tunnel Master User Manual—Version 3.0 Comm cable terminations must be made as in the following table. Table 23: Comm Cable Terminations First Entrance Keypad Second Entrance Keypad (Either Connector) (Either Connector) ENTRANCE KEYPAD JUMPER SETTINGS The following figure shows the Entrance Keypad circuit board and location of the various jumpers on the Entrance Keypad circuit board. -

Page 83: Entrance Keypad Dip Switch Settings

In Figure 23, “Keypad Circuit Board Jumper Settings,”, the jumper functions are displayed with their normal settings. By default, the keypad is address 5. There is no reason to change this unless advised by ICS. If you have two keypads, you should address the second as address 6. -

Page 84: Table 25. Dip Switch Settings

Table 25: DIP Switch Settings Switch Setting Function Address setting 1, 2 OFF = Address 5 1 OFF, 2 ON = Address 6 Address setting 1 ON, 2 OFF = Address 7 1, 2 ON = Address 8 Baud Rate OFF = 9600 ON = 38,400 Test Mode... -

Page 85: Optional Report/Receipt Printer Installation

User Manual—Version 3.0 Tunnel Master Jr. Optional Report/Receipt Printer Installation CHAPTER 7: OPTIONAL REPORT/RECEIPT PRINTER INSTALLATION The Epson TM-T811 thermal printer is utilized by the Tunnel Master Jr. System for both the report and receipt printer. These printers can be purchased as an option to the base system or purchased and added to the system after initial installation. -

Page 86: Mounting And Installation Of Report/Receipt Printer

Optional Report/Receipt Printer Installation Tunnel Master User Manual—Version 3.0 Figure 25. Epson Dot Matrix Report/Receipt Printer MOUNTING AND INSTALLATION OF REPORT/RECEIPT PRINTER Report Printer Mounting The report printer should be set on a shelf, which is securely mounted next to the Relay Box. - Page 87 Insert the cable with the 25-pin RS-232 connector attached (supplied by ICS) into the Relay Box. Allow excess cable outside the Relay Box for easy access to the backside of the report printer so that the RS-232 25-pin connector can be easily attached and removed.

-

Page 89: Trouble Shooting

CHAPTER 8: TROUBLE SHOOTING System Diagnosis The following diagnostic procedures are provided for use only when the ICS Tunnel Controller System has stopped responding or is not functioning. If you determine after reviewing the diagnostic procedures the system is malfunctioning, write down the specific conditions and contact... -

Page 90: Wash Controller Input Check

Trouble Shooting Tunnel Master User Manual—Version 3.0 Check the Logic light in the upper left corner of the relay box display panel. This light should be blinking indicating that the system processor is functioning. Wash Controller Input Check There are four possible inputs into the Controller that if not functioning could cause the system to not respond properly. -

Page 91: Entrance Keypad Diagnostics

User Manual—Version 3.0 Tunnel Master Trouble Shooting Entrance Keypad Diagnostics To test the keypad, there is a diagnostic mode you can put it in to verify its functionality. Remove the four screws and remove the top of the keypad. Flip it over, you will see the DIP switch settings. -

Page 92: Table 27. Entrance Keypad Troubleshooting

Loss of power to Entrance Check Power LED, if voltage present LED will flash. Keypad. Reconnect 120VAC to relay box. ICS Tunnel Master Jr. Relay Box has no power. Wires and/or plugs loose. Re-connect as necessary. Keypad and Relay box jumpers Check the proper jumper settings. -

Page 93: Table 28. Miscellaneous Troubleshooting

User Manual—Version 3.0 Tunnel Master Trouble Shooting Table 28: Miscellaneous Troubleshooting Symptom Cause Remedy Roller keep coming up. Check the pulse switch. Please refer to Wash Controller Input Check on page 67. Equipment timing is off. Check the pulse switch. Please refer to Wash Controller Input Check on page 67. - Page 95 User Manual—Version 3.0 Tunnel Master Appendix The following three appendixes are three different scenarios you might have at your car wash: Figure A - “1 Relay box, Keypad and Printer” Figure B - “2 Relay Boxes, Keypad and Printer” ...

-

Page 97: Figure 26. Appendix A - 1 Relay Box/1 Entrance Keypad/1 Receipt Printer

User Manual—Version 3.0 Tunnel Master 1 Relay box, Keypad and Printer APPENDIX A: 1 Relay box, Keypad and Printer Figure 26. Appendix A - 1 Relay Box/1 Entrance Keypad/1 Receipt Printer January 2016... -

Page 99: Figure 27. Appendix B - 2 Relay Boxes/1 Entrance Keypad/1 Receipt Report Printer

User Manual—Version 3.0 Tunnel Master 2 Relay Boxes, Keypad and Printer APPENDIX B: 2 Relay Boxes, Keypad and Printer Figure 27. Appendix B - 2 Relay Boxes/1 Entrance Keypad/1 Receipt Report Printer January 2016... -

Page 101: Figure 28. Appendix C - 2 Relay Boxes/2 Entrance Keypads/Report Receipt Printer

User Manual—Version 3.0 Tunnel Master 2 Relay Boxes, 2 Keypads, 2 Printers APPENDIX C: 2 Relay Boxes, 2 Keypads, 2 Printers Figure 28. Appendix C - 2 Relay Boxes/2 Entrance Keypads/Report Receipt Printer January 2016... - Page 103 User Manual—Version 3.0 Tunnel Master Index Index Actions 89 Add a Car to Stack 70 Add Retract 69 Anti 31 Anti-Collision Wiring 31, 32 Assign Outputs to Services 63 Audience 11 Bump a Shift or Manually Close Current Shift 73 Change Service and/or add Retract 69 Comm cable terminations 78 Communications wiring 75...

- Page 104 Index Tunnel Master User Manual—Version 3.0 Keypad Installation 75 Logging in 19 Output 15 Output overview 15 Output Settings 58 Outputs timed outputs 56 Panic 29 Panic Stop Circuit Wiring 29 Panic Stop Wiring 30 Password 45 Password Protected Menu 47 Pulse/Proximity Switch Wiring 20 Push Button Wiring 34 Push Button Wiring 1 Row 8 Columns 35...

- Page 105 User Manual—Version 3.0 Tunnel Master Index Tire inputs 17 Tire Switch Wiring 24 Trouble Shooting Clock Indicator 90 Entrance Keypad 89 Entrance Keypad Diagnostics 91 Gate Indicator 90 Panic Indicator 90 Tire Indicator 90 Wash Controller Input Check 90 Wash Controller Response 89 Troubleshooting Miscellaneous 93...

-

Page 107: Change History

Change History Document Date(s) Reviewer Initials Description Version 10/8/2010 MR, DP, J.M, First release. JL-S 07/31/2015 WLS, BM, ES, SS, Second release. 02/11/2016 WLS, BM, CB Third release. Updated Communication Cable Ter- mination drawing. Tunnel Master, Auto Sentry, and WashConnect are registered trademarks of Innovative Control Systems, Inc. Windows and Internet Explorer are registered trademarks of Microsoft Corporation.

Need help?

Do you have a question about the Tunnel Master Jr and is the answer not in the manual?

Questions and answers