Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for BOGBALLE M2

- Page 1 M-line M2(W) / M3(W) / M6W Operator’s Manual 0404-02-01-14 V15...

-

Page 2: Table Of Contents

M2(W) / M3(W) / M6W CONTENTS Page SUBJECT OVERVIEW …………………………………….. TECHNICAL SPECIFICATIONS …………………………………….. STANDARD EQUIPMENT …………………………………….. OPTIONAL EQUIPMENT …………………………………….. MAINTENANCE AND CARE …………………………………….. Normal maintenance………………….. Special maintenance……………………. 6 Lubrication………………………………. Generally…………………………………. 7 Spreading vanes…………………………. 7 GUARANTEE / RESPONSIBILITY …………………………………….. GENERALLY …………………………………….. -

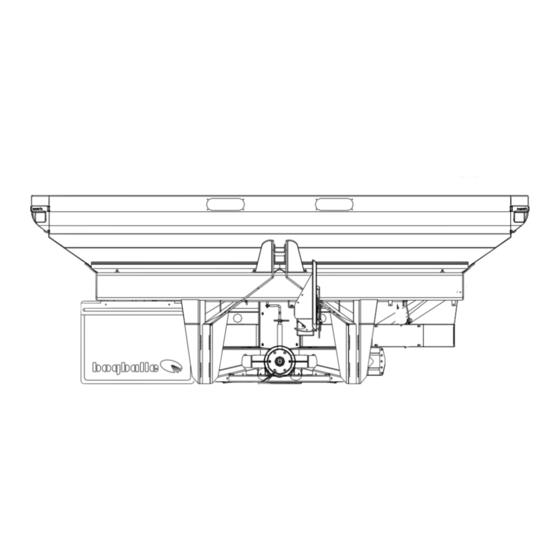

Page 3: Overview

M2(W) / M3(W) / M6W OVERVIEW – M3 illustration Setting pointer Top link fixture Connection rod Shutter Angle transmission Degree meter Link pins Telescope Cardan joint Serial No. plate Setting axle Friction clutch... -

Page 4: Technical Specifications

Cat. III / ISO730/I TECHNICAL SPECIFICATIONS, specific The volume of the M2/M2W base machine can be increased in steps of 550 litres by mounting modules (max. 2 modules). The volume of the M2/M2W plus machine can be increased in steps of respectively 450 litres and/or 750 litres by mounting modules. -

Page 5: Standard Equipment

4650-28 M() / M()W, System E8-T (L/R) – 42 metres 4650-36 M() / M()W, System U1-T (L/R) 12 – 18 metres 4650-50 All BOGBALLE products are subject to a continuous development. Therefore the list might not always be up-to-date. -

Page 6: Maintenance And Care

M2(W) / M3(W) / M6W MAINTENANCE AND CARE NORMAL MAINTENANCE The BOGBALLE machine is manufactured in such a way that it requires a minimum of maintenance. In the construction it is considered that cleaning and lubrication can be completed quickly and thoroughly – without taking apart the machine. -

Page 7: Special Maintenance

M2(W) / M3(W) / M6W SPECIAL MAINTENANCE, Friction clutch The transmission of the machine is equipped with friction/overload clutch. The friction clutch is a most important component protecting against overload – and a damaged transmission / PTO- shaft. -

Page 8: Lubrication

M2(W) / M3(W) / M6W LUBRICATION The components below must be greased according to below instruction. ” ” OVERVIEW See the explaining sketch in the paragraph LUBRICATION ONCE A DAY: POS. COMPONENT INSTRUCTION Cardan joint and lock of the PTO... -

Page 9: Guarantee / Responsibility

M2(W) / M3(W) / M6W GUARANTEE / RESPONSIBILITY • Claim conditions are according to Danish legislation. Service and repair are made free of cost within 12 months from date of purchase on the following conditions: • That the failure is due to construction or material faults (Normal wear, missing maintenance and misuse not included). -

Page 10: Spreading System

M2(W) / M3(W) / M6W SPREADING SYSTEM The BOGBALLE spreading system is base on an Integrated Center System – ICS, where the spreading discs of the machine during NORMAL spreading – rotate against each other – and spread in an angle on 180°, with full overlap. -

Page 11: Setting System

M2(W) / M3(W) / M6W SETTING SYSTEM The setting system consists of a scale pointer, different connection rods and outlet shutters. SETTING POINTER, Hydraulic / CALIBRATOR. ➊ ➊ ➋ & The connection rod of the setting pointer must be mounted / adjusted in such a way, that the shutters of the spreader are closed - when the setting pointer is placed on the scale ciffer ”0”. -

Page 12: Function - How To Do

The Trend sytem gives distribution of fertiliser a totally new dimension, where PRECISION, USER FRIENDLINESS and RELIABILITY, are the three main areas in which BOGBALLE M() / M()W – differs most essentially from the other products in the market. •... - Page 13 M2(W) / M3(W) / M6W • The Trend system ensures an optimum result, with a minimum of setting. • The transmission of the machine with reversible rotation direction together with the double function of the spreading vane ensure that the spreader can be transformed from NORMAL spreading to HEADLAND speading –...

-

Page 14: Machine Settings / Normal And Late Application

M2(W) / M3(W) / M6W MACHINE SETTINGS GENERAL GUIDANCE FOR MACHINE SETTINGS PTO- speed, NORMAL spreading rpm. TILT- angle See chart (°) WORKING HEIGHT, Standard WORKING HEIGHT, Late application Max. WORKING HEIGHT, Chassis kit QUANTITY SETTING... -

Page 15: Tilt Angle

M2(W) / M3(W) / M6W TILT ANGLE The machine must be ”tilted” as indicated in the spread chart. The tilt angle is important for the spread width and is – besides the quantity setting – in reality the only setting to be done on the machine. - Page 16 M2(W) / M3(W) / M6W WORKING HEIGHT – LATE APPLICATION Options are not necessary for late application in high crops. • The link pins of the spreader are moved to the lowest position in order to lift the machine as much as possible.

-

Page 17: Setting Of Quantity

varies with each delivery. If an exact quantity is required (Kg/Ha), it is recommended to CALIBRATE the machine by use of the BOGBALLE rate check kit. (See the paragraph ”USE OF RATE CHECK KIT”) The quantity (Kg/Ha) is set by the scale pointer of the machine. -

Page 18: Vane / Spread Widht

M2(W) / M3(W) / M6W U- cut VANE / SPREAD WIDTH Setting The vanes are mounted as standard in POS. 1-2 When mounting the fixing bolt must be pulled fully out into the U-shaped cut before tightening the nut. -

Page 19: Function Spreading Vane

M2(W) / M3(W) / M6W FUNCTION OF SPREADING VANE The spreading vane is a key part of the machine – for which reason it is very important to mount the vanes correctly – and that they are intact. The Trend system is using both sides of the spreading vanes with: FRONT SIDE for NORMAL- spreading –... -

Page 20: Trend System

M2(W) / M3(W) / M6W The Trend SYSTEM….. will basically: ”Use the rotation direction which is most suitable for NORMAL spreading ……and HEADLAND spreading respectively.” This means in practice that the system ensures with NORMAL rotation direction, full overlap at NORMAL spreading on the main area of the field ……and a limited spread pattern with single overlap towards the border at headland spreading –... - Page 21 M2(W) / M3(W) / M6W The spreading can be divided into two systems. • A system for NORMAL spreading on the NORMAL area of the field. • A system for HEADLAND spreading along the BORDER of the field. The HEADLAND- spreading can again be divided into two systems, say: •...

-

Page 22: Normal Spreading

The machine setting is based on spread tests made in BOGBALLE’s test hall. The spreading abilities of the fertiliser in question may vary in comparison to the abilities of the fertiliser which was tested at BOGBALLE – which formed the basis for the spread chart. -

Page 23: Test With Test Trays

BOGBALLE recommends normally only to use test trays in case the fertiliser type spread is not found in the spread chart or in case you are not sure about the quality of the fertiliser. - Page 24 M2(W) / M3(W) / M6W The contents of the test trays will indicate the distribution in the field. Optimum overlap Too SMALL spread width/overlap Too LARGE spread width/overlap Tilt angle must be increased Tilt angle must be decreased ...

-

Page 25: Examples Of Normal Spread Patterns

(small overlap) distribution. One of the big BOGBALLE strengths is that the 4-double overlap of the machine ensures a good flexibility – say a minimum Vk – over a very very large spectrum. (In this example from 6 to 21 metres) This means in practice that the machine is able to absorb deviations in the distance of tramlines, deviations in PTO speed and to a certain degree –... - Page 26 M2(W) / M3(W) / M6W Spread width meter Test with test trays Quantity Kg/Ha TILT- angle too SMALL Tendency Too SMALL overlap TILT ANGLE: 0° Spread and Overlap pattern Gram Spredekurve Overlap 18m Meter The ”DOWN BOW” of the spead pattern shows that there is not sufficient overlap between the tramlines.

-

Page 27: Headland Spreading To Border

M2(W) / M3(W) / M6W HEADLAND spreading TO BORDER with border to the right in the driving direction. The BOGBALLE machine can optionally …..be changed to HEADLAND spreading – without leaving the tractor cab. This way you have a very user friendly system – which ensures at the same time optimum headland spreading. - Page 28 M2(W) / M3(W) / M6W HEADLAND-spread width can be mentioned as 3 categories: Rate reduction MINIMUM Minimum quantity - 20 % over border MEDIUM Medium quantity - 10 % 25-70% at border MAXIMUM Maximum quantity - 0 %...

-

Page 29: Practical Test

. Such a test must be done very carefully - and the test can if it is not correct - be misleading. Not sold by BOGBALLE - information available from your dealer. The test has a primary purpose - by adjusting the PTO rotations on the machine, to ensure the required spreading to BORDER (see examples of HEADLAND spread patterns to border on the next pages). -

Page 30: Ex. Of Headland Spread Patterns

M2(W) / M3(W) / M6W Examples of HEADLAND spread patterns – TO BORDER. : 18 Spread width metres MINIMUM :250 NORMAL quantity Kg/Ha G ødningsgræ nse : 200 HEADLAND qty. Kg/Ha : 300 PTO speed rpm. S um curve... -

Page 31: Headland Spreading From Border

HEADLAND spreading, FROM BORDER with border to the right in the (Option) driving direction The BOGBALLE machine can be changed to HEADLAND spreading – without leaving the tractor cabin. While spreading on HEADLAND the NORMAL settings of the machine are retained - except: THE ROTATION DIRECTION OF THE SPREADING DISCS ... -

Page 32: Ex. Of Headland Spread Patterns

M2(W) / M3(W) / M6W The HEADLAND pattern FROM BORDER will only to a limited degree be changed when changing the PTO rpms. Examples of HEADLAND spread pattern, FROM BORDER. The HEADLAND spreading system FROM BORDER, is developed for spread widths from 12 –... -

Page 33: Reduced Spread Width

M2(W) / M3(W) / M6W The HEADLAND spreading system, FROM BORDER, is developed for considering the environment as much as possible – and considering at the same time the demands for optimum yield. • Please consider that the distance between the tramlines must be equal to the spread width. -

Page 34: Turning At The Headlands

M2(W) / M3(W) / M6W TURNINGS AT THE HEADLANDS When turning at the headlands, the below OPEN / CLOSE instructions should be followed. • If the instructions are followed the result will be full overlap to the end of the field and no fertiliser is spread outside the field. -

Page 35: Spreading On Non-Rectangular Fields

M2(W) / M3(W) / M6W SPREADING ON NON RECTANGULAR FIELDS When spreading in non rectangular fields, it is often the opinion that one side of the maschine should be closed in order to achieve a good result. Closing one side of the machine results in sharp overlaps in the areas where the closing is done. -

Page 36: Check The Tractor - Before Use

M2(W) / M3(W) / M6W CHECKS OF TRACTOR – before use It is important that the lift arms of the tractor are set horizontally. If this is not the case the spreader will ”tilt” and the fertiliser will not spread equally to both sides of the spreader. -

Page 37: Practical Hints

When driving in wet field and at high speed, mud, stones or may be water may be thrown up into the hopper from the rear wheels of the tractor. In such cases it is recommended to use the BOGBALLE hopper cover. •... -

Page 38: M2W/M3W - Special

M2(W) / M3(W) / M6W M()W – special M()W BOGBALLE ……….the ultimative solution! The M2W and M3W machine is respectively equipped with one and two parallel mounted 6 tons stainless load cells, which makes it possible together with CALIBRATOR – to have complete control during the field work. -

Page 39: Use Of Calibration Rate Check Kit

M2(W) / M3(W) / M6W How to use the quadro calibration system BOGBALLE M-line is as standard equipped with the quadro calibration system which is used for adjusting the spreader’s quantity and for rest emptying (see the enclosed quadro folder). - Page 40 M2(W) / M3(W) / M6W A: Lift up B: Move C: Remove handwheel D: Remove lid E: Turn disc F: Lock...

- Page 41 M2(W) / M3(W) / M6W G: Calibrate 30 sec. H: Remove lid PTO = 200-250 rpm. 30 sek. I: Turn hubs in position J: Insert lid K: Lock L: Fasten handwheel...

- Page 42 M2(W) / M3(W) / M6W M: Lift up N: Move back O: Weigh (kg) P: Make calculation E: Turn disc F: Lock...

- Page 43 M2(W) / M3(W) / M6W Flow Factor Calculation [Kg/Ha] x [M] x [Km/h] Flow Factor ► ► 250 rpm 30 sec. Flow [Kg/Ha] [Km/t] Factor NPK 21-3-10 X 24 25,7 3362 ► ► ► ► ► ► ► ► ►...

-

Page 44: Ec-Declaration Of Conformity

M2(W) / M3(W) / M6W EC-Declaration of Conformity Manufacturer: BOGBALLE A/S Bogballe · DK-7171 Uldum Phone +45 7589 3266 Fax +45 7589 3766 Declares that machine: Centrifugal fertiliser spreader: M2(W) / M3(W) Is made in conformity with: directive of 17 May 2006 conc. -

Page 45: Pictogram

M2(W) / M3(W) / M6W Pictogram Read Operator’s Manual and safety rules before starting. Stay under the machine is prohibited. Safety distance for flying material must be observed. Avoid contact with rotating parts. Avoid contact as long as parts are moving. -

Page 46: Notes

M2(W) / M3(W) / M6W NOTES: ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________... - Page 47 M2(W) / M3(W) / M6W NOTES: ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________...

- Page 48 M2(W) / M3(W) / M6W NOTES: ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________ ____________________________________...

Need help?

Do you have a question about the M2 and is the answer not in the manual?

Questions and answers