Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Sensidyne gilian gilibrator 2

- Page 1 Advanced Test Equipment Rentals www.atecorp.com 800-404-ATEC (2832) Gilibrator 2 CALIBRATION SYSTEM OPERATION & SERVICE MANUAL 16333 Bay Vista Dr. • Clearwater, FL 33760 • (800) 451-9444 • (727) 530-3602 • (727) 539-0550 [FAX] • www.Sensidyne.com Revision G • Document No. 850190M...

- Page 2 LETTER FROM THE PRESIDENT Thank you for purchasing your new Sensidyne air monitoring product. We stand behind all of the products we sell . . . each Sensidyne product has been designed and manufactured to provide unparalleled service, day after day. Our professional staff has tested each unit under the strictest conditions possible to ensure success- ful, accurate results every time.

-

Page 3: Packing List

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM PACKING LIST The following are shipped with the Gilian Gilibrator 2 Calibration System Standard Kits: • Control Unit Base • Flow Cell Assembly (Piston or Wet [High Flow, Standard Flow, or Low Flow]) • AC Charger •... -

Page 4: Notices

PROPRIETARY NOTICE This manual was prepared by Sensidyne, Inc. exclusively for the owner of the Gilian Gilibrator 2 Calibration System. The material within this manual is the proprietary information of Sensidyne, Inc. and is to be used only to understand, operate, and service the instrument. -

Page 5: Table Of Contents

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM TABLE OF CONTENTS • PREFACE • Packing List .......................... 3 • Notices ...........................4 • WARNING ..........................7 SECTION ONE: INTRODUCTION Overview ........................8 Theory of Operation ....................8 SECTION TWO: COMPONENTS Control Unit ........................ 9 2.1.1... - Page 6 GILIAN GILIBRATOR 2 CALIBRATION SYSTEM TABLE OF CONTENTS SECTION FOUR: OPERATION Piston Cell Operation ..................... 22 4.1.1 Start Up ......................22 4.1.2 Flow Readout ....................22 Wet Cell Operation ....................23 4.2.1 Start Up ......................23 4.2.2 Bubble Generation ..................23 4.2.3...

-

Page 7: Warning

Gilibrator 2 base, the unit will display a false SAMPLE# reading immediately after start-up. If this happens, your flow cell needs to be returned to Sensidyne to be upgraded. See Appendix C for more information. -

Page 8: Overview

INTRODUCTION 1.1 OVERVIEW 1.2 THEORY OF OPERATION The Gilian Gilibrator 2 Calibration System is an easy to To be a primary standard, all values must be absolute use Primary Standard for the calibration of air sampling and measured as absolute. A primary standard airflow equipment. -

Page 9: Control Unit

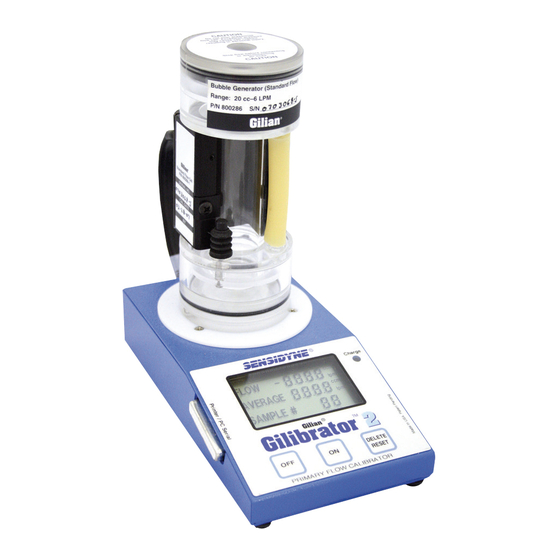

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM SECTION TWO COMPONENTS 2.1 CONTROL UNIT The Control Unit (refer to Figures 2.1 & 2.2) contains a LOW BAT crystal-controlled microprocessor timing system. This This warning is displayed if insufficient battery charge type of microprocessor, used in conjunction with the remains to operate the unit properly. -

Page 10: Control Unit

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Cable Assembly CE Base: 9-Pin connector non-CE Base: 15-pin connector Control Unit Base Mounting Plate Printer/PC Jack (side of unit) Display Charger Jack “OFF” Button “ON” Button Charging Indicator “DELETE/RESET” Button Figure 2.1 Control Unit —... -

Page 11: Liquid Crystal Display

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Charge FLOW AVERAGE SAMPLE # LOW BAT WAIT ERROR Gilibrator 2 DELETE RESET PRIMARY FLOW CALIBRATOR Figure 2.2 Liquid Crystal Display Sensidyne Document No. 850190M (Rev G) -

Page 12: Piston Cell Assembly

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM 2.2 PISTON CELL ASSEMBLY 2.3 WET CELL ASSEMBLY The Piston Cell Assembly (refer to Figure 2.2) is a The Wet Flow Cell Assembly (refer to Figure 2.4) con- single unit that need not be disassembled and requires sists of a Bubble Generator and Sensor Block. -

Page 13: Piston Cell Assembly

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Tube to Pump Bleeder Valve CAUTION DO NOT close this valve until Green CLOSE OPEN Ready Light (side Read caution before closing of cell) lights up. Bleeder Valve Gilibra Gilibrator 2 PISTON CEL PISTON CELL ASSEMBLY... -

Page 14: Sensor Block

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM 2.3.2 Sensor Block Bubble Initiate Button This push-button lowers the Bubble Generator Ring Surrounding the flow tube and secured between the into the soap solution reservoir. When the button is upper and lower chamber of the bubble generator, is released, the ring lifts out of the soap solution and a the Sensor Block (refer to Figure 2.4). -

Page 15: Wet Cell Assembly (Exploded View)

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Damper Plate Pulsation Damper Damper Plate O-Ring Sensor Block Assembly Spacer 9- Pin Connecting Jack Bubble Breaker Plate (back) Safety Tape Air Outlet Boss Flow Tube Bubble Initiate Button Sensor Block Locking Screws (2) Safety Tape... -

Page 16: System Set-Up

2 base, the unit will display a false SAMPLE# reading immediately after start-up. If this happens, your flow cell Flow Cell should mount flush with the Mounting needs to be returned to Sensidyne to be upgraded. See Plate. Appendix C (page 30) for more information. -

Page 17: Gilibrator 2 System Set-Up

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM PISTON CELL Gilibrator 2 PISTON CELL ASSEMBLY Made by 15-Pin Connector (back) IMPORTANT NOTE HIGH (effective 7/1/99) CE approved Control Unit Bases have 9-Pin cables and CANNOT be used with Piston Cells. Non-CE Control Unit Bases have 15-Pin cables and can be used with Piston Cells. -

Page 18: Cell Assembly Mounting (3-D View)

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Select the appropriate Cell Assembly and lower it onto the Mounting Plate. Align the Mounting Pins on the Cell Assembly bottom with Mounting Slots on the Mounting Plate (see Figure 3.3 for top view). If alignment is correct, the Cell Assembly bottom should mount flush with the Mounting Plate. -

Page 19: Cell Assembly Mounting (Top View)

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM IMPORTANT Mounting Pins & Mounting Slots should match up Cell Assembly (base = shaded area) Mounting Pins Mounting Slots (dark area) Mounting Plate (white area) Charge Charge FLOW AVERAGE SAMPLE # LOW BAT WAIT ERROR... -

Page 20: Cabling Connections

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM 3.2.2 Cabling Connections 2) The amount of soap needed is determined by de- IMPORTANT pressing the Bubble Initiate Button and holding it Turn off the unit before connecting any cables. down in the lower position. Continue to add... - Page 21 GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Flow Tube Air Inlet Boss Bubble Initiate Button Bubble Generator Soap Solution Reservoir (now empty) Storage Tube Fully press & hold Bubble Initiate Button while filling reservoir Angled Edge Fill Soap Solution Reservoir until bottom of Bubble Generator Ring is immersed in the solution Figure 3.4...

-

Page 22: Piston Cell Operation

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM SECTION FOUR OPERATION 4.1 PISTON CELL OPERATION If a printer is used, be sure it has completed its printing IMPORTANT NOTE sequence before pressing the button. DELETE/RESET CE approved Control Unit Bases have 9-Pin cables and When this button is pressed for less than 1 second, a CANNOT be used with Piston Cells. -

Page 23: Wet Cell Operation

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM 4.2 WET CELL OPERATION If a printer is used, be sure it has completed its printing 4.2.1 Start Up sequence before pressing the button. DELETE/RESET Turn on the sampling source. When this button is pressed for less than 1 second, a negative symbol appears on the Control Unit display. -

Page 24: Storage

You should also return the unit to the factory annually Turn Off the Control Unit, the sampling source, and for calibration. Contact the Sensidyne Service Depart- any attached output devices (if applicable). ment for an RMA number, information, and pricing (refer to Appendix C). -

Page 25: Wet Cell Maintenance

Contact 6) To replace the Damper Plate assembly, moisten the Sensidyne Service Department for an RMA num- the O-ring with soap solution and then press the ber, information, and pricing (refer to Appendix C). -

Page 26: Wet Cell Assembly Maintenance

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM Damper Plate Pulsation Damper Damper Plate O-Ring Space Bubble Breaker Plate Largest Hole Safety Tape Upper Cell Chamber Flow Tube Figure 5.1 Wet Cell Assembly Maintenance — PRELIMINARY — Sensidyne Document No. 850190M (Rev G) -

Page 27: Appendix Aparts List

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM APPENDIX A PARTS LIST Calibration Kits Basic: Control Unit, Battery Charger, Carrying Case, Calibration Certificate, Manual, and a Flow Cell (Pis- ton Cell, or a Low, Standard, or High Flow Wet Cell with tubing, soap solution, and dispenser). -

Page 28: Parts List

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM APPENDIX A PARTS LIST & ) y l & ) y l & t n I s l l ” 8 ” 4 ” 6 ” 8 ” 8 ” 6 i l i i l i... -

Page 29: Appendix B: Specifications

GILIAN GILIBRATOR 2 CALIBRATION SYSTEM APPENDIX B SPECIFICATIONS • SPECIFICATIONS General Specifications Base Unit Construction ......Painted aluminum sheet metal Unit Orientation ........Base: Horizontal, on flat surface Controls ............. “ON” Button “OFF” Button “DELETE/RESET” Button Indicators ........... Display (LCD) Charge Indicator (LED) Display Data .......... -

Page 30: Appendix C: Returned Material Authorization

Sensidyne’s re- SERVICE OPTIONS The Sensidyne Service Department offers a variety of service options which will minimize costly interruptions and maintenance costs. These options include initial training, on-site technical assistance, and full factory repairs. Sensidyne has developed several programs which offer options best suited to your applications and needs. - Page 32 16333 Bay Vista Dr. • Clearwater, FL 33760 • (800) 451-9444 • (727) 530-3602 • (727) 539-0550 [FAX] • www.Sensidyne.com Revision G • Document No. 850190M...

Need help?

Do you have a question about the gilian gilibrator 2 and is the answer not in the manual?

Questions and answers