Summary of Contents for TSI Incorporated portacount pro 8030

- Page 1 R e s p i r a t o r F i t T e s t i n g 8030 and 8038 Respirator Fit Testers Operation and Service Manual P/N 6001868, Revision B August 2008...

- Page 3 TSI Incorporated / 2008 / All rights reserved. Part Number 6001868 / Revision B / August 2008 Address TSI Incorporated / 500 Cardigan Road / Shoreview, MN 55126 / USA Fax No. (651) 490-3824 LIMITATION OF WARRANTY AND LIABILITY (effective July 2000)

- Page 4 C a u t i o n This instrument is a Class I laser device. Adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure. ® Disclaimer: The measurement provided by the P Respirator Fit ORTA OUNT Tester is an assessment of respirator fit during a fit test only.

-

Page 5: Table Of Contents

Contents Contents ....................... i ii 3 9 H Introduction and Overview ................4 0 H Database Operation When Operating in Stand-Alone Demo Mode..4 1 H Registration ..................... 4 2 H Why Fit Test .................... 4 3 H Preparations for Fit Testing ..............4 4 H Precautions for Fit Testing............... - Page 6 Reordering Supplies................7 3 H Shipping & Storage Precautions............. 7 4 H Changing the Alcohol Wick..............7 5 H Nozzle Cleaning ..................7 6 H Chapter 7 Troubleshooting................ 7 7 H On-line Troubleshooting Guides............. 7 8 H Appendix A Specifications ................ 7 9 H Flow Rate ....................

-

Page 7: Introduction And Overview

Introduction and Overview ® This manual describes both the Model 8030 P and 8038 ORTA OUNT ® + Respirator Fit Tester hardware and operation of the ORTA OUNT tester without the use of F Fit Test Software. ™ The Model 8030 is designed to measure fit factors of masks with an efficiency of 99% or greater. -

Page 8: Why Fit Test

Why Fit Test There are two primary reasons for respirator fit testing: • Verification of Training. After the individual has received respirator training, a fit test checks that the person has learned how to properly put on and wear a respirator without assistance. •... - Page 9 Fit Testing with Generated Aerosols ® The P fit tester is designed to operate using the ORTA OUNT microscopic particles in the ambient air. It can measure particle concentrations and fit factors when generated aerosols (like corn oil, salt or DOP) are used, however, these aerosols may cause the ®...

-

Page 11: Chapter 1 Unpack And Verify Shipment

Chapter 1 Unpack and Verify Shipment ® The following items are included with the P ORTA OUNT Respirator Fit Tester. If any are missing or damaged, please notify TSI immediately. Refer to C hapter 2 for photos and descriptions of each item. ®... - Page 12 ® Standard Items P (Models 8030 and 8038) ORTA OUNT Description CD Holder USB Cable USB Flash drive ® Additional Items P (Model 8038 only) ORTA OUNT Description Probe Assembly Tool Probe Kit (100 pieces) Neck Strap Chapter 1...

-

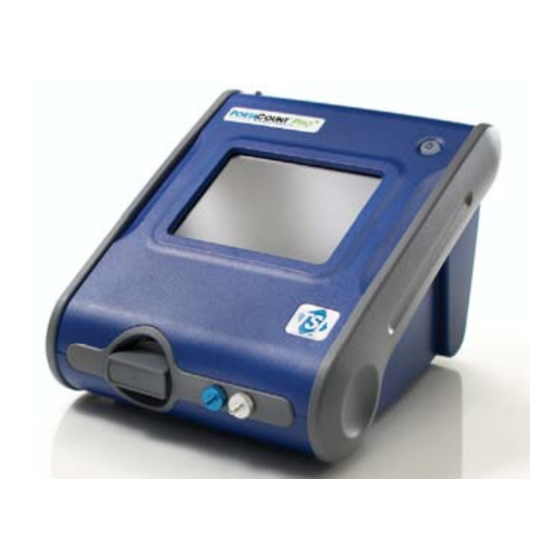

Page 13: Orta Count Pro

Chapter 2 ® Getting To Know The P ORTA OUNT Respirator Fit Tester Use the numbered paragraphs and correspondingly numbered arrows to identify the touch screen display, connectors, parts, and accessories of the ® fit tester. You need to be familiar with these items when ORTA OUNT following the instructions in this manual. - Page 14 The Sample Port is used when sampling air from a respirator during a fit test. The clear tube marked "SAMPLE" of the Twin Tube Assembly (3) connects here. The Sample Port fitting is silver and marked with the letter "S". The Ambient Port is used to sample ambient air during a fit test.

-

Page 15: Electrical Connections

Electrical Connections The USB Series “B” receptacle provides for communication between ® the P fit tester and a USB port on the PC. The USB ORTA OUNT ® cable provided with the P fit tester connects here. ORTA OUNT Two USB Series “A” receptacles let you connect a USB mouse, USB keyboard, or a USB flash drive (thumb drive). - Page 16 The AC Adapter plugs into the External Power Connector on the ® fit tester and an AC wall outlet. The AC Adapter ORTA OUNT senses the input voltage automatically. Chapter 2...

-

Page 17: Alcohol Related Parts

Alcohol Related Parts The Alcohol Cartridge holds the isopropyl alcohol consumed by the ® fit tester. A porous wick inside is soaked with ORTA OUNT alcohol. The Cartridge Cavity is where the Alcohol Cartridge is inserted during use. Make certain dirt and lint do not enter the Cartridge Cavity. Cover the Cartridge Cavity with the Storage Cap (10) when the instrument is not being used. -

Page 18: Miscellaneous Parts

Miscellaneous Parts 19&20 14 Spare Sampling Port Inlet Screens. These screens are used to help keep ® the P fit tester internal flow path clean by capturing ORTA OUNT large or fibrous particles. ® 15 Two Tube Adapters are shipped with each P fit tester. - Page 19 16 The Zero Check Filter is provided for the Zero Check and Max ® FitFactor Check on the P fit tester to make sure it is ORTA OUNT working properly. A spare filter is also provided. Note: TSI recommends that the Zero Check Filter be left attached to ®...

- Page 20 Additional Items (Model 8038 only) 24 Probe Assembly Tool. Used to install the sampling probes in filtering- facepiece (disposable) respirators. 25 Probe Kit. Includes 100 disposable probes. 26 Neck Strap. Supports the Twin Tube assembly when sampling running fit tests on filtering-facepiece (disposable) respirators. Chapter 2...

-

Page 21: Optional Accessories

Optional Accessories 27 Model 8026 Particle Generator (optional). If you do not have the minimum 1000 particles/cm ambient particle concentration needed for ® the P fit tester to do a fit test, this optional particle ORTA OUNT generator supplements naturally occurring room concentration with non-toxic salt (NaCl) particles in the right size range for the ®... -

Page 23: Chapter 3 About Respirators And Fit Testing

Chapter 3 About Respirators and Fit Testing The conventional way to quantitatively fit test is through the use of probed test respirators, but fit tests can also be performed on disposable respirators and positive pressure respirators. This chapter discusses the types of respirators and provides instructions on installing a sampling port to a disposable filtering-facepiece. -

Page 24: Probes For Filtering-Facepiece (Disposable) Respirators

Fit Testing with the Person's Own Assigned Respirator Some respirators, especially older models, do not have fit test adapters available. In that case, a permanently probed test respirator is the only option. Adapter’s Inhalation To P ORTA OUNT Sample Inlet Valve Class-100 Filter Suction Cup... -

Page 25: Inserting A Test Probe In A Disposable Respirator With The Tsi Model 8025-N95 Probe Kit

® Note: The P Model 8030 can successfully fit test class- ORTA OUNT 100, class-99, and P3 disposable respirators. Lower efficiency disposable respirators such as class 95, P2, and P1 will usually ® require use of the P + Model 8038. ORTA OUNT Inserting a Test Probe in a Disposable Respirator with the TSI... - Page 26 For flat “duckbill” style respirators, install the probe near the outer edge of the bottom panel where it cannot be blocked by the person’s chin. Bottom panel shown For respirators with center-mounted exhalation valves, install the probe to the left or right of the valve. Do not install the probe above or below the valve because this risks having the probe blocked by the person’s nose or chin.

- Page 27 For respirators with an outer mesh, install the probe normally as if the mesh was not present. The sampling probe and push nut will seal properly right through the mesh. 2. Slide the sampling probe onto the piercing tool. As the pointed end of the piercing tool is very sharp, be extremely careful when handling it! Sampling Probe 3.

- Page 28 Push Nut Positioned on Anvil Tool Sampling Probe Pushed Through Mask 5. Push the sampling probe through the mask until the end of the tool point is visible from the outside of the mask. Leave a few millimeters of the tool point visible.

-

Page 29: Positive Pressure Respirators

9. Inspect the sampling probe to be sure it is not plugged. Try to rotate the probe with your fingers. If it moves freely, use the probe insertion tool kit to press the push nut firmly onto the sampling probe and pinch the mask material more tightly. -

Page 31: Respirator Fit Tester

Chapter 4 ® Conducting a Fit Test with the P ORTA OUNT Respirator Fit Tester This chapter describes how to use the P fit tester as a ® ORTA OUNT stand-alone instrument to conduct a quantitative respirator fit test. You should learn to operate the P fit tester in this manner even ®... -

Page 32: Step 1-Prepare The Porta Count ® Pro Respirator Fit Tester For

5. Record the results. ® Step 1—Prepare the P Respirator Fit Tester for ORTA OUNT Fit Testing Follow the steps below to setup the P fit tester for fit ® ORTA OUNT testing without using the F Fit Test Software (stand-alone mode). ™... - Page 33 5. Open a bottle of alcohol. Invert the bottle and insert the nozzle end into the Alcohol Fill Capsule as far as possible to make certain you do not inadvertently spray alcohol anywhere except into the Capsule. Fill Line 6. Squeeze alcohol into the Alcohol Fill Capsule until it is even with or slightly above the fill-line.

- Page 34 9. Set the Alcohol Fill Capsule down and wait at least 2 minutes while the alcohol wick inside the Alcohol Cartridge soaks up alcohol. 10. Remove the Alcohol Cartridge from the Capsule and gently shake it to allow excess alcohol to drip back into the Alcohol Fill Capsule. Stop when excess alcohol is no longer dripping;...

-

Page 35: Step 2-Attach Flash Drive And Select Database (Optional)

Remember: Always recap alcohol fill capsule and other containers immediately to prevent absorption of moisture and the escape of alcohol vapors. Note: Always store the Alcohol Cartridge in the Alcohol Fill Capsule. The Alcohol Fill Capsule is designed to be a safe transportation and storage container for alcohol. -

Page 36: Step 3-Run Daily Checks

2. Insert the flash drive into one of the USB ports of the P ® ORTA OUNT fit tester. 3. Press the Database tab. 4. Press Select Database icon. 5. Select the database you want to use as the active database and press Load. - Page 37 3. Press Yes with the stylus or your finger tip, and follow the directions on the screen. 4. If you want to perform a Valve Check, select the “Enable Valve Check” box. The Valve Check is not part of the recommended Daily Checks. It is used to further diagnose the reason why the Max FitFactor Check failed.

-

Page 38: Step 4-Conducting Fit Tests

have good fits, thereby wasting time and effort. There is no possibility that failing the Zero Check could result in overstated fit factors. This is because any particles leaking into the P fit tester are ® ORTA OUNT interpreted as mask leakage, resulting in lower fit factors. 9. - Page 39 adjusting it to a comfortable position. The tubing support neck strap should be positioned so that the tubing does not pull the mask off the person’s face. Have the person tilt his or her head up and down, turn side to side, and bend over to see if the tubing pulls the mask away from their face.

- Page 40 3. On the Activities tab, press Fit Test [ ]. The People List dialog appears. 4. Select the person to fit test as follows: If the person shown on the dialog is the one you want to fit test, press Next to select the respirator for the fit test. Press Next to continue.

- Page 41 b. If you want to select a different respirator, click the arrow on the Respirator List field to display a list of all the respirators in the database. Use the stylus to select the respirator you want to use, click Next to select the current protocol. Note: You cannot add respirator records to the database here.

- Page 42 13. Press START. Fit testing begins immediately, and the first exercise name appears. The elapsed exercise time also appears as a graphic progress bar. As each exercise completes, the result appears in the Fit Factor column. The Ambient and Mask Concentration Values fields show the ambient and mask particle concentrations as they are measured.

- Page 43 Exercise Name Description Read a prepared paragraph (like the Rainbow Talking out loud Passage located in A ppendix G of this 2 1 H manual) or count out loud to simulate the workplace. Grimace Grimace by smiling and/or frowning to create a leak in the respirator face seal.

-

Page 44: Step 5-Record Results

Note: In the USA, OSHA requires a minimum fit factor of 100 for half masks and 500 for full-face masks. If necessary, consult the appropriate regulation or standard. • If the test was a Pass, the fit test is over. You will want to keep a record of the test on file if you are not using a database on the flash drive. - Page 45 The overall fit factor is the most important data item. It is the overall result of the fit test and usually the only fit factor value that must be retained as part of your record keeping. The fit factors for the individual exercises are not as important.

- Page 46 • Leaking respirator probe or fit test adapter Make certain the respirator probe (if used) or fit test adapter does not leak around the outside. • fit tester sample tube leaks where attached to probe ® ORTA OUNT or adapter due to wear. Cut a short piece off the end of the tube to expose a fresh end.

-

Page 47: Chapter 5 Operating Modes And User Interface

Chapter 5 Operating Modes and User Interface ® This chapter describes the operating modes of the P ORTA OUNT Respirator Fit Tester and describes the options available through the user interface (touch screen). Modes of Operation There are two modes of operation: External Control (using F ™... -

Page 48: User Interface

User Interface The touch screen provides the user interface to all functions when the instrument is operating in stand-alone mode. These functions are accessed through the tabs at the bottom of the display. The functions available through each tab are described below. Activities Tab The Activities tab lets you perform three functions: Fit Testing, Daily Checks, and Real-time fit factors. - Page 49 Before you start the real-time fit factor display, the test subject should put on the respirator and it should be properly attached to ® the P Respirator Fit Tester. ORTA OUNT When you press Realtime [ ] the Real-Time Fit Factor Display appears.

- Page 50 Database Tab The Database tab lets you select an active database to use for fit testing or view the People, Respirator, Protocols, and Fit Test records of active database. (See the F Fit Test Software ™ User Manual for instructions on how to configure the USB flash drive.) Note: Unless a flash drive with a valid database files is inserted in one of the USB ports, you cannot use an active database.

- Page 51 Fit Test Reports Select Fit Test Reports [ ] to view the Fit Test records of those individuals in the active database. Use the arrow at the right of the Selected Fit Test field to show all the records and select a record by pressing on the person’s name in the dropdown box.

-

Page 52: New Exercise Name

Protocol name in the dropdown box. This now becomes the active protocol for fit tests. 2. To add a new Protocol, press New, enter a name using the on- screen keyboard, edit the fields using the up/down arrows in the Protocol Details dialog, and then press OK. 3. -

Page 53: Setup Tab

Button or Field Name Description Number of months before the next fit test is due. Next Test In _ months This is typically 12 months, although some regulations call for 6 or 24 months. Consult the applicable regulations for additional information. Valid range from 1 to 99. -

Page 54: Touch Screen Calibration

2. To change the time, select the segment of time you want to change (hour, minute, second), then use the arrows to increase or decease the value. 3. Select the Date Format from the Date Format box. Note: When you set the date format here it does not change the date format that F software uses. -

Page 55: Chapter 6 Service And Maintenance

Chapter 6 Service and Maintenance Recalibration Interval ® TSI recommends that the P Respirator Fit Tester be ORTA OUNT cleaned and recalibrated annually. Try to arrange your fit testing schedule to allow for annual factory recalibration. If your fit testing schedule is seasonal or you expect heavy usage during an upcoming period (such as an outage), ®... -

Page 56: Reordering Supplies

Reordering Supplies TSI part numbers for consumable supplies and miscellaneous replacement parts are: Model/Part No. Description 8016 Box of 16, 30 ml bottles of isopropyl alcohol (480 ml total) 8033 Box of 10 Alcohol Wicks 803X-ZFLTR Zero Check Filter 8017 Sampling Hose Kit with 3 Twin Tube Assemblies and 10 each 3/16 in. -

Page 57: Changing The Alcohol Wick

Changing the Alcohol Wick The wick inside the Alcohol Cartridge may be changed in the field. Two ® spare wicks are included with the P Respirator Fit Tester. ORTA OUNT Normally, the wick does not need to be changed unless one of the following problems develops: •... - Page 58 3. Examine the white Alcohol Wick. Discard wicks that are severely discolored or physically damaged. Some light brownish-yellow discoloration of the wick is normal. If the wick is in good condition, dry it by placing it on a clean surface in a well-ventilated area and allow it to dry for at least two days.

-

Page 59: Nozzle Cleaning

Nozzle Cleaning If the small (pin-hole size) internal nozzle becomes clogged with lint or other debris, the following procedure should clear it. The symptom of a clogged nozzle is a low (perhaps zero) ambient particle count. This usually, but not always, causes the Particle Check and/or Max FitFactor Check to fail. - Page 60 ® Reinsert the alcohol cartridge. Turn the P Respirator Fit ORTA OUNT Tester on. Perform the Daily Checks. If the problem persists, try Procedure B. Procedure B Use this procedure only if Procedure A fails to clear the internal nozzle. ®...

- Page 61 Service and Maintenance...

-

Page 63: Chapter 7 Troubleshooting

Chapter 7 Troubleshooting This chapter lists a series of symptoms, their possible causes and recommended solutions for problems with the P ® ORTA OUNT Respirator Fit Tester. If your symptom is not listed, or if none of the solutions solves your problem, please contact TSI. Additional help is available from the TSI Web site w ww.tsi.com or by sending e-mail to... - Page 64 Symptom Possible Causes Solution Low Alcohol Low on alcohol. Refill Alcohol Cartridge. Level message Excessive moisture Change Alcohol Wick ® inside P inside Alcohol Cartridge. ORTA OUNT fit tester. Run 2 hours to dry optics (remove the alcohol cartridge and install storage cap).Dump old alcohol from the Alcohol Fill Capsule and add fresh...

- Page 65 Symptom Possible Causes Solution Low Particle Moisture build-up inside Change Alcohol Wick ® message inside the Alcohol ORTA OUNT (continued) tester. Cartridge. Dump old alcohol from the Alcohol Fill Capsule and add fresh alcohol. Run 2 hours to dry optics (remove the alcohol cartridge and install storage cap).

- Page 66 Symptom Possible Causes Solution Fails Zero Check O-ring on alcohol Replace O-ring. Smear a (continued) cartridge is not sealing. very small amount of grease (such as Vaseline™) on the O- ring. Tube fittings on Tighten fittings with ® pliers. ORTA OUNT tester are loose.

- Page 67 Symptom Possible Causes Solution ® Suspicious Run 2 hours to dry the ORTA OUNT readings tester is flooded with optics (remove cartridge alcohol. and install storage cap). Tube fittings on Tighten with pliers. (If the ® ORTA OUNT ORTA OUNT loose.

- Page 68 Symptom Possible Causes Solution Particle count is Inferior or contaminated Change Alcohol Wick zero or near zero alcohol. inside the Alcohol (continued) Cartridge. Use only approved alcohol. ® Run 2 hours to dry optics ORTA OUNT tester is flooded with (remove Alcohol alcohol.

-

Page 69: Appendix A Specifications

Appendix A Specifications (Specifications are subject to change.) Model 8030 P Respirator Fit Tester ® ORTA OUNT Size............... 9.5 x 8.5 x 6.75 in. (24 x 22 x 17 cm) Weight Unit only ..........5.0 lb. (2.7 kg) With standard accessories and case ..16 lb. (7.3 kg) Fit Factor Range ........ -

Page 70: Flow Rate

Respirator Facepieces that can be Fit Tested Full-face elastomeric Half-face elastomeric NIOSH series-100 filtering-facepiece NIOSH series-99 filtering-facepiece NIOSH series-95 filtering-facepiece (8038 upgrade required for series-95 only) Fit Factor Measurement Direct measurement of fit factor (Cout/Cin) (Mask leakage is measured simultaneously while test subject moves and breathes.) Model 8038 P + Respirator Fit Tester... - Page 71 Alcohol Hours per charge........6 hours at 70 o F (21 o C) Alcohol type........... Reagent grade isopropyl (99.5% or better) Carrying Case Size............21 x 14 x 9 in. (53 x 36 x 23 cm) Pass/Fail Settings........User-selectable: 0 to 10000 Factory Recalibration Interval....

-

Page 73: Appendix B Theory Of Operation

Appendix B Theory of Operation ® How the P Respirator Fit Tester Works ORTA OUNT ® The P fit tester measures respirator fit by comparing the ORTA OUNT concentration of microscopic particles outside the respirator to the concentration of particles that have leaked into the respirator. The ratio of these two concentrations is called a fit factor. - Page 74 The idea of CNCs/CPCs is not new. As early as 1888, Aitken described a dust counter that grew particles to detect them. In 1943 the Nolan-Pollack photoelectric CNC was described. In the 1950s and 1960s, commercial, automatic CNCs were available. However, none were of the continuous-flow type, and the P Respirator Fit Tester is the first highly portable ORTA...

- Page 75 Each particle passing through the sensing volume scatters light. The light is collected by the receiving optics and focused onto a photodetector. The photodetector generates an electrical pulse from the scattered light as each droplet passes through the sensing volume. The particle count is determined by counting the number of pulses generated during a given time period.

-

Page 77: Appendix C Calculating Fit Factor

Appendix C Calculating Fit Factor Fit factor is defined as the particle concentration outside the respirator divided by the particle concentration inside the respirator. ® Because ambient concentration can vary over time, the P ORTA OUNT Respirator Fit Tester calculates the fit factor by taking the average of the ambient concentrations measured before and after the respirator sample and then dividing by the concentration measured in the respirator. - Page 78 The following equation is used to calculate the overall fit factor in the ® fit tester: ORTA OUNT Overall where: FF = fit factor for test cycle number of test cycles (exercises). ® Disclaimer: The measurement provided by the P ORTA OUNT Respirator Fit Tester is an assessment of respirator fit during...

-

Page 79: Appendix D Calculating Particle Concentration

Appendix D Calculating Particle Concentration Particle concentration is calculated by counting the number of particles passing through the sensor in a given period of time. Since the flow rate is known (5.83 cm /sec), the particle concentration can be determined. In 1-Second Count Mode the equation is: Particle Concentrat... -

Page 81: Appendix E Timing In Fit Test Mode

Appendix E Timing in Fit Test Mode Test Sequence ® When performing a fit test, P Respirator Fit Tester ORTA OUNT automatically samples both the ambient air and the particles inside the respirator. An internal switching valve automatically switches between the two sampling ports. -

Page 83: Appendix F Using The Porta Count ® Pro Respirator Fit Tester To Fit Test Positive Pressure Respirators

Appendix F ® Using the P Respirator Fit ORTA OUNT Tester to Fit Test Positive Pressure Respirators On January 8, 1998, OSHA released the long-awaited revision to the Respiratory Protection Standard 29CFR1910.134. It replaces the standard with the same name and number that was released in 1971. This new revision has far reaching impact on a large number of existing OSHA standards in that it replaces certain provisions related to respirator use. - Page 84 Loose fitting respirators usually employ a hood that fits over a person's head and loosely seals around the neck. The quality of the seal is not dependent on a close physical match with the wearer's body. Since there is no "seal" to test, there is no requirement to do a fit test.

- Page 85 easily measure. Likewise, air from SCBA tanks, and from compressors, contain significant numbers of particles. Grade D breathing air is by no means particle free. The only way to overcome this problem is to pass the air through a HEPA filter just before it reaches the facepiece. There is no OSHA requirement to do this type of performance testing.

-

Page 87: Appendix G The Rainbow Passage

Appendix G The Rainbow Passage... -

Page 89: Index

Index clear tube, 8 common problems, 39 A receptacle, 9 conduct a fit test, 25 AC Adapter, 10 conduct fit test, 35 activities tab, 30, 34, 42 conducting fit test, 32 adapter connections homemade, 18 electrical, 9 alcohol supplies, 11 alcohol cartridge, 11, 26, 27 reassembling, 52 daily check, 42... - Page 90 fit test, 42 leaking (continued) conducting, 32 sample tube, 40 ORTA OUNT fit test adapter probe, 40 kit, 18 low alcohol level, 49 leaking, 40 low fit factors fit test mode common problems, 39 test sequence, 75 low particle, 49 fit test reports, 45 fit testing generated aerosols, 3...

- Page 91 parts respirator (continued) identifying, 7 probes for filtering facepiece, people list, 34 people table, 45 quantitative fit testing, 17 piercing tool, 21 testing positive pressure, 77 training, 2 ORTA OUNT sample tube leaking, 40 respirator list field, 35 theory of operation, 67 respirator table, 45 troubleshooting, 57 positive pressure respirator, 23...

- Page 92 test sequence, 75 testing a disposable respirator, 32 theory of operation, 67 thumb drive. (see flash drive) touch screen, 7, 41, 42 calibration, 48 training verification, 2 transporting or storing, 50 troubleshooting, 57 tube adapter, 8 tube adapters, 12 twin tube assembly, 8, 50 unpacking, 5 USB flash drive, 13, 29, 44 USB keyboard, 9...

- Page 93 TSI Incorporated – 500 Cardigan Road, Shoreview, MN 55126 U.S.A Tel: +1 800 874 2811 E-mail: info@tsi.com Website: www.tsi.com Tel: +44 149 4 459200 E-mail: tsiuk@tsi.com Website: www.tsiinc.co.uk France Tel: +33 491 95 21 90 E-mail: tsifrance@tsi.com Website: www.tsiinc.fr Germany Tel: +49 241 523030 E-mail: tsigmbh@tsi.com...

Need help?

Do you have a question about the portacount pro 8030 and is the answer not in the manual?

Questions and answers