Konica Minolta bizhub 20 Service Manual

Hide thumbs

Also See for bizhub 20:

- Software user's manual (227 pages) ,

- User manual (203 pages) ,

- Network user's manual (145 pages)

Table of Contents

Advertisement

Advertisement

Chapters

Table of Contents

Troubleshooting

Summary of Contents for Konica Minolta bizhub 20

-

Page 1: Service Manual

SERVICE MANUAL 2010.05 2010.05 Ver. 1.0 Ver. 1.0... - Page 2 TRADEMARKS KONICA MINOLTA and the KONICA MINOLTA logo are trademarks or registered trademarks of KONICA MINOLTA HOLDINGS, INC. bizhub and PageScope are trademarks or registered trademarks of KONICA MINOLTA BUSINESS TECHNOLOGIES, INC. Apple and Macintosh are trademarks of Apple Inc., registered in the United States and other countries.

-

Page 3: Overview

Multi-Function Center (hereinafter referred to as "the machine"). This information is vital to the service personnel to maintain the high printing quality and performance of the machine. This service manual covers the bizhub 20 machines. This manual consists of the following chapters:... - Page 4 APPENDIX 1: WORKER SWITCH (WSW) APPENDIX 2: DELETION OF USER SETTING INFORMATION, etc. Provides instructions on how to delete such as user setting information recorded in the machine. APPENDIX 3: SCREW CATALOGUE APPENDIX 4: REFERENCES APPENDIX 5: GLOSSARY Information in this manual is subject to change due to improvement or redesign of the product. A thorough understanding of this machine, based on information in this service manual, is required for maintaining its print quality performance and for improving the practical ability to find the cause of problems.

- Page 5 REGULATION For Europe and Other countries Radio interference (220 to 240 volt model only) This machine follows EN55022 (CISPR Publication 22)/Class B. Before you use this product, make sure that you use one of the following interface cables. (1) A shielded parallel interface cable with twisted-pair conductors and that it is marked IEEE 1284 compliant.

- Page 6 Internal laser radiation Maximum radiation power: 5 mW Wave length: 770 - 810 nm Laser class: Class 3B EU Directive 2002/96/EC and EN50419 (European Union only) This equipment is marked with the above recycling symbol. It means that at the end of the life of the equipment you must dispose of it separately at an appropriate collection point and not place it in the normal domestic unsorted waste stream.

- Page 7 For USA and Canada Federal Communications Commission (FCC) Declaration of Conformity (For USA) Responsible Party: KONICA MINOLTA BUSINESS SOLUTIONS U.S.A., INC. 100 Williams Drive Ramsey, NJ 07446 Phone: 201-825-4000 declares, that the products Product name: bizhub 20 complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

- Page 8 Industry Canada Compliance Statement (For Canada) This Class B digital apparatus complies with Canadian ICES-003. Cet appareil numérique de la classe B est conforme à la norme NMB-003 du Canada. Laser Safety (110 to 120 volt model only) This machine is certified as a Class 1 laser product under the U.S. Department of Health and Human Services (DHHS) Radiation Performance Standard according to the Radiation Control for Health and Safety Act of 1968.

- Page 9 SAFETY PRECAUTIONS To use the machine safely Please keep these instructions for later reference and read them before attempting any maintenance. Note : If there are faxes in the machine's memory, you need to print them or save them before you turn off the power and unplug the machine.

- Page 10 WARNING DO not use any type of spray to clean inside or outside of the machine. Doing this may cause a fire or electrical shock. WARNING - When you move the machine, grasp the side hand holds that are under the scanner. DO NOT carry the machine by holding it at the bottom.

- Page 11 CHOOSING A LOCATION Place your machine on a flat, stable surface that is free of vibration and shocks, such as a desk. Put the machine near a telephone wall jack and a standard, grounded AC power outlet. Choose a location where the temperature remains between 50°F and 90.5°F (10°C and 32.5°C).

- Page 12 CHAPTER SPECIFICATIONS...

-

Page 13: Table Of Contents

CHAPTER 1 SPECIFICATIONS This chapter lists the specifications of each model, which enables you to make a comparison of different models. CONTENTS 1. COMPONENTS ......................1-1 2. SPECIFICATIONS LIST ....................1-2 2.1 Printing ........................1-2 2.2 Functions ....................... 1-3 2.3 Electronics and Mechanics..................1-6 2.4 Network Connectivity..................... -

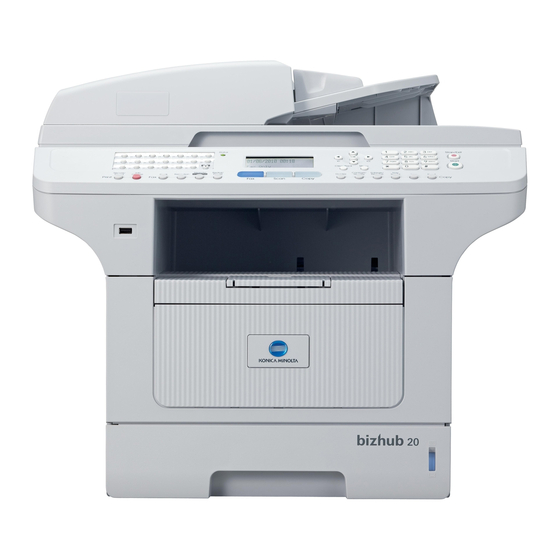

Page 14: Components

1. COMPONENTS The equipment consists of the following major components: ADF Unit Scanner Unit Panel Unit NCU PCB Speaker ASSY Joint Cover ASSY Driver PCB Back Cover Side Cover R Laser Unit Outer Chute ASSY Rear Chute ASSY Toner LED PCB Unit ASSY Fuser Unit Frame Unit Process Cover ASSY... -

Page 15: Specifications List

2. SPECIFICATIONS LIST Printing Model bizhub 20 Print method Electrophotography by semiconductor laser beam scanning Laser Method: 1 polygon motor, 1 laser beam Wavelength: 770 nm - 810 nm Output: 5 mW (Max) Laser class: Class3 B Resolution ® 1200 dpi... -

Page 16: Functions

Functions <Controller> Model bizhub 20 CPU (clock speed ) 300 MHz Back up Clock Yes (up to 60 hours) Memory Standard 64 MB Option 1 DIMM slot; expandable up to 576 MB Backup Yes (up to 60 hours) Interface IEEE 1284 Parallel, Hi-Speed USB 2.0, Ethernet 10/100 BASE-TX, USB Host ®... - Page 17 <Direct Print feature> Model bizhub 20 Direct Print PDF version1.7*1, JPEG, Exif+JPEG, PRN(created by bizhub 20 printer driver), TIFF (scanned by bizhub 20), ® PostScript 3™ (created by BR-Script3 printer driver), XPS version 1.0. PDF data including a JBIG2 images files, a JPEG2000 image file or transparency files are not supported.

- Page 18 <System requirements for printing function> Available Recom- Computer Platform & Minimum Hard Processor Speed mended Operating System Version Disk Space ® ® ® ® Windows Windows Intel Pentium 4 or 650MB equivalent 64-bit (32-bit) (32-bit) ® (Intel 64 or AMD64) supported CPU (64-bit) (64-bit)

-

Page 19: Electronics And Mechanics

Electronics and Mechanics Model bizhub 20 Power Copying Average 680 W at 25 °C (77 °F) consumption Ready Average 85 W at 25 °C (77 °F) Sleep Average 18 W at 25 °C Noise level Sound Pressure Printing: 56 dB (A) -

Page 20: Network Connectivity

Network Connectivity <Ethernet wired network> Network node type NC-6800h type2 ® ® ® ® Operating system Windows 2000 Professional, Windows XP, Windows 7, Windows ® ® support XP Professional x64 Edition, Windows Vista , Windows Server 2003, ® ® Windows Server 2003 x64 Edition, Windows Server 2008 ®... -

Page 21: Service Information

Service Information These are key service information to maintain the product. Machine life: 200,000 pages or 5 years, whichever comes first MTBF (Meantime between failure): 4,000 hours MTTR (Meantime to repair): Average 0.5 hours Maximum monthly volume: 30,000 pages Periodical maintenance parts: Parts Approximate Life (pages) ADF unit... -

Page 22: Paper

Paper 2.6.1 Paper handling Model bizhub 20 Paper Standard 250 sheets Input tray Multi- 50 sheets (Plain)/ 3 sheets (Envelope) purpose tray Option 250 sheets Up to 50 sheets (Xerox4024 20lbs, environment: temp. 20-30C Humidity 50-70%) Paper Output Tray 150 sheets... -

Page 23: Media Specifications

2.6.2 Media specifications Model bizhub 20 Media type Paper tray Plain paper, Bond paper, Recycled paper, (Standard) Transparencies , Thin paper Multi-purpose Plain paper, Thick paper, Bond paper, Recycled paper, tray Envelope , Label, Transparencies , Thin paper Optional tray... -

Page 24: Type And Size Of Paper

2.6.3 Type and size of paper The machine loads paper from the installed paper tray or the multi-purpose tray. The name for the paper trays in the printer driver as follows; The name for the paper trays The name for the paper trays in the printer driver Paper tray Tray 1... - Page 25 <Media type> Choose the Tray 1/2 MP Tray Duplex media type from the printer driver Plain paper Plain paper 75 to 105 g/m (20 to 28 lb) Recycled paper Recycled paper Bond paper Bond paper Rough paper- 60 to105 g/m 60 to161 g/m 60 to 161 g/m (16 to 28 lb.)

-

Page 26: Printable Area

Printable Area PCL emulation When using PCL emulation, the edges of the paper that cannot be printed on are shown below. Portrait Physical page Printable area Logical page Physical page length Maximum logical page length Distance from edge of physical page to edge of logical page Note : •... - Page 27 The table below shows the printable areas when printing on Portrait for each paper size. Size Letter 215.9mm 279.4mm 203.2mm 279.4mm 6.3mm 4.2mm 8.5" 11.0" 8.0" 11.0" 0.2" 0.16" (2,550dots) (3,300dots) (2,400dots) (3,300dots) (75dots) (50dots) Legal 215.9mm 355.6mm 203.2mm 355.6mm 4.2mm ↑...

- Page 28 Size A5 Long 210.0mm 148.5mm 198.0mm 148.5mm 6.0mm 4.2mm 8.27" 5.85" 7.79" 5.85" 0.2" 0.16" (2,480dots) (1,754dots) (2,338dots) (1,754dots) (71dots) (50dots) DL Long 220.0mm 110.0mm 207.0mm 110.0mm 6.26mm 4.2mm Edge 8.66" 4.33" 8.17" 4.33" 0.25" 0.16" (2,598dots) (1,299dots) (2,450dots) (1,299dots) (74dots) (50dots) 76.2mm...

- Page 29 Landscape Physical page Printable area Logical page Physical page length Maximum logical page length Distance from edge of physical page to edge of logical page Note : • "Logical page" shows the printable area for a PCL driver. • "Printable area" shows mechanical printable area of the machine. •...

- Page 30 The table below shows the printable areas when printing on Landscape for each paper size. Size Letter 279.4mm 215.9mm 269.3mm 215.9mm 5.0mm 4.2mm 11.0" 8.5" 10.6" 8.5" 0.2" 0.16" (3,300dots) (2,550dots) (3,180dots) (2,550dots) (60dots) (50dots) Legal 355.6mm 215.9mm 345.5mm 215.9mm 4.2mm ↑...

- Page 31 Size A5 Long 148.5mm 210.0mm 138.5mm 210.0mm 5.0mm 4.2mm 5.58" 8.27" 5.45" 8.27" 0.20" 0.16" (1,754dots) (2,480dots) (1,636dots) (2,480dots) (60dots) (50dots) DL Long 110mm 220mm 102mm 220mm 4.0mm 4.2mm Edge 4.33" 8.66" 4.00" 8.66" 0.16" 0.16" (1,299dots) (2,598dots) (1,199dots) (2,598dots) (50dots) (50dots) 127mm...

-

Page 32: Print Speeds With Various Settings

Print Speeds with Various Settings Print speed is up to 30 ppm for A4 size and 32ppm for Letter size when loading A4 or Letter size paper from the paper tray 1 in the plain paper mode. Actual print speed varies depending on the media type or paper size as shown in the tables below;... -

Page 33: Telephone

Telephone Model bizhub 20 Handset Chain Dialing Automatic Redial PBX Feature No (Europe:Yes) Speaker Phone Hold/Mute Key Music on Hold Handset Volume Speaker Volume Yes (3 steps + OFF) Ring Volume Yes (3 steps + OFF) Beeper Volume Yes (3 steps + OFF) -

Page 34: Fax

2.10 Fax Model bizhub 20 Modem Speed 33.600 bps ITU-T Group Super G3 Coding Method MH / MR / MMR / JBIG Color FAX Fax/Tel Switch Superfine Yes (TX & RX) Grayscale 8 bit / 256 Contrast Yes (Auto/Light/Dark) Smoothing... - Page 35 Model bizhub 20 Receiving Easy Receive/ Fax Detect Polling Receiving Auto Reduction Duplex Fax Receive Out-of-Paper Up to 500 pages (ITU-T Test Chart, Standard Resolution, JBIG) Reception (ITU-T Chart) Fax Rx Stamp Yes Memory Transmission Up to 500 pages (ITU-T Test Chart, Standard Resolution, JBIG)

-

Page 36: List/Report

2.11 List/Report Model bizhub 20 Activity Report/Journal Yes (up to 200) Report Transmission Verification Report Cover page Help List Call Back Message Caller ID List Tel Index ListNumeric/ Yes/Yes Alphabetic Memory Status List System Setup (User Setting) List Specifications are subject to change without notice. -

Page 37: Copy

2.12 Copy Model bizhub 20 First Copy Out Time Less than 10.5 sec ( From READY mode ) Multi Copy Stack Yes (up to 99) Sort Reduction/ 25% - 400% in 1% increments Enlargement (%) Resolution (dpi) Maximum. 1200 (horizontal scan) x 600 (vertical scan) dpi... -

Page 38: Document Scanner

2.13 Document Scanner Model bizhub 20 Color/Mono Color Resolution Scanner Maximum 600 (horizontal scan) x 2400 (vertical scan) dpi (Optical) Glass Maximum 600 (horizontal scan) x 1200 (vertical scan) dpi Resolution 19,200 (horizontal scan) x 19,200 (vertical scan) dpi (Interpolated) Scanning Monochrome A4: 3.03 seconds... -

Page 39: Theory Of Operation

CHAPTER THEORY OF OPERATION Confidential... - Page 40 CHAPTER 2 THEORY OF OPERATION This chapter gives an overview of the scanning and printing mechanisms as well as the sensors, actuators, and control electronics. It aids in understanding the basic principles of operation as well as locating defects for troubleshooting CONTENTS 1.

-

Page 42: Electronics

2. ELECTRONICS General Block Diagram (Main fan) Low-voltage power supply Main fan Toner High-voltage sensor PCB power supply (Light Rear relay Power supply fan reception) Fuser thermistor Regist front sensor Paper eject Duplex unit Sensor PCB sensor sensor PCB (PE+PEDGE) Regist rear sensor MP sensor PCB... -

Page 45: Scanner Mechanism

Scanner Mechanism This mechanism consists of the document cover, the document scanner unit (scanner cover), and the automatic document feeder (ADF). The document scanner unit consists of a scanner top cover, CCD module and scanner base. Document cover ADF & document cover ASSY Scanner top cover White-level reference film... -

Page 46: Document Scanner Unit

3.2.1 Document scanner unit The document scanner unit is equipment which scans the paper using the scanner module. This machine prints the scanning data (copy) or sends data as FAX (FAX transmission). There are two kinds of scanning method of the document scanner unit. One is operation to scan with the document scanner unit, the paper is placed on the document glass, the scanner module moves under the document glass, and it scans the paper, and the other one is operation to scan in cooperation with the ADF unit, scan the paper which has been sent... - Page 47 6. Scanning operation (The scanner module moves under the immovable document.) Open the document cover, place a sheet of the document (or opened book) onto the document glass, and close the document cover. Then, the machine starts scanning by the operation of the panel, and the scanner drive mechanism is started and the scanning operation is started.

-

Page 48: Adf Unit

3.2.2 ADF unit The ADF unit is equipment which sends one document or the document for every plurality to the ADF scanning part of the document scanner unit, and performs continuation scanning. As for the ADF of this machine, the duplex scanning is also possible. Performance of the ADF - The number of maximum capacity: Up to 50 sheets. - Page 49 3. Function of each motor/solenoid - ADF motor Driving source of overall ADF. - Paper feed solenoid The paper feed solenoid disable pick-up roller and separation roller while the machine is taking action scanning to prevent the next document from being drawn into the ADF. - Switch back solenoid Switches the direction of rotation of the switch back roller ASSY.

- Page 50 5. ADF simplex scanning (The document moves over the immovable scanner module.) (1) Set the document face up into the paper feed chute ASSY. When the machine starts simplex scanning, the ADF motor is rotated clockwise, the pick-up roller draws the document, and the separation roller and separation rubber send a sheet of the document to the ADF one by one from the top page of the stacked documents.

- Page 51 6. ADF duplex scanning (The document moves over the immovable scanner module.) (1) Set the document face up into the document chute. When the machine starts duplex scanning, the ADF motor is rotated clockwise, the pick-up roller draws the document, and the separation roller and separation pad send a sheet of the document to the ADF one by one from the top page of the stacked documents.

- Page 52 (4) The switch back roller ASSY is turned counter again, and the document is drawn again. The document is passed through the paper feed rollers 1, 2 and 3, and ejected to the document cover by the eject roller. Switch back roller ASSY Paper feed roller 2 Eject roller Paper feed roller 3...

-

Page 54: Plate-Up Function Of The Paper Tray

3.3.1 Plate-up Function of the Paper Tray The plate ASSY in the paper tray is pushed up with the motor drive and not with the spring in order to maintain the constant pressure to the feed roller and to give the paper feeding performance. -

Page 55: Paper Supply

3.3.2 Paper supply The feed roller picks up a few sheets or one sheet of paper from the paper tray every time it is rotated and feeds it to the separation roller. Pinch roller Regist roller Regist actuator rear Feed roller Regist actuator front Pressure roller PE actuator... -

Page 56: Paper Registration

3.3.3 Paper registration After the paper top position is detected by the regist actuator front, the paper, separated into individual sheets by the separation roller, is fed further for a specified time, and the paper top position reaches the regist roller so that the paper skew is adjusted. Then, the regist solenoid is turned on, the regist roller starts turning, and the paper is fed to the transfer roller in the drum/toner ASSY. -

Page 57: Paper Eject

3.3.4 Paper eject After the printing image on the exposure drum is transferred onto the paper, the paper is fed to the fuser unit to fix unfixed toner onto the paper by the heat roller and the pressure roller in the fuser unit. -

Page 58: Duplex Printing

3.3.5 Duplex printing After the paper exits from the eject roller ASSY 2 with the front of sheet printed, the eject roller ASSY 2 rotates conversely and feeds the paper to the Duplex unit, where the paper skew is adjusted. Afterwards, the paper is ejected from the Duplex unit to the path through the regist roller and to the transfer block in the drum unit again for process of printing on the back of sheet. -

Page 59: Paper Feeding From The Mp Tray

3.3.6 Paper feeding from the MP tray The separation roller MP is connected with the feed roller through the gear in the MP roller holder ASSY. When the separation roller is driven, therefore, the feed roller is also driven. At this time, the paper is drawn out of the MP tray by rotation of the paper feed roller MP contacted with the paper. -

Page 60: Toner Cartridge

Toner Cartridge 3.4.1 Methods for Detecting Toner Life When the machine detects the toner life end, "Replace Toner" is displayed. The toner life is displayed through the following two ways. First, such indication is displayed when detection is performed by the toner sensor; second, it is displayed at the time when a cumulative rotation of the develop roller reaches its upper limit. -

Page 61: Cartridge Life

3.4.2 Cartridge life A new toner cartridge can print approximately 8,000 A4 or Letter size single-sided pages at normal duty (ISO/IEC19752). In the case of low-duty printing, if the number of printed pages are reached the cartridge life, "Replace Toner" message appears on the LCD before the toner runs out because the developer roller surface or other toner sealing is worn out due to a rotation of the rollers. -

Page 62: New Toner Detection

3.4.3 New toner detection This machine is equipped with the function to detect that the residual quantities of the toner are not enough by examining the degree that the toner in the cartridge blocks the light by the transmission light sensor. This function informs the user's that the toner cartridge has reached its life. - Page 63 When the new toner detection machanism detects that the toner cartridge is replaced with a new one, the developing bias voltage is initialized at the same time. The toner used for the machine has a property that print density is light first and gradually darker in the course of usage.

- Page 64 <When a toner cartridge in use is inserted after "Replace Toner" is displayed by toner sensor detection > A count value before changes is continuously indicated as a number of the rotation for the develop roller. Irrespective of the amount of toner, printing becomes disabled when the number of the rotation for the develop roller reaches the upper limit.

-

Page 65: Print

Print 3.5.1 Basic Principle The printing process consists broadly of 5 processes: electrification, exposure, development, transfer and fusing. 1. Charging: The surface of an exposure drum is electrically charged. 2. Exposure: A printed image is formed on the surface of the drum by applying laser beam. 3. -

Page 66: Print Process

3.5.2 Print Process (1) Charging The flow of the ion charge is controlled by constant voltage of the grid 850 V to ensure it is distributed evenly on the drum surface. In order to coat toner on the exposure drum, the drum needs to be evenly electrified. - Page 67 (2) Exposure The laser beam radiated from a laser diode inside the laser unit is concentrated into a constant width by a slit in the CO lens cell and then reflected by a polygon mirror rotating at high speed. The evenly charged exposure drum is irradiated with reflected light and exposed. Surface potential is lowered by such exposure and a printed image is formed.

- Page 68 (3) Development Toner is attracted to a printed-image area on the exposure drum where surface potential is lowered due to exposure. By controlling developing bias voltage supplied to the develop roller, the amount of toner taken to the drum is adjusted to keep printing density constant. Charging Laser beam 400 V to approx.

- Page 69 (4) Transfer By applying a minus charge to the transfer roller, the toner adhered to the exposure drum is transferred to paper. Supply roller Toner cartridge Develop roller Exposure drum Toner Transfer roller Fig. 2-27 Memo : • Control of transfer bias The transfer bias applied in the transfer roller is adjusted according to types and sizes of paper so as to keep excellent image quality.

- Page 70 (5) Fusing The toner transferred on paper passes between the heat roller and the pressure roller in the fuser unit, being fused by heat and pressure. The thermistor detects surface temperature of the heat roller and turns ON/OFF the halogen heater lamp. The temperature is kept constant. Fuser unit Heat roller Halogen heater...

-

Page 71: Sensors Position

Sensors position Sensor name Type Located on Function High-voltage PS Detect the paper top position Regist front sensor Photo sensor or absence of paper. High-voltage PS Control the first print Regist rear sensor Photo sensor position on the paper. Detect whether the paper is Paper eject sensor Photo sensor Relay rear PCB... - Page 72 Document front sensor 1 Switch back sensor Document front sensor 2 ADF unit Regist frame Document cover sensor Document rear sensor Toner LED PCB (Light emission) Home position sensor Frame R Frame L Paper eject sensor MP PE sensor (Relay rear PCB) PE EG sensor Duplex tray sensor New toner sensor (Relay front PCB)

- Page 73 CHAPTER ERROR INDICATION AND TROUBLESHOOTING...

- Page 74 CHAPTER 3 ERROR INDICATION AND TROUBLESHOOTING This chapter details error messages and codes that the incorporated self-diagnostic functions display if any error or malfunction occurs. If any error message appears, refer to this chapter to find which components should be checked or replaced. The latter half of this chapter provides sample problems that could occur in the main sections of the machine and related troubleshooting procedures.

- Page 75 11. DOCUMENT FEEDING PROBLEMS................3-77 11.1 No Feeding ......................3-77 11.2 Double Feeding ....................3-78 11.3 Paper Jam ......................3-78 11.4 Wrinkles....................... 3-80 12. SCANNING IMAGE DEFECT TROUBLESHOOTING..........3-81 12.1 Image Defect Examples ..................3-81 12.2 Troubleshooting Image Defect ................3-81 13.

-

Page 76: Introduction

1. INTRODUCTION Troubleshooting is the countermeasure procedures that the service personnel should follow if an error or malfunction occurs with the machine. It is impossible to anticipate all of the possible troubles which may occur in future and determine the troubleshooting procedures, so this chapter covers some sample troubles. -

Page 77: Part Names

Part names ADF Unit Scanner Unit Panel Unit NCU PCB Speaker ASSY Joint Cover ASSY Driver PCB Back Cover Side Cover R Laser Unit Outer Chute ASSY Rear Chute ASSY Toner LED PCB Unit ASSY Fuser Unit Frame Unit Process Cover ASSY Main PCB Access Cover MP Tray Cover ASSY... -

Page 78: Initial Check

Initial Check Check the following items before attempting to repair the machine. ■ Operating Environment (1) Put your machine on a flat, stable surface such as a desk that is free of vibration and shocks. (2) Use the machine in a well-ventilated room; use the machine within the following ranges of temperature and humidity: temperature between 10°C and 32.5°C (50°F to 90.5°F), and the relative humidity is maintained between 20% and 80%. - Page 79 (2) Cleaning Use a soft dry cloth. warning DO NOT use flammable substances such as alcohol, benzine, thinner or any type of spray to clean the inside or outside of the machine. Doing this may cause a fire or electrical shock. Confidential...

-

Page 80: Distinguish Error Cause

2. DISTINGUISH ERROR CAUSE ERROR INDICATION To help the user or the service personnel promptly locate the cause of a problem (if any), the facsimile equipment incorporates the self-diagnostic functions which display error messages for machine errors and communications errors. For the communications errors, the machine also prints out the transmission verification report and the communications list. - Page 81 Refer Error Message Type of Error Action Document Jam The document was not Remove the jammed paper from the inserted or fed properly, or ADF. the document scanned 3-29 from the ADF was too long. DR Mode in Use The machine is set to Set Distinctive Ring to Off.

- Page 82 Refer Error Message Type of Error Action Not Registered You tried to access a One Set up the One Touch or Speed Dial Touch or Speed Dial number. 3-74 number that is not programmed. Out of Memory The machine’s memory is Fax sending or copy operation in full.

- Page 83 Refer Error Message Type of Error Action Replace Parts It is time to replace the Replace the PF Kit 2. PF Kit 2 or paper feeding kit for Tray 3-15 Replace PF Kit 2 Replace Toner The toner cartridge is used Replace the toner cartridge with a up and printing is not new one.

-

Page 84: Error Codes

3. ERROR CODES This machine includes a self-diagnosis function. If the machine does not work normally it judges that an error has occurred, and indicates the corresponding error message on the LCD, which in turn helps the end user to quickly find out the problem. Error Indication Error Refer... - Page 85 Error Refer Error Refer Problem Problem codes codes Fax paper setting mismatch DMA transfer error (The setting paper becomes 3-23 3-31 besides the A4/Letter/Legal/ Folio) (Not applicable) Fax paper size is incorrect (The Document scanner home paper is smaller 10mm than the position sensor is not turned on.

- Page 86 Error Refer Error Refer Problem Problem codes codes E1 Main PCB failure 3-38 EF LVPS PCB failure 3-39 Central temperature of heat Battery connection error 3-38 3-39 roller exceeds 280°C EEPROM error EEPROM customizing code 3-38 3-39 error The data reading error for Excess current to USB HOST 3-38 3-40...

-

Page 87: Error Code Cause And Remedy

Error Code Cause and Remedy These errors are recoverable by following the message indicated on the LCD or following the items indicated in User Check. ■ Error code 1E Drum End Soon The drum unit reached its life and requires replacement. <User Check>... - Page 88 ■ Error code 35 Print Unable 35 Turn the power off and then back on again. EEPROM of main PCB failure Step Cause Remedy Main PCB failure Replace the main PCB ASSY. ■ Error code 36 Print Unable 36 Turn the power off and then back on again. HVPS PCB during standby failure Step Cause...

- Page 89 ■ Error code 44 No Toner Open the Front Cover, then install Toner Cartridge. No toner cartridge <User Check> • Install a new toner cartridge. Step Cause Remedy Dirt on electrodes on toner Clean both electrodes. cartridge and machine body (Refer to Fig.

- Page 90 ■ Error code 52 Replace Parts PF Kit 1 The paper feed kit tray 1 reached its life and requires replacement. <User Check> • Replace the paper feed kit tray 1 with a new one. Step Cause Remedy Replacement time of the paper Replace the paper feed kit tray 1.

- Page 91 ■ Error code 56 Cover is Open Close the Fuser Cover which can be found behind the Back Cover up the machine. Back cover is open <User Check> • Close the back cover. • Install the Duplex unit. Step Cause Remedy Harness connection failure of relay Check the harness connection of the relay...

-

Page 92: Error Code 58-67

■ Error code 58 Fuser Error Turn the power off, then on again. Leave the machine for 15 min. Fuser unit failure Error code 59 Self-Diagnostic Will Automatically Restart within 15 minutes. Fuser unit failure (Detect fuser failure at start-up) <User Check>... - Page 93 ■ Error code 68 Print Unable 68 Turn the power off and then back on again. Temperature rise when heater is off Step Cause Remedy Fuser unit failure Replace the fuser unit Main PCB failure Replace the main PCB ASSY. ■...

-

Page 94: Error Code 6A-6F

■ Error code 6A Print Unable 6A Turn the power off and then back on again. Fuser temperature does not reach 60°C within the specified time (center thermistor) Error code 6B Print Unable 6B Turn the power off and then back on again. Fuser temperature does not reach 100°C within the specified time (center thermistor) Error code 6C Print Unable 6C... - Page 95 ■ Error code 70 Print Unable 70 Turn the power off and then back on again. Fuser motor error Step Cause Remedy Motor failure Replace the main motor. Main PCB failure Replace the main PCB ASSY. ■ Error code 71 Print Unable 71 Turn the power off and then back on again.

-

Page 96: Error Code 76-7D

■ Error code 76 Print Unable 76 Turn the power off and then back on again. Rapid temperature rising failure (center thermistor) Error code 78 Print Unable 78 Turn the power off and then back on again. Rapid temperature falling failure (center thermistor) Step Cause Remedy... - Page 97 ■ Electrodes location of the toner/drum unit (4) Grid Drum Unit (2) Charge (6) Cleaner (1) Exposure (3) Developer drum roller (5) Transfer roller Fig. 3-2 ■ Electrodes location of the machine Cleaner Grid Charge Developer roller Exposure drum Transfer roller Fig.

- Page 98 ■ Error code 7F Size mismatch Fax received. Set correct paper size in menu. Fax paper setting mismatch (The setting paper is besides the A4/Letter/Legal/Folio) Error code 80 Size mismatch Reload correct paper, then press Start. Fax paper size is incorrect (The paper is smaller 10mm than the letter size (11inch) in Fax List/Report) NOTE : •...

- Page 99 ■ Error code 84 Jam Rear Open the Back Cover and remove the jammed paper, then press Start. Paper jam in the back cover <User Check> • Check if the paper is jammed around the opened back cover. If jammed, remove it. Step Cause Remedy...

- Page 100 ■ Error code 88 Jam Inside Open the Front Cover, pull out the Drum Unit completely and remove the jammed paper. Paper jam inside the machine <User Check> • Check if the paper is jammed around the removed drum unit. If jammed, remove it. Step Cause Remedy...

- Page 101 ■ Error code 8A Jam Tray 1 Remove the jammed paper from Tray 1. Paper jam (Tray 1) Error code 8B Jam Tray 2 Remove the jammed paper from Tray 2. Paper jam (Tray 2) Error code 8C Jam MP Tray Remove the jammed paper from Multi Purpose Tray and press Start.

- Page 102 ■ Error code 8D Cover is Open Make sure there is no paper jammed inside the machine and close the Back Cover, then press Start. Paper jam near eject tray <User Check> • Check if the paper is jammed in the back cover. If jammed, remove it. Step Cause Remedy...

- Page 103 ■ Error code 9F No Paper Reload paper, then press Start. Paper empty <User Check> • Replenish the paper in the paper tray. Step Cause Remedy Dirt on PE sensor Clean the PE sensor. Harness connection failure of PE Check the harness connection of the PE EG sensor PCB ASSY.

- Page 104 ■ Error code A2 Document Jam Clear the scanner jam, then press the Stop Key. During scanning, 90 cm or longer of a document is detected <User Check> • Check if the document is jammed in the ADF. If it is jammed, remove it. Step Cause Remedy...

- Page 105 ■ Error code A5 Scan Unable A5 Remove the original document. Turn the power off, then on again. Fax scanning error (Warning: Document scanner unit malfunction of first time) Step Cause Remedy Scanning failure Turn the power switch off and on. Then, try scanning again.

- Page 106 ■ Error code AD Scan Unable AD Remove the original document. Turn the power off, then on again. DMA transfer error Step Cause Remedy Scanner module failure Replace the CCD module. Main PCB failure Replace the main PCB ASSY. ■ Error code AE Scan Unable AE See Troubleshooting and routine maintenance chapter in User's Guide.

- Page 107 ■ Error code AF Scanner Locked Open the Document Cover and release Scanner lock lever. Press Stop key. Document Scanner home position sensor is not turned off. <User Check> • Check that the scanner lock lever is unlocked. Step Cause Remedy Home position sensor harness not Reconnect the home position sensor...

- Page 108 ■ Error code B1 Scanner Error Dark level offset data level error for scanning * This error is indicated on the LCD in the maintenance mode. Error code B2 Scanner Error Gain control data level error for scanning * This error is indicated on the LCD in the maintenance mode. Error code B7 Scanner Error A/D converter standard voltage failure;...

- Page 109 ■ Error code B9 Scanner Error Scanning light adjustment error. * This error is indicated on the LCD in the maintenance mode. Error code BB Scanner Error White level data error * This error is indicated on the LCD in the maintenance mode. Error code BD Scanner Error Black level data error...

- Page 110 ■ Error code C0 Cartridge Error Put the Toner Cartridge back in. New toner detection failure <User Check> • Install the toner cartridges into the machine properly. Step Cause Remedy Power off or front cover opened Reset the developing bias voltage and while detecting a new toner develop roller counter.

- Page 111 ■ Error code C9 DIMM Error Make sure that the DIMM is inserted correctly. The failed DIMM is installed, or the DIMM is not installed correctly. <User Check> • Install the DIMM correctly. Step Cause Remedy Main PCB failure Replace the main PCB ASSY. ■...

- Page 112 ■ Error code D1 Machine Error D1 Modem initialization failed Step Cause Remedy Main PCB failure Replace the main PCB ASSY. ■ Error code DD Fuser Error Turn the power off, then on again. Leave the machine for 15min. Fuser error other than 58, 59, 68, 69, 6A, 6B, 6C, 6D, 6E, 6F, 76, 78, DE and E2 are occurred.

- Page 113 ■ Error code E1 Print Unable E1 Turn the power off and then back on again. Main PCB failure Step Cause Remedy Main PCB failure Replace the main PCB ASSY. ■ Error code E2 Fuser Error Turn the power off, then on again. Leave the machine for 15 min. Central temperature of heat roller exceeds 280°C Step Cause...

- Page 114 ■ Error code EC Print Unable EC See Troubleshooting and routine maintenance chapter in User's Guide. Fuser fan failure Step Cause Remedy Main fan failure Replace the main fan ASSY. Main PCB failure Replace the main PCB ASSY. ■ Error code EF Print Unable EF Turn the power off and then back on again.

- Page 115 ■ Error code FF Unusable Device Remove the Device. Turn the power off and back on again. Excess current to USB HOST PCB ASSY error Step Cause Remedy USB HOST PCB failure Replace the USB HOST PCB ASSY. Main PCB failure Replace the main PCB ASSY.

-

Page 116: Paper Feeding Problems

4. PAPER FEEDING PROBLEMS Problems related to paper feeding are end user recoverable if following the User Check items. If the same problem occurs again, follow each procedure in the order of the number described in the Step column in the tables below. No Feeding Step Cause... -

Page 117: Paper Jam

Paper Jam ■ Paper jam in the paper tray and front cover Step Cause Check Result Remedy Dirt on edge Is there paper powder in Clean the edge sensor. sensor the edge sensor? Registration front Does the registration front Re-assemble the actuator/edge actuator/edge actuator registration front actuator/... - Page 118 ■ Paper jam in the back cover and paper eject section Step Cause Check Result Remedy Foreign object Is there a foreign object Remove the foreign around fuser unit around the fuser unit? object. Paper eject Does the paper eject Replace the paper eject actuator failure actuator move smoothly?

-

Page 119: Dirt On Paper

Dirt on Paper <User Check> - Check if the paper is loaded into the paper tray correctly. - Turn over the stack of paper in the paper tray, or try rotating the paper 180° in the paper tray. Step Cause Check Result Remedy... -

Page 120: Curl In The Paper

Curl in the paper The curl in the left figure. <User Check> - Change the paper. Step Cause Check Result Remedy Mismatch the Is the problem solved by Change the position of the setting the paper changing the position of anti-curl lever. -

Page 121: Troubleshooting For Print Image Defect From Pc/Usb/Fax Reception

5. TROUBLESHOOTING FOR PRINT IMAGE DEFECT FROM PC/USB/FAX RECEPTION Image Defect Examples Light Faulty registration Dark Poor fixing Completely blank Vertical streaks Dirt on the back of paper Image distortion All black Black vertical streaks Black horizontal White vertical White horizontal Faint print in a light background stripes... -

Page 122: The Pitch Which Appears In The Image Caused By Failure Of A Roller

The pitch which appears in the image caused by failure of a roller. Image defects which appear periodically may be caused by failure of a roller. Specify the cause referring to the pitch which appears in the image as shown in the table below. The pitch which appears in the image Parts name... -

Page 123: Troubleshooting For Image Defect

Troubleshooting for image Defect Image defect related problems are end user recoverable if following the User Check items. If the same problem occurs, follow each procedure in the order of the number described in the Step column in the tables below. ■... - Page 124 <Location of the leser beam window> Fig. 3-6 ■ Faulty registration <User Check> - Check that the appropriate media type is selected in the printer driver. Step Cause Check Result Remedy Registration rear Does the registration Re-assemble the actuator catching rear actuator move registration rear actuator.

- Page 125 ■ Dark <User Check> - Check the machine's environment. High temperature and high humidity conditions can cause this problem. - Replace the drum unit with a new one. - Replace the toner cartridge with a new one. Step Cause Check Result Remedy Drum unit...

-

Page 126: Poor Fixing

Poor fixing ■ <User Check> - Replace the drum unit with a new one. - Replace the toner cartridge with a new one. Step Cause Check Result Remedy Low pressure of Is the problem solved by Change the position of the pressure roller in changing the position of anti-curl lever. -

Page 127: Image Distortion

■ Completely blank <User Check> - Replace the drum unit with a new one. - Replace the toner cartridge with a new one. Step Cause Check Result Remedy Developing bias Are the electrodes on Clean both electrodes. voltage the drum unit and (Refer to Fig. - Page 128 ■ All black Step Cause Check Result Remedy Corona wire Are the electrodes on Clean both electrodes. failure the drum unit and (Refer to Fig. 3-2, Fig. 3-3.) machine body dirty? Is the corona wire Replace the drum unit. damaged? Scanner harness Is the scanner harness Reconnect the scanner...

- Page 129 ■ Dirt on the back of paper <User Check> - This problem may disappear after printing approximately 10 pages of completely blank sheets. Step Cause Check Result Remedy Scratch and Dirt Is the pressure roller Print approximate 10 pages. on the fuser unit ASSY dirty? Is any other Replace the fuser unit.

- Page 130 ■ Black horizontal stripes <User Check> - Clean the inside of the machine and the corona wire in the drum unit. - Replace the drum unit with a new one. Step Cause Check Result Remedy Dirt on the Are the electrodes on Clean both electrodes.

- Page 131 ■ White vertical streaks <User Check> - Clean the scanner windows of the laser unit with a soft lint-free cloth. (Refer to Fig. 3-6.) - Replace the toner cartridge with a new one. - Check the machine’s environment. High temperature and high humidity conditions can cause this problem.

-

Page 132: Faint Print

■ Faint print <User Check> - Check that the machine is installed on a level surface. - Replace the toner cartridge with a new one. - Clean the scanner windows of the toner unit with a soft cloth. (Refer to Fig. - Page 133 <Clean the drum unit as follows> If you have print quality problems, clean the drum unit as follows: (1) Put the print sample in front of the drum unit, and find the exact position of the poor print. Fig. 3-8 (2) Turn the drum unit gear to the direction of the arrow of the figure by hand while looking at the surface of the exposure drum.

-

Page 134: Black Spots

■ Black spots <User Check> - Damp (wet) paper might be used. Try to change to freshly unpacked paper. - Toner may be empty. Replace the toner cartridge with a new one. - If the problem is not solved after printing a few pages, the drum unit may have glue from label stock on the exposure drum surface. -

Page 135: Horizontal Lines

■ Downward fogging of solid color <User Check> - Toner may be empty. Replace the toner cartridge with a new one. Step Cause Check Result Remedy HVPS PCB Is the problem solved Replace the HVPS PCB failure after replacing the ASSY. - Page 136 ■ Ghost <User Check> - Check the machine's environment, conditions such as high or low humidity may cause this situation to occur. - Check that the appropriate media type or size is selected in the printer driver. - Replace the drum unit with a new one. Step Cause Check...

- Page 137 ■ Hollow print by condensation <User Check> - Turn the power on and leave the machine for a few minutes. Step Cause Check Result Remedy Condensation of Is the problem solved Drum condensation drum unit by high after setting the drum countermeasure mode is humidity condensation...

-

Page 138: Software Setting Problems

80)" in Chapter 6.) Machine For Macintosh, has the Verify the product connection product ID been ID.Product ID: verified? bizhub 20 0216h USB host relay Is the problem solved Replace the USB host PCB failure after replacing the USB relay PCB ASSY. -

Page 139: Network Problems

7. NETWORK PROBLEMS <User Check> - Check the descriptions in the network user’s guide. - Try resetting the factory settings. Step Cause Check Result Remedy Main PCB failure Is the problem solved Replace the main PCB after replacing the main ASSY. -

Page 140: Troubleshooting Of The Communications Errors

8. TROUBLESHOOTING OF THE COMMUNICATIONS ERRORS If a communications error occurs, the facsimile equipment (1) Gives the alarm (intermittent bleep) for approximately four seconds. (2) Indicates the appropriate error message on the LCD. (3) Prints the transmission report during fax transmission. ■... - Page 141 (2) Command reception Code 1 Code 2 Causes Unable to detect a flag field. Carrier was OFF for 200 ms or longer. Abort detected (“1” in succession for 7 bits or more). Overrun detected. A frame for 3 seconds or more received. CRC error in answerback.

- Page 142 (4) Instructions received from the remote terminal [checking the NSC, DTC, NSS, and DCS] Code 1 Code 2 Causes Illegal coding system requested. Illegal recording width requested. ECM requested although not allowed. Polled while not ready. No document to send when polled. Nation code or manufacturer code not correct.

- Page 143 (9) Signal isolation Code 1 Code 2 Causes Unable to detect video signals and commands within 6 seconds after CFR is transmitted. Received PPS containing invalid page count or block count. (10) Video signal reception Code 1 Code 2 Causes Error correction sequence not terminated even at the final transmission speed for fallback.

- Page 144 (11) General communications-related Code 1 Code 2 Causes Unable to receive the next-page data. Unable to receive polling even during turn-around transmission due to call reservation. PC interface error. Communication canceled by pressing the Stop/Exit button before establishment of FAX communication*. Communication canceled by pressing the Stop/Exit button after establishment of FAX communication*.

- Page 145 (13) Maintenance mode Code 1 Code 2 Causes Failed to detect 1300 Hz signal in burn-in operation. Failed to detect PB signals in burn-in operation. (14) Machine error Code 1 Code 2 Causes Machine error (For X X, refer to "2.1 ERROR INDICATION") 3-70...

-

Page 146: Troubleshooting Of The Control Panel

9. TROUBLESHOOTING OF THE CONTROL PANEL ■ Nothing is displayed on the LCD. <User Check> - Verify if the power switch is turned off. Step Possible cause Check Result Remedy Connection Are the main PCB and Reconnect the connector between main control panel PCB properly. - Page 147 ■ The control panel does not work. <User Check> - Check whether the function lock is not set. Step Possible cause Check Result Remedy Key sticking Is there a key on the Clean up the panel cover, control panel stuck? or remove the burrs from panel cover and panel keys.

-

Page 148: Troubleshooting Of Fax Functions

10. TROUBLESHOOTING OF FAX FUNCTIONS ■ Can not send FAX. <User Check> - Verify that the telephone cord is securely inserted into the right socket. Step Possible cause Check Result Remedy Dialing mode Does a dialing signal Check the dialing mode Setting (PB or DP) come out setting at customer's... - Page 149 ■ Speed dialing and One-touch dialing can't be used. Step Possible cause Check Result Remedy Dialing mode Does a dialing signal Check the dialing mode Setting (PB or DP) come out setting at customer's normally in each mode? again. (Use telephone line Check the telephone line emulator.) cord between machine and...

-

Page 150: No Bell Ring

■ No bell ring. Step Possible cause Check Result Remedy Ring delay Ring delay is set to “0”. Change the ring delay settings to another value. Ring volume Ring volume is set to Change the ring volume “OFF”. setting to another value. Connection Are the main PCB and Reconnect the connector... - Page 151 ■ Speaker is silent during on-hook dialing. Step Possible cause Check Result Remedy Connection Are the main PCB and Reconnect the connector between main speaker connected properly. PCB and properly? speaker Connection Are the main PCB and Reconnect the connector between main NCU PCB connected properly.

-

Page 152: Document Feeding Problems

11. DOCUMENT FEEDING PROBLEMS Problems related to document feeding are end user recoverable if following the User Check items. If the same problem occurs again, follow each procedure in the order of the number described in the Step column in the tables below. 11.1 No Feeding <User Check>... -

Page 153: Double Feeding

11.2 Double Feeding <User Check> - Check whether the document does not use the paper which is thinner than the specification. Step Cause Check Result Remedy Feed roller holder Is the surface of the Replace the feed roller ASSY failure separation roller worn holder ASSY. - Page 154 ■ Paper jam in the ADF <User Check> - Check whether length does not use paper equal to or less than 148 mm. Step Cause Check Result Remedy Foreign object Is there a foreign object Remove the foreign inside ADF inside ADF? object.

-

Page 155: Wrinkles

■ Paper jam at the duplex scanning <User Check> - Use the A4 or Letter size. - Use the document without warpage. - Use the document which is not so too thin. (thickness of paper) Step Cause Check Result Remedy Foreign object Is there a foreign object Remove the foreign... -

Page 156: Scanning Image Defect Troubleshooting

12. SCANNING IMAGE DEFECT TROUBLESHOOTING 12.1 Image Defect Examples Faulty registration Light Dark Vertical streaks Completely blank White vertical streaks Fig. 3-11 12.2 Troubleshooting Image Defect Image defect related problems are end user recoverable if following the User Check items. If the same problem occurs, follow each procedure in the order of the number described in the Step column in the tables below. - Page 157 ■ Faulty registration 1. ADF Step Cause Check Result Remedy Document rear Does the document rear Re-assembly the document actuator catching actuator move rear actuator. on some position smoothly? Fine adjustment Is the problem solved by Perform the fine of scan start performing the fine adjustment of scan start position...

- Page 158 ■ Completely blank Step Cause Check Result Remedy White level data Is the problem solved by Perform the acquisition of malfunction performing the white level data. (Function acquisition of white level code 55) data. (Function code 55) Scanner module Is the problem solved by Replace the CCD module.

- Page 159 ■ White vertical streaks <User Check> - Check if the ADF glass or document glass is not stained. Step Cause Check Result Remedy Scanner module Is the problem solved by Replace the CCD module. failure replacing the CCD unit. ADF or Is the problem solved by Replace the top cover document glass...

-

Page 160: Others Problems

13. OTHERS PROBLEMS ■ The machine is not turned on, or the LCD indication does not appear. Step Cause Check Result Remedy Harness Is the harness of the Reconnect the LCD panel connection LCD panel PCB ASSY PCB ASSY harness. failure of LCD connected correctly? panel PCB... - Page 161 ■ Pickup function of paper tray does not work. Step Cause Remedy Lift arm catching on some position Re-assemble the lift arm. Pickup roller holder ASSY catching Re-assemble the pickup roller holder on some position ASSY catching on some position. Roller holder ASSY failure Replace the roller holder ASSY.

- Page 162 CHAPTER PERIODICAL MAINTENANCE Confidential...

- Page 163 CHAPTER 4 PERIODICAL MAINTENANCE CONTENTS 1. PERIODICAL MAINTENANCE PARTS ................ 4-1 1.1 Periodical Maintenance Parts................4-2 1.2 Procedures to Replace Periodical Maintenance Parts .......... 4-3 1.2.1 Fuser unit and laser unit................4-3 1.2.2 Paper feeding kit for tray 1, 2 ..............4-30 1.2.3 Paper feeding kit for MP tray..............

-

Page 164: Periodical Maintenance Parts

1. PERIODICAL MAINTENANCE PARTS To avoid creating secondary problems by mishandling, follow the warnings below during maintenance work. WARNING • Always turn off the power switch and unplug the power cord from the power outlet before accessing any parts inside the machine. •... - Page 165 Periodical Maintenance Parts Periodical maintenance parts are the parts to be replaced periodically to maintain product quality. These parts would affect the product quality greatly if they lost their function even if they do not appear to be damaged or there is no change in their appearance. The periodical maintenance parts listed below should be replaced at the service center referring to the service life.

-

Page 166: Procedures To Replace Periodical Maintenance Parts

Procedures to Replace Periodical Maintenance Parts Fuser unit and laser unit 1.2.1 <Uninstalling Procedure> Check that the following before entering the procedures. • Make sure that the AC cord is disconnected from the machine. • Make sure that the Drum/toner ASSY is removed. •... - Page 167 (3) Remove the Pins of the Outer chute ASSY from the Back cover. (4) Remove the Back cover. Outer chute ASSY Back cover Outer chute ASSY Back cover Fig. 4-2 Confidential...

- Page 168 (5) Hold the Knobs on the Rear chute ASSY and pull down this to your side. (6) Remove the Arms of the Rear chute ASSY from the Pins. (7) Remove the Rear chute ASSY. Knob Rear chute ASSY Knob Fig. 4-3 (8) Remove the pan B M4x20 Taptite screw.

- Page 169 (9) Disconnect the connector of the Heater terminal while pressing the Hook of the connector of the Fuser unit. Fuser unit Hook Heater terminal Frame R Fig. 4-5 (10) Pull the FU harness cover 2 to the direction of 10a while pressing the Hook and pull out the FU harness cover 2 from the back of the machine.

- Page 170 (11) Disconnect the connectors of the Thermistor ASSY M and Thermistor ASSY S from the Relay rear PCB ASSY, and remove the harnesses of these thermistors. Hook Thermistor ASSY M Fuser unit Hook Relay rear PCB ASSY Thermistor ASSY S Relay rear PCB ASSY Fig.

- Page 171 (13) Open the Front cover, remove the two bind B M4x12 Taptite screws, and then remove the Side cover L by releasing the Hooks in the order of 13a to 13d. Taptite bind B M4x12 Hook Front cover Side cover L Taptite bind B M4x12 Hooks Hooks...

- Page 172 (15) Remove the two bind B M4x12 Taptite screws, and release the Hooks by following direction from 15a to 15d, then remove the Side cover R. Hook Taptite bind B M4x12 Side cover R Taptite bind B M4x12 Hooks Hook Hooks Fig.

- Page 173 (19) Disconnect the connector of the Scanner motor harness from the Driver PCB. (20) Disconnect the connectors of the Home Position sensor harness and FFC cable from the Main PCB. Note : • After disconnecting flat cable(s), check that each cable is not damaged at its end or short-circuited.

- Page 174 (22) Remove the two bind B M4x12 Taptite screws, and then remove the Document scanner. Document scanner <Back side> Taptite, bind B M4x12 Taptite, bind B M4x12 Fig. 4-15 (23) Remove the two cup B M4x20 Taptite screws. Lift up the rear of the Scanner unit slightly and remove the Scanner unit.

- Page 175 (24) Remove the cup S M3x6 SR Taptite screw, and remove the Screw pan (S/P washer) M3.5x6 of the NCU FG harness ASSY. Screw, pan (S/P washer) M3.5X6 NCU unit NCU FG harness ASSY Joint cover ASSY Driver PCB shield Taptite cup S M3x6 SR Fig.

- Page 176 (28) Slide the Sub duct to the direction of 28b while pressing the Hook to the direction of 28a and remove the Sub duct from the Air duct. Air duct <Back side> Sub duct Hook Fig. 4-19 (29) Remove the Filter from the Air duct. Note : •...

- Page 177 (30) Remove the Hook of the Air duct from the frame. Slide the Air duct to the direction of 30b and remove the Air duct. Laser unit Hook Hook Hook Hook Air duct Hook Fig. 4-21 4-14 Confidential...

- Page 178 (31) Remove the two Flat cables from the Main PCB. Note : • After disconnecting flat cable(s), check that each cable is not damaged at its end or short-circuited. (32) Remove the six cup S M3x6 Taptite screws. (33) Remove the Protective film from the Flat cable. (34) Pull out the two Flat cables from the Core.

- Page 179 < Installing Procedure > (1) Secure the Laser unit with the six cup S M3x6 Taptite screws. (2) Put the Flat cable (LD harness connector) through the Core. (3) Put the Flat cable (Polygon motor connector) through the Core and Protective film. (Refer to "7.

- Page 180 (5) Install the Air duct into the Laser unit. Laser unit Air duct Fig. 4-24 (6) Install the Filter into the Air duct. Air duct Filter Fig. 4-25 4-17 Confidential...

- Page 181 (7) Install the Sub duct into the Air duct. Air duct <Back side> Sub duct Fig. 4-26 (8) Insert the bosses of the Joint cover and hook on the cover, then secure the Joint cover with the four bind B M4x12 Taptite screws. Joint cover Bosses Taptite bind B M4x12...

- Page 182 (9) Secure the Screw pan (S/P washer) M3.5x6 of the NCU FG harness ASSY. (10) Secure the cup S M3x6 SR Taptite screw. Screw, pan (S/P washer) M3.5X6 NCU unit NCU FG harness ASSY Joint cover ASSY Driver PCB shield Taptite cup S M3x6 SR Fig.

- Page 183 (12) Secure the Document scanner with the two bind B M4x12 Taptite screws. Document scanner <Back side> Taptite, bind B M4x12 Taptite, bind B M4x12 Fig. 4-30 (13) Connect the two Connectors into the Main PCB. (14) Connect the Connector into Driver PCB. (15) Secure the ADF FG harness and FB FG harness with the cup S M3x6 Taptite screw.

- Page 184 (16) Connect the connectors of the Home Position sensor harness and FFC cable into the Main PCB. Note : • When connecting flat cable(s), do not insert them at an angle. After insertion, check that the cables are not at an angle. (17) Connect the connector of the Scanner motor harness into the Driver PCB.

- Page 185 (19) Catch the Hooks in the order of the arrows and secure the Side cover R with the two bind B M4x12 Taptite screws. Hook Taptite bind B M4x12 Side cover R Taptite bind B M4x12 Hooks Hook Hooks Fig. 4-34 (20) Secure the Shield cover ASSY and two FG harnesses with the four cup S M3x6 SR Taptite screws.

- Page 186 (21) Catch the Hooks in the order of the arrows and secure the Side cover L with the two bind B M4x12 Taptite screws. Taptite bind B M4x12 Hook Front cover Side cover L Taptite bind B M4x12 Hooks Hooks Fig.

- Page 187 Precautions before installing the fuser unit CAUTION • DO NOT subject the fuser unit to strong physical shocks or vibrations. • DO NOT touch the rollers and the electrodes to prevent damage to the fuser unit In the following figures. •...

- Page 188 (22) Secure the Fuser unit with the pan B M4x20 Taptite screw. Taptite pan B M4x20 Fuser unit Fig. 4-37 4-25 Confidential...

- Page 189 (23) Connect the connectors of the Thermistor ASSY M and Thermistor ASSY S onto the Relay rear PCB ASSY. Hook Thermistor ASSY M Fuser unit Hook Relay rear PCB ASSY Thermistor ASSY S Relay rear PCB ASSY Fig. 4-38 (24) Install the FU harness cover 2. FU harness cover 2 Hook Fig.

- Page 190 (25) Install the connector of the Heater Terminal to the connector to the Fuser unit. Fuser unit Connector Heater terminal Frame R Fig. 4-40 (26) Secure the FU harness cover 1 with the pan B M4x20 Taptite screw. Taptite pan B M4x20 FU harness cover 1 Hooks Fig.

- Page 191 (27) Catch the Arm of the Rear chute ASSY onto the Pin of the machine body and install the Rear chute ASSY. Rear chute ASSY Fig. 4-42 (28) Catch the Pins of the Outer chute ASSY onto the Back cover. Outer chute ASSY Back cover Outer chute ASSY...

- Page 192 (29) Catch the Arm of the Back cover onto the Pin of the machine body and install the Back cover, and close the Back cover. Back cover Fig. 4-44 Set the following parts after assembling. • Set the Duplex feed ASSY. •...

-

Page 193: Paper Feeding Kit For Tray 1, 2

Paper feeding kit for tray 1, 2 1.2.2 < Uninstalling Procedure > Check that the following before entering the procedures. • Make sure that the AC cord is disconnected from the machine. • Make sure that the Paper tray is removed from the machine. •... - Page 194 (5) Turn the machine upside down. Note : • Pull out and put into the paper tray so that the Roller holder ASSY is lowered. • If the Roller holder ASSY is remained up, it cannot be removed. (6) Push the Lift arm to the direction of the arrow 6a and pull out the pin of the Roller holder ASSY.

- Page 195 (7) Slide the Roller holder ASSY to the direction of the arrow 7a. Then, lift up the gear side of the Roller holder ASSY to the direction of the arrow 7b and pull it out to the direction of the arrow 7c to remove. Roller holder ASSY Paper feed frame Fig.

- Page 196 < Installing Procedure > (1) Install the Roller holder ASSY. Note : • When assembling the roller holder ASSY, align the section "A" on the shaft of the roller holder ASSY with the hole on the paper feed frame. Roller holder ASSY "A"...

- Page 197 (2) Assemble the Lift arm onto the Pin of the Roller holder ASSY. (3) Place the machine on its base. Lift arm Roller holder ASSY Paper feed frame Fig. 4-49 (4) Install the Duplex feed ASSY, and install the Drum/toner ASSY. 4-34 Confidential...

- Page 198 (5) Set the Separation pad spring. (6) Put the Hooks of the Separation pad ASSY into the Paper tray, and turn the Separation pad ASSY to the direction of the arrow 6c to catch the Hooks into the Paper tray. Note : •...

-

Page 199: Paper Feeding Kit For Mp Tray

Paper feeding kit for MP tray 1.2.3 < Uninstalling Procedure > Check that the following before entering the procedures. • Make sure that the AC cord is disconnected from the machine. • Make sure that the Drum/toner ASSY is removed. (1) Open the MP feed frame cover. - Page 200 (2) Remove the Holder bearing MP. Holder bearing MP Hook MP feed frame Fig. 4-52 (3) Lift up the Lift arm MP to release it from the Pin of the MP roller holder ASSY. (4) Slide the MP roller holder ASSY to the direction of the arrow 4a and put it up to remove. MP roller holder ASSY Lift arm MP MP feed frame...

- Page 201 (5) Turn the back side of the Separation pad ASSY MP to the direction of the arrow 5a and put it up to remove. Separation pad ASSY MP MP feed frame MP frame Fig. 4-54 4-38 Confidential...

- Page 202 < Installing Procedure > (1) Put the Hook of the Separation pad ASSY MP into the MP feed frame and pull down the Separation pad ASSY MP to the direction of the arrow 1b until it is locked. Separation pad ASSY MP MP feed frame MP frame Fig.

- Page 203 (3) Put the Holder bearing MP into the MP feed frame and turn the Holder bearing MP to the direction of the arrow 3c to lock. Holder bearing MP Hook MP feed frame Fig. 4-57 (4) Close the MP feed frame cover. MP feed frame MP feed frame cover Front cover...

- Page 204 CHAPTER DISASSEMBLY/REASSEMBLY...

- Page 205 CHAPTER 5 DISASSEMBLY/REASSEMBLY This chapter details procedures for disassembling and reassembling the machine together with related notes. The disassembly order flow provided enables you to see at a glance the quickest way to get to component(s) involved. At the start of a disassembly job, you check the disassembly order flow that guides you through a shortcut to the object components.

- Page 206 9.8.15 ADF Motor ....................5-62 9.8.16 Switch Back Solenoid ASSY ............... 5-63 9.8.17 PF Solenoid ASSY ..................5-63 9.8.18 ADF Relay PCB................... 5-64 9.8.19 Paper Feed Chute ASSY ................5-65 9.8.20 Document Front Actuator 1 / Document Front Sensor 1 ......5-66 9.8.21 Document Front Actuator 2 / Document Front Sensor 2 ......

- Page 207 9.12 NCU PCB ASSY ....................5-97 9.13 Speaker ASSY ....................5-100 9.14 Driver PCB ....................... 5-101 9.15 USB HOST PCB ASSY..................5-103 9.16 Side Cover R....................5-105 9.17 Battery......................5-106 9.18 Joint Cover ASSY .................... 5-107 9.19 Main PCB......................5-108 9.20 Gear Plate Calking ASSY / Develop Joint / Main Motor ASSY......

- Page 208 10. DISASSEMBLY PROCEDURE OPTIONAL LOWER TRAY (PF-P10) ..... 5-155 10.1 Paper Tray ....................... 5-155 10.2 Tray 2 Front Cover ASSY ................5-158 10.3 Tray 2 Rear Cover.................... 5-159 10.4 Tray 2 Side Cover L ..................5-160 10.5 Tray 2 Side Cover R..................5-161 10.6 tray 2 PCB ASSY .....................

-

Page 209: Safety Precautions

1. SAFETY PRECAUTIONS To avoid creating secondary problems by mishandling, follow the warnings and precautions below during maintenance work. WARNING • Always turn off the power switch and unplug the power cord from the power outlet before accessing any parts inside the machine. •... -

Page 210: Transferring Received Fax Data

2. TRANSFERRING RECEIVED FAX DATA When the machine at the user site requires to be repaired, unplugging the power cord from the wall socket for sending the machine for repair will lose received FAX data if unprinted and left in the machine. To prevent such data loss, the service personnel should instruct end users (e.g., by telephone) to transfer data to another facsimile machine using the procedure below. - Page 211 (7) With the "2.ACTIVITY," "3.DOCUMENTS," "4.COM.LIST (NEW)," or "5.COM.LIST (ERR3)" being displayed, press the [OK] button. The "ENTER NO. &SET" appears. (8) Enter the telephone number of the receiver machine and press the [OK] button again. Note: • Be sure to type the telephone number with the numerical keys. No one-touch dialing is allowed in this procedure.

-

Page 212: Screw Torque List

3. SCREW TORQUE LIST Tightening Location of screw Screw type Q’ty torque N m (kgf · cm) FU harness cover 1 Taptite pan B M4x20 0.7±0.1 (7±1) Fuser unit Taptite pan B M4x20 0.7±0.1 (7±1) Process cover stopper Taptite cup B M4x10 0.5±0.1 (5±1) Emblem cover Taptite bind B M3x10... - Page 213 Tightening Location of screw Screw type Q’ty torque N m (kgf · cm) Screw, pan (S/P washer) Scanner motor FB 0.7±0.1 (7±1) M3X6 Pulley ASSY Taptite B M3x6 0.4±0.05 (4±0.5) Panel unit ASSY Taptite cup B M4x12 0.7±0.1 (7±1) Panel cover generic Taptite cup B M3x10 0.5±0.1 (5±1) Screw, pan (S/P washer)

- Page 214 Tightening Location of screw Screw type Q’ty torque N m (kgf · cm) Base plate HV Taptite bind B M4x12 0.8±0.1 (8±1) HV insulation sheet Taptite bind B M4x12 0.8±0.1 (8±1) High-voltage PS PCB ASSY Taptite bind B M4x12 0.8±0.1 (8±1) Toner LED PCB unit ASSY Taptite pan B M3x8 0.5±0.1 (5±1)

-

Page 215: Lubrication

4. LUBRICATION The kind of the lubricating oil Lubrication point Quantity of lubrication (Maker name) BG-MU Dev gear 37R joint drive 2mm dia. ball (Kanto Kasei) Main motor ASSY Drum gear 82R EM-D110 (Dow Corning) Separation pad ASSY 2mm dia. ball Gear 82R Apply grease on the cogs... - Page 216 Separation pad ASSY 4 places Fig. 5-2 Confidential...

-

Page 220: Harness Routing

7. HARNESS ROUTING MP PE sensor ASSY Hook "A" MP feed frame Machine top side (Machine body upside down) Hole Hook "B" Hook "A" MP PE sensor ASSY MP feed frame High-voltage PS PCB ASSY 5-12 Confidential... - Page 221 PE EG sensor ASSY Hook "B" PE EG sensor ASSY Hole "A" Machine top side (Machine body upside down) Hook "B" Paper feed frame Hole "A" PE EG sensor ASSY Paper Feed frame Hook "A" High-voltage PS PCB ASSY Front Cover Sensor ASSY Relay front PCB ASSY Hooks Front cover sensor ASSY...

- Page 222 Toner sensor PCB ASSY Relay front PCB ASSY Hooks Frame L Hook Hook Hook Toner sensor PCB unit ASSY Regist solenoid ASSY Relay front PCB ASSY Hooks Frame L Hook Hook Hook Hook Hook Register solenoid ASSY 5-14 Confidential...

- Page 223 MP solenoid ASSY Relay front PCB ASSY Hooks Frame L Hooks Hook MP solenoid ASSY Tray 1 solenoid ASSY Relay front PCB ASSY Hooks Frame L Hooks Hook Tray 1 solenoid ASSY 5-15 Confidential...

- Page 224 Relay front PCB ASSY Frame L Hook Relay front PCB ASSY Main PCB Laser unit Frame L Laser unit Core Hole LD harness (Flat cable) Main PCB Hook Protective film Gear cover Polygon motor (Flat cable) 5-16 Confidential...

- Page 225 Fan motor 60 unit Frame R Hooks Fan motor 60 unit Toner LED PCB unit ASSY Fan motor 60 unit LV Hooks Hook Frame R Hook Hook Toner LED PCB unit ASSY Fan motor 60 unit LV 5-17 Confidential...

- Page 226 Toner LED PCB unit ASSY Hooks Frame R Hook Toner LED PCB unit ASSY Hook Hole High-voltage PS PCB ASSY Hook Hooks Machine top side (Machine body upside down) Hole 5-18 Confidential...

- Page 227 LVPS PCB unit Machine top side (Machine body upside down) Base plate LV LVPS PCB unit Hook SW holder ASSY Power supply switch LVPS PCB <A view> unit terminal <A view> Core Hooks Inlet harness ASSY FG harness FG harness Shield cover ASSY Main PCB Main PCB...

- Page 228 ADF unit <A view> ADF motor harness ADF FG harness ADF Relay harness ADF Relay PCB ADF motor ADF harness Hole "B" Document cover Document cover sensor sensor harness ADF unit Hole "B" ADF harness Hole Drive PCB Document scanner unit ADF motor harness ADF FG harness Document cover sensor harness...

- Page 229 ADF unit (Document front sensor 1, Document front sensor 2) <A view> Motor frame ASSY Hook Hole "C" Hooks Document front sensor 2 Document front Paper feed chute ASSY sensor 1 ADF Relay PCB Document front Hole "C" sensor 1 <A view>...

- Page 230 ADF unit (Document rear sensor, Switch back sensor) Switch back sensor <A view> Switch back sensor Actuator Document rear sensor Switch back sensor harness switch back ADF Relay PCB Hook <A view> Hook Document Document Switch back sensor Hooks rear sensor rear actuator harness harness...

- Page 231 Document scanner unit (CCD module, Home position sensor) Drive plate ASSY Hook FFC plate Scanner unit CCD module Home position sensor Drive plate ASSY Hole Home position sensor Home position sensor harness FFC cable Main PCB Document scanner unit (Scanner motor, FB FG harness) Scanner motor FB Hole Scanner unit...

- Page 232 Panel unit Panel unit ASSY Tape Hook Panel PCB Panel unit ASSY Hole Panel PCB harness Main PCB Panel PCB harness Speaker ASSY Speaker ASSY Hook Hook Joint cover ASSY Hole Main PCB 5-24 Confidential...

- Page 233 NCU unit NCU unit NCU FG harness Joint cover ASSY NCU FG harness Frame L NCU harness Hole Hole Base plate LV Main PCB Machine top side (Machine body upside down) Fuser unit Thermistor ASSY M LVPS PCB unit Hooks Fuser unit Thermistor ASSY S Relay rear PCB ASSY...

- Page 234 Relay rear PCB ASSY, Ejector solenoid Ejector solenoid Duplex tray sensor Frame L Main shield plate ASSY Main PCB sheet Main PCB Relay rear PCB ASSY Insulation sheet LVPS PCB unit, High-voltage PS PCB ASSY Frame L Main PCB sheet LVPS PCB unit Insulation sheet...

- Page 235 Main motor ASSY, Thermistor ASSY, tray 2 connector Frame L Thermistor ASSY Thermistor ASSY Tray 2 connector Main PCB Main motor ASSY Driver PCB, Battery Battery harness Battery Joint cover ASSY Hole Drive PCB Driver harness Main PCB 5-27 Confidential...

- Page 236 USB HOST PCB Joint cover ASSY USB HOST harness ASSY Hooks USB HOST PCB Hole Main PCB USB PCB holder 5-28 Confidential...

-

Page 238: Disassembly Procedure

9. DISASSEMBLY PROCEDURE ■ Preparation Prior to proceeding with the disassembly procedure, (1) Unplug • the AC cord, • the USB cable, if connected, • the LAN cable, if connected. (2) Remove • the Paper tray, • the Toner cartridge and Drum unit, •... -

Page 239: Paper Tray

Paper Tray (1) Pull up the back side of the Separation pad ASSY. (2) Push the Hooks provided on both sides of the Separation pad ASSY inwards. (3) Pull up the Separation pad ASSY. Separation pad ASSY Hooks Hook Hook Paper tray Fig. - Page 240 (4) Remove the Separation pad spring. Separation pad spring Paper tray Fig. 5-6 (5) Push the hook of the lift gear 46 while pushing up the plate up plate, and remove the Lift gear 46. Plate up plate Plate up plate Lift gear 46 Hook Paper tray...

- Page 241 (6) Remove the Gear 21-16. Gear 21-16 Paper tray Fig. 5-8 (7) Remove the Gear 15. Gear 15 Paper tray Fig. 5-9 5-34 Confidential...

-

Page 242: Back Cover

Back Cover (1) Open the Back cover. (2) Remove the Arm of the Back cover from the Pin. Back cover Fig. 5-10 5-35 Confidential... - Page 243 (3) Remove the Pins of the Outer chute ASSY from the Back cover. (4) Remove the Back cover. Outer chute ASSY Back cover Outer chute ASSY Back cover Fig. 5-11 5-36 Confidential...

-

Page 244: Rear Chute Assy

Rear Chute ASSY (1) Hold the Knobs on the Rear chute ASSY and pull down this to your side. (2) Remove the Arms of the Rear chute ASSY from the Pins. (3) Remove the Rear chute ASSY. Knob Rear chute ASSY Knob Fig. - Page 245 (5) Push the Hook of the Rear chute (indicated by the arrow 5a), and move the Eject actuator to the direction of 5b. (6) Lift up the Eject actuator to remove. (7) Remove the Eject actuator spring. Eject actuator spring Eject actuator Rear chute Hook...

-

Page 246: Fuser Unit

Fuser Unit (1) Remove the pan B M4x20 Taptite screw. Release the Hooks in the order of 1a, 1b and 1c. Remove the FU harness cover 1. Taptite, pan B M4x20 FU harness cover 1 Hooks Fig. 5-16 (2) Disconnect the connector of the Heater terminal while pressing the Hook of the connector of the Fuser unit. - Page 247 (3) Pull the FU harness cover 2 to the direction of 3a while pressing the hook and pull out the FU harness cover 2 at the back. FU harness cover 2 Hook Fig. 5-18 (4) Disconnect the connectors of the Thermistor ASSY M and Thermistor ASSY S from the Relay rear PCB ASSY, and remove the harnesses of these thermistors.

- Page 248 CAUTION • DO NOT subject the fuser unit to strong physical shocks or vibrations. • DO NOT touch the rollers and the electrodes to prevent damage to the fuser unit In the following figures. (5) Remove the pan B M4x20 Taptite screw, and then remove Fuser unit. Taptite, pan B M4x20 Fuser unit Fig.

- Page 249 Assembling Note: • To prevent the deformation of the pressure roller, the fuser unit spare part is shipped with its pressure roller at low nip pressure. Before installing the fuser unit, turn back the levers to the normal position by following instructions below. (1) Put the fuser unit on a flat, horizontal surface.

-

Page 250: Tray Mp Assy

Tray MP ASSY (1) Open the MP tray cover ASSY. (2) Release the Pins of the Tray MP ASSY from the MP tray cover ASSY. (3) Remove the Tray MP ASSY. Process cover ASSY MP tray cover ASSY Tray MP ASSY Fig. -

Page 251: Mp Tray Cover Assy / Process Cover Assy / Emblem Cover

MP Tray Cover ASSY / Process Cover ASSY / Emblem cover (1) Push the front cover release button. (2) Open Process cover ASSY. (3) Release the Hook to remove the Process cover stopper. Front cover release button Process cover ASSY Drive release link Hook MP tray cover ASSY... - Page 252 (4) Remove the MP tray cover ASSY and the Process cover ASSY to the direction of 4a and 4b to release the Pins, and remove them. Process cover ASSY MP tray cover ASSY Fig. 5-25 (5) Pull the Arm outwards and remove the Process cover ASSY from the MP tray cover ASSY. Process cover ASSY MP tray cover ASSY Fig.

- Page 253 (6) Remove the cup B M4x10 Taptite screw, and then remove the Process cover stopper. Process cover Process cover stopper Taptite, cup B M4x10 Fig. 5-27 (7) Remove the Support flap 1 from the Process cover. Support flap 1 Process cover Fig.

- Page 254 (8) Remove the Hook of the right side, and then remove the MP tray extention from the MP tray cover ASSY. Hook MP tray extention MP tray cover ASSY Fig. 5-29 (9) Remove the two bind B M3x10 Taptite screws, and then remove the Emblem cover from the MP tray cover.

-

Page 255: Access Cover / Side Cover L

Access Cover / Side Cover L (1) Remove the Access cover. Access cover Fig. 5-31 (2) Remove the two bind B M4x12 Taptite screws, and then remove the Side cover L by releasing the Hooks from 2a to 2d. Taptite, bind B M4x12 Hook Side cover L Taptite, bind B M4x12... -

Page 256: Adf Unit

ADF Unit ADF Unit 9.8.1 (1) Remove the four cup S M3x6 SR Taptite screws, remove the two FG harnesses and then remove the Shield cover ASSY. FG harness Taptite cup S M3x6 SR Label Shield cover ASSY FG harness Taptite cup S M3x6 SR Fig. - Page 257 (2) Remove the cup S M3x6 Taptite screw, remove the ADF FG harness and FB FG harness. (3) Disconnect the Connector from the Driver PCB. (4) Disconnect the two Connectors from the Main PCB. Driver PCB <Left side> Connector (ADF motor harness) ADF FG harness FB FG harness Taptite cup S M3x6...

-

Page 258: Hinge Arm R

Hinge Arm R 9.8.2 (1) Turn the Document cover LGL upside down. Remove the Hinge arm R from the Hinge base R. Hinge arm R <Lower side> Document cover LGL Hinge base R Fig. 5-36 Hinge Base R 9.8.3 (1) Remove the three cup B M3x10 Taptite screws, and then remove the Hinge base R. Taptite cup B M3x10 Hinge base R <Lower side>... -

Page 259: Hinge Assy L

Hinge ASSY L 9.8.4 (1) Remove the two cup B M3x10 Taptite screws and the cup S M3x12 Taptite screw, and then remove the Hinge ASSY L. Taptite cup B M3x10 Taptite cup S M3x12 Hinge ASSY L <Lower side> Document cover LGL Fig. -

Page 260: Adf Side Cover F

ADF Side Cover F 9.8.6 (1) Push the Hook from underneath the ADF unit to release the Latch, and remove the cup S M3x8 Taptite screw and cup B M3x10 Taptite screw from the ADF Side cover F. (2) Remove the ADF side cover F from the ADF unit. Taptite cup S M3x8 ADF side cover F Taptite cup B M3x10... -

Page 261: Adf Chute Assy

ADF Chute ASSY 9.8.8 (1) Disconnect the 7 connectors from the ADF relay PCB. (2) Disconnect the connector of the ADF motor harness from the ADF motor. (3) Remove the cup S M3x8 Taptite screw and ADF FG harness. ADF motor harness ADF motor Taptite cup S M3x8 ADF FG harness... - Page 262 (5) Turn the Document cover LGL the correct way up and remove the four cup B M3x10 Taptite screws from the ADF chute ASSY. (6) Release the hook to remove the ADF chute ASSY from the Document cover LGL. Hook Taptite cup B M3x10 Taptite cup B M3x10 ADF chute ASSY...

-

Page 263: Sub Chute Assy / Sx Chute

Sub Chute ASSY / SX Chute 9.8.9 (1) Remove the two cup S M3x8 Taptite screws. (2) Remove the Sub chute ASSY or SX chute from the ADF chute ASSY. Taptite cup S M3x8 Sub chute ASSY or SX chute Taptite cup S M3x8 ADF chute ASSY <Front side>... -

Page 264: Earth Spring

9.8.11 Earth Spring (1) Turn the Exit chute cover ASSY upside down. Remove the Earth spring from the Exit chute cover ASSY. Earth spring Exit chute cover ASSY Antistatic brush Fig. 5-48 Assembling Note: • When assembling the Earth spring, ensure that the end of the Earth spring is attached onto the Antistatic brush as shown in the figure below. -

Page 265: Pf Roller Holder Assy

9.8.12 PF Roller Holder ASSY (1) Turn the ADF chute ASSY upside down. Release the Hooks of the Conductive bushing A to remove the Conductive bushing A. (2) Remove the Bushing from the ADF chute ASSY, and remove the PF roller holder ASSY from the ADF chute ASSY. -

Page 266: Lf Roller 1 Assy

9.8.13 LF Roller 1 ASSY (1) Release the Hooks of the Conductive bushing A to remove the Conductive bushing A. (2) Release the Lock lever and then remove the Bushing from the ADF chute ASSY, and remove the LF roller 1 ASSY from the ADF chute ASSY. Bushing LF roller 1 ASSY Conductive bushing A... -

Page 267: Switch Back Roller Assy