Summary of Contents for Bosch Rexroth A10VOH145 60 Series

- Page 1 Instruction manual Axial piston variable pump A10VOH145 series 60 RE 92704-01-B/2022-12-07, replaces: 2020-01-21, EN...

- Page 2 © Bosch Rexroth AG 2020. All rights reserved, also regarding any disposal, exploitation, reproduction, editing, distribution, as well as in the event of applications for industrial property rights. The data specified within only serves to describe the product. No statements concerning a certain condition or suitability for a certain application can be derived from...

-

Page 3: Table Of Contents

7.4.7 Remove the spacer (for version with through drive) ........33 7.4.8 Completion of installation ................34 7.4.9 Hydraulically connecting the axial piston unit ..........35 7.4.10 Electrically connecting the axial piston unit ..........39 Performing flushing cycle ................40 RE 92704-01-B/2022-12-07, Bosch Rexroth AG... - Page 4 Preparing the components for storage or further use ......... 48 Disposal ������������������������������������������������������������������������������������������������� 49 Extension and conversion ����������������������������������������������������������������������� 49 Troubleshooting ������������������������������������������������������������������������������������� 50 14.1 How to proceed for troubleshooting ............50 14.2 Malfunction table ..................51 Technical data ���������������������������������������������������������������������������������������� 54 Alphabetical index ��������������������������������������������������������������������������������� 55 Bosch Rexroth AG, RE 92704-01-B/2022-12-07...

-

Page 5: About This Documentation

Describes the requirements on a mineral oil-based hydraulic fluid and related hydrocarbons for operation with Rexroth hydraulic components and assists you in selecting a hydraulic fluid for your hydraulic system. Bosch Rexroth Fluid Rating List for Rexroth hydraulic components 90245 Data sheet (pumps and motors) Contains the hydraulic fluids positively evaluated by Bosch Rexroth. -

Page 6: Representation Of Information

WARNING or serious injury if it is not avoided. Identifies a dangerous situation that may result in minor CAUTION to moderate injury if it is not avoided. NOTICE Property damage: The product or surrounding area may be damaged. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 7: Symbols

Electric proportional control International Organization for Standardization Japan Industrial Standard Rexroth document in the English language VDI 2230 Guideline for the systematic calculation of heavy-duty threaded connections and cylindrical screw joints from the VDI (Verein Deutscher Ingenieure - Association of German Engineers) RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 8: Safety Instructions

2�3 Improper use Any use other than that described as intended use is considered improper. Bosch Rexroth AG is not liable for damage resulting from improper use. The user is solely responsible for any risks arising from improper use. The following foreseeable forms of faulty usage are also considered improper (this list is not exhaustive): •... -

Page 9: Personnel Qualifications

• In particular, fully understanding the relationships with regard to safety devices • Knowledge regarding the function and interaction of hydraulic components. Bosch Rexroth offers you measures supporting training in specific areas. You can find an overview of the training contents on the Internet at: www.boschrexroth.com/training. -

Page 10: General Safety Instructions

EMI. Potential electromagnetic interference (EMI) exists if the solenoid is energized with a modulated direct current (e.g. PWM signal). Appropriate testing and measures should be taken by the machine manufacturer to ensure other components or operators (e.g. with pacemaker) are not affected by this potential. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 11: Product-Specific Safety Instructions

Operating the unit above the maximum permissible pressure can cause components to burst and hydraulic fluid to escape under high pressure. ▶ Changes to the factory settings may only be made by Bosch Rexroth specialists. ▶ In addition, a pressure relief valve is required in the hydraulic system as back-up. - Page 12 ▶ Check whether your application requires remedial measures on your machine in order to bring the driven consumer to a safe position (e.g. safe stop). ▶ If necessary, make sure these are appropriately implemented. Bosch Rexroth AG, RE 92704-01-B/2022-12-07...

-

Page 13: Personal Protective Equipment

▶ Check how to safely get on top of the machine/system. 2�7 Personal protective equipment Personal protective equipment is the responsibility of the user of the axial piston unit. Observe the safety regulations in your country. All pieces of personal protective equipment must be intact. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 14: General Instructions On Property Damage And Product Damage

Make certain that the axial piston pump does suck in hydraulic fluid and build up pressure directly after start-up. In case of longer standstill, suitable measures have to be taken to prevent draining of the suction line. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... - Page 15 ▶ Dispose of the axial piston unit, hydraulic fluid and packaging in accordance with the regulations in your country. ▶ Dispose of the hydraulic fluid in accordance with the applicable safety data sheet for the hydraulic fluid. RE 92704-01-B/2022-12-07, Bosch Rexroth AG...

- Page 16 The warranty only applies to the machine configuration as delivered. The warranty will be voided if the product is incorrectly installed, commissioned or operated, or if it is used or handled improperly. Bosch Rexroth AG, RE 92704-01-B/2022-12-07...

-

Page 17: Scope Of Delivery

• Protective covers (1) • Protective plug/threaded plugs (2) • Connector protective covers (3) • for version with through drive, spacer (4) made of plastic (serves as transport protection) • for version with through drive, protective cover incl. mounting bolts (5) RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

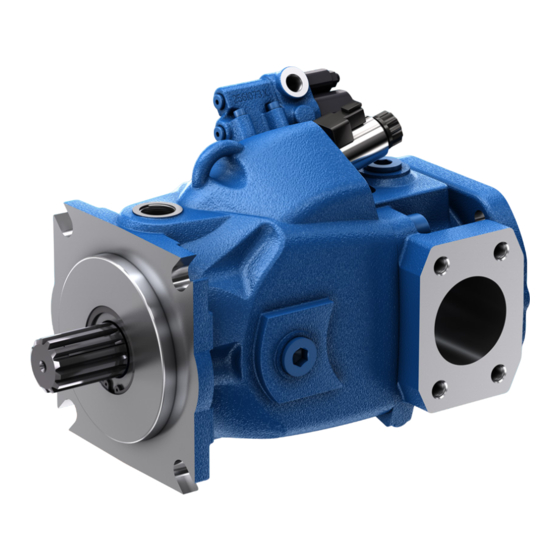

Page 18: About This Product

1 Drive shaft 6 High-pressure side 10 Cylinder 2 Spring 7 Control plate 11 Piston 3 Retaining plate (Distributor plate) 12 Slipper pad 4 Stroking piston 8 Port plate 13 Cradle 5 Control valve 9 Suction side Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 19: Functional Description

Increasing the swivel angle increases the displacement; reducing the angle reduces displacement accordingly. Various control devices are available depending on requirements. Information about this can be found in data sheet 92704. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 20: Product Identification

15 Direction of rotation 5 Type code (viewed on drive shaft) – 6 Manufacturing date here: clockwise 7 Serial number 16 Internal plant designation 8 Rotational speed (optional) 17 QR code 9 Pressure controller setting (optional) 10 Displacement (optional) Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 21: Transport And Storage

▶ Use your personal protective equipment (e.g. safety goggles, safety gloves, suitable working clothes, safety shoes). ▶ Do not transport the axial piston unit by sensitive assembled parts (e.g. sensors or valves). ▶ Carefully place the axial piston unit on the seating to prevent it from being damaged. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 22: Transport With Lifting Devices

▶ Place the lifting strap around the axial piston unit in such a way that it does not pass over assembled parts (e.g. valves, piping) and that the axial piston unit is not suspended from assembled parts (see Fig. 5). Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 23: Storing The Axial Piston Unit

• Do not stack axial piston units and store them in a shock-proof manner. • Do not store the axial piston unit on the drive shaft or assembled parts, e.g. sensors or valves. • For other storage conditions, see Table 7. ▶ Check the axial piston unit monthly to ensure professional storage. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... - Page 24 Once the max. storage time has elapsed, we recommend that you have the axial piston unit checked by your Bosch Rexroth service partner. For questions regarding repair and spare parts, contact your proper Bosch Rexroth service partner or the service department of the manufacturer's plant of the axial piston unit, see chapter 10.5 "Spare parts"...

- Page 25 In such a case, consult your local contact person; you can find their contact information at https://addresses.boschrexroth.com Bosch Rexroth recommends the following procedure: 1� Clean the axial piston unit, see chapter 10.1 "Cleaning and care" on page 45. 2� Drain the axial piston unit.

-

Page 26: Installation

• Installation drawing for the axial piston unit (can be obtained from your contact person at Bosch Rexroth, if required) • Hydraulic circuit diagram for the axial piston unit (in the data sheet and on the installation drawing) •... - Page 27 ▶ Use fiber-free cleaning cloths for cleaning. ▶ Use suitable, mild cleaning agents to remove lubricants and other heavy contamination. Do not allow cleaning agents to enter into the hydraulic system. RE 92704-01-B/2022-12-07, Bosch Rexroth AG...

-

Page 28: Installation Position 1

7�3�1 Below-reservoir installation (standard) Below-reservoir installation means that the axial piston unit is installed outside of the reservoir below the minimum fluid level. Installation position 1 Installation position 2 Air bleed Filling Air bleed Filling t min t min Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 29: Inside-Reservoir Installation

Please consult your proper contact person at Bosch Rexroth to commission an examination of the medium compatibility. With small tank sizes or unfavorable suction conditions, we recommend fitting a suction pipe to suction port S and fitting a pipe to drain port L... -

Page 30: Above-Reservoir Installation

4� Check the permissible direction of rotation of the axial piston unit (on the name plate) and make sure that this corresponds to the direction of rotation of the drive motor. Fig� 7: Direction of rotation Counter-clockwise Clockwise Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 31: Dimensions

The version of installation for the axial piston unit depends on the connecting elements to the drive side. The following descriptions explain the installation of the axial piston unit: • With a coupling • On a gearbox • On a cardan shaft RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 32: Installation With A Coupling

▶ Fasten the axial piston unit at the installation location. For attachment via gear No spline forces higher than the permissible axial and radial forces should act on wheel or helical gear shaft the shaft; if necessary, support the gear wheel at the gearbox output separately. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 33: Installation With Cardan Shaft

Bosch Rexroth Service partner. Use a suitable tool for this to prevent damage to the functional surfaces. If functional surfaces are damaged, contact your Bosch Rexroth service partner or the service department of the factory that manufactured the axial piston unit. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 34: Completion Of Installation

Use a suitable tool for this to prevent damage to the sealing and functional surfaces. If sealing or functional surfaces are damaged, contact your Bosch Rexroth service partner or the service department of the manufacturer's plant of the axial piston unit. Fig� 9: Removing transport protection... -

Page 35: Hydraulically Connecting The Axial Piston Unit

(pressure, flow, hydraulic fluid, temperature) with the necessary safety factors. Connect only hydraulic lines that are match the axial piston unit port (pressure level, size, system of units). RE 92704-01-B/2022-12-07, Bosch Rexroth AG... - Page 36 ▶ Use the drawings (installation drawing) to determine the required stud end for each fitting. ▶ Make sure the right fittings, mounting bolts and threaded plugs are installed. ▶ For all female threads, use a stud end from the same system of units and of the correct size. Bosch Rexroth AG, RE 92704-01-B/2022-12-07...

- Page 37 M apply. Please refer to Table 9 for the values. • Mounting bolts: For mounting bolts with metric ISO threads according to DIN 13 and/or ASME B1.1 threads, we recommend checking the tightening torque in individual cases in accordance with VDI 2230. RE 92704-01-B/2022-12-07, Bosch Rexroth AG...

- Page 38 Mark all properly tightened fittings, e.g. with a permanent marker. 6� Check all pipes and hose lines and every combination of connecting pieces, couplings or connecting points with hoses or pipes to ensure they are in safe working condition. Bosch Rexroth AG, RE 92704-01-B/2022-12-07...

-

Page 39: Electrically Connecting The Axial Piston Unit

1� Loosen the mounting nut (1) of the solenoid. To do this, turn the mounting nut (1) one turn counterclockwise. 2� Turn the solenoid body (2) to the desired position. 3� Re-tighten the mounting nut. Tightening torque of the mounting nut: 5+1 Nm (width across flats SW26, 12kt DIN 3124). RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 40: Performing Flushing Cycle

A10VOH145 series 60 | Installation 7�5 Performing flushing cycle In order to remove foreign particles from the system, Bosch Rexroth recommends a flushing cycle for the hydraulic system before the first commissioning. To avoid internal contamination, do not include the axial piston unit in the flushing cycle. -

Page 41: Commissioning

▶ Make sure all electrical and hydraulic ports are connected or plugged. ▶ Commission only a fully installed, fully functioning product with original accessories from Bosch Rexroth. 8�1 Initial commissioning During all commissioning work on the axial piston unit, observe the general safety instructions and intended use detailed in chapter 2 "Safety instructions"... - Page 42 Bosch Rexroth evaluates hydraulic fluids on the basis of the Fluid Rating according to data sheet 90235. For hydraulic fluids which have been positively evaluated in the Fluid Rating, please refer to data sheet 90245 "Bosch Rexroth fluid rating list for Rexroth hydraulic components (pumps and motors)".

-

Page 43: Testing The Hydraulic Fluid Supply

The axial piston unit is tested for functional capability and performance before delivery according to the technical data. During commissioning, make sure the axial piston unit was installed in the machine/system as intended. RE 92704-01-B/2022-12-07, Bosch Rexroth AG... -

Page 44: Running-In Phase

▶ After the running-in phase, have a hydraulic fluid sample analyzed for the required cleanliness level. ▶ Change the hydraulic fluid if the required cleanliness level is not reached. If a laboratory test is not carried out after the running-in phase, Bosch Rexroth recommends changing the hydraulic fluid. 8�3 Recommissioning after standstill Depending on the installation conditions and ambient conditions, changes may occur in the hydraulic system which make recommissioning necessary. -

Page 45: Operation

10�2 Inspection In order for the axial piston unit to be reliable and long-lasting, Bosch Rexroth recommends inspecting the hydraulic system and axial piston unit on a regular basis, and documenting and archiving the following operating conditions:... -

Page 46: Maintenance

Early detection of hydraulic fluid loss can help to find faults on the machine/system and rectify them. This is why Bosch Rexroth recommends always keeping the axial piston unit and system clean. Check axial piston unit for unusual noise development. -

Page 47: Repair

Maintenance and repair | A10VOH145 series 60 47/56 10�4 Repair Bosch Rexroth offers a comprehensive range of services for the repair of Rexroth axial piston units. Repairs on the axial piston unit and its assembled parts should only be performed by service centers certified by Bosch Rexroth. -

Page 48: Removal And Replacement

6� Remove the axial piston unit. Use a suitable lifting device. 7� Completely drain the axial piston unit. 8� Plug all openings. 11�4 Preparing the components for storage or further use ▶ Proceed as described in chapter 6.2 "Storing the axial piston unit" on page 23. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 49: Disposal

Changes to settings on the customer side should only be made using the product-specific setting instructions. The warranty from Bosch Rexroth only applies to the configuration as delivered. The warranty will be voided if the unit is modified or extended. Adjusting the setting screws will render the warranty void. If you need to change the settings, please contact your local contact person;... -

Page 50: Troubleshooting

▶ Try to get a clear idea of the cause of the fault. Directly ask the (machine) operator. ▶ Document the work carried out. ▶ If the fault cannot be corrected, please refer to one of the contract addresses at: https://addresses.boschrexroth.com Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 51: Malfunction Table

Optimize the adjustment of the controller of the axial piston unit and the pressure limitation in the hydraulic system Mechanical damage to the axial piston unit Replace axial piston unit (e.g. bearing damage) Contact Bosch Rexroth Service Increased, unusual vibration Bearings worn Contact Bosch Rexroth Service RE 92704-01-B/2022-12-07, Bosch Rexroth AG... - Page 52 Malfunction of the control device or Contact Bosch Rexroth Service controller of the axial piston unit Control of the control device defective Check control (contact machine/system manufacturer or Bosch Rexroth Service) Wear or mechanical damage to the Replace axial piston unit axial piston unit Contact Bosch Rexroth Service...

- Page 53 Malfunction of the control device or controller Contact Bosch Rexroth Service of the axial piston unit Control of the control device defective Check control (contact machine/system manufacturer or Bosch Rexroth Service) Wear or mechanical damage to the Replace axial piston unit axial piston unit Contact Bosch Rexroth Service...

-

Page 54: Technical Data

The permissible technical data for your axial piston unit can be found on the data sheet 92704. The data sheet can be found on the Internet at www.boschrexroth.com/p-A10VOH-6x Order-related technical data for your axial piston unit can be found in the order confirmation. Bosch Rexroth AG, RE 92704-01-B/2022-12-07... -

Page 55: Alphabetical Index

Inspection ......45 Performing ......48 Installation ......26 Preparation ......48 Completion ......34 Repair ........47 General instructions ..... 31 Replacement ......48 On a gearbox ......32 Required documentation ..5 On gearbox ......32 RE 92704-01-B/2022-12-07, Bosch Rexroth AG... - Page 56 Bosch Rexroth AG An den Kelterwiesen 14 72160 Horb a.N. Germany Phone +49 7451 92-0 info.ma@boschrexroth.de www.boschrexroth.com Your local contact person can be found at: https://addresses.boschrexroth.com Subject to change RE 92704-01-B/2022-12-07...