Table of Contents

Advertisement

Quick Links

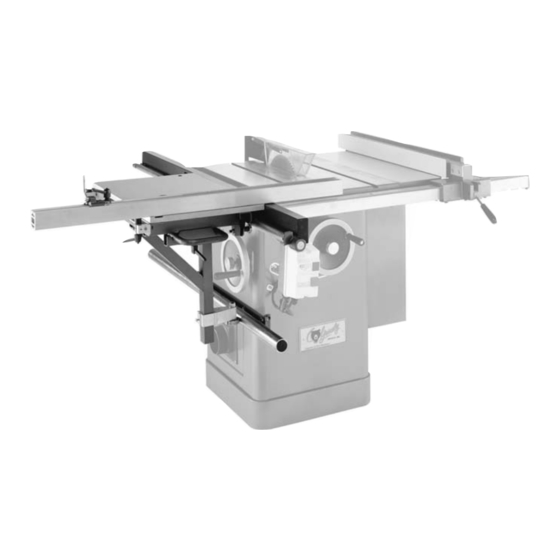

SLIDING TABLE

MODEL G4227

INSTRUCTION MANUAL

COPYRIGHT © 1996 BY GRIZZLY INDUSTRIAL, INC. TX 4-344-567

Warning: No portion of this manual may be reproduced in any shape

or form without the written approval of Grizzly Industrial, Inc.

REVISED JULY, 2002. PRINTED IN TAIWAN.

ONLINE MANUAL DISCLAIMER

THE INFORMATION IN THIS MANUAL REPRESENTS THE CONFIGURATION OF THE MACHINE AS IT IS CURRENTLY BEING SHIPPED. THE

MACHINE CONFIGURATION CAN CHANGE AS PRODUCT IMPROVEMENTS ARE INCORPORATED. IF YOU OWN AN EARLIER VERSION OF

THE MACHINE, THIS MANUAL MAY NOT EXACTLY DEPICT YOUR MACHINE. CONTACT CUSTOMER SERVICE IF YOU HAVE ANY QUESTIONS

ABOUT DIFFERENCES. PREVIOUS VERSIONS ARE NOT AVAILABLE ONLINE.

Advertisement

Table of Contents

Summary of Contents for Grizzly G4227

-

Page 1: Sliding Table

COPYRIGHT © 1996 BY GRIZZLY INDUSTRIAL, INC. TX 4-344-567 Warning: No portion of this manual may be reproduced in any shape or form without the written approval of Grizzly Industrial, Inc. REVISED JULY, 2002. PRINTED IN TAIWAN. ONLINE MANUAL DISCLAIMER THE INFORMATION IN THIS MANUAL REPRESENTS THE CONFIGURATION OF THE MACHINE AS IT IS CURRENTLY BEING SHIPPED. -

Page 2: Table Of Contents

SAFETY RULES FOR ALL TOOLS ...2-3 INTRODUCTION ...4 SAFETY RULES ...4 COMMENTARY ...4-5 UNPACKING ...5 CLEAN UP...5 PIECE INVENTORY...5-6 OVERVIEW OF PARTS ...6 HARDWARE RECOGNITION CHART ...7 SITE PLANNING ...8 ORDER OF ASSEMBLY ...8 INSTALLATION ...9 MOUNTING ...10-14 OPERATIONS...15 GENERAL USE ...15 TEST RUN...15 MAINTENANCE ...16 LUBRICATION ...16... -

Page 3: Safety Rules For All Tools

7. DON’T FORCE TOOL. It will do the job better and safer at the rate for which it was designed. 8. USE RIGHT TOOL. Don’t force tool or attachment to do a job for which it was not designed. CHILDREN VISITORS G4227 Sliding Table... - Page 4 Consult the owner’s manual for recom- mended accessories. The use of improper accessories may cause risk of injury. G4227 Sliding Table 16. REDUCE THE RISK OF UNINTENTION- AL STARTING. On machines with mag- netic contact starting switches there is a risk of starting if the machine is bumped or jarred.

-

Page 5: Introduction

Commentary Grizzly Industrial, Inc. is proud to offer the Model G4227 Sliding Table. The Model G4227 is part of Grizzly’s growing family of fine woodworking and metalworking tools. When used according to the guidelines stated in this manual, you can expect years of trouble-free, enjoyable operation. -

Page 6: Unpacking

Web Site: http:⁄⁄www.grizzly.com The specifications, drawings, and photographs illustrated in this manual represent the Model G4227 as supplied when the manual was pre- pared. To operate this sliding table on a tablesaw or shaper safely and efficiently, it is essen- tial to become as familiar with the charac- teristics of both as much as possible. -

Page 7: Piece Inventory

However, if an unusual amount of fasteners or proprietary parts are missing, please contact our service department. Overview Of Parts The photo below, Figure 1, Shows all the parts provided to assemble the Model G4227 Sliding Table. Figure 1. Overview of parts. ⁄ " Cap Screws... -

Page 8: Hardware Recognition Chart

Use this chart to match up hardware pieces during the assembly process! Thumb ⁄ Screw ⁄ ⁄ Screw ⁄ ⁄ Setscrew ⁄ Washer 10mm 12mm 16mm G4227 Sliding Table Lock Countersunk Phillips Phillips Head Head Screw Screw Carriage Bolt Head Bolt Lock Washer ⁄ ⁄... -

Page 9: Site Planning

Site Planning When placing the Model G4227 Sliding Table in your shop, two major considerations should be addressed: working clearances and lighting. Working clearances can be defined as the safe distance between other machines and obstacles that may limit material being processed or person(s) operating those machines. -

Page 10: Installation

Drill two pilot holes using a ⁄ '' drill bit then finish with a Figure 3. Please note that Grizzly machines are pre-drilled. Figure 3. Drilling the mounting holes. A l w a y s w e a r s a f e t y glasses throughout the entire assembly process. - Page 11 If this detail is overlooked, the head of the cap screws will not allow the fence to swing to 45˚. Figure 6. Lower rail alignment. ''-20 x ⁄ '' cap screws, flat washers and Figure 7. Mounting the bracket. G4227 Sliding Table...

- Page 12 Figure 9. Front stop installation. 11. Install the rear stop using the #10-24 x Phillip head screw provided. Figure 10. G4227 Sliding Table Figure 10. Rear stop installation. 12. Slightly loosen the lower front and rear pinch roller nuts with a 14mm wrench. Now turn their eccentric shafts with a 17mm wrench until they are at their lowest position.

- Page 13 NOTE: If the eccentric does not provide sufficient travel, the threaded mounting studs on the lower guide rail assembly can be adjusted by turning the nuts on either side of the bracket. Figure 15. Adjusting the lower guide. Figure 14. Mounting the fence. G4227 Sliding Table...

- Page 14 Attach the pinch bracket to the bottom/front of the table using the lock handle with stud. Figure G4227 Sliding Table Figure 18. Installing auxiliary handle. Stop bolt 21. The fence can also be mounted at the rear of the sliding table in the same manner as it attaches in the front.

- Page 15 -14- G4227 Sliding Table...

-

Page 16: Operations

SECTION 4: OPERATIONS General Use The Model G4227 Sliding Table, when attached to your table saw or shaper, allows you to easily handle cumbersome material when crosscutting or cross shaping. The sliding table fence safely supports your work which is guided on rails and ball-bearing rollers. -

Page 17: Maintenance

Your sliding table is equipped with shielded and pre-lubricated ball bearings that require no lubri- cation for the life of the bearings. All bearings are common sizes and are readily available from a local bearing supply house or through the Grizzly Industrial parts department. -16- General Make a habit of inspecting your sliding table each time you use it. -

Page 18: Closure

As with all table saws and shapers, there is the potential for danger when using the Model G4227 Sliding Table. Use the table saw or shaper with respect and caution to lessen the possibility of operator injury or mechani- cal damage. -

Page 19: Machine Specifications

Customer Service #: (570) 546-9663 • To Order Call: (800) 523-4777 • Fax #: (800) 438-5901 GRIZZLY MODEL G4227 SLIDING TABLE Design Type...Rails with Ball Bearing Rollers Overall Dimensions: Table Size ...15 Fence Size ...2" x 2" x 42" Fence Positions ...Front 0˚ - 45˚... -

Page 20: Parts Breakdown

G4227 Sliding Table -19-... -

Page 21: Parts List

P4227075 BEARING BRACKET P4227076 SPACER P6304 BEARING 6304-2RS P4227078 AXLE PB05 HEX BOLT ⁄ ''-20 X PW07 FLAT WASHER ⁄ PB03 HEX BOLT ⁄ "-18 X 1'' G4227 Sliding Table " " ⁄ " ⁄ " ⁄ " " ⁄... -

Page 22: Notes

Notes G4227 Sliding Table -21-... -

Page 23: Warranty And Returns

SECTION 7: Warranty and Returns Grizzly Industrial, Inc. warrants every product it sells for a period of 1 year to the original purchaser from the date of purchase. This warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence, accidents, repairs or alterations or lack of maintenance. -

Page 24: Warranty Card

Do you think your purchase represents good value? ___Yes Would you recommend Grizzly Industrial to a friend? ___Yes Would you allow us to use your name as a reference for Grizzly customers in your area? Note: We never use names more than three times. ___Yes Comments:_________________________________________________... - Page 25 FOLD ALONG DOTTED LINE FOLD ALONG DOTTED LINE Send a Grizzly Catalog to a friend: TAPE ALONG EDGES--PLEASE DO NOT STAPLE GRIZZLY INDUSTRIAL, INC. P.O. BOX 2069 BELLINGHAM, WA 98227-2069 Name_______________________________ Street_______________________________ City______________State______Zip______ Place Stamp Here...