Table of Contents

Advertisement

Quick Links

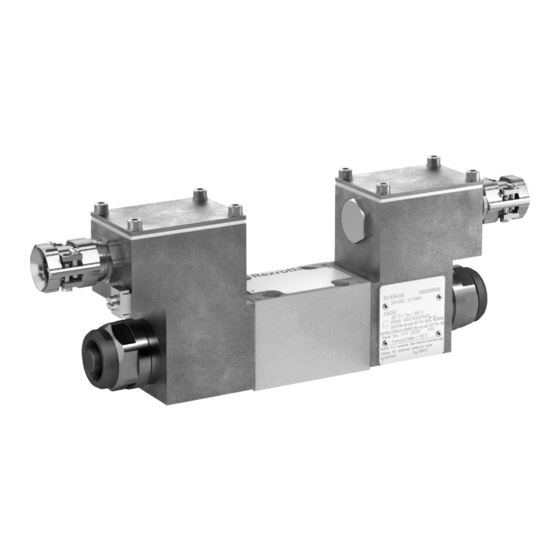

Directional spool valves,

direct operated,

with solenoid actuation

(Area of application according to the Explosion Protection Directive

2014/34/EU: II 2G, II 2D)

Type WE6..6X/...XE...

(IECEx Konformitätsbescheinigung

(IECEx certificate of conformity

der Magnetspule)

of the solenoid coil)

Operating instructions

RE23178-XE-B/10.20

Replaces: 07.19

Document no.: RA78485567_AC

English

Advertisement

Table of Contents

Summary of Contents for Bosch retroth WE6 6X Series

- Page 1 Directional spool valves, direct operated, with solenoid actuation (Area of application according to the Explosion Protection Directive 2014/34/EU: II 2G, II 2D) Type WE6..6X/...XE... Replaces: 07.19 Operating instructions Document no.: RA78485567_AC (IECEx Konformitätsbescheinigung (IECEx certificate of conformity RE23178-XE-B/10.20 English der Magnetspule) of the solenoid coil)

- Page 2 BG: Въвеждането в експлоатация на този продукт може да се извърши едва тогава, когато разполагате с това ръководство за експлоатация на разбираем за Вас официален език на ЕС и сте разбрали неговото съдържание. Ако това не е така, обърнете се към Вашия партньор Bosch Rexroth или към компетентен сервиз. Ще го намерите на www.boschrexroth.com.

- Page 3 UE que você entenda e se você tiver compreendido seu conteúdo. Se não for esse o caso, entre em contato com a pessoa de contato da Bosch Rexroth ou com o centro de serviço responsável.

- Page 4 Our products are subject to a natural process of wear and aging. © All rights with Bosch Rexroth AG, also in case of applications for industrial property protection. It may not be reproduced or given to third parties without consent of Bosch Rexroth AG.

-

Page 5: Table Of Contents

10.1 Cleaning and care 10.2 Inspection and maintenance 10.3 Maintenance schedule 10.4 Repair 10.5 Rectifying external leakages 10.6 Spare parts Disassembly and removal Disposal 12.1 Environmental protection 12.2 Return to Bosch Rexroth AG 12.3 Packaging 12.4 Materials used RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... - Page 6 6/52 12.5 Recycling Extension and modification Troubleshooting 14.1 How to proceed for troubleshooting Technical data Appendix 16.1 List of addresses Declaration of conformity Index Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

-

Page 7: About This Documentation

The hazard avoidance measures described must be observed. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... - Page 8 The following abbreviations are used in this documentation: Table 4: Abbreviations Abbreviation Meaning ATEX EU Directive for Explosion Protection (Atmosphère explosible) European Standard International Organization for Standardization International Electrotechnical Commission Rexroth document in English language Ingress protection class of electric operating equipment Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

-

Page 9: Safety Instructions

You can find details about the device group, category, temperature class and equipment protection level (EPL) in accordance with ATEX Directive 2014/34/EU and the derived standards in "Data sheet 23178-XE" under "Information on explosion protection" and on the name plate of the valve. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... -

Page 10: Improper Use

Changes and/or modifications to the valve are not admissible, refer to chapter 13 "Extension and modification". Bosch Rexroth AG does not assume any liability for damage caused by improper use. The user assumes all risks involved with improper use. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... -

Page 11: Qualification Of Personnel

• Understanding of the additional importance of work authorization systems and safe electrical isolation with regards to the explosion protection Bosch Rexroth offers measures supporting training in specific fields. You can find an overview of the training contents on the Internet at: http://www.boschrexroth.de/didactic... -

Page 12: General Safety Instructions

• Only use original Bosch Rexroth accessories and spare parts in order to prevent any hazard to persons due to unsuitable spare parts. • Comply with the technical data and environmental conditions specified in the product documentation. -

Page 13: Product-Specific Safety Instructions

▶ Ensure before working at the hydraulic product that the hydraulic system is depressurized and the electrical control de-energized. ▶ Completely depressurize machines and systems before working at the valve. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... - Page 14 To prevent the valve from becoming loose and causing a risk of injury: ▶ Exchange the valves with corrosion damage as soon as possible. ▶ Check the surface protection on the valve and the valve mounting screws at regular intervals. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

-

Page 15: Notes On The Valve Use

The machine end-user of the Bosch Rexroth valve is responsible that • the valve is only being used according to the intended use as defined in these operating instructions. -

Page 16: General Information On Damage To Property And Damage To Product

Ensure that no cleaning agents are able to penetrate the hydraulic system. Environmentally harmful hydraulic fluid! Leaking hydraulic fluid leads to environmental pollution. ▶ Immediately remedy possible leakage. ▶ Dispose of the hydraulic fluid in accordance with the currently applicable national regulations in your country. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... -

Page 17: Scope Of Delivery

▶ Check the scope of delivery for possible transport damage, see chapter 6 "Transport and storage". In case of complaints, please contact Bosch Rexroth AG, see chapter 16.1 "List of addresses". Accessories such as valve subplates and valve mounting screws are not included in the scope of delivery and must be ordered separately. See chapter 7.6 "Required accessories". -

Page 18: Product Identification

- according to ATEX Directive 2014/34/EU - for the type of protection of the mechanical part according to EN 80079-36 Mark - according to ATEX Directive 2014/34/EU - for the type of protection of the mechanical part according to EN 80079-36 Bosch Rexroth QR code Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... - Page 19 Data matrix code of the solenoid coil manufacturer Depending on valve sizes and the configuration of the solenoid coils, higher ambient temperatures of up to 70 °C are admissible. Also observe the "Special conditions for safe use" in "Data sheet 23178-XE". RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 20 High safety level. Potentially explosive atmospheres where an explosive atmosphere due to stirred dust (= device group II) is normally not present or occurs only rarely or short-time. Corresponds to zone 22 according to Directive 1999/92/EC. Normal safety level. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

-

Page 21: Transport And Storage

Danger of cut injuries! ▶ Wear suitable protective equipment for the transport of the valve. Further information regarding transport is available from Bosch Rexroth, see chapter 16.1 "List of addresses". Report any transport damage to your responsible sales contact person within one week. The addresses of the sales subsidiaries can be found on the Internet at: http:/www.boschrexroth.com/adressen... - Page 22 12 months After expiry of the maximum storage time, we recommend having the valve checked by the Bosch Rexroth service department responsible for you. In case of questions regarding spare parts, please contact the Bosch Rexroth service responsible for your valve, see chapter 10.6 "Spare parts".

-

Page 23: Assembly

It is imperative to ensure absolute cleanliness. The valve must be protected from dirt during installation. Contamination of the hydraulic fluid may considerably reduce the life cycle of the valve. ▶ Observe the installation position specified in "Data sheet 23178-XE". RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... -

Page 24: Prior To Assembly

Also observe the safety instructions in chapter 2.6 "Product-specific safety instructions". ▶ Transport protection elements (e.g. cover plates, protective plugs) must be removed prior to use in an explosive atmosphere. 7.5 Required tools Assembly of the valve only requires standard tools. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... -

Page 25: Required Accessories

Subplates with dimensions for valves with porting pattern according to ISO 4401 are listed in the "Data sheet 45100". Ordering address for The address of our responsible sales organizations can be found on the Intranet at accessories and valves www.boschrexroth.com and in appendix 16.1 "List of addresses". RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... -

Page 26: Assembling The Valve

▶ Do not remove the protective caps of the valve until assembly. ▶ After disassembly, seal the hydraulic fluid bores with suitable cap elements. ▶ Immediately remove hydraulic fluid that has leaked out. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... - Page 27 Place the valve on the contact surface. Only use valve mounting screws with the thread diameters, screw lengths and strength properties listed in chapter 10.6 "Spare parts"! Always fasten the valve with all 4 valve mounting screws, otherwise leak-tightness is not guaranteed. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 28 Make sure that all pipes and hose lines and every combination of connection pieces, couplings or connection points with hoses or pipes are checked for their operational safety by a person with appropriate knowledge and experience. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 29 ▶ Only use connection lines without shielding or sheathing. For information on the prescribed pre-fuse, refer to "Data sheet 23178-XE". RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 30 15 cm of the cable and line entry. The connection of the solenoid coil is polarity-independent. Solenoid coils for connection to alternating voltage have a bridge rectifier which is integrated into the solenoid coil. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 31 Remove the outer sheath of the connection line and the insulation of the individual conductors. Press the wire end ferrules to the individual conductors. For the stripping lengths, refer to Fig. 4 and Table 9. Fig. 4: Stripping lengths RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 32 Remove the blind plug (hexagon, wrench size 22). Remove the cable and line entry. To do this, unscrew the cable and line entry from the double nipple (2). Make sure not to lose the O-ring (1) between housing and double nipple. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 33 Assemble the O-ring onto the pole tube and slide it forward up to the solenoid coil. Re-tighten the mounting nut of the valve solenoid (hexagon nut, wrench size 32, tightening torque 4 + 1 Nm). Afterwards, there must be no visible gap between the solenoid coil and the valve housing. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

-

Page 34: Commissioning

The following applies to all valves irrespective of the type of connection: ▶ The connection line must be checked for proper condition by or under line the guidance and supervision of a specialized electrician before the initial commissioning or any re-commissioning. ▶ Replace damaged connection lines. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... - Page 35 Ensure that no hydraulic fluid leaks at the valve and the connections during operation. ▶ Check for internal leakage. The check must be carried out according to the possibilities present at the hydraulic system. Internal leakage can be valve-specific but does not necessarily affect the functionality of the valve. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

-

Page 36: Operation

Changing the settings at the valve is not admissible. For information on the operation, please refer to the operating instructions for the hydraulic system into which the valve is installed. If errors occur, refer to chapter 14 "Troubleshooting". Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... -

Page 37: Operating The Manual Override (Only Relevant For Type .We6.6X/.Nxe

The manual override is only intended for manual operation. It is not suitable for frequently recurring manual operations. The manual override is located on the side of the valve solenoid facing away from the valve. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... -

Page 38: Maintenance And Repair

- expected deficiencies are identified in good time. The check must, however, at least be carried out every three years from the date of manufacture of the valve. The date of manufacture of the valve is indicated on the name plate. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... - Page 39 10.6. Re-assemble the cover of the terminal box with the seal beneath it. Tighten the mounting screws with the spring washers diagonally, one after the other. Tightening torque of the cover screws: 1...1.1 Nm. RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

-

Page 40: Maintenance Schedule

40/52 Maintenance and repair 10.3 Maintenance schedule Valves require low maintenance if used as intended. For a long and reliable operation of the valve, Bosch Rexroth recommends regularly checking the hydraulic system and the valve. 10.3.1 Checking for leakage Check the valve for leakage. An early detection of hydraulic fluid loss may help you to identify and remedy errors. -

Page 41: Spare Parts

In case of questions about spare parts, please contact your responsible Bosch Rexroth Service: Bosch Rexroth AG Service Hydraulics Bürgermeister-Dr.-Nebel-Str. 8 97816 Lohr am Main Tel: +49 (0) 9352/40 50 60 service@boschrexroth.de For the addresses of our sales and service network please refer to: www.boschrexroth.com/adressen RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG... -

Page 42: Disassembly And Removal

Close the hydraulic channels of the subplate (on the customer side) to avoid contamination. If the valve is exchanged, all further steps are analogous to mounting, see chapter 7 "Assembly". Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20... -

Page 43: Disposal

The materials for disposable packaging are mostly cardboard, wood, and expanded polystyrene. They can be recycled without any problems. For environmental reasons, disposable packaging should not be used for returning products to Bosch Rexroth. 12.4 Materials used Hydraulic components from Bosch Rexroth do not contain any hazardous materials that could be released during intended use. - Page 44 What were they? – Was the valve and/or the machine used as intended? – How did the fault become apparent? ▶ Try to get a clear idea of the cause of error. Ask the direct (machine) operator, if necessary. Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 45 15 Technical data For the technical data of your valve please refer to "Data sheet 23178-XE". RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 46 Headquarters Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Phone +49 (0) 9352/40 30 20 Email my.support@boschrexroth.de The addresses of our sales and service network and sales organizations can be found at www.boschrexroth.com/adressen Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 47 Declaration of conformity 47/52 17 Declaration of conformity RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 48 ▶ L Valve subplate Leakage Valve use List of addresses ▶ M Maintenance Maintenance schedule Manual override Materials used Modification Mounting elements ▶ N Name plate Noise development ▶ O Obligations of the machine end-user Operation Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 49 Index 49/52 RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 50 50/52 Index Bosch Rexroth AG, WE6..6X/...XE..., RE23178-XE-B/10.20...

- Page 51 Index 51/52 RE23178-XE-B/10.20, WE6..6X/...XE..., Bosch Rexroth AG...

- Page 52 Bosch Rexroth AG Zum Eisengießer 1 97816 Lohr am Main Germany Tel: +49 (0) 9352/40 30 20 my.support@boschrexroth.de www.boschrexroth.com Subject to change without notice Printed in Germany RE23178-XE-B/10.20...