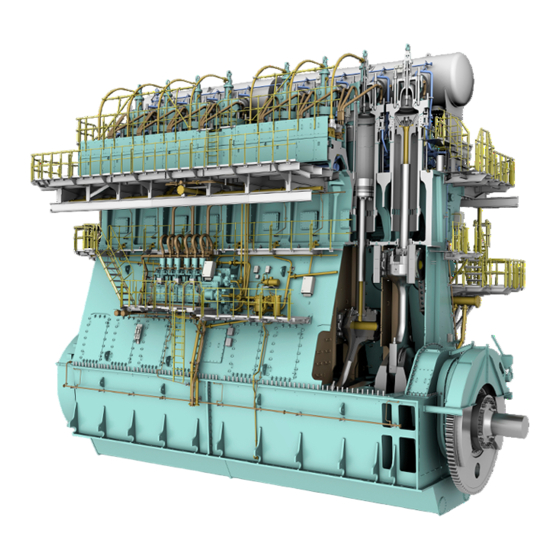

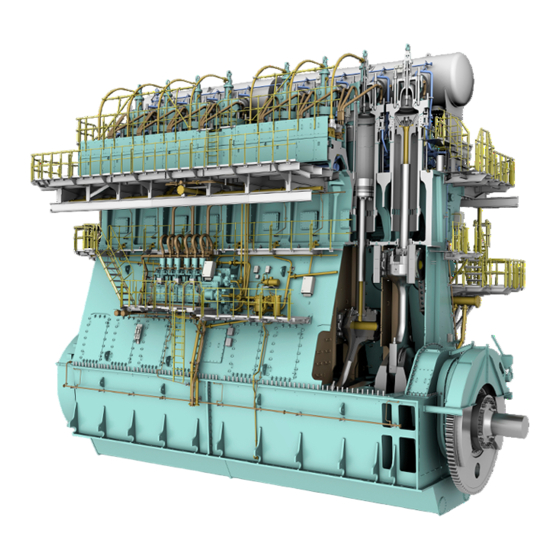

WinGD X92-B Manuals

Manuals and User Guides for WinGD X92-B. We have 1 WinGD X92-B manual available for free PDF download: Operation Manual

Advertisement

Advertisement

Advertisement

Advertisement