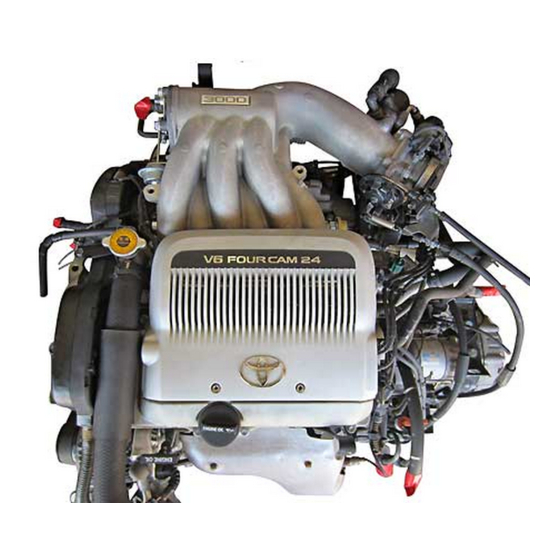

Toyota 3VZ-FE Manuals

Manuals and User Guides for Toyota 3VZ-FE. We have 1 Toyota 3VZ-FE manual available for free PDF download: Troubleshooting Manual

Toyota 3VZ-FE Troubleshooting Manual (529 pages)

Table of Contents

-

Tune–Up11

-

Start Engine25

-

Clean Valves62

-

Components98

-

Clean Piston110

-

Inspect Piston111

-

Install Bearings121

-

Post Assembly126

-

Install Flywheel128

-

Install Ps Pump131

-

Connect Ps Acv132

-

Install Starter134

-

Service Data139

-

System Purpose144

-

Equipment144

-

Tvv Inspection151

-

Check Egr Valve154

-

Sfi System159

-

Fuel System160

-

Remove Connector178

-

Inspect Leakage183

-

Injectors187

-

Precautions200

-

Terminals204

-

Idl-E2204

-

Vta-E2204

-

VC-E2204

-

Iac Valve211

-

Inspect Iacv215

-

Iacv Removal215

-

Sfi Main Relay221

-

Warm up Engine230

-

Ecm Inspection235

-

Fuel Cut Rpm239

-

Vs-E2240

-

Ñ Ñ Ñ Ñ Ñ Ñ241

-

Thw-E2241

-

0.5 or Less241

-

Radiator244

-

Radiator Cap244

-

Reservoir Tank244

-

Water Pump244

-

Radiator Removal258

-

Assembly of Sst260

-

Caulk Lock Plate262

-

Hydraulic Motor271

-

Install Oil Seal276

-

Remove Oil Seal276

-

Ñ Ñ Ñ Ñ Ñ Ñ Ñ288

-

Oil Pump290

-

Oil Filter290

-

Drain Engine Oil295

-

Oil Pump Removal297

-

Remove Oil Pan298

-

Remove Oil Pump300

-

Install Oil Pan308

-

Ñ Ñ Ñ Ñ Ñ Ñ312

-

Kgf CM Ft Lbf312

-

65 In. Lbf312

-

Diagnosis System323

-

Fail–Safe Chart335

-

Back–Up Function335

-

Set Test Mode336

-

Basic Inspection337

-

Parts Location340

-

Wiring Diagram341

-

Terminals of Ecm343

-

Diagnostic Chart358

-

Ignition System461

-

Pickup Coils462

-

Distributor462

-

Ignition Coil462

-

Igniter462

-

Spark Test467

-

Remove Rotor477

-

Starter Removal487

-

Remove Starter488

-

Inspect Bearings495

-

Magnetic Switch496

-

Starter Assembly496

-

Remove Generator516

-

Remove Pulley518

-

Install Pulley524

Advertisement