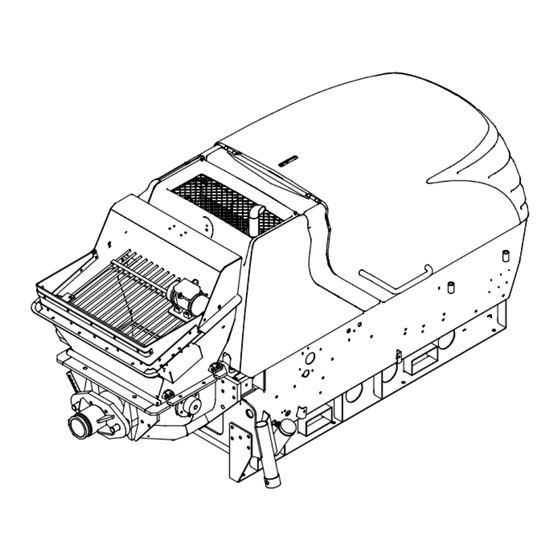

Putzmeister P 718 TD Manuals

Manuals and User Guides for Putzmeister P 718 TD. We have 1 Putzmeister P 718 TD manual available for free PDF download: Translation Of The Original Operating Instruction

Putzmeister P 718 TD Translation Of The Original Operating Instruction (346 pages)

Piston pump

Brand: Putzmeister

|

Category: Water Pump

|

Size: 11.85 MB

Table of Contents

Advertisement

Advertisement