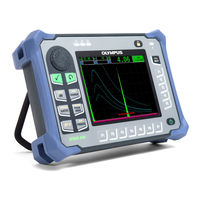

Olympus EPOCH 650 Manuals

Manuals and User Guides for Olympus EPOCH 650. We have 2 Olympus EPOCH 650 manuals available for free PDF download: User Manual, Getting Started Manual

Olympus EPOCH 650 User Manual (362 pages)

Ultrasonic Flaw Detector

Brand: Olympus

|

Category: Measuring Instruments

|

Size: 5.38 MB

Table of Contents

-

-

-

Intended Use17

-

Safety21

-

Warnings21

-

China Rohs24

-

-

Introduction

27 -

-

-

Front Panel32

-

Connectors45

-

-

-

-

-

Escape Key65

-

Lock Key65

-

Submenus66

-

Sensitivity67

-

Pulser68

-

Receiver68

-

3.10 Gates70

-

Gate Setup71

-

-

-

-

Button Types86

-

Flags90

-

Setup98

-

Grid Setup Page103

-

About Page110

-

Clock Setup Page111

-

Misc Setup Page112

-

-

-

-

-

Reject127

-

Peak Memory128

-

Peak Hold130

-

Freeze130

-

Grid Modes131

-

Baseline Break134

-

-

7 Gates

135-

Gate Alarms145

-

9 Calibration

155-

Basic Setup155

-

-

Angle Beam Modes157

-

-

-

-

10 Data Logger

199-

-

2-D Epri201

-

2-D Matrix Grid201

-

Sequential201

-

Boiler202

-

-

File Menu203

-

Create204

-

Open209

-

Quick Recall216

-

Memo217

-

Manage Menu220

-

Reset221

-

Export222

-

Import223

-

Edit225

-

Copy226

-

Import Memo228

-

-

Grid View229

-

Screen Capture233

-

-

-

-

Dynamic DAC/TCG238

-

Jis Dac250

-

Dgs/Avg252

-

Scanning Gain265

-

Envelope Mode270

-

Crack Sizing271

-

Manual Mode273

-

Crack Sizing276

-

Interface Gate283

-

B-Scan297

-

B-Scan Setup299

-

Template Storage304

-

-

-

-

Troubleshooting311

-

-

-

B.3.3 2-D Epri329

-

-

-

B.3.6 Boiler331

-

-

List of Figures

347-

List of Tables

353 -

Index

355

-

Advertisement

Olympus EPOCH 650 Getting Started Manual (13 pages)

Ultrasonic Flaw Detector

Brand: Olympus

|

Category: Security Sensors

|

Size: 1.36 MB