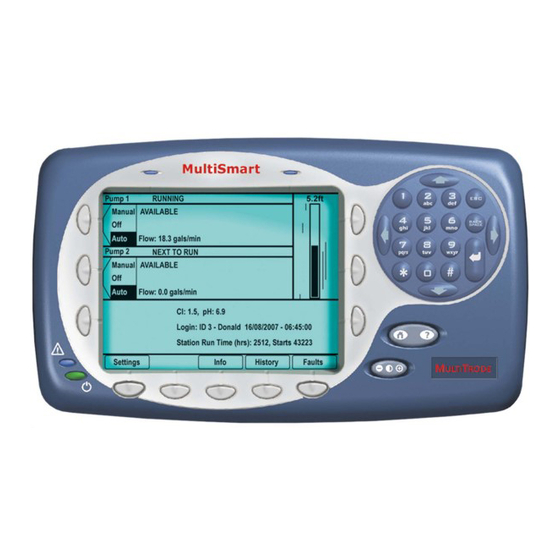

MultiTrode MultiSmart Manuals

Manuals and User Guides for MultiTrode MultiSmart. We have 2 MultiTrode MultiSmart manuals available for free PDF download: Installation & Operation Manual, Integrator Manual

MultiTrode MultiSmart Installation & Operation Manual (260 pages)

Pump Station Manager & RTU

Brand: MultiTrode

|

Category: Controller

|

Size: 12.9 MB

Table of Contents

Advertisement

MultiTrode MultiSmart Integrator Manual (20 pages)

Pump Station Manager

Brand: MultiTrode

|

Category: Industrial Equipment

|

Size: 0.24 MB

Table of Contents

Advertisement