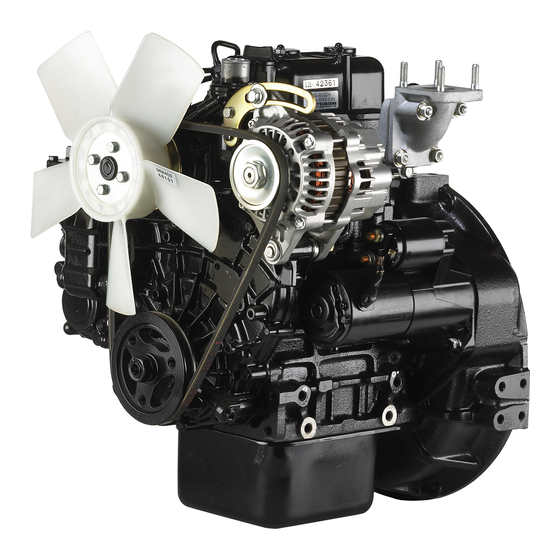

Mitsubishi L3E Industrial Engine Manuals

Manuals and User Guides for Mitsubishi L3E Industrial Engine. We have 5 Mitsubishi L3E Industrial Engine manuals available for free PDF download: Service Manual, Operation & Maintenance Manual, Operation Manual

Mitsubishi L3E Service Manual (254 pages)

Brand: Mitsubishi

|

Category: Engine

|

Size: 6.77 MB

Table of Contents

-

-

General17

-

Reassembling31

-

Service Data

33-

-

Basic Engine34

-

Fuel System37

-

Fuel System42

-

-

-

-

-

-

-

-

-

Fuel System

115-

-

Removing Tappets127

-

Removing Plunger127

-

-

-

Cooling System

157 -

Advertisement

Mitsubishi L3E Service Manual (236 pages)

Brand: Mitsubishi

|

Category: Engine

|

Size: 4.93 MB

Table of Contents

-

General14

-

Basic Tools44

-

Flywheel100

-

Fuel System107

-

Removing Tappets119

-

Removing Plunger119

-

Governor132

-

Fuel Filter135

-

Cooling System146

-

Removing Starter157

-

Checking Output159

Mitsubishi Heavy Industries L3E Operation & Maintenance Manual (89 pages)

Diesel Engines

Brand: Mitsubishi Heavy Industries

|

Category: Engine

|

Size: 2.95 MB

Table of Contents

-

-

-

-

Viscosity46

-

Flash Point46

-

Insoluble46

-

-

Genuine LLC48

-

Glassy - Llc48

Advertisement

Mitsubishi L3E Service Manual (155 pages)

L-Series

Brand: Mitsubishi

|

Category: Engine

|

Size: 3.41 MB

Table of Contents

-

General

12 -

3 Features

16 -

-

7 General

40 -

-

Disassembly49

-

Removal50

-

Installation51

-

-

-

Disassembly52

-

Inspection52

-

-

-

Disassembly59

-

Removal60

-

Inspection60

-

-

-

Disassembly62

-

Inspection64

-

Installation65

-

-

-

Disassembly66

-

Removal67

-

Inspection68

-

Installation69

-

-

-

Disassembly78

-

Inspection79

-

General82

-

-

-

Fuel System85

-

General86

-

Disassembly88

-

-

-

Disassembly93

-

Inspection94

-

Installation95

-

General98

-

Disassembly99

-

Mitsubishi L3E Operation Manual (44 pages)

SL-Series Diesel Engines

Brand: Mitsubishi

|

Category: Engine

|

Size: 1.22 MB

Table of Contents

-

-

1 Safety

5 -

5 Operation

21

-

-

-

10 Storage

39 -

-

11.1 General40

-

-