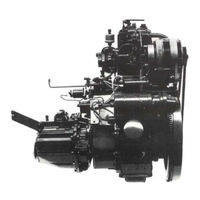

User Manuals: Bukh DV20 Marine Diesel Engine

Manuals and User Guides for Bukh DV20 Marine Diesel Engine. We have 2 Bukh DV20 Marine Diesel Engine manuals available for free PDF download: Workshop Manual

Advertisement

Advertisement