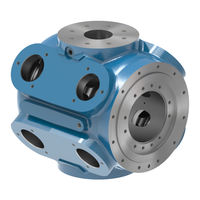

Ariel JGJ/2 Reciprocating Compressor Manuals

Manuals and User Guides for Ariel JGJ/2 Reciprocating Compressor. We have 1 Ariel JGJ/2 Reciprocating Compressor manual available for free PDF download: Technical Manual

Ariel JGJ/2 Technical Manual (141 pages)

Heavy Duty Balanced Opposed Compressors

Brand: Ariel

|

Category: Air Compressor

|

Size: 2.86 MB

Table of Contents

Advertisement

Advertisement