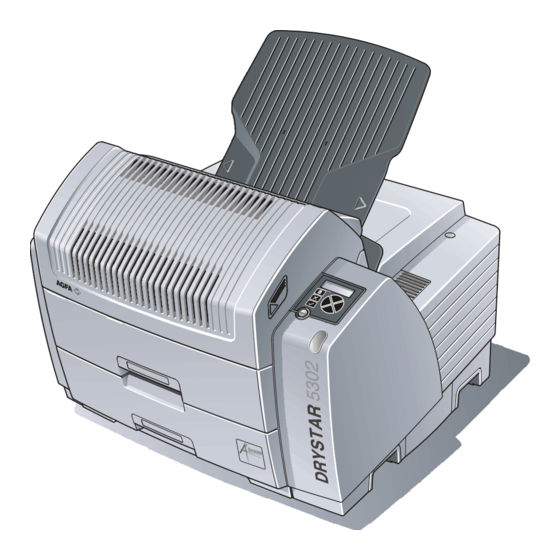

User Manuals: AGFA DRYSTAR 5302 5366 X-Ray Printer

Manuals and User Guides for AGFA DRYSTAR 5302 5366 X-Ray Printer. We have 1 AGFA DRYSTAR 5302 5366 X-Ray Printer manual available for free PDF download: Service Manual

Advertisement