Summary of Contents for BENSON HEATING LTD RS/UHA2 50

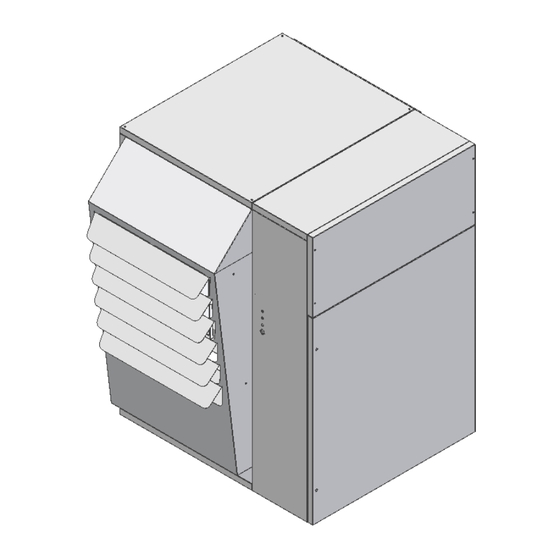

- Page 1 Gas room sealed unit heaters 2 stage TECHNICAL INFORMATION ASSEMBLY INSTRUCTIONS, USE AND MAINTENANCE RS/UHA-2 BENSON HEATING LUDLOW ROAD KNIGHTON POWYS LD7 1LP Benson Heating is a divison of MAY 2003 Benson Climate Systems Ltd...

-

Page 2: Compliance Notices

Warning is used when failure to heed or implement the instruction(s) can lead to not only component damage, but also to a hazardous situation being created where there is a risk of personal injury. Notified Body PIN Reference is RANGE Type Model Code RS/UHA2 50 3TAIT2C016 RS/UHA2 80 3TAIT2C026 RS/UHA2 105 3TAIT2C036 RS/UHA2 140... -

Page 3: For The User

INDEX GENERAL Description of equipment page. Identification “ Description “ Identification “ Description “ Technical data “ Wiring diagram “ Remote control connections “ Regulating air flow “ FOR THE USER Operation “ Servicing “ Heater indication lights “ Receipt of product “... - Page 4 Heaters type 1-2-3-4-5 FAN 1 FAN 2 I° II° RSTR IGN1 KEY: Temperature probe Differential pressure switch Regulatory control thermostat (auto reset) IGN1 Ignition transformer LIMIT thermostat (manual reset) Spark electrode EVG1-I° Gas solenoid valve1 Ionisation probe EVG1-II° Second stage gas valve 2 Electrical control board Fan capacitor IMT (*)

- Page 5 Heater type 6-7 FAN 1 FAN 2 FAN 3 I° II° RSTR IGN1 IGN2 Lockout reset button KEY: Flue venter Temperature probe Differential pressure switch Regulatory control thermostat (auto reset) IGN1 Ignition transformer 1 LIMIT thermostat (manual reset) IGN2 Ignition transformer 2 EVG1-I°...

-

Page 6: Gas Conversion

GAS CONVERSION The heaters are supplied ready for use with (G20) Natural Gas as per the table below Conversion kits are available from the manufacturer: Natural Gas (G20) TYPE Number of injectors N° Diameter of injectors 3,10 mm/100 Gas supply pressure mBar Head pressure high fire 11,0... -

Page 7: Gas Valve

If the gas line has not been correctly purged ignition may not take place at the first attempt resulting in the heater going to lockout Reset the lockout before re starting ignition sequence The heater must only be operated with the burner compartment door(s) closed Before each attempt at ignition it is necessary to wait at least 10 seconds... -

Page 8: Gas Pressure Regulation

Assembly of primary air diaphragm: Diagram showing the fitting of a primary air diaphragm to single burner manifold (1-2-3-4-6) Diagram showing the fitting of a primary air diaphragm for a two burner manifold type (7) Warning the diaphragm plates should only GAS PRESSURE REGULATION be used when using propane gas G31. - Page 9 Gas valve head pressure setting high fire Propane G31: When setting the gas pressure for propane high fire Remove the plastic cover from the adjuster RP1 RP2 (second stage ) contact SF should be closed the high With a screw driver hold the adjuster RP1 stationary fire pressure adjusting screw on the gas valve must be and using a spanner, screw adjuster RP2 clockwise to excluded.

-

Page 10: Fault Finding

FAULT FINDING If the heater is not working firstly check the following : • Check electrical supply • Check voltage is as stated +15%, -15% • Check gas supply is on • Check that the pressure is as stated in the TECHNICAL DATA FAULT CAUSE SOLUTION... - Page 11 Burner lights but locks out Live and neutral inverted Check electrical connections after 5 seconds Poor earth Check electrical connection on probe. Faulty ionisation probe Check probe for cracks or damage. Replace ionisation probe . Check the gas type is suitable for the heater.

- Page 12 Check inlet gas pressure Burner goes out due to the intervention Check burner head pressure thermostat and is restarted Excessive heat exchanger automatically when the heater Check that gas type is suitable temperature has cooled down . for heater Yellow indication light on. Check injector size is correct for the heater.

- Page 13 Check inlet gas pressure Burner goes out due to the Check burner head pressure intervention LIMIT Excessive heat exchanger thermostat (LM). Check that gas type is suitable temperature. for heater Yellow light flashing Check injector size is correct for the heater. Check the fan blades are clean Check that the horizontal and (vertical if fitted) louvers are...

- Page 14 The control panel will not Replace flame control reset . Faulty flame control module module after first checking the electrical connections Red light on Change fan control or SND Fan works intermittently Defective fan control thermostat Check that the gas type is suitable for the heater .

- Page 15 : Single flue option with condensate tee and roof terminal combustion air from inside the room Type 1 – 2 – 3 – 4...

- Page 16 Ø100 MIN 300 ✴ 157 mm type 1 – 2 – 3 165 mm type 4 ITEM DESCRIPTION Pipe M/F ∅100 L=1000 with seal Terminal with guard ∅100 Condensate Tee with drain point Pipe M/M ∅100 L=200 without seal NOTE IMPORTANT: MODEL 1-2-3-4 ∅...

- Page 17 : Single flue option with condensate tee and roof terminal combustion air from inside the room Type 5 – 6 – 7 Ø100 MIN 340 ITEM DESCRIPTION Pipe M/F ∅100 L=1000 with seal Terminal with guard ∅100 Condensate tee with drain point Pipe M/F ∅100 L=250 with seal NOTE IMPORTANT: MODEL...

- Page 18 Installation showing Vertical co axial flue terminal with condensate drain Type 1 – 2 – 3 – 4 Ø150 Ø100 Ø100 MIN 300 ✴ 157 mm type 1 – 2 – 3 165 mm type 4 ITEM DESCRIPTION Flue pipe M/F ∅100 L=1000 with seal Bend 90°...

- Page 19 Installation showing Vertical co axial roof terminal with condensate drain Type 5 – 6 – 7 Ø160 Ø150 Ø100 MIN 340 ITEM DESCRIPTION Pipe M/F ∅100 L=1000 with seal Pipe M/F ∅150 L=1000 with seal Bend 90° M/F ∅150 with seal Vertical co axial roof terminal kit ∅100-150 Adaptor F/F ∅150 L=200 with seal Bend 45°...

Need help?

Do you have a question about the RS/UHA2 50 and is the answer not in the manual?

Questions and answers