Yanmar 6LPA-STP2 Service Manual

6lpa series

Hide thumbs

Also See for 6LPA-STP2:

- Operation manual (106 pages) ,

- Service manual (11 pages) ,

- Operation manual (110 pages)

Summary of Contents for Yanmar 6LPA-STP2

- Page 1 6LPA series SERVICE MANUAL 6LPA Service Manual 6LPA-STP2 6LPA-STZP2 P/N: 0B6LP-G00100 MARINE ENGINES...

- Page 2 This Service Manual has been developed for the exclusive use of service and repair professionals such as Yanmar authorized Distributors and Yanmar authorized Dealers. It is written with these professionals in mind and may not contain the necessary detail or safety statements that may be required for a non-professional to perform the service or repair properly and / or safely.

- Page 3 General Service Information ............. 3-1 Periodic Maintenance ................. 4-1 Engine ....................5-1 Fuel System ..................6-1 Cooling System ................... 7-1 Lubrication................... 8-1 Turbocharger ..................9-1 Starter Motor..................10-1 Alternator ................... 11-1 Troubleshooting ................12-1 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 4 TABLE OF CONTENTS This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 5 6LPA Service Manual Section 1 INTRODUCTION This manual gives specific instructions for the Along with standard tools, Yanmar recommends the proper repair of Yanmar 6LPA-STP2/STZP2 series use of special tools, necessary to perform repairs marine engines. correctly. Please follow the procedures carefully to ensure Yanmar products are continuously undergoing quality service.

- Page 6 Revision Control Table. Discard the older, obsolete information. Revision Control Table Revision Date New Page Numbers Initiating Remarks Revision Number Involved Dept. Jun 2007 Initial Release Rev. 0 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 7 6LPA Service Manual Section 2 SAFETY SAFETY STATEMENTS Yanmar is concerned for your safety and the Indicates a hazardous situation which, if not condition of your marine engine. Safety statements avoided, will result in death or serious injury. are one of the primary ways to call your attention to the potential hazards associated with Yanmar marine engines.

- Page 8 NEVER use a shop rag to catch the fuel. • Safety signs and decals are additional reminders for safe operating and maintenance techniques. Wipe up all spills immediately. • See your authorized Yanmar marine dealer or distributor for additional training. NEVER refuel with the engine running. Crush Hazard...

- Page 9 ALWAYS use a piece of wood or cardboard. Have parts cleaners, primers, sealants and sealant your authorized Yanmar marine dealer or distributor removers. repair the damage. Undersized wiring systems can cause an electrical Flying Object Hazard fire.

- Page 10 • When welding is completed, reconnect the leads to the alternator and engine control unit prior to reconnecting the batteries. 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 11 Tool Hazard Always remove any tools or shop rags used during maintenance from the area before operation. 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 12 Make sure the engine is installed on a level surface. or cause it to operate improperly. If a Yanmar Marine Engine is installed at an angle that exceeds the specifications stated in the Yanmar Marine Installation manuals, engine oil may Only use replacement parts specified.

-

Page 13: Table Of Contents

Diesel Fuel ..................3-18 Diesel Fuel Specifications ............3-18 Handling Diesel Fuel ............... 3-19 Diesel Fuel Lines ..............3-19 Fuel Tank................. 3-20 Filling the Fuel Tank ..............3-20 Bleeding the Fuel System............3-21 6LPA Service Manual © 2007 Yanmar Marine International... - Page 14 Special Service Materials (Locally Available)......... 3-46 Special Service Materials Reference (Locally Available) ..3-47 Wiring Diagrams................3-48 B-Type Instrument Panel............3-48 C/D-Type x B-Type Instrument Panel ........3-49 C/D-Type x C-Type Instrument Panel ........3-50 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 15: Safety Precautions

Before you service the engine, read the following safety information and review the Safety Section on page 2-1. LOCATION OF SAFETY DECALS Figure 3-1 shows the location of safety decals on Yanmar 6LPA-STP2/STZP2 series marine engines. Figure 3-1 DANGER NEVER pour the... -

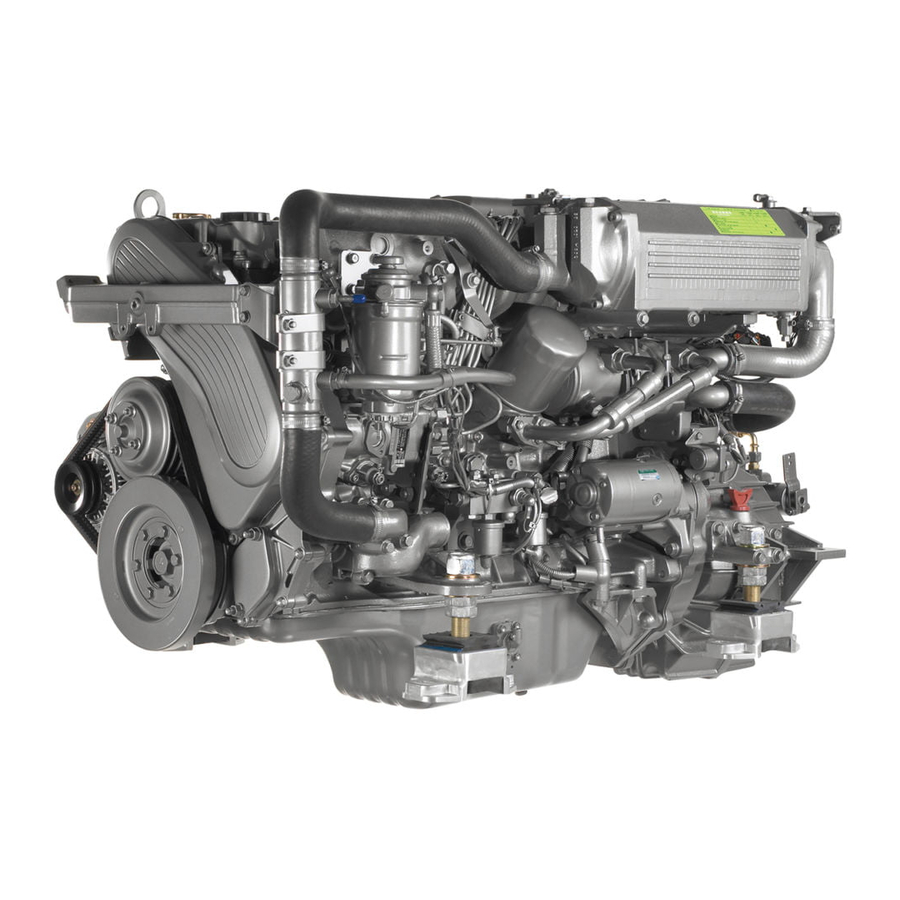

Page 16: Component Identification

10 – Fuel Injection Pump 4 – Engine Oil Filter 11 – Seawater Pump 5 – Intercooler 12 – Stern Drive 6 – Mixing Elbow Note: 6LPA-STZP2 Series with stern drive shown 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 17: Alternator

9 – Engine Oil Dipstick Series Only) 10 – Freshwater Cooler 5 – Freshwater Filler Cap 11 – V-Belt 6 – Engine Oil Filler Cap Note: 6LPA-STZP2 Series with stern drive shown 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 18: Engine Piping Diagrams

GENERAL SERVICE INFORMATION Engine Piping Diagrams ENGINE PIPING DIAGRAMS 6LPA-STP2 Figure 3-4 (26) (25) (24) (23) (22) (21) (20) (19) (18) (17) (16) (15) (14) (10) (13) (12) (11) 0004891 Figure 3-4 6LPA Service Manual © 2007 Yanmar Marine International... - Page 19 23 – Engine Oil Pump 12 – Cooling Seawater Pump 24 – Engine Oil Inlet Filter 13 – Fuel Return Pipe (To Fuel Tank) 25 – Water Inlet From Heater 26 – Thermostat 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 20: 6Lpa-Stzp2

GENERAL SERVICE INFORMATION Engine Piping Diagrams 6LPA-STZP2 Figure 3-5 (30) (29) (28) (27) (26) (25) (24) (23) (22) (21) (20) (10) (19) (11) (18) (14) (13) (12) (17) (16) (15) 0004892 Figure 3-5 6LPA Service Manual © 2007 Yanmar Marine International... - Page 21 27 – Engine Oil Pump 13 – Power Steering Oil Cooler 28 – Engine Oil Inlet Filter 14 – Fuel Injection Pump 29 – Water Inlet From Heater 15 – Seawater Inlet 30 – Thermostat 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 22: External Views

GENERAL SERVICE INFORMATION External Views EXTERNAL VIEWS 6LPA-STP2 Figure 3-6 (12) (11) (10) (13) (14) (15) (20) (16) (19) (18) (17) 0005564 Figure 3-6 6LPA Service Manual 3-10 © 2007 Yanmar Marine International... - Page 23 7 – Marine Gear 18 – Marine Gear 8 – Lube Oil Cooler (2) 19 – Lube Oil Cooler for Marine Gear 9 – Starter 20 – Turbocharger 10 – Lube Oil Cooler (1) 6LPA Service Manual 3-11 © 2007 Yanmar Marine International...

-

Page 24: Engine Sender And Switch Locations

7 – Engine Oil Pressure Switch 3 – Freshwater Temperature Switch 8 – Engine Oil Pressure Sender 4 – Freshwater Temperature Sender 9 – Boost Sender 5 – Fuel Filter Switch 10 – Boost Switch 6LPA Service Manual 3-12 © 2007 Yanmar Marine International... -

Page 25: Instrument Panel (Optional)

5 – Panel Illumination Switch 6 – Engine Stop Switch 7 – Starter Key Switch 8 – Alarm Buzzer 9 – Hour Meter 10 – Warning Lamp Unit - 10 Lamp Type 6LPA Service Manual 3-13 © 2007 Yanmar Marine International... -

Page 26: Performance Curve Charts

Performance Curve Charts PERFORMANCE CURVE CHARTS Figure 3-11 6LPA-STP2 At Typical Propeller Load (Exp. 2.5) At Crankshaft Crankshaft Power Typical Constant Rack Power With Clutchout Typical Propeller Load (Exp. 2.5) 0005558 Figure 3-11 6LPA Service Manual 3-14 © 2007 Yanmar Marine International... - Page 27 GENERAL SERVICE INFORMATION 12/05 Figure 3-12 6LPA-STZP2 At Typical Propeller Load (Exp. 2.5) At Crankshaft Crankshaft Power Typical Constant Rack Power With Clutchout Typical Propeller Load (Exp. 2.5) 0005557 Figure 3-12 6LPA Service Manual 3-15 © 2007 Yanmar Marine International...

-

Page 28: Front Power Take-Off (Pto) Output

800 1000 1200 1400 1600 1800 2000 2200 2400 2600 2800 3000 3200 3400 3600 3800 0005556 Figure 3-13 1 – Allowable Front PTO Output (hp) 2 – Engine Speed (rpm) 6LPA Service Manual 3-16 © 2007 Yanmar Marine International... - Page 29 0.065 kg·cm sec (0.63 N·cm sec 0005552 Figure 3-14 1 – Pulley Thickness Should be 10 mm (0.393 in.) 2 – Viscous Damper 3 – Crankshaft 4 – PTO Pulley (Aluminum) 6LPA Service Manual 3-17 © 2007 Yanmar Marine International...

-

Page 30: Location Of Nameplate

GENERAL SERVICE INFORMATION Location of Nameplate DIESEL FUEL LOCATION OF NAMEPLATE The nameplate of the Yanmar 6LPA series engines Diesel Fuel Specifications is shown in Figure 3-16. The nameplate is located CAUTION! Only use diesel fuels recommended on the engine rocker arm cover. -

Page 31: Handling Diesel Fuel

Install a fuel filter / water separator (Figure 3-18, (6)) and a fuel filter (Figure 3-18, (1)) Figure 3-17 between the fuel tank and the fuel injection pump. 0004512_s1 Figure 3-17 6LPA Service Manual 3-19 © 2007 Yanmar Marine International... -

Page 32: Fuel Tank

(Figure 3-19, (1)). The fuel outlet should be positioned 20 to 30 mm (0.75 to 1.125 in.) above the bottom of the tank to ensure clean fuel is delivered to the engine. 6LPA Service Manual 3-20 © 2007 Yanmar Marine International... -

Page 33: Bleeding The Fuel System

2. Open the fuel cock of the fuel tank. WARNING! ALWAYS wear safety glasses when bleeding the fuel system. 3. Loosen the air bleed screw (Figure 3-20, (2)) 2 to 3 turns. 6LPA Service Manual 3-21 © 2007 Yanmar Marine International... -

Page 34: Engine Oil

• Engine oil should be changed at the specified operated. See the SAE Service Grade intervals, regardless if the engine has been Viscosity Chart (Figure 3-21). operated • Yanmar does not recommend the use of engine oil “additives.” 6LPA Service Manual 3-22 © 2007 Yanmar Marine International... -

Page 35: Checking The Engine Oil

Remove the oil filler port cap check and fill the marine drive oil. (Figure 3-22, (4)) from filler port (Figure 3-22, (5)) and fill with engine oil. 6LPA Service Manual 3-23 © 2007 Yanmar Marine International... -

Page 36: Checking And Adding Power Steering Oil (6Lpa-Stzp2 Models)

• Remove scale from the cooling system periodically by flushing the system. NEVER mix different brands of antifreeze. Chemical reactions may make the antifreeze useless and engine problems may result. 6LPA Service Manual 3-24 © 2007 Yanmar Marine International... -

Page 37: Checking And Adding Engine Coolant

NOTICE: If the coolant runs low too often or only the coolant level in the coolant tank drops without any change in the level in the coolant recovery tank, there may be water or air leaks in the cooling system. 6LPA Service Manual 3-25 © 2007 Yanmar Marine International... -

Page 38: Draining The Freshwater And Seawater Cooling System

3. Remove the four bolts attaching the seawater pump cover. Remove the cover and drain the seawater. 4. Install cover and tighten bolts. 5. Close all the drain cocks. ( 4 ) 0004906_s1 Figure 3-28 6LPA Service Manual 3-26 © 2007 Yanmar Marine International... -

Page 39: Principal Engine Specifications

1 Density of fuel: 0.840 g/cm3 at 15°C. Diesel fuel temperature 25°C at the inlet of the fuel injection pump. Rating condition: ISO 3046-1, 8665. Note: 1 hp = 0.7355 kW 6LPA Service Manual 3-27 © 2007 Yanmar Marine International... -

Page 40: Marine Gear (Optional)

1.36 1.50 1.36 ZF63A1: 1.56/1.58 2.13/2.13 1.50 1.65 1.50 Ahead/Astern 2.04/2.10 2.43/2.43 1.81 1.65 Bravo X-1, 2, 3: Both Ahead and Astern 2.52/2.53 2.00 1.81 See manufacturer’s documentation for additional information. 6LPA Service Manual 3-28 © 2007 Yanmar Marine International... -

Page 41: Special Torque Chart

Engine mounting bracket x Cylinder block 700 kgf/cm , 68.65 N·m (50.6 lb-ft) Rear oil seal case x Cylinder block 65 kgf/cm , 6.37 N·m (56.4 lb-in.) * Apply oil to threads and seat before tightening. 6LPA Service Manual 3-29 © 2007 Yanmar Marine International... -

Page 42: Tightening Torques For Standard Bolts And Nuts

5.1 ± 0.5 9.2 ± 1.0 14.3 ± 1.0 23.5 ± 1.0 lb-ft 19.0 ± 2.1 37 ± 3.6 66.0 ± 7.2 103 ± 7.2 170 ± 7.2 lb-in. 96 ± 9.0 6LPA Service Manual 3-30 © 2007 Yanmar Marine International... -

Page 43: Abbreviations And Symbols

Aqueous (water) μ micro in.Hg inches Mercury percent in-lb inch pound** joule * Work torque such as engine torque JASO Japanese Automobile ** Work torque such as starter motor torque kelvin 6LPA Service Manual 3-31 © 2007 Yanmar Marine International... -

Page 44: Unit Conversions

1.3410221 = hp SAE 0.2248 = lbf 0.1020 = kgf Units of Temperature 2.2050 = lbf 9.8070 °F = (1.8 x °C) + 32 °C = 0.556 x (°F - 32) 6LPA Service Manual 3-32 © 2007 Yanmar Marine International... -

Page 45: Special Service Tools

Note: The tool numbers used in this section are either Yanmar or Toyota part numbers. Yanmar part numbers are referred to as Yanmar Part No. Toyota part numbers are referred to as Toyota Part No. Tools not having part numbers must be obtained locally. - Page 46 0005490 Injection pump Toyota Part No. 09214-76011 drive gear oil seal for injection pump drive gear 0005491 bearing Connecting rod Toyota Part No. 09222-17010 bushing remover & replacer 0005492 6LPA Service Manual 3-34 © 2007 Yanmar Marine International...

- Page 47 0005500 Oil seal puller for Toyota Part No. 09308-10010 crankshaft front oil seal 0005501 Companion Yanmar Part No. 119770-01120 flange holding Toyota Part No. 09330-00021 tool for crankshaft pulley 0005502 6LPA Service Manual 3-35 © 2007 Yanmar Marine International...

- Page 48 Arm 25 for No. 1 Toyota Part No. 09954-04010 camshaft timing pulley, oil pump drive shaft gear, 0005508 crankshaft timing gear and injection pump drive gear bearing 6LPA Service Manual 3-36 © 2007 Yanmar Marine International...

- Page 49 Claw No. 2 for Toyota Part No. 09954-05020 crankshaft pulley and injection pump drive gear 0005515 Handle set Toyota Part No. 09950-70010 0005516 Handle 100 for Toyota Part No. 09951-07100 valve guide bushing 0005517 6LPA Service Manual 3-37 © 2007 Yanmar Marine International...

- Page 50 Toyota Part No. 09228-64010 0005524 Water pump Toyota Part No. 09236-00101 overhaul tool set 0005525 Injection pump Toyota Part No. 09285-76010 camshaft bearing cone replacer for rotor rear bearing 0005526 cover 6LPA Service Manual 3-38 © 2007 Yanmar Marine International...

- Page 51 0005531 Replacer 26 Toyota Part No. 09951-00260 0005532 Replacer 50 Toyota Part No. 09951-00500 0005533 Adapter Toyota Part No. 09950-06010 0005534 Gauge assembly Toyota Part No. 09992-00211 0005535 6LPA Service Manual 3-39 © 2007 Yanmar Marine International...

- Page 52 Socket 14 mm Toyota Part No. 09269-54020 0005542 Tweezers Toyota Part No. 09269-54030 0005543 Governor lever Toyota Part No. 09269-54040 support bolt wrench 0005544 Regulator valve Toyota Part No. 09262-54020 wrench 0005545 6LPA Service Manual 3-40 © 2007 Yanmar Marine International...

- Page 53 0005547 Toyota electrical Toyota Part No. 09082-00050 tester set 0005548 Engine adjust kit Toyota Part No. 09200-00010 0005549 Hose plug set for Toyota Part No. 09258-00030 plug for fuel hose 0005501 6LPA Service Manual 3-41 © 2007 Yanmar Marine International...

-

Page 54: Equipment (Locally Available)

Starter Motor Dial indicator Commutator Magnetic finger Pull scale Brush spring Sandpaper Commutator Torque wrench V-block Vernier calipers Commutator, Brush Engine Oil Oil pressure gauge Pump Precision straight edge Torque wrench 6LPA Service Manual 3-42 © 2007 Yanmar Marine International... - Page 55 Angle gauge Brass brush Dial indicator with magnetic base Graduated cylinder Injection nozzle tester Injection pump tester Inner pressure gauge Micrometer Steel square Timer measuring device Torque wrench Vernier caliper Wooden stick 6LPA Service Manual 3-43 © 2007 Yanmar Marine International...

-

Page 56: Measuring Instruments

Cylinder Bore Gauge For measuring the inside diameters of cylinder liners, bearing bores, etc. 0000835 Calipers For measuring outside diameters, depth, thickness and width 0000836 Depth Micrometer For measuring valve recession 0000837 6LPA Service Manual 3-44 © 2007 Yanmar Marine International... - Page 57 Torque Wrench For tightening nuts and bolts to the specified torque 0000840 Feeler Gauge For measuring piston ring gaps, piston ring clearance, fuel injector adjustment clearance, and valve adjustment clearance 0000841 6LPA Service Manual 3-45 © 2007 Yanmar Marine International...

-

Page 58: Special Service Materials (Locally Available)

Water temperature sender gauge (FIPG - formed in place gasket) 08833-00070 Adhesive 1344, Three Bond 1344, Loctite 242 or equivalent Oil pressure sender gauge Taper screw plug on timing gear case 6LPA Service Manual 3-46 © 2007 Yanmar Marine International... -

Page 59: Special Service Materials Reference (Locally Available)

4. If a gasket is used, do not use sealant TB1212. 1. Build up each sealant bead equally. 2. For bolt holes, apply liquid gasket to the inside surface of each hole. 6LPA Service Manual 3-47 © 2007 Yanmar Marine International... -

Page 60: Wiring Diagrams

GENERAL SERVICE INFORMATION Wiring Diagrams WIRING DIAGRAMS B-Type Instrument Panel Figure 3-30 Figure 3-30 6LPA Service Manual 3-48 © 2007 Yanmar Marine International... -

Page 61: C/D-Type X B-Type Instrument Panel

Wiring Diagrams GENERAL SERVICE INFORMATION 12/05 C/D-Type x B-Type Instrument Panel Figure 3-31 Figure 3-31 6LPA Service Manual 3-49 © 2007 Yanmar Marine International... -

Page 62: C/D-Type X C-Type Instrument Panel

GENERAL SERVICE INFORMATION Wiring Diagrams C/D-Type x C-Type Instrument Panel Figure 3-32 Figure 3-32 6LPA Service Manual 3-50 © 2007 Yanmar Marine International... - Page 63 Safety Precautions ................4-3 Introduction..................4-4 The Importance of Periodic Maintenance........4-4 Performing Periodic Maintenance ..........4-4 Yanmar Replacement Parts ............4-4 Tools Required ................4-4 EPA Requirements................4-4 EPA Requirements for USA and Other Applicable Countries ... 4-4 Conditions to Ensure Compliance with EPA Emission Standards ..................

-

Page 64: 6Lpa Service Manual

PERIODIC MAINTENANCE This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 65: Safety Precautions

Modifications may impair the engine’s safety and performance characteristics and shorten the engine’s life. Any alterations to this engine may void Shock Hazard its warranty. Be sure to use Yanmar genuine ALWAYS turn off the battery switch (if replacement parts. equipped) or disconnect the negative battery cable before servicing the equipment. -

Page 66: Introduction

Yanmar Replacement Parts Yanmar recommends that you use genuine Yanmar parts when replacement parts are needed. Genuine replacement parts help ensure long engine life. -

Page 67: Conditions To Ensure Compliance With Epa Emission Standards

• Replacing the fuel filter • Cleaning the intake silencer (air cleaner) Note: Inspections are divided into two sections in accordance with who is responsible for performing the inspection: the user or the manufacturer. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 68: Periodic Maintenance Schedule

Check the fuel injector pressure and nozzle spray pattern* Check the engine oil level Change the engine Initial 50 Lubricating System Replace the engine oil filter element Initial 50 Wash the engine oil cooler 6LPA Service Manual © 2007 Yanmar Marine International... - Page 69 Control Handle Adjust the remote control cable Wash turbocharger blower Clean air cleaner Intake and Exhaust Adjust the intake and System exhaust valves Initial 250 Lap the intake and exhaust valves 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 70: Inspection And Maintenance Of Epa Emission-Related Parts

Check turbocharger adjustment Check electronic engine control unit (ECU) and its associated sensors and actuators Note: The inspection and maintenance items shown above are to be performed by a Yanmar Marine dealer. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 71: Periodic Maintenance Procedures

10. Approximately 10 minutes after stopping the engine, remove the oil dipstick and check the oil level. Add oil if the level is too low. 11. Dispose of waste properly. NOTICE: ALWAYS be environmentally responsible. 6LPA Service Manual © 2007 Yanmar Marine International... - Page 72 4 – O-Ring 5 – Filter Element 1. Close the fuel cock on the fuel tank. 2. Remove the two mounting screws (Figure 4-3, (1)) and the housing (Figure 4-3, (2)). 6LPA Service Manual 4-10 © 2007 Yanmar Marine International...

-

Page 73: Every 50 Hours Of Operation

In valve. If heavy deposits of water and sediment are such conditions, inspect the battery drained, also drain the fuel tank. earlier than specified. 6LPA Service Manual 4-11 © 2007 Yanmar Marine International... -

Page 74: Every 125 Hours Of Operation

See Changing the Engine Oil and Replacing the operation continues with insufficient battery Engine Oil Filter Element on page 4-9. fluid, the battery life is shortened, and the battery may overheat and explode. Figure 4-6 0004566_s1 Figure 4-6 6LPA Service Manual 4-12 © 2007 Yanmar Marine International... -

Page 75: After Initial 250 Hours Of Operation

1. Drain the freshwater cooling system. See Draining the Freshwater Cooling System on page 3-26. 2. Fill the cooling system with clean coolant. See Checking and Adding Engine Coolant on page 3-25. 6LPA Service Manual 4-13 © 2007 Yanmar Marine International... - Page 76 12.7 x 25.4 mm (0.5 x 1.0 in.) Figure 4-9 Freshwater Cooler Intercooler 119574-18790 Note: Some marine drives have additional zinc anodes. Check the manufacturer's documentation for location and other information. 6LPA Service Manual 4-14 © 2007 Yanmar Marine International...

- Page 77 2. Clean the air cleaner with detergent 3. Allow to air dry and install on the air inlet. ( 2 ) NOTICE: Replace the air cleaner if unable to clean or if damaged. 0004921_s1 Figure 4-12 6LPA Service Manual 4-15 © 2007 Yanmar Marine International...

-

Page 78: Every 500 Hours Of Operation

2. Loosen the alternator bolt (Figure 4-14, (2)) and move the alternator to adjust the V-belt tension. 3. Replace the V-belt if required. Alternator V-Belt Part Number 119775–77260 6LPA Service Manual 4-16 © 2007 Yanmar Marine International... -

Page 79: Every 1000 Hours Of Operation

Figure 4-16 119787–26540 ( 2 ) ( 1 ) ( 3 ) ( 4 ) 0004914 Figure 4-16 1 – Impeller 2 – O-Ring 3 – Cover 4 – Cover Bolts 6LPA Service Manual 4-17 © 2007 Yanmar Marine International... -

Page 80: Every 1250 Hours Of Operation

Replacing the Timing Belt See Timing Belt Removal on page 5-69. Washing Engine Oil Cooler See Oil Cooler Removal on page 8-14. Replacing the Front Rubber Damper Replace the Front Rubber Damper. 6LPA Service Manual 4-18 © 2007 Yanmar Marine International... - Page 81 Inspection and Servicing of Crankshaft ........5-59 Crankshaft Oil Seal Replacement ........... 5-60 Piston and Connecting Rod Assembly ........5-61 Cylinder Block Assembly ............5-63 Rear Crankshaft Oil Seal Installation........5-66 Final Engine Assembly and Adjustments ........5-67 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 82 Valve Clearance Inspection and Adjustment ......... 5-90 Valve Clearance Inspection............5-90 Valve Clearance Adjustment ............ 5-91 Injection Timing Inspection and Adjustment ........5-93 Inspection of Injection Timing........... 5-93 Adjustment of Injection Timing ..........5-95 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 83: Safety Precautions

NEVER attempt to adjust the low or high idle speed limit screw. This may impair the safety and performance of the engine and shorten its life. If adjustment is ever required, see your authorized Yanmar marine dealer or distributor. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 84: Specifications

1.6 to 2.0 mm (0.063 to 0.079 in.) Standard 10.800 to 11.000 mm (0.425 to 0.433 in.) Head bolt thread diameter Limit 10.55 mm (0.415 in.) Valve 7.010 to 7.030 mm (0.276 to 0.277 in.) Inside Diameter guide 6LPA Service Manual © 2007 Yanmar Marine International... - Page 85 Valve rocker arm shaft diameter 19.972 to 19.993 mm (0.786 to 0.787 in.) rocker arm and shaft Standard 0.019 to 0.061 mm (0.0007 to 0.0024 in.) Oil clearance Limit 0.10 mm (0.004 in.) 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 86 94.020 to 94.030 mm (3.7015 to 3.7019 in.) block Limit 94.23 mm (3.7098 in.) Main bearing cap bolt Standard 11.800 to 12.000 mm (0.4645 to 0.4724 in.) thread Outside diameter Minimum 11.50 mm (0.453 in.) 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 87 0.200 to 0.500 mm (0.008 to 0.020 in.) Piston ring end gap Limit: No. 1 0.85 mm (0.0334 in.) Limit: No. 2 0.90 mm (0.0354 in.) Limit Oil 0.88 mm (0.0346 in.) 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 88 Standard Mark 1 66.994 to 67.00 mm (2.6375 to 2.6377 in.) Standard Mark 2 66.988 to 66.994 mm (2.6373 to 2.6375 in.) Standard Mark 3 66.982 to 66.988 mm (2.6370 to 2.6373 in.) 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 89 58.982 to 58.988 mm (2.3221 to 2.3223 in.) Circle runout Limit 0.06 mm (0.0023 in.) Journal taper and 0.02 mm (0.0008 in.) Limit out-of-round Crank pin taper and 0.02 mm (0.0008 in.) Limit out-of-round 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 90: Adjustment Specifications

10 mm (0.393 in.) or more Lift at full open Pump shaft speed at 3800 rpm Delivery capacity of seawater pump 135L (142.6 qt) or more Total head: 10 m Aq, 98kPa (14.2 psi) 6LPA Service Manual 5-10 © 2007 Yanmar Marine International... -

Page 91: Special Torque Chart

Engine mounting bracket x Cylinder block 700 kgf/cm , 68.65 N·m (50.6 lb-ft) Rear oil seal case x Cylinder block 65 kgf/cm , 6.37 N·m (56.4 lb-in.) * Apply oil to threads and seat before tightening. 6LPA Service Manual 5-11 © 2007 Yanmar Marine International... -

Page 92: Cylinder Head

Note: Cylinder number No. 1 and No. 2 are located starting from the gear case side. Component Views Cylinder Head and Camshaft Figure 5-1 (12) (13) (24) (14) (23) (15) (16) (19) (17) (20) (18) (25) (21) (10) (22) (11) 0004923 Figure 5-1 6LPA Service Manual 5-12 © 2007 Yanmar Marine International... - Page 93 23 – Rocker Arm Shaft Bolt (14 Qty.) 11 – Camshaft Timing Pulley 24 – Rocker Arm Shaft Bolt (6 Qty.) 12 – Fuel Return Pipe 25 – Cylinder Head Bolt (26 Qty.) 6LPA Service Manual 5-13 © 2007 Yanmar Marine International...

- Page 94 Camshaft Bearing Cap, Valve Rocker Arm, Nozzle Holder Clamp and Rocker Shaft Assembly Figure 5-2 0004924 Figure 5-2 1 – Camshaft Bearing Cap 3 – Valve Rocker Shaft 2 – Nozzle Holder Clamp 4 – Valve Rocker Arm 6LPA Service Manual 5-14 © 2007 Yanmar Marine International...

- Page 95 1 – Valve Bridge 5 – Spring Seat 2 – Cotter 6 – Stem Seal (Non-Reusable Part) 3 – Spring Retainer 7 – Valve Guide 4 – Valve Spring 8 – Valve 6LPA Service Manual 5-15 © 2007 Yanmar Marine International...

-

Page 96: Cylinder Head Removal

Figure 5-4 1 – Oil Filter 2 – Fuel Pump 3 – Freshwater Drain Cock 0004928 Figure 5-6 1 – Freshwater Cooler 2 – Seawater Drain Plug 3 – Freshwater Drain Plug 6LPA Service Manual 5-16 © 2007 Yanmar Marine International... - Page 97 1 – Fuel Filter Injection Nozzle Removal on page 6-14. 2 – Intercooler 3 – Fuel Pump 8. Remove the 12 rocker cover bolts, seal washers, rocker cover and gasket (Figure 5-9). 6LPA Service Manual 5-17 © 2007 Yanmar Marine International...

- Page 98 16. Loosen and remove the 26 cylinder head bolts 0004935 uniformly in sequence as shown in Figure 5-12. Figure 5-13 NOTICE: NEVER remove the bolts at random or the head may warp or crack. 6LPA Service Manual 5-18 © 2007 Yanmar Marine International...

-

Page 99: Cylinder Head Disassembly

Perform for all valves. Note: Keep the valve, valve spring, spring seat and spring retainer together and in the order as disassembled, to ensure reassembly into their original positions. Figure 5-15 0004940 Figure 5-15 6LPA Service Manual 5-19 © 2007 Yanmar Marine International... -

Page 100: Cleaning, Inspection And Servicing

ALWAYS wear protective goggles when using compressed air. 4. Remove all gasket materials from the cylinder head deck surface, using a scraper (Figure 5-19). NOTICE: AVOID damaging the cylinder head deck surface during cleaning. 6LPA Service Manual 5-20 © 2007 Yanmar Marine International... - Page 101 8. Measure the flatness of the cylinder head deck surface using a straight edge and feeler gauge (Figure 5-23). • Maximum warpage: 0.20 mm If the measured warpage exceeds the specified maximum, replace the cylinder head. 6LPA Service Manual 5-21 © 2007 Yanmar Marine International...

- Page 102 Intake and Exhaust Valve Cleaning and Inspection 1. Remove all carbon deposits from the valves using a scraper and wire brush (Figure 5-26). Figure 5-26 0004953 Figure 5-28 0004951 Figure 5-26 6LPA Service Manual 5-22 © 2007 Yanmar Marine International...

- Page 103 If the measured margin thickness is below the specified minimum, replace the valve. Figure 5-29 0004955 Figure 5-30 1 – Overall Length 0004954 Figure 5-29 1 – Margin Thickness 2 – Valve Face 6LPA Service Manual 5-23 © 2007 Yanmar Marine International...

- Page 104 • Inspect the valve seat for proper contact width Figure 5-33 (Figure 5-31, (1)) and proper location within 1 – 45° Angle the middle of valve face. 2 – 25° Angle 6LPA Service Manual 5-24 © 2007 Yanmar Marine International...

- Page 105 • Blue Mark: 49.6 mm (1.953 in.) If the measured free length is not within specifications, replace the valve spring. Figure 5-37 0004960 Figure 5-35 5. After lapping, clean the valve and valve seat. 0004962 Figure 5-37 6LPA Service Manual 5-25 © 2007 Yanmar Marine International...

- Page 106 • 24.2 to 26.8 kgf, 237.32 to 262.82 N (53.3 to 59.1 lb-ft) at 39.5-mm (1.555 in.) position. If the spring force is not within the specified range, replace the valve spring. Figure 5-38 0004964 Figure 5-39 0004963 Figure 5-38 6LPA Service Manual 5-26 © 2007 Yanmar Marine International...

- Page 107 5 – Valve Rocker Arms 11 – Camshaft Bearing Cap (With Mark 7) 6 – Valve Rocker Arm (Intake Side) 12 – Camshaft Bearing Cap (With Mark 2, 3, 4, 5, or 6) 6LPA Service Manual 5-27 © 2007 Yanmar Marine International...

- Page 108 • Standard oil clearance: 0.019 to 0.061 mm (0.007 to 0.0024 in.) • Maximum oil clearance: 0.10 mm (0.004 in.) 6LPA Service Manual 5-28 © 2007 Yanmar Marine International...

- Page 109 Figure 5-45 4. Check the camshaft bearings for flaking (peeling) or scoring (scratches) (Figure 5-46). If the bearing is damaged, replace the bearing cap and cylinder head at the same time. 6LPA Service Manual 5-29 © 2007 Yanmar Marine International...

- Page 110 (j) Install the 7 bearing caps to the valve rocker (g) Remove the 7 bearing caps. shaft. Figure 5-49 (13) (11) (10) (14) (12) 0005076 Figure 5-49 (h) Measure the plastigage at the widest point (Figure 5-50). 6LPA Service Manual 5-30 © 2007 Yanmar Marine International...

-

Page 111: Camshaft Oil Seal Replacement

3. Using a suitable tool (Figure 5-53, (1)) tap in a Figure 5-51 new oil seal until its surface is level with the end surface of oil seal retainer. Figure 5-53 0005080 Figure 5-53 6LPA Service Manual 5-31 © 2007 Yanmar Marine International... -

Page 112: Cylinder Head Assembly

2 – Spring Seat 3 – Valve Spring 4 – Spring Retainer 0005082 3. Using special tool P/N 119770-02000 Figure 5-55 (Figure 5-58, (1)) compress the valve spring and install the spring retainer. 6LPA Service Manual 5-32 © 2007 Yanmar Marine International... -

Page 113: Cylinder Head Installation

0005086 piston head before reading the dial Figure 5-59 indicator. 5. Install the valve bridge. Figure 5-61 6. Inspect the valve bridge for smooth operation (Figure 5-60). 0005089 Figure 5-61 6LPA Service Manual 5-33 © 2007 Yanmar Marine International... - Page 114 Mark No. 1 0.85 to 0.95 mm (0.033 to 0.037 in.) Mark No. 3 0.95 to 1.05 mm (0.037 to 0.041 in.) Mark No. 5 1.05 to 1.15 mm (0.041 to 0.045 in.) 6LPA Service Manual 5-34 © 2007 Yanmar Marine International...

- Page 115 0005093 Figure 5-65 10. Install a new cylinder head gasket in position on the cylinder block (Figure 5-66). Note: Install the gasket in the correct position. 6LPA Service Manual 5-35 © 2007 Yanmar Marine International...

- Page 116 90° (Figure 5-68, (4)). together with the camshaft bearing cap at the position of cylinder head journal No. 1. Install the 20 mm (0.787 in.) bearing at the other position. 6LPA Service Manual 5-36 © 2007 Yanmar Marine International...

- Page 117 5. Install the bearing cap and other parts. Injection Nozzle Installation on page 6-25. 6. Install 7 bearing caps, 12 rocker arms, 6 holder clamps and the rocker shaft assembly (Figure 5-72). 6LPA Service Manual 5-37 © 2007 Yanmar Marine International...

- Page 118 Figure 5-74 0005104 Figure 5-74 3. Install the oil seal retainer using 4 bolts (Figure 5-75, (1)). Tighten the bolts uniformly in steps and torque to 200 kgf·cm,19.61 N·m (14.5 lb-ft). 6LPA Service Manual 5-38 © 2007 Yanmar Marine International...

- Page 119 4. Completely remove all packing material from the rocker cover sealing area. 5. Apply seal packing to the cylinder head as shown in Figure 5-77. (Seal packing: TOYOTA P/N 08826-00080 or equivalent) 6LPA Service Manual 5-39 © 2007 Yanmar Marine International...

-

Page 120: Cylinder Block

ENGINE Cylinder Block CYLINDER BLOCK Components Figure 5-78 (10) (11) (12) (13) (14) (15) (17) (16) (18) (19) (20) (21) (22) (23) (24) (25) (26) (27) 0005108 Figure 5-78 6LPA Service Manual 5-40 © 2007 Yanmar Marine International... - Page 121 12 – Connection Rod Cap 25 – Lower Main Bearing 13 – Rod Bolt 26 – Main Bearing Cap Bolt (Inside) 14 – Cylinder Block 27 – Main Bearing Cap Bolt (Outside) 6LPA Service Manual 5-41 © 2007 Yanmar Marine International...

-

Page 122: Preparation For Disassembly

• Maximum thrust clearance: 0.30 mm (0.011 in.) If the thrust clearance measured exceeds the maximum specification, replace the connecting rod assembly and inspect and replace the crankshaft if needed. Figure 5-80 0005110 Figure 5-80 6LPA Service Manual 5-42 © 2007 Yanmar Marine International... - Page 123 5. Move the connecting rod cap transversely (Figure 5-82, (1)) using two removed connecting rod cap bolts, to remove the connecting rod cap. Figure 5-82 ( 1 ) 0005114 Figure 5-84 0005112 Figure 5-82 6LPA Service Manual 5-43 © 2007 Yanmar Marine International...

- Page 124 5 – No. 5 Mark 6 – No. 6 Mark 7 – Mark No. 1, 2 or 3 8 – Mark No. 2, 3, 4, 5, or 6 0005116 Figure 5-86 6LPA Service Manual 5-44 © 2007 Yanmar Marine International...

- Page 125 (0.0586 to 0.0587 in.) Mark “5” 1.495 to 1.498 mm 119770-01030 (0.0587 to 0.0588 in.) Mark “6” 1.498 to 1.501 mm 119770-01040 (0.0589 to 0.0590 in.) 12. Completely remove the plastigage. 6LPA Service Manual 5-45 © 2007 Yanmar Marine International...

- Page 126 Figure 5-90 reassembly. 17. Uniformly loosen and remove the 14 main 20. Clean the main journals and bearings. bearing cap bolts (12 pointed head) in the order shown in Figure 5-91. 6LPA Service Manual 5-46 © 2007 Yanmar Marine International...

- Page 127 24. Install the main bearing cap with the 14 bolts (12 pointed head) (Figure 5-95). See steps 13 to 18 starting at Cylinder Block Assembly on 0004878 page 5-63. NOTICE: NEVER turn the Figure 5-96 crankshaft. 6LPA Service Manual 5-47 © 2007 Yanmar Marine International...

- Page 128 9 – Mark 1, 2 or 3 (0.0785 to 0.0786 in.) 10 – Mark 2, 3, 4, 5 or 6 Mark “8” 1.997 to 2.000 mm 119770-01170 (0.0786 to 0.0787 in.) 6LPA Service Manual 5-48 © 2007 Yanmar Marine International...

- Page 129 70.985~70.986 mm 66.985~66.986 mm (2.79467~2.79471 in.) (2.63719~2.63723 in.) 70.984~70.985 mm 66.984~66.985 mm (2.79463~2.79467 in.) (2.63715~2.63719 in.) 70.983~70.984 mm 66.983~66.984 mm (2.79459~2.79463 in.) (2.63711~2.63715 in.) 70.982~70.983 mm 66.982~66.983 mm (2.79455~2.79459 in.) (2.63707~2.63711 in.) 6LPA Service Manual 5-49 © 2007 Yanmar Marine International...

- Page 130 Cylinder Block E N G I N E Crankshaft Main Journal Mark 6LPA Service Manual 5-50 © 2007 Yanmar Marine International...

- Page 131 1. Use a scraper to remove any remaining gasket material from the top of the cylinder block (Figure 5-99). Figure 5-99 0005024 Figure 5-101 0005022 Figure 5-99 2. Thoroughly clean the cylinder block using a soft brush and solvent. 6LPA Service Manual 5-51 © 2007 Yanmar Marine International...

- Page 132 • Mark “3”: 94.020 to 94.030 mm (3.7015 in. to 3.7019 in.) Maximum bore diameter: • 94.23 mm (3.7098 in.) If the measured bore diameter exceeds the 0005027 specified maximum, bore the cylinders or Figure 5-104 replace as needed. 6LPA Service Manual 5-52 © 2007 Yanmar Marine International...

-

Page 133: Piston And Connecting Rod Disassembly

(Figure 5-107). 2 – 40 mm (1.57 in.) Figure 5-107 0005030 Figure 5-107 3. Manually remove the coil for the oil ring. Store the rings in the correct order for reassembly. 6LPA Service Manual 5-53 © 2007 Yanmar Marine International... - Page 134 (Figure 5-110). Figure 5-112 Store the piston and pin as a set. Store the pistons, pins, rings and connecting rods together in correct order for reassembly. Figure 5-110 0005033 Figure 5-110 6LPA Service Manual 5-54 © 2007 Yanmar Marine International...

- Page 135 5 – No. 5 1 – SIze Mark 6 – No. 6 2 – Front Mark (Arrow) 7 – Mark 1, 2 or 3 3 – “L” Position 8 – Front Mark (Arrow) 6LPA Service Manual 5-55 © 2007 Yanmar Marine International...

- Page 136 No. 2 ring (second ring) and oil ring: Measure the clearance between the new piston ring and ring groove using a thickness gauge 0005041 (Figure 5-117). Figure 5-118 6LPA Service Manual 5-56 © 2007 Yanmar Marine International...

- Page 137 9. Inspect the piston pin fit to the piston. If the piston pin can be pressed into the piston by hand after heating the piston to about 80°C, the fit is acceptable (Figure 5-120). 0005044 Figure 5-121 6LPA Service Manual 5-57 © 2007 Yanmar Marine International...

- Page 138 When necessary, replace the piston and piston pin as an assembly. Note: If the piston pin bearing needs to be replaced, replace by the connecting rod assembly. 6LPA Service Manual 5-58 © 2007 Yanmar Marine International...

-

Page 139: Inspection And Servicing Of Crankshaft

Figure 5-126 0005050 0005049 Figure 5-127 Figure 5-126 2. Inspect and measure diameters of each crank journal (Figure 5-127, (1)) and crank pin (Figure 5-127, (2)) using a micrometer. 6LPA Service Manual 5-59 © 2007 Yanmar Marine International... -

Page 140: Crankshaft Oil Seal Replacement

Figure 5-131 Figure 5-129 0005054 Figure 5-131 0005052 Figure 5-129 3. Apply grease to the oil seal lip. 6LPA Service Manual 5-60 © 2007 Yanmar Marine International... -

Page 141: Piston And Connecting Rod Assembly

6. Manually install the coil for the oil piston ring (Figure 5-136). 4. Align the marks of the piston and connecting rod and press the piston pin in by hand Figure 5-136 (Figure 5-134). 0005059 Figure 5-136 6LPA Service Manual 5-61 © 2007 Yanmar Marine International... - Page 142 1 – No. 1 Piston Ring ID Mark Figure 5-140 2 – No. 2 Piston Ring ID Mark 9. Install the piston rings with the ring end gaps as shown in Figure 5-139. 6LPA Service Manual 5-62 © 2007 Yanmar Marine International...

-

Page 143: Cylinder Block Assembly

7. Clean all components and remove all foreign matter. 8. Clean the sealing surface using clean solvent. 0005064 Figure 5-141 4. Place the crankshaft on the cylinder block (Figure 5-142). Figure 5-142 0005065 Figure 5-142 6LPA Service Manual 5-63 © 2007 Yanmar Marine International... - Page 144 90° from the starting Note: Replace any main bearing cap bolts that front point. are broken, damaged or deformed. 17. Check that the crankshaft rotates smoothly. 6LPA Service Manual 5-64 © 2007 Yanmar Marine International...

- Page 145 • Torque: 375 kgf·cm, 36.77 N·m (27.1 lb-ft) Figure 5-149 Note: If any of the connecting rod cap bolts fails to satisfy the torque specification, replace the cap bolt. Figure 5-151 0005072 Figure 5-149 0005148 Figure 5-151 6LPA Service Manual 5-65 © 2007 Yanmar Marine International...

-

Page 146: Rear Crankshaft Oil Seal Installation

4. Apply seal packing (TOYOTA P/N 08826-00080 or equivalent) to the case as shown (Figure 5-153). Apply the seal packing in a width of 2 to 3 mm (0.08 to 0.12 in.) (Figure 5-153, (1)). 6LPA Service Manual 5-66 © 2007 Yanmar Marine International... -

Page 147: Final Engine Assembly And Adjustments

Figure 5-155. Torque the bolts to 1300 kgf·cm, 127.40 N·m (93.9 lb-ft). 6. Install the flywheel housing set bolts and torque to 185 kgf·cm, 18.13 N·m (13.3 lb-ft). 6LPA Service Manual 5-67 © 2007 Yanmar Marine International... -

Page 148: Timing Belt

12 – Timing Belt 5 – No. 2 Camshaft Timing Pulley 13 – Gasket 6 – No. 1 Flange 14 – Insulator 7 – No. 2 Flange 15 – Seal Washer 8 – Clip 6LPA Service Manual 5-68 © 2007 Yanmar Marine International... - Page 149 NEVER turn the crankshaft with the timing belt disconnected and always make sure to set the crankshaft pulley at the correct angle when installing the belt. 0005156 Figure 5-159 6LPA Service Manual 5-69 © 2007 Yanmar Marine International...

- Page 150 4. Remove the pivot bolt, idler pulley (Figure 5-161, (1)) and plate washer (Figure 5-161, (2)) using an 8 mm hex / allen wrench (Figure 5-161, (3)). Figure 5-161 0005161 Figure 5-163 0005159 Figure 5-161 6LPA Service Manual 5-70 © 2007 Yanmar Marine International...

- Page 151 • Breaking or parting at the joints (Figure 5-166). • Check the timing belt cover and gasket for damage and for correct installation. Figure 5-166 0005164 Figure 5-166 6LPA Service Manual 5-71 © 2007 Yanmar Marine International...

- Page 152 (Figure 5-169). 2. Inspect the idler pulley for smooth rotation. Replace the idler pulley as necessary Figure 5-169 (Figure 5-172). Figure 5-172 0005167 Figure 5-169 0005170 Figure 5-172 6LPA Service Manual 5-72 © 2007 Yanmar Marine International...

-

Page 153: Timing Belt Installation

(Figure 5-175, (1)) from the end of housing. 6. Apply seal packing to 3 positions of the cylinder head. • Protrusion: 9.0 to 9.8 mm (0.354 to 0.386 in.) 7. Install the gasket to the rocker cover. 6LPA Service Manual 5-73 © 2007 Yanmar Marine International... - Page 154 8 mm allen / hex wrench 15. Prepare to install the timing belt. WARNING! (Figure 5-179, (3)). ONLY install the timing belt when the engine • Torque specification: is cool. 350 kgf·cm, 34.32 N·m (25.3 lb-ft). 6LPA Service Manual 5-74 © 2007 Yanmar Marine International...

- Page 155 (b) Align the push rod to the hole in the housing and carry out positioning of the push rod by passing a 1.5 mm allen / hex wrench (Figure 5-182, (1)) through the hole. 0005183 Figure 5-183 6LPA Service Manual 5-75 © 2007 Yanmar Marine International...

- Page 156 19. Apply seal packing (TOYOTA P/N 08826-00080 or equivalent) to the camshaft oil seal retainer and timing belt cover as shown in Figure 5-185. Figure 5-185 0005185 Figure 5-185 6LPA Service Manual 5-76 © 2007 Yanmar Marine International...

- Page 157 Timing Belt ENGINE 12/05 This Page Intentionally Left Blank 6LPA Service Manual 5-77 © 2007 Yanmar Marine International...

-

Page 158: Timing Gear

ENGINE Timing Gear TIMING GEAR Components Figure 5-187 (10) (11) (16) (13) (14) (12) (15) 0005187 Figure 5-187 6LPA Service Manual 5-78 © 2007 Yanmar Marine International... - Page 159 13 – Crankshaft Front Oil Seal (Non-Reusable 7 – Oil Pump Drive Shaft Gear Part) 8 – Idler Gear 14 – Crankshaft Pulley 15 – O-Ring (Non-Reusable Part) 16 – Bolt - 6 Used 6LPA Service Manual 5-79 © 2007 Yanmar Marine International...

-

Page 160: Timing Gear Removal

6LPA Service Manual 5-80 © 2007 Yanmar Marine International... - Page 161 Inspect the idler gear and idler gear shaft and replace as necessary. Figure 5-192 0005194 Figure 5-194 0005192 Figure 5-192 14. Remove the 2 bolts securing the idler gear and thrust plate. 6LPA Service Manual 5-81 © 2007 Yanmar Marine International...

- Page 162 2. Measure the outside diameter of the idler gear shaft using a micrometer (Figure 5-198). • Outside diameter of idle gear shaft: 44.950 to 44.975 mm (1.769 to 1.770 in.) Figure 5-198 0005196 Figure 5-196 0005198 Figure 5-198 6LPA Service Manual 5-82 © 2007 Yanmar Marine International...

- Page 163 5. To replace the fuel injection pump drive gear bearing, remove the bearing using a suitable tool (Figure 5-200, (1)). Use the fuel injection pump drive gear nut (Figure 5-200, (2)) as a pressing point for the puller. 6LPA Service Manual 5-83 © 2007 Yanmar Marine International...

- Page 164 2 – Fuel Injection Pump Drive Gear to Idler Gear 3 – Oil Pump Drive Shaft Gear to Oil Pump Gear 4 – Move in Both Directions 8. Remove the timing gears. 6LPA Service Manual 5-84 © 2007 Yanmar Marine International...

-

Page 165: Front Crankshaft Oil Seal Replacement

P/N 119770-01100 (Figure 5-204, (1)), until the Figure 5-206 surface is level with that of the timing gear cover. 3. Apply grease to the oil seal lip. Figure 5-204 0005206 Figure 5-206 0005204 Figure 5-204 6LPA Service Manual 5-85 © 2007 Yanmar Marine International... -

Page 166: Fuel Injection Pump Drive Gear Oil Seal Replacement

(Figure 5-208, (1)), until the surface is level with that of the timing gear cover. Figure 5-210 Figure 5-208 0005210 0005208 Figure 5-210 Figure 5-208 3. Apply grease to the oil seal lip. 6LPA Service Manual 5-86 © 2007 Yanmar Marine International... -

Page 167: Timing Gear Installation

6. Install the gear nut. 68.06 N·m (50.2 lb-ft). 7. Tighten the gear nut and torque to Figure 5-214 1,000 kgf·cm, 98.07 N·m (72.3 lb-ft) (Figure 5-212). Figure 5-212 0005214 Figure 5-214 0005212 Figure 5-212 6LPA Service Manual 5-87 © 2007 Yanmar Marine International... - Page 168 16. Install the alternator adjusting bar. cover as shown in Figure 5-216. • Attach a nozzle cut to a sealing width of 2 to 3 mm (0.078 to 0.118 in.) (Figure 5-216, (1)). 6LPA Service Manual 5-88 © 2007 Yanmar Marine International...

- Page 169 Torque viscous damper bolts to causing engine damage. 380 kgf·m, 37.27 N·m (27.5 lb-ft). 25. Install the freshwater pump, see Freshwater Figure 5-217 Pump Installation on page 7-6 and alternator V-belt. 0005216 Figure 5-217 6LPA Service Manual 5-89 © 2007 Yanmar Marine International...

-

Page 170: Valve Clearance Inspection And Adjustment

(about 90°). If Figure 5-220 not, turn the crankshaft 360° and position the mark as shown (Figure 5-218, (2)). 0005219 Figure 5-220 6LPA Service Manual 5-90 © 2007 Yanmar Marine International... -

Page 171: Valve Clearance Adjustment

0.50 mm feeler gauge (Figure 5-222, (1)) for the exhaust side. 0005222 Figure 5-223 1 – Slide Feeler Gauge 2 – Loosen Adjusting Screw 3 – Adjusting Screw 4 – Valve Bridge 6LPA Service Manual 5-91 © 2007 Yanmar Marine International... - Page 172 3 – Turn Adjusting Screw 2 – Valve Bridge 4 – Adjusting Screw 3 – Tighten Adjusting Screw 5 – Valve Rocker Arm 4 – Adjusting Screw 5 – Tighten Nut 6LPA Service Manual 5-92 © 2007 Yanmar Marine International...

-

Page 173: Injection Timing Inspection And Adjustment

3. Loosen the two union nuts securing the fuel injection pump to No. 1 and No. 5 fuel injection pipes and position them out of the way (Figure 5-227). Figure 5-227 0005228 Figure 5-227 6LPA Service Manual 5-93 © 2007 Yanmar Marine International... - Page 174 Figure 5-230 Figure 5-229 0005230 Figure 5-229 0005231 Figure 5-230 8. Slowly turn the crankshaft pulley clockwise (Figure 5-230, (1)) to align its groove to that of the timing gear cover. 6LPA Service Manual 5-94 © 2007 Yanmar Marine International...

-

Page 175: Adjustment Of Injection Timing

185 kgf·cm, 18.14 N·m (13.3 lb-ft). 4. Install and torque the two bolts securing the fuel injection pump to the fuel injection pump to 700 kgf·cm, 68.65 N·m (50.6 lb-ft). 6LPA Service Manual 5-95 © 2007 Yanmar Marine International... - Page 176 ENGINE Injection Timing Inspection and Adjustment This Page Intentionally Left Blank 6LPA Service Manual 5-96 © 2007 Yanmar Marine International...

- Page 177 Adjusting No. 1 Opening Pressure .......... 6-25 Fuel Injection Nozzle Installation ..........6-25 Fuel Injection Pump............... 6-28 Components ................6-28 Fuel Injection Pump Removal..........6-29 Components ................6-30 Fuel Injection Pump Installation..........6-34 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 178: Fuel System

FUEL SYSTEM This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 179: Safety Precautions

NEVER use a shop rag to catch the fuel. Wipe up all spills immediately. NEVER refuel with the engine running. Store any containers containing fuel in a well-ventilated area, away from any combustibles or sources of ignition. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 180: Introduction

FUEL SYSTEM Introduction INTRODUCTION This section of the Service Manual describes the procedures necessary to remove, install, and adjust the injectors and their associated system components as used on the Yanmar 6LPA-STP2/STZP2 engines. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 181: Specifications

2.050 mm (0.081 in.) 0.825 to 1.950 mm (0.032 to 0.077 in.) No. 1 opening pressure adjusting shim (0.075 mm (0.003 in.) steps) thickness 2.000 to 2.100 mm (0.008 to 0.083 in.) 6LPA Service Manual © 2007 Yanmar Marine International... - Page 182 (0.075 to 0.126 in.) in 0.01 mm (0.0004 in.) steps. Boost compensator There are 12 types of shims having thickness from 1.1 to 3.3 mm diaphragm adjusting shim (0.043 to 0.130 in.) in 0.2 mm (0.0008 in.) steps. thickness 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 183: Special Torque Chart

Injection pump x timing gear case 185 kgf·cm, 18.14 N·m (13.4 lb-ft) Pump stay x injection pump 700 kgf·cm, 68.65 N·m (50.1 lb-ft) Injection pump drive gear x injection pump 1050 kgf·cm, 102.9 N·m (76 lb-ft) 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 184: Fuel Injection Pump Specifications

2 x 6 x 840 mm (0.08 x 0.23 x 269.2 in.) Measurement Conditions Diesel fuel feed pressure 0.2 kgf/cm , 0.02 MPa (3 psi) Test oil JIS No. 2 fuel oil Diesel fuel temperature 40°C (104°F) (at overflow portion) 6LPA Service Manual © 2007 Yanmar Marine International... - Page 185 Figure 6-2 Injection Volume: Q (mm /st) BCS Characteristics Figure 6-3 BCS Characteristics Injection Volume: Q (mm /st) Pump Speed: NP (rpm) 0005577 Figure 6-1 Boost Pressure: PB (kPa) 0005579 Figure 6-3 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 186: Fuel Filter Replacement

NOTICE: Avoid damaging the alarm switch during removal. Figure 6-5 0005251 Figure 6-5 5. Lubricate a new alarm switch O-ring with clean diesel fuel and install the alarm switch and O-ring to the new fuel filter. 6LPA Service Manual 6-10 © 2007 Yanmar Marine International... - Page 187 Figure 6-7 0005253 Figure 6-7 9. Start the engine to check for fuel leakage. Repair any leaks as necessary. WARNING! NEVER check for fuel leaks with your hand. 6LPA Service Manual 6-11 © 2007 Yanmar Marine International...

-

Page 188: Fuel Injection Nozzle

FUEL SYSTEM Fuel Injection Nozzle FUEL INJECTION NOZZLE Components Figure 6-8 (12) (13) (14) (11) (10) 0005254 Figure 6-8 6LPA Service Manual 6-12 © 2007 Yanmar Marine International... - Page 189 11 – Injection Pipe 5 – No. 3 Fuel Return Pipe 12 – Injection Nozzle 6 – Gasket (Non-Reusable) 13 – Nozzle Holder Seal 7 – Gasket (Non-Reusable) 14 – Nozzle Seat (Non-Reusable) 6LPA Service Manual 6-13 © 2007 Yanmar Marine International...

-

Page 190: Fuel Injection Nozzle Removal

5. Remove the union nut of the fuel injection pipe screwdriver to pry the nozzle holder from the from the fuel injection nozzle (Figure 6-10). cylinder head (Figure 6-13). Figure 6-10 Figure 6-13 0005259 0005262 Figure 6-10 Figure 6-13 6LPA Service Manual 6-14 © 2007 Yanmar Marine International... -

Page 191: Fuel Injection Nozzle Testing

Check the spray condition for an even spray pattern (Figure 6-16, (1)). If the spray condition is improper (Figure 6-16, (2)), replace or clean the nozzle. Figure 6-16 0005265 Figure 6-16 6LPA Service Manual 6-15 © 2007 Yanmar Marine International... -

Page 192: Fuel Injection Nozzle Components

5 – Adjusting Shim 13 – No. 1 Pressure Spring 6 – Tip Packing 14 – Adjusting Shim 7 – Straight Pins 15 – Nozzle Holder Body 8 – No. 2 Pressure Spring Seat 6LPA Service Manual 6-16 © 2007 Yanmar Marine International... -

Page 193: Fuel Injection Nozzle Disassembly And Inspection

If damage or corrosion (Figure 6-19, (1)) with a wooden stick. is present, replace the nozzle assembly Figure 6-19 (Figure 6-21). Figure 6-21 0005270 Figure 6-19 0005272 Figure 6-21 6LPA Service Manual 6-17 © 2007 Yanmar Marine International... -

Page 194: Fuel Injection Nozzle Adjustment

2. Adjust the dial indicator reading on the special tool or square block to zero, using the special smoothly, replace the nozzle assembly. tool (Figure 6-25, (1)). Figure 6-23 Figure 6-25 0005285 0005274 Figure 6-25 Figure 6-23 6LPA Service Manual 6-18 © 2007 Yanmar Marine International... - Page 195 5. Set the special tool (Figure 6-27, (3)) on the nozzle and measure dimension (A). • Dimension (L1) = ( t ) - (A) 6. Remove the special tool and needle tip from the nozzle body. 0005287 Figure 6-27 6LPA Service Manual 6-19 © 2007 Yanmar Marine International...

- Page 196 Increasing the shim thickness reduces the needle lift. • Needle lift = (L1+L2) - L3 • Needle lift: 0.26 to 0.31 mm (0.0102 to 0.0122 in.) Figure 6-30 (L3) 0005290 Figure 6-30 6LPA Service Manual 6-20 © 2007 Yanmar Marine International...

- Page 197 1 – No. 2 Pressure Spring Seat 2 – Special Tool (B) 3 – Top 4 – Bottom 2. Set the special tool on the nozzle and measure dimension (B). • Dimension (C) = (B) - (t) 6LPA Service Manual 6-21 © 2007 Yanmar Marine International...

- Page 198 • Pre-lift standard: 0.08 to 0.10 mm (0.003 to 2 – (E) 0.004 in.) 3 – Pre-lift Figure 6-34 4 – Needle lift 5 – Detailed View of (E) (L5) 0005294 Figure 6-34 6LPA Service Manual 6-22 © 2007 Yanmar Marine International...

-

Page 199: Checking No. 2 Opening Pressure

2. Tighten the nozzle holder retaining nut using a 14 mm socket (Figure 6-38, (1)) torque to: 300 kgf·cm, 29.42 N·m (22 lb-ft). NOTICE: NEVER tighten excessively. Otherwise, deformation, adhesion or other defects may occur. 6LPA Service Manual 6-23 © 2007 Yanmar Marine International... - Page 200 1 – Normal Spray During Operation 2 – Undesired - Leakage After Operation 3 – Normal - No leakage After Operation 8. Disassemble the nozzle after checking the No. 2 opening pressure. 6LPA Service Manual 6-24 © 2007 Yanmar Marine International...

-

Page 201: Adjusting No. 1 Opening Pressure

(0.0826 in.) 2.175 mm (0.0856 in.) Note: Changing the adjusting shim thickness 0005306 by 0.025 mm changes the valve opening Figure 6-43 pressure by approximately 3.8 kgf/cm 0.37 MPa (54 psi). 6LPA Service Manual 6-25 © 2007 Yanmar Marine International... - Page 202 Figure 6-47 0005308 Figure 6-45 1 – No. 1 0005310 2 – No. 2 Figure 6-47 3 – No. 3 4 – No. 4 5 – No. 5 6 – No. 6 6LPA Service Manual 6-26 © 2007 Yanmar Marine International...

- Page 203 1 – Joint Bolt 2 – New Gasket (A) 3 – Turbocharger Pressure Gauge Tool 4 – No. 1 Nozzle Fuel Return Pipe 5 – New Gasket (B) 6 – Cylinder Head 6LPA Service Manual 6-27 © 2007 Yanmar Marine International...

-

Page 204: Fuel Injection Pump

1 – Fuel Injection Pipe 5 – O-ring (Non-Reusable) 2 – Clamp 6 – Boost Compensator Hose 3 – No. 3 Nozzle Return Pipe 7 – Injection Pump 4 – Clamp 6LPA Service Manual 6-28 © 2007 Yanmar Marine International... -

Page 205: Fuel Injection Pump Removal

7. Remove two fuel injection pump stay set bolts (Figure 6-51, (1)). Figure 6-51 0005316 Figure 6-53 11. Remove the O-ring from the fuel injection pump. 0005314 Figure 6-51 6LPA Service Manual 6-29 © 2007 Yanmar Marine International... -

Page 206: Components

(12) (11) (10) (19) (22) (23) (20) (21) (24) (25) (26) (29) (27) (28) (30) (33) (31) (32) (35) (34) (36) (37) (41) (38) (39) (40) (43) (42) 0005317 Figure 6-54 6LPA Service Manual 6-30 © 2007 Yanmar Marine International... - Page 207 22 – Maximum Speed adjustment Screw 23 – No. 2 Fuel Return Pipe Note: Since professional knowledge and special equipment are required for disassembly and adjustment of the fuel injection pump, consult DENSO. 6LPA Service Manual 6-31 © 2007 Yanmar Marine International...

- Page 208 ( 9 ) ( 32 ) ( 2 ) ( 33 ) ( 7 ) ( 34 ) ( 6 ) ( 5 ) ( 3 ) 0005318 ( 1 ) Figure 6-55 6LPA Service Manual 6-32 © 2007 Yanmar Marine International...

- Page 209 75 – Spring Seat 37 – Governor Gear Adjusting Washer 76 – Spring 38 – No. 1 Flyweight Washer 77 – Delivery Valve 39 – Flyweight Holder 78 – Fuel Injection Pump Stay 6LPA Service Manual 6-33 © 2007 Yanmar Marine International...

-

Page 210: Fuel Injection Pump Installation

1050 kgf·cm, 102.97 N·m (76 lb-ft). NOTICE: NEVER turn the crankshaft pulley as damage will occur if the valve heads and piston tops contact. Figure 6-59 0005320 Figure 6-57 0005322 Figure 6-59 6LPA Service Manual 6-34 © 2007 Yanmar Marine International... - Page 211 Inspection and Adjustment on page 5-93. 14. Fill the engine fresh water line with engine coolant. 15. Start the engine and check for fuel leakage. WARNING! NEVER check for a fuel leak with your hand. 6LPA Service Manual 6-35 © 2007 Yanmar Marine International...

- Page 212 FUEL SYSTEM Fuel Injection Pump This Page Intentionally Left Blank 6LPA Service Manual 6-36 © 2007 Yanmar Marine International...

- Page 213 Seawater Pump Reassembly ............ 7-8 Thermostat Removal ............... 7-10 Thermostat Installation ............7-11 Components Related to Cooling System ........7-12 Freshwater Tank..............7-12 Freshwater Cooler ..............7-13 Coolant Recovery Tank ............7-14 Page 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 214: Cooling System

COOLING SYSTEM This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International... - Page 215 This section of the Service Manual describes the following safety information and review the Safety procedures necessary to service the Section on page 2-1. 6LPA-STP2/STZP2 marine engine cooling systems. The safety message that follows has CAUTION level hazards. The safety message describes a hazardous situation which, if not avoided, could result in minor or moderate injury.

-

Page 216: Freshwater Pump Related Components

( 3 ) ( 2 ) ( 1 ) 0005329 Figure 7-1 1 – Freshwater Pump 3 – Camshaft Oil Seal (Non-Reusable Part) 2 – Gasket (Non-Reusable Part) 4 – Camshaft Oil Seal Retainer 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 217: Freshwater Pump Removal

5. Remove the camshaft oil seal retainer. See step Figure 7-4 11 starting in Cylinder Head Removal on page 5-16. 6. Remove the three bolts and alternator adjusting bar (Figure 7-3, (1)). 0005332 Figure 7-4 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 218: Freshwater Pump Installation

Figure 7-5 3. Install the camshaft oil seal retainer. Camshaft Oil Seal Retainer Installation. 4. Install No. 1 camshaft timing pulley, idler pulley and timing belt. See Timing Belt Installation on page 5-73. 6LPA Service Manual © 2007 Yanmar Marine International... - Page 219 9 – Cam 3 – Impeller 10 – Set Screw 4 – Oil Seal 11 – Shaft 5 – O-ring 12 – Retaining Ring 6 – Spacer 13 – Bearing 7 – Oil Seal 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 220: Seawater Pump Disassembly

Seawater Pump Reassembly 1. Apply grease to the oil seal and bearing. 2. Insert the impeller while turning it in the operating direction (clockwise). 6LPA Service Manual © 2007 Yanmar Marine International... - Page 221 Thermostat Components COOLING SYSTEM 12/05 THERMOSTAT COMPONENTS Figure 7-8 ( 3 ) ( 2 ) ( 1 ) 0005336 Figure 7-8 1 – Thermostat Cover 2 – Gasket 3 – Thermostat 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 222: Thermostat Removal

Figure 7-10 ( 1 ) ( 2 ) 6. Immerse the thermostat in water and slowly heat it (Figure 7-11). The valve opening temperature is indicated on the thermostat. 0005340 Figure 7-12 6LPA Service Manual 7-10 © 2007 Yanmar Marine International... -

Page 223: Thermostat Installation

Figure 7-14 ( 1 ) 4. Secure the rubber hose with the hose band. 5. Fill with engine coolant (fresh water). 6. Start the engine and check for leakage. 0005341 Figure 7-13 6LPA Service Manual 7-11 © 2007 Yanmar Marine International... -

Page 224: Components Related To Cooling System

• Standard valve opening pressure: 0.75 to 1.05 kgf/cm , 0.07 to 0.10 MPa (10.6 to 14.9 psi) • Minimum valve opening pressure: 0.6 kgf/cm 0.06 MPa (8.5 psi) 0005345 Figure 7-17 6LPA Service Manual 7-12 © 2007 Yanmar Marine International... -

Page 225: Freshwater Cooler

Replace it before failures occur. Check the hose band (Figure 7-18, (3)) for damage to the screw, nut and the plate. Replace as needed. Figure 7-18 ( 3 ) ( 1 ) ( 2 ) 0005346 Figure 7-18 6LPA Service Manual 7-13 © 2007 Yanmar Marine International... -

Page 226: Coolant Recovery Tank

If the coolant recovery tank leaks air the coolant ( 2 ) recovery tank will not function correctly. 0005348 Figure 7-20 1 – Full Mark 2 – Low Mark 6LPA Service Manual 7-14 © 2007 Yanmar Marine International... - Page 227 If the boat is operated with the seacock closed, no seawater is fed to the engine and pump and will cause engine overheating or failure. 6LPA Service Manual 7-15 © 2007 Yanmar Marine International...

- Page 228 COOLING SYSTEM Components Related to Cooling System This Page Intentionally Left Blank 6LPA Service Manual 7-16 © 2007 Yanmar Marine International...

- Page 229 Oil Cooler Removal ..............8-14 Oil Cooler Disassembly and Inspection........8-14 Oil Cooler Installation .............. 8-15 Piston Cooling Oil Nozzle.............. 8-16 Components ................8-16 Oil Nozzle Disassembly and Inspection ........8-17 Oil Nozzle Installation .............. 8-17 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 230 LUBRICATION This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 231: Safety Precautions

Safety Precautions LUBRICATION 12/05 SAFETY PRECAUTIONS INTRODUCTION Before you service the 6LPA-STP2/STZP2 marine This section of the Service Manual describes the engine lubrication system, read the following safety procedures necessary to service the information and review the Safety Section on 6LPA-STP2/STZP2 marine engine lubrication page 2-1. -

Page 232: Specifications

Relief Valve x Oil Cooler Cover 400 kgf·m, 39.23 N·m (347.2 lb-in.) Check Valve x Oil Cooler Cover 275 kgf·m, 26.97 N·m (238.7 lb-in.) Oil Nozzle x Cylinder Block 275 kgf·m, 26.97 N·m (238.7 lb-in.) 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 233: Testing Oil Pressure

Inspection Item Test RPM Specification 0.3 kgf/cm , 0.03 MPa or more (4.26 psi) Oil Pressure 3800 4.5 kgf/cm , 0.44 MPa (64 psi) 4. Remove the oil pressure gauge. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 234: Oil Pump

14 – Gasket (Non-Reusable) 6 – Gasket (Non-Reusable) 15 – Spring 7 – Oil Strainer 16 – Relief Valve 8 – Bolt (27 used) 17 – Driven Rotor 9 – Oil Pan 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 235: Oil Pump Removal

6. Remove the 7 bolts securing the timing gear case to the cylinder block. 7. Insert a screwdriver (Figure 8-5, (1)) between the oil pump and cylinder block and pry to remove the oil pump. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 236: Oil Pump Disassembly And Inspection

(Figure 8-9) and check if the drive shaft turns (Figure 8-11). If the measured clearance smoothly and the bearing has no play. If exceeds the specified maximum, replace the oil needed, replace the oil pump assembly. pump assembly. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 237: Oil Pump Reassembly

Figure 8-14 Rotor side clearance: • Standard: 0.030 to 0.090 mm (0.011 to 0.035 in.) • Maximum: 0.15 mm (0.005 in.) Figure 8-12 0005366 Figure 8-14 0005364 Figure 8-12 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 238: Oil Pump Installation

5. Install a new O-ring (Figure 8-18, (1)) onto the Remove the nozzle from the tube immediately fuel injection pump. after use and protect it with a cap. 6LPA Service Manual 8-10 © 2007 Yanmar Marine International... - Page 239 9. Apply TOYOTA P/N 08833-00070, THREE BOND 1344, LOCTITE 242 or equivalent adhesive (Figure 8-20, (1)) to the threaded portion of taper screw plug (2 to 3 threads). 0005373 Figure 8-21 6LPA Service Manual 8-11 © 2007 Yanmar Marine International...

- Page 240 Checking and Adding Engine Coolant on page 3-25. 17. Start the engine and check for oil leakage. 18. Check the oil level again, fill to the upper limit of the oil dipstick as needed. 6LPA Service Manual 8-12 © 2007 Yanmar Marine International...

-

Page 241: Oil Cooler

8 – Gasket (Non-Reusable part) 3 – Oil Cooler 9 – Check Valve 4 – Gasket (Non-Reusable part) 10 – Oil Filter 5 – Oil Cooler Cover Assembly 11 – Gasket 6 – Relief Valve 6LPA Service Manual 8-13 © 2007 Yanmar Marine International... -

Page 242: Oil Cooler Removal

Figure 8-26 0005375 Figure 8-23 0005378 Figure 8-26 7. Remove 13 bolts, 2 nuts, oil cooler, cover assembly and gasket. Discard the gasket. Figure 8-24 0005565 Figure 8-24 6LPA Service Manual 8-14 © 2007 Yanmar Marine International... -

Page 243: Oil Cooler Installation

9. Fill with engine coolant (fresh water). 10. Start the engine and check for oil leakage. 11. Check the engine oil level again, if needed fill to the upper limit of the oil dipstick. 6LPA Service Manual 8-15 © 2007 Yanmar Marine International... -

Page 244: Piston Cooling Oil Nozzle

PISTON COOLING OIL NOZZLE Components Figure 8-31 0005383 Figure 8-31 1 – Piston Cooling Oil Nozzle 4 – Gasket (Non-Reusable part) 2 – Check Valve 5 – Drain Plug 3 – Oil Pan 6LPA Service Manual 8-16 © 2007 Yanmar Marine International... -

Page 245: Oil Nozzle Disassembly And Inspection

4. Inspect the oil nozzle (Figure 8-34) for damage, restrictions and clogs. If needed, replace the oil nozzle. 0005387 Figure 8-35 3. Install the oil pan. See step 11 starting in Oil Pump Installation on page 8-10. 6LPA Service Manual 8-17 © 2007 Yanmar Marine International... - Page 246 LUBRICATION Piston Cooling Oil Nozzle This Page Intentionally Left Blank 6LPA Service Manual 8-18 © 2007 Yanmar Marine International...

-

Page 247: Troubleshooting

Introduction..................9-3 Turbocharger................... 9-4 Components and Operation ............9-4 Service Specifications ............... 9-8 Periodic Inspection ..............9-11 Disassembly ................9-12 Inspection and Cleaning ............9-14 Reassembly................9-17 Installation ................9-19 Troubleshooting............... 9-20 Page 6LPA Service Manual © 2007 Yanmar Marine International... - Page 248 TURBOCHARGER This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 249: Safety Precautions

SAFETY PRECAUTIONS INTRODUCTION Before you service the engine turbocharger, review This section of the Service Manual describes the the Safety Section on page 2-1. procedures necessary to service the 6LPA-STP2/STZP2 marine engine turbocharger. 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 250: Turbocharger

A seal ring and oil defensive plate are air intake pipe and into the engine. This is called also used to seal intake air and oil. the compressor or blower. 6LPA Service Manual © 2007 Yanmar Marine International... - Page 251 Turbocharger TURBOCHARGER 12/05 This Page Intentionally Left Blank 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 252 (6) (7) 0005234 Figure 9-1 Components (RHE6W Turbocharger) Figure 9-2 (33) (31) (65) (54) (11) (12) (53) (2) (22) (21) (63) (52) (64) (61) (44) (44) (51) (42) (41) (62) 0005235 Figure 9-2 6LPA Service Manual © 2007 Yanmar Marine International...

- Page 253 Torque: 230 ± 10 kgf·m, 23 ± 1 N·m (17 ± 0.7 lb-ft) Liquid gasket Apply Loctite No. 242 Liquid gasket Apply liquid gasket Waste gate actuator E-Type retaining ring Boost hose Hose clip Boost pipe 6LPA Service Manual © 2007 Yanmar Marine International...

-

Page 254: Service Specifications

Thrust bushing groove to groove distance 4.480 mm (0.176 in.) Seal ring Turbine side (bearing wheel chamber) 17.030 mm (0.670 in.) inserting Compressor side (seal plate) 14.050 mm (0.553 in.) area 6LPA Service Manual © 2007 Yanmar Marine International... -

Page 255: Special Tools

For installing compressor housing for M8: Universal type) 230 kgf·cm, 23 ± 1 N·m (17 ± 0.7 lb-ft) For installing seal plate for M8: 230 kgf·cm, 23 ± 1 N·m (17 ± 0.7 lb-ft) Available Locally 6LPA Service Manual © 2007 Yanmar Marine International... - Page 256 For fixing turbine shaft (14mm x 12 pointed head) (Box part alone may be used.) 0005244 Probe For measuring play in axial and radial directions (To be attached to a dial indicator) (1) To be knurled here (rolette) 0005245 6LPA Service Manual 9-10 © 2007 Yanmar Marine International...

-

Page 257: Periodic Inspection

Note: Move the turbine shaft in an axial direction (Figure 9-4, (5)). Figure 9-4 0005237 Figure 9-4 1 – Oil Inlet 2 – Dial Indicator 3 – Magnet Base 4 – Turbine Wheel Chamber 6LPA Service Manual 9-11 © 2007 Yanmar Marine International... -

Page 258: Disassembly

Note: Liquid gasket is applied to the compressor housing (Figure 9-2, (31)) and seal plate (Figure 9-2, (11)) mounting surfaces. Note: Avoid damaging the compressor impellers when disassembling the compressor housing. 6LPA Service Manual 9-12 © 2007 Yanmar Marine International... - Page 259 (Figure 9-2, (1)). (Figure 9-2, (3)). Note: If the turbine shaft is tight, lightly tap the shaft end on the blower side with a wood or plastic hammer. 6LPA Service Manual 9-13 © 2007 Yanmar Marine International...

-

Page 260: Inspection And Cleaning

Clean all other parts with diesel oil. Avoid damaging parts while All other cleaning. Lightly coat parts with oil Diesel Fuel Clean all lubricating oil passages and parts to prevent corrosion until dry with compressed air. assembled. 6LPA Service Manual 9-14 © 2007 Yanmar Marine International... - Page 261 Check the thermal insulation plate surface defects. Replace the floating bearing if (Figure 9-2, (42)) for damage, contact traces, necessary. thermal deformation or corrosion. Replace the thermal insulation plate if necessary. 6LPA Service Manual 9-15 © 2007 Yanmar Marine International...

- Page 262 2. Measure the seal ring insertion hole (Figure 9-8, (H)) on the compressor side. Replace the seal ring if the measured value exceeds the wear limit. • Wear limit: 14.05 mm (0.553 in.) 6LPA Service Manual 9-16 © 2007 Yanmar Marine International...

-

Page 263: Reassembly

5. Fit the seal ring (Figure 9-2, (6)) onto the turbine shaft (Figure 9-2, (1)). 6. Install the thermal insulation plate (Figure 9-2, (42)) to the bearing housing (Figure 9-2, (51)) on the turbine side. 6LPA Service Manual 9-17 © 2007 Yanmar Marine International... - Page 264 • Liquid gasket thickness: 0.1 to 0.2 mm (0.004 (Figure 9-2, (7)) to 80 ± 5 kgf·cm, to 0.008 in.) 7.84 ± 0.5 N·m (69 ± 4 lb-in.). Note: The shaft end nut uses left-handed threads. 6LPA Service Manual 9-18 © 2007 Yanmar Marine International...

-

Page 265: Installation

2. Connect the exhaust pipes securely to prevent 0.004 in.) exhaust gas leaks at each pipe joint. • Turbine shaft radial play: Service standard: 0.10 to 0.17 mm (0.004 to 0.007 in.) 6LPA Service Manual 9-19 © 2007 Yanmar Marine International... -

Page 266: Troubleshooting

1. Oil flowing to the compressor or turbine side out due to a Repair or replace the piping. clogged oil return pipe 2. Abnormal wear or damage to seal ring by excessive wear of Disassemble and repair the turbocharger. bearing 6LPA Service Manual 9-20 © 2007 Yanmar Marine International... - Page 267 3. Unbalanced rotating part Repair or replace the rotating part. 6LPA Service Manual 9-21 © 2007 Yanmar Marine International...

- Page 268 TURBOCHARGER Turbocharger This Page Intentionally Left Blank 6LPA Service Manual 9-22 © 2007 Yanmar Marine International...

- Page 269 Safety Precautions ................ 10-3 Introduction..................10-3 Starter Specifications ..............10-4 Starter.................... 10-5 Components ................10-5 Starter Disassembly ..............10-6 Starter Inspection and Testing..........10-8 Starter Reassembly ............... 10-14 Performance Testing ............. 10-17 6LPA Service Manual 10-1 © 2007 Yanmar Marine International...

- Page 270 STARTER MOTOR This Page Intentionally Left Blank 6LPA Service Manual 10-2 © 2007 Yanmar Marine International...

-

Page 271: Safety Precautions

Safety procedures necessary to service the Section on page 2-1. 6LPA-STP2/STZP2 marine engine starter motor. These safety messages that follow have warning level hazards. These safety messages describe a hazardous situation, which, if not avoided, could result in death or serious injury. -

Page 272: Starter Specifications

95 kgf·cm, 9.32 N·m (82.4 lb-in.) End cover, starter housing 95 kgf·cm, 9.32 N·m (82.4 lb-in.) Lead wire, terminal 50 41 kgf·cm, 4.02 N·m (35.5 lb-in.) Lead wire, terminal C 215 kgf·cm, 21.08 N·m (186.5 lb-in.) 6LPA Service Manual 10-4 © 2007 Yanmar Marine International... -

Page 273: Starter

22 – Field Coil Frame 10 – Idle Gear 23 – Front Bearing 11 – Bearing 24 – Armature 12 – Starter Housing 25 – Rear Bearing 13 – Compression Spring 26 – Felt Washer 6LPA Service Manual 10-5 © 2007 Yanmar Marine International... -

Page 274: Starter Disassembly

3. Remove the 2 through bolts (Figure 10-4, (1)) and spring washers then pull the field coil frame from the magnetic switch, together with the armature and remove the felt washer from the rear bearing. 6LPA Service Manual 10-6 © 2007 Yanmar Marine International... - Page 275 (Figure 10-7). Figure 10-9 Figure 10-7 0005396 Figure 10-9 0005394 8. Remove the armature (Figure 10-1, (24)) from Figure 10-7 the field coil frame (Figure 10-1, (22)). 6LPA Service Manual 10-7 © 2007 Yanmar Marine International...

- Page 276 3. Inspect the commutator surface for damage, dirt and burning. If the commutator surface is lightly damaged, imperfections may be corrected with #400 emery cloth or by turning on a lathe. 6LPA Service Manual 10-8 © 2007 Yanmar Marine International...

- Page 277 • Standard 0.7 to 0.9 mm (0.027 to 0.035 in.) Figure 10-16 • Minimum 0.2 mm (0.007 in.) Figure 10-14 0005403 0005401 Figure 10-16 Figure 10-14 6LPA Service Manual 10-9 © 2007 Yanmar Marine International...

- Page 278 Figure 10-19 mounting load is out of the specified range, replace the brush spring. Brush spring mounting load: • 1.9 to 3.6 kgf, 18.63 to 35.30 N (4.1 lbf to 7.9 lbf) 6LPA Service Manual 10-10 © 2007 Yanmar Marine International...

- Page 279 1 – Stop Collar 2 – Pinion Gear 3 – Retainer 4 – Spring 5 – Starter Housing 6 – Starter Clutch 7 – Compression Spring 8 – Clutch Shaft 0005408 Figure 10-21 6LPA Service Manual 10-11 © 2007 Yanmar Marine International...

- Page 280 0005412 Figure 10-27 Figure 10-25 1 – Clutch Shaft and Starter Clutch 2 – Starter Housing 3 – Compression Spring 4 – Retainer 5 – Pinion Gear 6 – Stop Collar 6LPA Service Manual 10-12 © 2007 Yanmar Marine International...

- Page 281 1. Remove the front and rear bearings using a special tool (Figure 10-29). Figure 10-29 0005417 Figure 10-29 2. Press in a new front and rear bearing using the a press (Figure 10-30). 6LPA Service Manual 10-13 © 2007 Yanmar Marine International...

-

Page 282: Starter Reassembly

4. Install the end cover to the field coil frame using 0005420 two screws (Figure 10-35, (1)). Figure 10-32 Starter Reassembly 1. Apply grease to the armature bearing and install the armature in the field frame (Figure 10-33). 6LPA Service Manual 10-14 © 2007 Yanmar Marine International... - Page 283 3 screws (Figure 10-38). Figure 10-38 ( 1 ) 0005426 0005424 Figure 10-38 Figure 10-36 8. Install the idler gear (Figure 10-37, (1)) and bearing (Figure 10-37, (2)) to the starter housing. 6LPA Service Manual 10-15 © 2007 Yanmar Marine International...

- Page 284 215 kgf·cm, 21.08 N·m (186.5 lb-in.). Figure 10-40 12. Assemble the field coil frame and armature assembly using two through bolts (Figure 10-41, (1)) and torque to 95 kgf·cm, 9.32 N·m (82.4 lb-in.). 6LPA Service Manual 10-16 © 2007 Yanmar Marine International...

-

Page 285: Performance Testing

(-) lead to the grounded 0005434 housing (Figure 10-44, (4)). Check that the Figure 10-46 clutch pinion gear moves outwards. If the clutch pinion gear does not move, replace the magnetic switch assembly. 6LPA Service Manual 10-17 © 2007 Yanmar Marine International... - Page 286 Standard no load current: • 12V Type - 180A or less at 11.0V • 24V Type - 90A or less at 24.0V Figure 10-47 0005435 Figure 10-47 6LPA Service Manual 10-18 © 2007 Yanmar Marine International...

- Page 287 Check Charging Circuit Under No Load ........11-9 Check Charging Circuit Under Load........11-10 Alternator Service................ 11-10 Disassembly ................11-10 Inspection and Testing ............11-13 Bearing Service ..............11-15 Assembly ................11-18 6LPA Service Manual 11-1 © 2007 Yanmar Marine International...