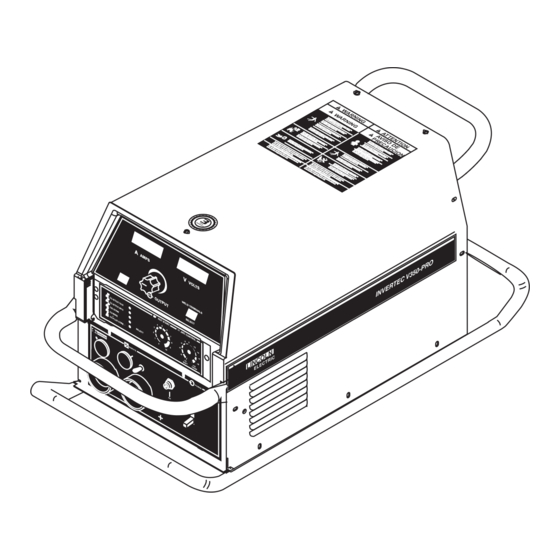

Lincoln Electric INVERTEC V350-PRO Operator's Manual

Lincoln electric welder user manual

Hide thumbs

Also See for INVERTEC V350-PRO:

- Service manual (168 pages) ,

- Operator's manual (56 pages) ,

- Technical specifications (8 pages)

Table of Contents

Advertisement

INVERTEC

Safety Depends on You

Lincoln arc welding and cutting

equipment is designed and built

with safety in mind. However, your

overall safety can be increased by

proper installation ... and thought-

ful operation on your part. DO

NOT INSTALL, OPERATE OR

REPAIR THIS EQUIPMENT

WITHOUT

READING

THIS

MANUAL AND THE SAFETY

PRECAUTIONS CONTAINED

THROUGHOUT. And, most

importantly, think before you act

and be careful.

• Sales and Service through Subsidiaries and Distributors Worldwide •

Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com

RETURN TO MAIN MENU

V350-PRO

®

F F o o r r u u s s e e w w i i t t h h m m a a c c h h i i n n e e s s C C o o d d e e 1 1 0 0 8 8 7 7 3 3 , , 1 1 0 0 8 8 7 7 4 4 , , 1 1 0 0 8 8 7 7 6 6 , , 1 1 0 0 9 9 3 3 4 4 , , 1 1 1 1 4 4 4 4 5 5

C C

-S

T IC

K

C C

7 0

-S

1 8

T IC

K

T IG

6 0

1 0

G TA

W

C V

-W

IR

E

C V

-F L

U X

C O

R E

D

W A

R N

IN

G

R E

w

NRTL/C

OPERATOR'S MANUAL

• World's Leader in Welding and Cutting Products •

1 1 1 1 4 4 8 8 1 1 , , 1 1 1 1 4 4 8 8 2 2 , , 1 1 1 1 4 4 8 8 4 4

A

A M

P S

V

V O

L T

S

A

O U

T P

W E

U T

L D

T E

R M

IN A

L S

H O

S E

T S

L E

T A

C T

R T

4

5

3

S E

6

L E

C T

2

A R

C

C O

7

N T

1

R O

L

-2

8

-4

0

0

9

-6

+ 2

M O

10

T E

+ 4

-8

+ 6

-1 0

S O

F T

+ 8

+ 10

C R

IS P

P O

W

E R

O N

O F

F

Copyright © Lincoln Global Inc.

IM731-C

October, 2007

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Lincoln Electric INVERTEC V350-PRO

- Page 1 INVERTEC F F o o r r u u s s e e w w i i t t h h m m a a c c h h i i n n e e s s C C o o d d e e 1 1 0 0 8 8 7 7 3 3 , , 1 1 0 0 8 8 7 7 4 4 , , 1 1 0 0 8 8 7 7 6 6 , , 1 1 0 0 9 9 3 3 4 4 , , 1 1 1 1 4 4 4 4 5 5 Safety Depends on You Lincoln arc welding and cutting equipment is designed and built...

-

Page 2: California Proposition 65 Warnings

351040, Miami, Florida 33135 or CSA Standard W117.2-1974. A Free copy of “Arc Welding Safety” booklet E205 is available from the Lincoln Electric Company, 22801 St. Clair Avenue, Cleveland, Ohio 44117-1199. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS. -

Page 3: Electric Shock Can Kill

ELECTRIC SHOCK can kill. 3.a. The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these “hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands. - Page 4 WELDING and CUTTING SPARKS can cause fire or explosion. 6.a. Remove fire hazards from the welding area. If this is not possible, cover them to prevent the welding sparks from starting a fire. Remember that welding materials from welding can easily go through small cracks and openings to adjacent areas.

- Page 5 PRÉCAUTIONS DE SÛRETÉ Pour votre propre protection lire et observer toutes les instructions et les précautions de sûreté specifiques qui parraissent dans ce manuel aussi bien que les précautions de sûreté générales suiv- antes: Sûreté Pour Soudage A LʼArc 1. Protegez-vous contre la secousse électrique: a.

- Page 6 Electric for advice or information about their use of our products. We respond to our customers based on the best information in our posses- sion at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability, with respect to such infor- mation or advice.

-

Page 7: Table Of Contents

TABLE OF CONTENTS Installation ...Section A Technical Specifications ...A-1 Physical Dimensions ...A-2 Safety Precautions ...A-3 Select Suitable Location...A-3 Stacking ...A-3 Tilting...A-3 Input and Grounding Connections ...A-3 Power Cord Connection ...A-3 Connection of Wire Feeders to V350-PRO ...A-3,A-4 Remote Control of Invertec ...A-5 Undercarriage Mountings...A-5 Parallel Operations...A-5 ________________________________________________________________________... -

Page 8: Installation

Select The output cable size based upon the following chart. Cable sizes for Combined Length of Electrode and Work Cable (Copper) 75C rated: DUTY CYCLE CURRENT 100% INSTALLATION INVERTEC V350-PRO INPUT AT RATED OUTPUT Rated DC Output Output Amps/Volt Range... -

Page 9: Physical Dimensions

Height Construction and Factory 14.8”(373mm) Advanced Process 14.8”(373mm) and Rack OPERATING TEMPERATURE RANGE -20°C to +40°C * Overall Length Including Handle, 27.8” (706mm) INSTALLATION PHYSICAL DIMENSIONS Width Depth 13.3”(338mm) 27.8” *(706mm*) 13.3”(338mm) 27.8” *(706mm*) TEMPERATURE RANGES STORAGE TEMPERATURE RANGE INVERTEC® V350-PRO Weight with Cord 81.0 Lbs.(36.7 Kg) 81.5 Lbs.(37.0 Kg) -

Page 10: Safety Precautions

U.S.National Electrical Code. ---------------------------------------------------------------------- SELECT SUITABLE LOCATION The Invertec V350-PRO will operate in harsh environments. Even so, it is important that simple preventative measures are followed in order to assure long life and reliable opera- tion. - Page 11 LN-10 Connection Instructions An LN-10 can only be used with the “Factory” & “Advanced Process” versions of the 350-Pro. • Turn the Invertec power switch "off" • Connect the K1505 control cable from the LN-10 to the 14-pin MS-style connector. •...

-

Page 12: Remote Control Of Invertec

General Instructions for Connection of Wire Feeders to V350-Pro Wire feeders other than those listed above may be used provided that the auxiliary power supply rating of the V350-Pro is not exceeded. K867 universal adapter plug is required. See connection diagram S24985 on page F-4. -

Page 13: Operation

----------------------------------------------------------- GENERAL DESCRIPTION The Invertec V350-Pro offers multi-process CV, CC, and DC welding and is rated 350 amps, 34 volts at a 60% duty cycle. The V350-Pro is available in either a Construction version (no wire feeder connection and auxiliary power) and a Factory &... - Page 14 STICK = ON CV = REMOTE TIG = REMOTE if remote output controls are attached to the machine. TIG = 0N if remote output controls are not attached to the machine. For all versions, these trigger modes can be over-ridden (switched) with the WELD TERMINALS push button.

- Page 15 • The Arc Control regulates the Arc Force to adjust the short circuit current. The minimum setting (-10) will produce a "soft" arc and will produce minimal spatter. The maximum setting (+10) will produce a "crisp" arc and will minimize electrode sticking. TIG GTAW: The TIG mode features continuous con- trol from 5 to 425 amps.

-

Page 16: Advanced Process Panel

7A. ADVANCED PROCESS PANEL (See Figure 2) To program Welding modes. Select knob is used to Scroll through all Welding modes. The Memory button is used to store and access Welding modes into loca- tions M1 thru M8. Modes: In addition to the 5 welding modes described in SEC- TION 7, the Advance Process Panel allows you to select the Following additional modes. - Page 17 You will need to push the Memory button to recall the original settings in M1. Note: After all memoryʼs M1 thru M8 are used and the welder needs to store another welding process, a new welding process will overwrite what was originally in the memory and will read,...

-

Page 18: Weld Mode Details

WELD MODE DETAILS: Mode Range Stick Soft 5 - 425 amps Stick Crisp 5 - 425 amps GTAW (Tig mode) 5 - 425 amps GMAW - CV 10 - 45 volts FCAW-SS 10 - 45 volts ADVANCED PULSE PANEL WELDING PROGRAMS Gouging 60 - 425 amps The gouging mode is a low power version of other Lincoln welding GMAW - Power... -

Page 19: Pulse Programs

MODE .030 Steel 65 - 1200 .035 Steel 55 - 800 .045 Steel 50 - 700 .052 Steel 75 - 550 .045 Metal Core 50 - 650 .052 Metal Core 50 - 500 .030 Stainless Ar Blends 85 - 770 .030 Stainless He Ar CO2 110 - 770 .035 Stainless Ar Blends... -

Page 20: Lower Case Panel

V350-Pro or the welding output) The supply should be capable of supplying at least 20mA. • 0 volts supplied to 76 will set the Invertec V350-Pro to minimum output for the mode that has been selected while 10 volts supplied to 76 will set the Invertec V350-Pro to the maximum output for the mode. -

Page 21: Auxiliary Power

AUXILIARY POWER • 115VAC, 42VAC and 24VAC power is available from the 14-pin MS-style connector. The Construction model of the Invertec V350-Pro does not have the 14-pin MS-style connector) These sup- plies are intended to supply power for auxiliary equipment like wire feeders and the TIG Module. -

Page 22: Accessories

OPTIONS / ACCESSORIES • K2176-1 Twist-Mate to Lug Adapter • K1764-1 Inverter and Feeder Cart • K1557 Swivel Kit • K1702-1 Dual Cylinder Kit (For K1764-1) • K1838-1 Valet Style Undercarriage Welding Cable Connectors: • K852-70 1/0-2/0 cable • K852-95 2/0-3/0 cable Twist-Mate Plugs and Receptacles are not used with Code 11445. -

Page 23: Maintenance

SAFETY PRECAUTIONS WARNING ELECTRIC SHOCK can kill. • Do not touch electrically live parts or electrode with skin or wet clothing. • Insulate yourself from work and ground • Always wear dry insulating gloves. ------------------------------------------------------------------------ EXPLODING PARTS can cause injury. •... -

Page 24: How To Use Troubleshooting Guide

HOW TO USE TROUBLESHOOTING GUIDE Service and Repair should only be performed by Lincoln Electric Factory Trained Personnel. Unauthorized repairs performed on this equipment may result in danger to the technician and machine operator and will invalidate your factory warranty. For your safety and to avoid Electrical Shock, please observe all safety notes and precautions detailed throughout this manual. -

Page 25: Troubleshooting

Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed. TROUBLESHOOTING POSSIBLE CAUSE 1. Contact your local authorized Lincoln Electric Field Service facil- ity for technical assistance. 1. Make certain that the fuses or breakers are properly sized. See installation section of the manual for recommended fuse and break- er sizes. - Page 26 Observe all Safety Guidelines detailed throughout this manual PROBLEMS (SYMPTOMS) Thermal symbol is lit Wire feeder wonʼt work. Apparently no power to wire feeder If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

-

Page 27: Fault Codes

Observe all Safety Guidelines detailed throughout this manual Code Description Primary over current. CAP bank A under voltage. CAP bank B under voltage. CAP bank A over voltage. CAP bank B over voltage. Soft start Failed. Glitch on the primary over current fault interrupt;... -

Page 28: Displays

Observe all Safety Guidelines detailed throughout this manual Displays Description Scrolling dash Appears at power up while the machine is going through its self configu- ration "Err" "####" Fault code display. The first fault to occur will be displayed for three seconds. - Page 29 DIAGRAMS INVERTEC® V350-PRO...

- Page 30 DIAGRAMS INVERTEC® V350-PRO...

- Page 31 DIAGRAMS INVERTEC® V350-PRO...

- Page 32 DIAGRAMS INVERTEC® V350-PRO...

- Page 33 DIAGRAMS INVERTEC® V350-PRO...

- Page 34 DIAGRAMS INVERTEC® V350-PRO...

- Page 35 DIAGRAMS INVERTEC® V350-PRO...

- Page 36 DIAGRAMS INVERTEC® V350-PRO...

-

Page 37: Dimension Print

DIMENSION PRINT INVERTEC® V350-PRO... - Page 38 ● WARNING ● Spanish ● AVISO DE PRECAUCION ● French ● ATTENTION ● ● German WARNUNG ● Portuguese ● ATENÇÃO ● Japanese Chinese Korean Arabic ● ● ● ● ● ● ● ● ● ●...

- Page 39 ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● ● Spanish ● PRECAUCION French ● ATTENTION ● German WARNUNG Portuguese ● ● Japanese Chinese Korean Arabic WARNING AVISO DE ATENÇÃO...

- Page 40 • World's Leader in Welding and Cutting Products • • Sales and Service through Subsidiaries and Distributors Worldwide • Cleveland, Ohio 44117-1199 U.S.A. TEL: 216.481.8100 FAX: 216.486.1751 WEB SITE: www.lincolnelectric.com...

Need help?

Do you have a question about the INVERTEC V350-PRO and is the answer not in the manual?

Questions and answers