Koden MDC-2900 Series Installation Manual

Hide thumbs

Also See for MDC-2900 Series:

- Operation manual (191 pages) ,

- Installation manual (81 pages) ,

- Operation manual (153 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Koden MDC-2900 Series

- Page 2 Koden Electronics Co., Ltd. The technical descriptions contained in this publication are subject to change without notice. Koden assumes no responsibility for any errors, incidental or consequential damages caused by misinterpretation of the descriptions contained in this publication.

-

Page 3: Important Notice

Koden is not liable for damages of accompaniment (change/loss of memorized content, loss of business profit, stop of business) arisen from use or failure of our products. If the stored data are changed or lost, irrespective of causes of troubles and damages, Koden is not liable for them. ... -

Page 4: For Your Safe Operation

MDC-2900 Series For Your Safe Operation For Your Safe Operation Symbol used in this Installation Manual This m anual uses the following symbols. Understand the meaning of each symbol and implement the maintenance and inspection. Symbol Meaning Mark for warning This symbol denotes that there is a risk of death or serious injury when not dealing with it correctly. -

Page 5: Caution Item On Equipment

For Your Safe Operation MDC-2900 Series Caution Item on Equipment Caution on a high voltage inside. A high voltage, which may risk your life, is used. This high voltage remains in the circuit after you have powered off switch. To prevent touching the high voltage circuit inadvertently, the protective cover is provided to the high voltage circuit and the high voltage caution label is affixed. -

Page 6: Caution Item On Handling

MDC-2900 Series For Your Safe Operation Caution Item on Handling Caution on the rotating aerial The radar antenna may start to rotate without notice. Please stand clear from the antenna for your safety. Caution on electromagnetic disturbance The operating Antenna & Scanner unit radiates high-energy electromagnetic wave. - Page 7 For Your Safe Operation MDC-2900 Series Do not disassemble or modify. It may lead to trouble, fire, smoking or electric shock. In case of trouble, contact our dealer or our company. In case of smoke or fire, switch off the power in the boat and the power of equipment.

-

Page 8: Disposal Of Used Cell And This Radar

MDC-2900 Series Disposal of used cell and this radar Disposal of used cell and this radar A high-energy density lithium ion cell is built in this radar. Improper disposal of a lithium ion cell is discouraged as the cell has a possibility of short-circuiting. -

Page 9: Table Of Contents

Contents MDC-2900 Series Contents Document Revision History ...................... i Important Notice ........................ii For Your Safe Operation......................iii Symbol used in this Installation Manual ..................iii Caution Item on Equipment ....................iv Caution Item on Handling ......................v Disposal of used cell and this radar ..................vii Contents .......................... - Page 10 MDC-2900 Series Contents 2.4.3 Connecting the Display unit to GPS Compass (KGC-1) ........... 2-15 2.4.4 Connecting the KGC-1 or GTD-110/150 to a Display unit ......... 2-16 2.4.5 Connecting the Display unit to KGC-1, GTD-110/150 and KGB-3 ......2-17 2.4.6 Connecting the 2nd monitor with MRD-105 .............. 2-18 2.4.7 Connecting the VDR or the 2nd Monitor (MRM-105) and the Alarm output ....

-

Page 11: Contents

Contents MDC-2900 Series 3.3.2 Setting when there is difference in GAIN at changeover of range ......3-12 3.3.3 Preset of SEA AUTO level ..................3-13 3.3.4 Change of maximum value of [SEA] knob ..............3-14 3.3.5 Use of PRE-SEA suppression under the Manual SEA ..........3-14 3.3.6 When there is difference in the effect in Manual SEA suppression at changeover of... - Page 12 MDC-2900 Series Contents 4.3.2.5 No response from the Antenna Scanner unit ............4-12 4.3.2.6 Sensitivity failure ....................4-13 4.3.2.7 No display of ship’s bearing, speed and latitude/longitude ........4-14 4.3.2.8 Operation unit abnormality ..................4-15 4.3.2.9 Antenna Scanner unit abnormality ................. 4-16 4.3.2.10 Synchronization of screen abnormality ..............

-

Page 13: System Configuration

System Configuration MDC-2900 Series System Configuration MDC-2960/2910/2920 series system configuration Antenna RW701A-04 RW701A-06 Scanner unit RB717A RB718A RB719A Connecting cable 242J159098B-15M (Standard) 242J159098C-20M 242J159098D-30M 242J159098E-**M (100m Max.) Alarm out 10P J1 CW-576-0.5M Display unit CW-560-2M CW-387-5M MRD-105 12P J3 CW-561-10M... - Page 14 MDC-2900 Series System Configuration MDC-2960BB/2910BB/2920BB series system configuration Antenna RW701A-04 RW701A-06 Scanner unit RB717A RB718A RB719A Connecting cable 242J159098B-15M (Standard) 242J159098C-20M 242J159098D-30M 242J159098E-**M (100m Max.) Alarm out SXGA 10P J1 CW-576-0.5M Monitor Display Processor unit CW-560-2M CW-387-5M MRM-105 12P J3...

-

Page 15: Configuration Equipment

Configuration Equipment MDC-2900 Series Configuration Equipment Standard configuration list MDC-2960 Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft 6 kg RW701A-06 6 ft 8 kg Scanner unit RB717A 6 kW 17 kg Display unit MRD-105 15 kg Operation unit MRO-105 1.8 kg... - Page 16 MDC-2900 Series Configuration Equipment MDC-2920 Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft RW701A-06 6 ft 8 kg Scanner unit RB719A 25 kW 21 kg Display unit MRD-105 15 kg Operation unit MRO-105 1.8 kg Connecting cable 242J159098B-15M...

- Page 17 Configuration Equipment MDC-2900 Series MDC-2910BB No. Name Type Comment Weight/ Quantity Length Antenna RW701A-04 4 ft 6 kg RW701A-06 6 ft 8 kg Scanner unit RB718A 12 kW 17 kg Processor unit MRM-105 12.4 kg Operation unit MRO-105 1.8 kg...

- Page 18 MDC-2900 Series Configuration Equipment Spare parts list SP-100 Name Specification Comment Type Quantity Usage (Dimension) Fuse F-1065-15A Normal Tubular Main power type (·6.4 x 30) Fuse MF51NN250V5A Normal Tubular Motor power type (·5.2 x 20) Fuse FGMB-A 250V0.5A Normal Tubular...

- Page 19 Configuration Equipment MDC-2900 Series Options (Common) Name Specification Comment Weight /Dimension /Quantity Gyro converter qwerty-electronik S2N, U/N 9028C Log pulse NMEA qwerty-electronik L1N, U/N 9181A converter 200pulse/NM only Power rectifier unit PS-010 5A fuse attached 3.5 kg VL-PGS001 VEINLAND GmbH 4.5kg...

-

Page 20: Chapter 1 Prior To Installation

MDC-2900 Series Chapter 1 Prior to installation Chapter 1 Prior to installation 1.1 Installation precautions In order to obtain the maximum performance of radar systems, this radar system should be installed by qualified engineers in charge of installation and maintenance. Installation procedures include the following: (1) Unpacking of components;... - Page 21 Chapter 1 Prior to installation MDC-2900 Series This area is prohibited from setting up of the structure. When the antenna height Minimum range rises, Minimum Range becomes long. 16° Antenna Antenna Minimum =15m height -3.5)×3.49 height(m) range (m) Navigation buoy with corner reflector Figure 1.1 Vertical pattern of recommended antenna installation position.

-

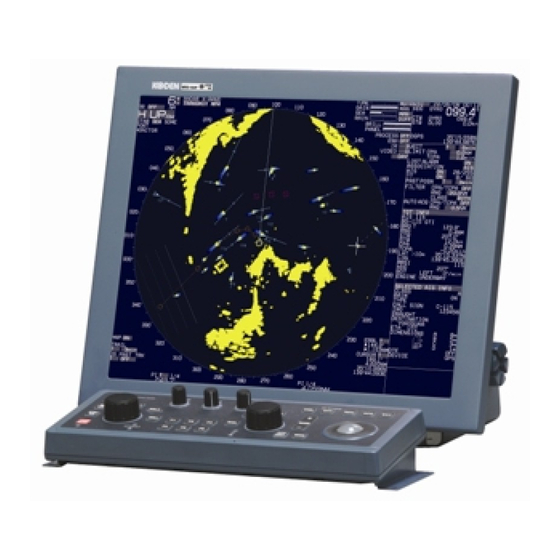

Page 22: Display Unit And Operation Unit

MDC-2900 Series Chapter 1 Prior to installation 1.4.2 Display unit and Operation unit (1) The orientation of the Display unit shall be such that the user is looking ahead, the lookout view is not obscured and there is minimum ambient light on the display viewing surface. -

Page 23: Chapter 2 Method Of Installation

MDC-2900 Series Chapter 2 Method of installation Chapter 2 Method of installation 2.1 How to install the Antenna-Scanner unit 2.1.1 Installation of the Antenna-Scanner unit The Antenna-Scanner unit is equipped to orient the notch of the attachment to stern as shown in Figure 2.1. -

Page 24: Mounting Antenna

(1) Remove the protective cap on top of the Scanner unit rotational shaft. (2) Remove four bolts tentatively fixed to the base of the antenna and install the Scanner unit to the rotating base. Align the direction of antenna radiation side (KODEN –mark side) with the projection mark on the rotating base. -

Page 25: Connecting The Cables

MDC-2900 Series Chapter 2 Method of installation 2.1.3 Connecting the cables Open Antenna 6kW (RB717A), 12kW (RB718A) (1) Make sure power supply of the Scanner unit is OFF. (2) Disassemble the front cover of the Scanner unit from the rear cover by loosening fixing bolts. - Page 26 Chapter 2 Method of installation MDC-2900 Series Open Antenna 25kW (RB719A) (1) Make sure power supply of the Scanner unit is OFF. (2) Disassemble the front cover of the Scanner unit from the rear cover by loosening fixing bolts. (3) Remove the TR unit by disconnecting the connector J3 and J4 after loosening fixing bolts of the TR unit.

-

Page 27: Interconnection Diagram Of Cable

MDC-2900 Series Chapter 2 Method of installation 2.2 Interconnection diagram of cable Antenna-Scanner unit Display unit Description Cable colour Cable colour Description +250V Purple Purple +250V Blue +24V Yellow Orange (thick) +12V +40V Red (thick) Yellow +40V Yellow (thick) Shield... -

Page 28: Installation Of The Display Unit

Chapter 2 Method of installation MDC-2900 Series 2.3 Installation of the Display unit The Display unit can be mounted on a table or a panel. The procedure is as follows. 2.3.1 Installation of MRD-105 2.3.1.1 Table mounting of MRD-105 (1) Remove four knob bolts from which the Display unit is secured on the mounting bracket. - Page 29 MDC-2900 Series Chapter 2 Method of installation NOTE: In the case of mounting the Display unit on the table, some maintenance space is required for cabling, connector access, fuse replacement, fastening of bolts, etc. as shown in the following figure.

-

Page 30: Flush Mounting Of Mrd-105

Chapter 2 Method of installation MDC-2900 Series 2.3.1.2 Flush Mounting of MRD-105 Preparation: (1) Cut an opening and drill 4.5 mm eight holes with the size shown in Figure 2.8, on the side for attachment of a display unit on a panel. -

Page 31: Installation Of Mrm-105

MDC-2900 Series Chapter 2 Method of installation 2.3.2 Installation of MRM-105 The Processor unit MRM-105 can be mounted on a table or a panel. The procedure is as follows. (1) Drill four nut-holes with the size shown in Figure 2.10. -

Page 32: Installation Of Mro-105

Chapter 2 Method of installation MDC-2900 Series 2.3.3 Installation of MRO-105 2.3.3.1 Installation of Operation unit MRO-105 Remove the corner guard caps of four places on the Operation unit. Insert the tip of a small flat-blade screwdriver carefully between a corner guard cap and the front bezel of Operation unit to make a gap, and then pinch and pull up the corner guard cap with fingers. - Page 33 MDC-2900 Series Chapter 2 Method of installation Mounting dimesions (15 5/32) (1 37/64) (1 37/64) Unit : mm(inch) Maintenance space Figure2.12 Maintenance space necessary for Operation unit 0092629012-07 2-11...

-

Page 34: Installation Of Flush Mounting The Operation Unit Mro-105

Chapter 2 Method of installation MDC-2900 Series 2.3.3.2 Installation of Flush mounting the Operation unit MRO-105 Preparation: (1) Cut an opening with the size as shown in Figure 2.13 on the side for mounting a Display unit on the panel. -

Page 35: Cable Connection To A Display Unit

MDC-2900 Series Chapter 2 Method of installation 2.4 Cable connection to a Display unit 2.4.1 Cable connection for MRD-105 Display unit Attach the connectors of cables from an Antenna-Scanner unit, power source and Operation unit, to corresponding receptacles as shown in Figure 2.15. -

Page 36: Cable Connection For Mrm-105 Processor Unit

Chapter 2 Method of installation MDC-2900 Series 2.4.2 Cable connection for MRM-105 Processor unit Attach the connectors of cables from an Antenna-Scanner unit, power source and Operation unit, to corresponding receptacles as shown in Figure 2.16. The monitor should be able to input analog RGB. -

Page 37: Connecting The Display Unit To Gps Compass (Kgc-1)

MDC-2900 Series Chapter 2 Method of installation 2.4.3 Connecting the Display unit to GPS Compass (KGC-1) When using the GPS Compass (KGC-1), connect the J6 port of the Display unit to DATA2 connector of KGC-1. This connection allows high data speed. -

Page 38: Connecting The Kgc-1 Or Gtd-110/150 To A Display Unit

Chapter 2 Method of installation MDC-2900 Series 2.4.4 Connecting the KGC-1 or GTD-110/150 to a Display unit Note: Refer to each operation manual for the connections to other devices. GPS Plotter GTD-110/150 NMEA for Zoom GTD-110/150 GPS sencer for GTD-110/150... -

Page 39: Connecting The Display Unit To Kgc-1, Gtd-110/150 And Kgb-3

MDC-2900 Series Chapter 2 Method of installation 2.4.5 Connecting the Display unit to KGC-1, GTD-110/150 and KGB-3 Note: Refer to each operation manual for the other devices. KBG-3 GTD-110/150 GPS Plotter GTD-110/150 +12V KGC-1 NMEA for Zoom GTD-110/150 N.C. Wiring diagram in JB-10... -

Page 40: Connecting The 2Nd Monitor With Mrd-105

Chapter 2 Method of installation MDC-2900 Series 2.4.6 Connecting the 2nd monitor with MRD-105 The monitor should be able to input analog RGB. The resolution is SXGA of the VESA standard. mini D-sub15pin connector CW-560-2M or equivalent (VGA cable) Figure2.20 Cable connection of Display unit to ext. monitor 2.4.7 Connecting the VDR or the 2nd Monitor (MRM-105) and the Alarm output... -

Page 41: Connecting The Gyro Converter Unit Or Thd

MDC-2900 Series Chapter 2 Method of installation 2.4.8 Connecting the Gyro converter unit or THD GYRO SYNCHRO or Step signal S2N Gyro converter or NSK unit Zoom CW-406-5M CFQ-6998 Serial signal CW-406-5M IEC 61162-2 Cable connector pin assignment CW-406 Signal Cautions: 1. -

Page 42: Cable Connection For Nav, Epfs And Sdme Or Log

Chapter 2 Method of installation MDC-2900 Series 2.4.10 Cable connection for NAV, EPFS and SDME or Log Zoom CW-376 cable connecter pin assignment Gyro CW-376 CW-376 L1N Log pulse CW-376 NMEA converter J4, J5 & J6 or NSK unit EPFS... -

Page 43: Cable Connection For Interswitch

MDC-2900 Series Chapter 2 Method of installation 2.4.11 Cable connection for interswitch 2.4.11.1 Cable connection for cross, dual and independent connection In the case of a dual, cross, or master/slave connection using two sets of radar system or Display unit, the remote cable and data cable are connected as shown in the figure. -

Page 44: Cable Connection For Secondary Display Unit Used As A Monitor

Chapter 2 Method of installation MDC-2900 Series 2.4.11.2 Cable connection for secondary Display unit used as a monitor When the secondary Display unit for radar is used as monitor, the remote cable is connected as follows. Primary Display unit (MRD-105)/... -

Page 45: Chapter 3 Setup After Installation

MDC-2900 Series Chapter 3 Setup after installation Chapter 3 Setup after installation Some setup procedures are required after system installation. Before performing the setup procedures, please check the following items for normal operation: The onboard power supply powering the radar system has the specified voltage. -

Page 46: Adjustment Of Transmitting Delay Time (Trigger Delay)

Chapter 3 Setup after installation MDC-2900 Series (1) Change the range scale to 12 NM or more by pressing “+” (or “-”) key on the Operation unit. Find the stable object such as the mountain or the island of 6 NM or more as far as possible. -

Page 47: Display Bearing Adjustment

MDC-2900 Series Chapter 3 Setup after installation 3.1.5 Display bearing adjustment The bearing of a target on the radar screen can be adjusted. (1) Change the range scale to 1 NM or more by pressing “+” (or “-”) key on the Operation unit. -

Page 48: Function Key Usage

Chapter 3 Setup after installation MDC-2900 Series 3.1.7 Function key usage For quick function access, this radar is provided with six dedicated function keys (“F1”, “F2”, “F3” , “F4” , “F5” , “F6”). You can switch to a prespecified function by pushing each key. -

Page 49: Setup Interface

MDC-2900 Series Chapter 3 Setup after installation 3.2 Setup Interface For display mode, TT(ARPA), true ship’s trail and own ship’s trail, it is necessary to input ship’s bearing data and ship’s speed data from other devices. In addition, for AIS, mapping function, display of own ship’s information and display of latitude and longitude, it is necessary to input... -

Page 50: Setup Time

Chapter 3 Setup after installation MDC-2900 Series 3.2.1 Setup TIME Set up time related items to be displayed in the top right part of the screen. Select information source of time to be indicated. Select [MAINTENANCE] => [I/O] => [TIME] => [EPFS or CLOCK] and then press [ENT] key. -

Page 51: Set Up Heading Interfaces

MDC-2900 Series Chapter 3 Setup after installation When way point and Rout are not input (Plotter and ECDIS are not connected): [MAP] => [MONITORED ROUT] => [OFF], and then press [ENT] key after selection. [MAP] => [WPT ID DISP] => [OFF], and then press [ENT] key after selection. -

Page 52: Connection Of Output Device Of Ship's Bearing (Thd) Such As Gyro To Obtain Ship's Bearing Signal

Chapter 3 Setup after installation MDC-2900 Series 3.2.3.3 Connection of output device of ship’s bearing (THD) such as gyro to obtain ship’s bearing signal In the case of a gyro with analogue signal output such as step signal or synchronous signal (see 2.4.6 for connection), insert a S2N gyro convertor or a NSK unit between them, convert the... -

Page 53: Setting Of Cog/Sog To Be Used For Ground Stab

MDC-2900 Series Chapter 3 Setup after installation AUTO: Selection is done in order to priority shown in the table in 6.1.2. Caution: In NSK, speed pulses are required to have been input from speed LOG unit. Stability against water can be reached with calculation of ship’s bearing and speed against water. -

Page 54: Setting Of Output Of Nav And Epfs

Chapter 3 Setup after installation MDC-2900 Series Selection of sentences to be used for [OFFSET] When the geodetic system in navigator and that in the map used are different, the position may become different even with the same values of latitude and longitude. In this case, input of [OFFSET] allows these positions to be matched. -

Page 55: Alr Output

MDC-2900 Series Chapter 3 Setup after installation [MAINTENANCE] => [I/O] => [DETAIL] => [TLL OUT] => [TT, MARK or TARGET], and then press [ENT] key after selection. Set values: [TT], [MARK], [TARGET] TT: The position of automatic tracking target captured is output with the cycle set in 3.2.8. -

Page 56: Changing Of Formats Of Input/Output Ports Of Navigation Devices, Position And Ship Speed (Iec 61162)

Chapter 3 Setup after installation MDC-2900 Series 3.2.12 Changing of formats of input/output ports of navigation devices, position and ship speed (IEC 61162). When the data is correctly input in each port and is not displayed on the screen, the formats of signals (IEC 61162) may be unmatched. -

Page 57: Preset Of Sea Auto Level

MDC-2900 Series Chapter 3 Setup after installation Adjustment method: Press [ + ] key (or [ - ]) key of the range on the transmission screen to set the range of the screen at 6 NM. Press [SP/LP] key to set pulse width to be [LP 1]. -

Page 58: Change Of Maximum Value Of [Sea] Knob

Chapter 3 Setup after installation MDC-2900 Series 3. Follow the steps below. Select [MAINTENANCE] => [PRESET] => [SEA AUTO LAND] => to highlight the last digit value. Enter the same value by rolling the trackball up and down as SEA AUTO SEA. And then press [ENT] key. -

Page 59: When There Is Difference In The Effect In Manual Sea Suppression At Changeover Of Ranges

MDC-2900 Series Chapter 3 Setup after installation 3.3.6 When there is difference in the effect in Manual SEA suppression at changeover of ranges The level of suppression effect of Manual SEA can be set for each pulse width corresponding to each range. -

Page 60: Set Preset Diff (Ftc)

Chapter 3 Setup after installation MDC-2900 Series 3.3.9 Set preset DIFF (FTC) Preset FTC can be set. This is a function to make FTC effective even when anti-rain clutter suppression knob is set at minimum. This function has also effect to moderate the effect against turned angle of the knob and to make adjustment easy. -

Page 61: Change Of Background Noise And Target Signal Gradation

MDC-2900 Series Chapter 3 Setup after installation 3.3.13 Change of background noise and target signal gradation With this function, it is possible to make edges of target images sharper and also to change the colors of sea clutter and rain to different colors with more neutral tone. -

Page 62: Setting Of Ccrp (Common Reference Position) And Own Ship Profile

Chapter 3 Setup after installation MDC-2900 Series 3.4 Setting of CCRP (common reference position) and own ship profile To match the measured values with those of GPS and gyro, a common reference position can be set. In addition, own ship profile can be displayed overlapping on the radar screen. -

Page 63: Backup Of Set Values

MDC-2900 Series Chapter 3 Setup after installation 3.6 Backup of set values The set values of radar functions can be stored internally and externally to retrieve them. All changes after delivery from plant such as menu settings, screen setting and mapping input data can be recorded. -

Page 64: Use Of Interswitch Function

Chapter 3 Setup after installation MDC-2900 Series 3.7 Use of interswitch function Connecting 2 sets of radars or 2 sets of Display units, the radars can be used with switching over. As for cable connection, see 2.4.11. 3.7.1 Cross connection... -

Page 65: Master/Slave Connection

MDC-2900 Series Chapter 3 Setup after installation When there are 2 sets of radars and one of the 2 aerial wires has been put out of commission due to degradation of its performance, images from normal aerial wire can be seen on the both Display units. -

Page 66: Connection Of Monitor

Chapter 3 Setup after installation MDC-2900 Series pulse width from SLAVE to be changed without permission. However, it is necessary to set the range of SLAVE in line with the pulse width of the range used in MASTER because SLAVE cannot control aerial wires. -

Page 67: Setup Of Antenna Location Information

Therefore, environmental factors affect on each set of radar will be different. MDC-2900 series radars are equipped with a function to display antenna position on the screen to remind operators of these environmental factors. Example of setting: (1) Press [MENU] key and follow [SYSTEM] =>... -

Page 68: Chapter 4 Troubleshooting And On-Board Repair

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair Chapter 4 Troubleshooting and on-board repair In this chapter we provide troubleshooting procedures to find malfunction parts on a ship. 4.1 Necessary information at the time of repair request Please note the following items:... -

Page 69: Alarm Display List

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.2.1.1 Alarm display list Table 4.1 Alarm display list of radar Contents Cause TT(ARPA) has been lost. Tracked target is lost. Ref tracked target is lost. Ref tracked target is lost. Tracked target exceeded the Tracked target has turned in dangerous target. - Page 70 MDC-2900 Series Chapter 4 Troubleshooting and on-board repair Version No. of backup data does not agree. Illegal data of loading. Write-in of backup data into logic PCB has Flash memory error. failed. Connector of Antenna may not be connected Antenna not connected.

-

Page 71: Warning Display List

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.2.1.2 Warning display list Warning is displayed when the function is not available because of lack of information required for its operation. Table 4.2 Warning list Contents Cause Captured targets beyond the maximum tracking Tracked target full. - Page 72 MDC-2900 Series Chapter 4 Troubleshooting and on-board repair Attempted to change mode during operation of Mode Hold. performance monitor. The mode is fixed at H-UP. During starting up of performance monitor, attempted Range Hold. to change the range. The range is fixed at 24 NM.

-

Page 73: Status Indicator Lamp

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.2.2 Status indicator lamp Three LED (Light Emitting Diodes) lamps are provided on the logic PCB in the Display unit. The operational conditions are indicated by these LED's. Refer to the following table for details. -

Page 74: Malfunction Diagnostics

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3 Malfunction diagnostics This chapter specifies necessary information required troubleshooting and repair of the radar system. 4.3.1 Malfunction detection step As a first step of on-board repair, refer to the following tables describing outlines of malfunction diagnostics procedure. -

Page 75: Malfunction Diagnostics Flow Chart

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2 Malfunction diagnostics flow chart The following malfunction analysis chart can be used by service personnel for malfunction diagnostics and location of defect module. This chart shows flow chart of dignostics for basic malfunction troubleshooting. -

Page 76: Initial Malfunction Diagnostics 2

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.2 Initial malfunction diagnostics 2 Is the Operation unit Connect connectors connector connected to the correctly. Display unit correctly? Is the main power fuse (F1) Is fuse properly rated? Replace fuse. blown? -

Page 77: Other Faults (Display Unit)

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.3 Other faults (Display unit) Other faults Is there a part displayed Is the screen display in white or black on the LCD unit failure normal? screen because any signal is not displayed? Is there a part not After "ALL RESET"... -

Page 78: Abnormal Display

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.4 Abnormal display LCD completely blank or it doesn't display Is brilliance control of Display brilliance is set in display set to maximum? the maximum. Go to Is the screen [4.3.2.10 Synchronization... -

Page 79: No Response From The Antenna Scanner Unit

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.5 No response from the Antenna Scanner unit Is an antenna connector P7 of the Display connected Connect the antenna connection correctly? connector P7 correctly. Pull out antenna connector P7 in the Display. -

Page 80: Sensitivity Failure

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.6 Sensitivity failure Is noise observed in Go to Is the alarm message background of radar [4.3.2.9 Antenna Scanner "Alarm, Radar video picture at maximum unit abnormality] in page abnormal" displayed? gain? -

Page 81: No Display Of Ship's Bearing, Speed And Latitude/Longitude

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.7 No display of ship’s bearing, speed and latitude/longitude Is the navigation data (IEC 61162-1) normally input from the connectors (J4, J5, J6) and displayed? When a connector number to be checked is selected in Is the polarity of signals the process of MENU >... -

Page 82: Operation Unit Abnormality

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.8 Operation unit abnormality Is the connection of the Can radar power on? (Is following logic PCBs normal? the lamp of power source Connect them in (1) J710 and power supply ON, and does the buzzer normal way. -

Page 83: Antenna Scanner Unit Abnormality

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.9 Antenna Scanner unit abnormality When MENU > SYSTEM > BITE > ANT MONITOR > is displayed, are there any abnormal items? IF PCB failure Go to [4.3.2.11 High voltage abnormality] Is the HIGH VOLTAGE abnormal? -

Page 84: Synchronization Of Screen Abnormality

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.10 Synchronization of screen abnormality Synchronization of display is unstable or not synchronized. Can the following signals be observed at the connectors J1-7 and J1-8 at the rear of the Display unit? -

Page 85: Pulse Length Control Failure

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.12 Pulse length control failure Pulse length control failure TP2 wave form Is transmitter unit drive signal Modulator PCB failure (modulator PCB TP2) normal? Pulse length A(ns) B(ms) 0.45 to 0.55 Antenna Scanner unit Is +24 V (J1-1 pin of the 0.45 to 0.55... -

Page 86: Rotary Abnormality

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.13 Rotary abnormality Rotary is abnormal. When the antenna rotation is set to regular rotation (24rpm), observe "MENU> SYSTEM> BITE> RATE OF ROTATION". In the Antenna unit, the MOTOR (-) wire of the... -

Page 87: Heading Line And Azimuth Abnormality

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.14 Heading line and Azimuth abnormality Heading line / Azimuth is abnormal. Is “synthesized bearing signal pulse” of modulator PCB J1-7 Pin normal? 1.2 msec Bearing signal Display unit failure 2.5V Heading line signal J1-7 synthesizedbearing signal pulse Is “bearing signal pulse”... -

Page 88: Tt (Arpa) Abnormality

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.15 TT (ARPA) abnormality TT (ARPA) is abnormal. At the placing Is TT in the figure shown the cursor on below ON? Check whether TT OFF, and (ARPA) PCB is present and pushing “ENT”... -

Page 89: Map Display Abnormality

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.16 Map display abnormality Display of map is abnormal. Is the map card Insert the map card Is map displayed on correctly into the card correctly inserted into the screen? the holder? holder. -

Page 90: No Display Of Ais

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.3.2.17 No display of AIS Note: About self diagnosis: AIS is not displayed. When any setting is changed and “AIS self diagnosis” is used for confirmation of the change, close the MENU once and start displaying again. -

Page 91: Other Faults (Antenna Scanner Unit)

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.3.2.18 Other faults (Antenna Scanner unit) No transmission TP2 wave form Is transmitter high voltage Modulator PCB failure fuse (F3) blown? Check connecting cable Is + 250 VDC (J2-1) on between Display unit and... - Page 92 MDC-2900 Series Chapter 4 Troubleshooting and on-board repair Tuning meter failure Is tuning meter voltage of IF IF PCB failure PCB J1-13 about 2 V? Confirm connection between IF PCB J1 and modulator PCB. Auto tuning inoperable Re-initialize auto tuning function.

-

Page 93: Repair

Chapter 4 Troubleshooting and on-board repair MDC-2900 Series 4.4 Repair 4.4.1 Replacement of fuse The location of the fuses is on the back panel of Display unit. Fuse type and rating Application Type, dimension (mm) Fuse characteristic Rating Main power Tubular (φ6.4 x 30) -

Page 94: Replacement Of Internal Battery

MDC-2900 Series Chapter 4 Troubleshooting and on-board repair 4.4.2 Replacement of Internal Battery Internal Battery is used for settings backup. When the battery runs low, all initial settings must be re-setup every time the power is turned on. Exchange method of the internal battery is explained as below. -

Page 95: Chapter 5 Maintenance

MDC-2900 Series Chapter 5 Maintenance Chapter 5 Maintenance 5.1 Regular service and cleaning up Periodic inspection and cleaning is essential to keep the radar system in the good working order for the life of the radar. 5.1.1 Monthly inspection (1) Check whether there is any dirt or soot on the radiating part of the Antenna unit. If any, wipe it with soft cloth soaked in water or soap detergent. - Page 96 Chapter 5 Maintenance MDC-2900 Series Internal structure of the antenna housing Motor Motor brush Turn the screw slowly to counterclockwise using a Motor screwdriver to remove an old motor brush. Motor brush Figure 5.2 Changing the motor brushes 0092629012-07...

-

Page 97: Chapter 6 Input/Output Data

MDC-2900 Series Chapter 6 Input/output data Chapter 6 Input/output data 6.1 Input data 6.1.1 Details of the data input format Check sum: All the data from $ to the check sum position * is calculated by exclusive-OR operation and used as checksum. - Page 98 Chapter 6 Input/output data MDC-2900 Series Datum reference $ - - DTM, ccc, a, x.x, a, x.x, a, x.x, ccc*hh <CR><LF> Check sum Reference datum Formatter Altitude offset, m Talker W84 : WGS84 Lon offset, min, E/W device W72 : WGS72...

- Page 99 MDC-2900 Series Chapter 6 Input/output data Heading true $ - - HDT, xxx.x, T*hh <CR><LF> Check sum Formatter Heading, degrees true Talker device Start of Note for Talker device identifer : sentence Only HE and HN are accepted Water temperature $ - - MTW, x.x, C*hh <CR><LF>...

- Page 100 Chapter 6 Input/output data MDC-2900 Series Routes $ - - RTE, , , W, , c-c, c-c, c-c, c-c*hh <CR><LF> Check sum Current waypoint Formatter Waypoint ID : The first 4 digits are valid to designate Waypoint ID, Talker This field is not used which can be assigned up to 8 kinds maximum.

- Page 101 MDC-2900 Series Chapter 6 Input/output data Waypoint location $ - - WPL, xxxx.xxx, N/S, xxxxx.xxx, E/W, c-c*hh <CR><LF> Check sum Formatter Waypoint identifier : Talker The first 4 digits are valid to designate device Waypoint longitude, E/W waypoint identifier, which can be assigned...

-

Page 102: Priority Of Received Data

Chapter 6 Input/output data MDC-2900 Series 6.1.2 Priority of received data Receiving item Ship’s bearing information HDT > HDM > VTG (True) > VTG (Magnetic) > RMC (HDG) Speed against water (SPD) VHW > VBW (Speed against water in axis direction) Speed against ground VBW (2-axis against ground) >... -

Page 103: Details Of The Radar Data Output

MDC-2900 Series Chapter 6 Input/output data Tracked target message $ RA TTM, x, x x, xxx, T, xx x, xx x, T, x x, x x, N, xx , a, , , M*hh <CR><LF> Check sum Target course, Formatter Type of aquisition... -

Page 104: Interface Specification

Chapter 6 Input/output data MDC-2900 Series 6.4 Interface specification 6.4.1 NAV (J4), EPFS (J5) and SDME (J6) serial data input/output specification Input connector: J4, J5 and J6 Connector used: LTWD-06PMMP-LC Connector acceptable: LTWD-06BFFA-L180 Data connector pin assignment J4-J6 Data connector pin assignment J4, J5 &... -

Page 105: Vdr (External Monitor) And Alarm Output Signal Specification

MDC-2900 Series Chapter 6 Input/output data 6.4.2 VDR (external monitor) and Alarm output signal specification VDR & External Alarm connector Output connector name: VDR & Alarm pin assignment Connector used: LTWBU-10PMMP-LC Pin number Signal name Connector acceptable: LTWBU-10BFFA-L180 R-GND Pin location is shown below. - Page 106 Chapter 6 Input/output data MDC-2900 Series Alarm Output specification Main fuse 15 A On board power Inside of J736 display unit supply + BZ (+) J737 21.6-41.6 VDC Filter BZ (-) On board power supply - I=1 A max Short-circuit...

-

Page 107: Ais Input/Output Specification (J2)

MDC-2900 Series Chapter 6 Input/output data 6.4.3 AIS input/output specification (J2) I/O connector AIS (J2) +Vcc Connector used: LTWD-08PMMP-LC Connector acceptable: LTWBD-08BFFA-L180 Data input A TLP115A IN-A Serial data input (Listener): Data input B Standard signals conforming to IEC61162-2 is IN-B acceptable. -

Page 108: Radar Input/Output Signal Specification

Chapter 6 Input/output data MDC-2900 Series 6.4.4 Radar input/output signal specification I/O connector: J3 Inter Switch Inter Switch connector pin assignment Pin number Signal name Connector used: LTWU-12PMMP-LC VIDEO OUT Connector acceptable: LTWBU-12BFFA-L180 TRIG OUT J3 Remote connector pin assignment... -

Page 109: Talker Device Code Of The Data Output Devices

MDC-2900 Series Chapter 6 Input/output data 6.4.6 Talker device code of the data output devices The device code displayed as talker is shown in the table below. Data output device Talker device code Displayed code Decca navigator device Global positioning system (GPS)

Need help?

Do you have a question about the MDC-2900 Series and is the answer not in the manual?

Questions and answers