Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for usha Sewing Machine

- Page 1 Instruction Manual...

-

Page 2: Table Of Contents

INDICE SECTION 1. ESSENTIAL PARTS Name of Parts ......................... 2 SECTION 2. GETTING READY TO SEW Extension Table ....................... 3 Standard Accessories ..................... 3 Accessories Storage Box ....................3 Connecting the Machine to the Power Supply ..............4 Foot Control ........................4 Presser Foot Lifter ...................... -

Page 3: Section 1. Essential Parts

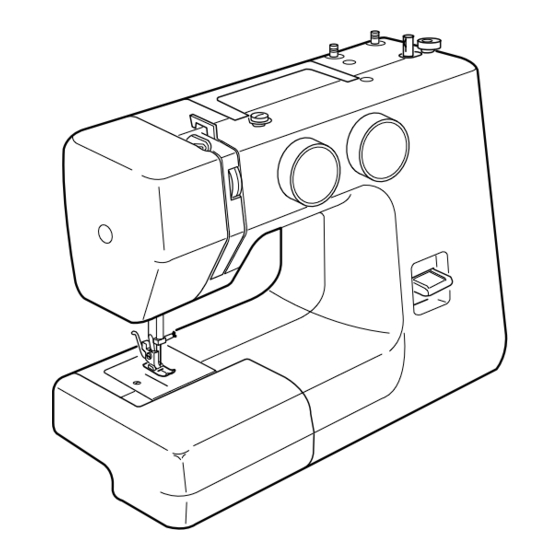

SECTION 1. ESSENTIAL PARTS Name of Parts q Reverse stitch button w Pattern selector dial e Stitch length dial r Bobbin winder stopper t Bobbin winder spindle y Spool pins u Bobbin winder thread guide i Thread guide o Thread take-up lever !0 Thread tension dial !1 Face plate !2 Needle plate... -

Page 4: Section 2. Getting Ready To Sew Extension Table

SECTION 2. GETTING READY TO SEW Extension Table The extension table provides added sewing surface and can be easily removed for free arm sewing. Detaching the table: Pull the table away from the machine. Attaching the table: Push the extension table until it snaps into the machine. -

Page 5: Connecting The Machine To The Power Supply

Connecting the Machine to the Power Supply Before connecting the power cord, make sure the voltage and frequency shown on the machine conform to your electrical power. 1. Turn off the power switch. 2. Insert the machine plug into the machine socket. -

Page 6: Presser Foot Lifter

Presser Foot Lifter The presser foot lifter raises and lowers your presser foot. You can raise it about 0.6 cm (1/4˝) higher than the normal up position for easy removal of the presser foot or to help you to place heavy fabric under the foot. q Normal up position w Highest position To Attach and Remove the Presser Foot... -

Page 7: Changing Needle

Changing Needle CAUTION: Turn off the power switch when changing a needle. Raise the needle by turning the handwheel toward you and lower the presser foot. Loosen the needle clamp screw by turning it counter- clockwise. Remove the needle from the clamp. Insert the new needle into the clamp with the flat side away from you. -

Page 8: Setting Spool Pins

Setting Spool Pins The spool pins are used for holding the spool of thread in order to feed thread to the machine. To use, pull up the spool pin. Push down for storage. Removing or Inserting the Bobbin Case Open the hook cover. Hook cover Raise the needle by turning the handwheel toward you. -

Page 9: Winding The Bobbin

Winding the Bobbin 1 Pull the handwheel out. 2 Draw the thread from spool. Guide the thread around the bobbin winder thread guide. 3 Insert the thread through the hole in the bobbin from the inside to the outside. Align the notch q of bobbin to the bobbin winder spindle rib w. -

Page 10: Threading The Machine

Threading the Machine Raise the take-up lever to its highest position by turning the handwheel toward you. Raise the presser foot. Place a spool on the spool pin as shown, with thread coming from back of the spool. 1 Draw the thread into thread guide using both hands. 2 While holding the thread near spool, draw thread down into the tension area and then around the check spring holder. -

Page 11: Drawing Up Bobbin Thread

Drawing Up Bobbin Thread 1 Raise the presser foot and hold the needle thread lightly with your left hand. 2 Turn the handwheel slowly toward you with your right hand until the needle goes down and continue turning the handwheel until the take–up lever is at its highest position. -

Page 12: Balancing Needle Thread Tension

Balancing Needle Thread Tension 1 Correct tension The thread tension is adjusted depending on the sewing materials, layers of fabric and sewing method. * The ideal straight stitch has threads looked between two layers of fabric, as illustrated (magnifies to show detail). * For an ideal zigzag stitch, the bobbin thread does not show on the right side (top side) of the fabric, and the needle thread shows slightly on the wrong... -

Page 13: Pattern Selector Dial

Pattern Selector Dial Raise the needle and presser foot. Turn the pattern selector dial to select the letter at the setting mark. Setting mark Note: Do not turn the pattern selector dial while the needle is in the material. -

Page 14: Stitch Length Dial

Stitch Length Dial Turn the stitch length dial to set the desired stitch length at the setting mark. The higher the number, the longer the stitch length q Setting mark • " " is the recommended setting for buttonhole stitching. •... -

Page 15: Reverse Stitch Button

Reverse Stitch Button As long as you keep the reverse stitch button depressed, the machine sews backwards. Darning Plate To set the darning plate: Position the darning plate with the 3 pins on the bottom. Fit the darning plate pins into the needle plate holes. The feed dogs will show through the darning plate holes. -

Page 16: Section 3. Basic Sewing Straight Stitch Sewing

SECTION 3. BASIC SEWING Straight Stitch Sewing q Pattern selector: A or B w Presser foot: Zigzag foot e Thread tension: 2–6 r Stitch length: 1.5–4 z Raise the presser foot and position the fabric with its edge lining up with a seam guide line on the needle plate. -

Page 17: Seam Guide Line

Seam Guide Line The numbers on the needle plate indicate the distance between the center needle position and the line r. The numbers in front are centimeters. The numbers in back are fractions of an inch. Number 3/8˝ 4/8˝ 5/8˝ 6/8˝... -

Page 18: Zigzag Stitching

Zigzag Stitching q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 2–5 r Stitch length: 0.5–4 Simple zigzag stitching is widely used for overcasting, sewing on buttons, etc. -

Page 19: Tricot Stitch

Tricot Stitch q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 1–4 r Stitch length: 0.5–4 Place the fabric under the presser foot so that the edge is just inside the right edge of the presser foot. Guide the work so the right hand stitches fall off the edge of the fabric. -

Page 20: Triple Stitch

Triple Stitch q Pattern selector: A or B w Presser foot: Zigzag foot e Thread tension: 2–6 r Stitch length: S.S. The stitch is sewn with two stitches forward and one stitch backward forming a seam that does not rip easiIy. Garments should be basted for fitting before seaming. -

Page 21: Sewing Buttons

Sewing Buttons q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 1–3 r Stitch length: t Darning plate Use the darning plate for button sewing. (see page 14.) Set the Pattern Selector at B (left needle position). Mark the button placements on the fabric. Position the darning plate onto the needle plate. -

Page 22: Buttonhole

Buttonhole q Pattern selector: w Presser foot: Buttonhole foot e Thread tension: 1–5 r Stitch length: To adjust buttonhole stitch density: Set the stitch length dial between 0.5 and 1.0 to adjust the buttonhole stitch density. 1 Carefully mark buttonhole length on fabric. Place the fabric under the foot with the buttonhole marking running toward you. -

Page 23: Blind Hem Stitch

Blind Hem Stitch q Pattern selector: E or F w Presser foot: Zigzag foot e Thread tension: 2–4 r Stitch length: 1–3 z On heavyweight fabrics that ravel, the raw edge should be overcast first. Then fold the hem, as illustrated, leaving 1/4˝... -

Page 24: Section 4. Decorative Stitches Shell Tuck

SECTION 4. DECORATIVE STITCHES Shell Tuck q Pattern selector: w Presser foot: Buttonhole foot e Thread tension: 6–8 r Stitch length: 2–3 Place the folded edge along the slot of foot. The needle should fall off the edge of the fabric on the right forming a tuck. -

Page 25: Smocking

Smocking q Pattern selector: w Presser foot: Zigzag foot e Thread tension: 1–4 r Stitch length: S.S. With the stitch length at “4”, sew straight stitching lines 1 cm (3/8˝) apart, across the area to be smocked. Knot the threads along one edge. Pull the bobbin threads and distribute the gathers evenly. -

Page 26: Section 5. Care Of Your Machine

SECTION 5. CARE OF YOUR MACHINE Dismantling and Assembling Shuttle Race Unit Note :Turn off the power switch and/or unplug the machine. To dismantle shuttle race unit: Raise the needle to its highest position and open the hook cover. Open the hinged latch of bobbin case and take it out of the machine. -

Page 27: Sewing Light

Sewing Light The sewing light is located behind the face plate. To change the bulb, take the face plate off the sewing machine by removing the set screw. • Unplug the power supply before changing the bulb. • To remove, turn the bulb to the left. -

Page 28: Trougleshooting

Troubleshooting Cause Condition Reference The needle thread 1. The needle thread is not threaded properly. See Page 9 2. The needle thread tension is too tight. breaks. See Page 11 3. The needle is bent or blunt. See Page 6 4. -

Page 29: Important Safety Instructions

Use only attachments recommended by the manufacturer as contained in this owner’s manual. 3. Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if it has been dropped or damaged, or dropped into water. - Page 30 Printed in Thailand 743-801-380...

Need help?

Do you have a question about the Sewing Machine and is the answer not in the manual?

Questions and answers