Table of Contents

Advertisement

OWNER'S MANUAL

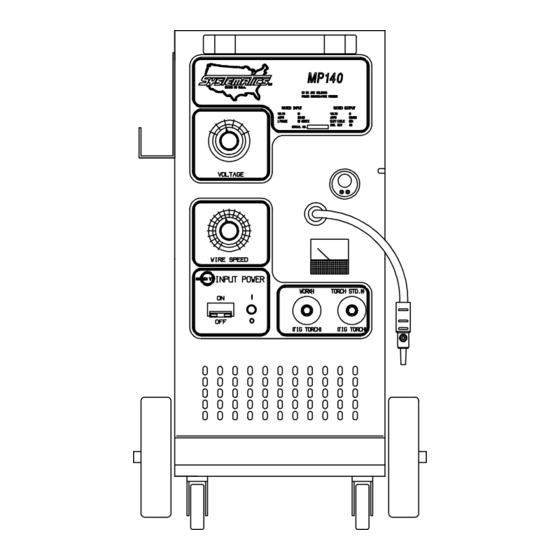

MP140 MIG COMBINATION UNIT

MP140

THE

REPRESENTS THE LATEST TECHNOLOGY

IN MIG COMBINATION UNITS. THE MP140 OPERATES

ON 115 VOLT AC SINGLE PHASE CURRENT, AND FEATURES

"SMOOTH ARC" TRANSFORMER DESIGN CONCEPT.

FOR TECH. SERVICE, CALL 1-610-696-9040

INSTALLATION

OPERATION

MAINTENANCE

FORM WC5342

Rev. 8/00

Advertisement

Table of Contents

Summary of Contents for Systematics MP140

- Page 1 OWNER'S MANUAL MP140 MIG COMBINATION UNIT MP140 REPRESENTS THE LATEST TECHNOLOGY IN MIG COMBINATION UNITS. THE MP140 OPERATES ON 115 VOLT AC SINGLE PHASE CURRENT, AND FEATURES "SMOOTH ARC" TRANSFORMER DESIGN CONCEPT. FOR TECH. SERVICE, CALL 1-610-696-9040 INSTALLATION OPERATION MAINTENANCE FORM WC5342 Rev.

-

Page 2: Table Of Contents

TROUBLE SHOOTING CHART..........15 CONNECTING TIGIT2 OR MHG7 SPOOL GUN ......20 CONSUMABLE PARTS BREAKDOWN ........22 PARTS BREAKDOWN - MIG TORCH ........23 OPTIONS - TIGIT2, MHG7 SPOOL GUN ........24 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 3: Electrical Supply Requirements

12 Gauge 30 Amp 10 Gauge Do not rely on the circuit breaker built into the MP140 to protect your wiring. This circuit breaker protects the MP140 internal wiring only. Do not use undersized extension cords. Follow the cord manufacturer's recommendations as to current carrying capacities. -

Page 4: Introduction

The consumable electrode wire is minimum which limits distortion melted and transferred to the weld and makes possible the welding of puddle by the "short arc" or "dip" thin sheet material. transfer mode. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 5: Specifications

(air) DUTY CYCLE TIME PERIOD: 10 minutes RATING - 60% DUTY CYCLE: With Argon/CO2 gas 200 amps OPEN CIRCUIT VOLTAGE: With CO2 gas 225 amps 18 - 33 volts DC Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 6: Check List (Contents)

INLET OUTLET ventilation and maintenance. FITTING FITTING TANK ELECTRICAL SUPPLY WELDING MACHINE Follow Electrical Supply Requirements on page 1. FIG. 3. GAS FLOW ADJUSTMENT Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 7 "B" SIDE FACING IN FOR .040" - .045" STEEL WIRES AND 3/64" ALUMINUM WIRES THUMB SCREW DRIVE DRIVE ROLL ASSEMBLY FIG. 5. DOUBLE GROOVE DRIVE ROLL FIGURE 4. TORCH CONNECTION (continued on following page) Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 8 For aluminum The wire is electrically or stainless steel welding, NO HOT when the torch trigger anti-spatter compound can be is actuated. used as it will contaminate the weld. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

-

Page 9: Operation

WORK (GROUND) CABLE ground wire on the welder. Uncoil the work cable and plug it into the negative (-) terminal on the machine. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 10: Process Selection

C. CIRCUIT BREAKER polarity welding on very light Primary power switch and over- sheet metal or for using flux load protection device. cored gasless wire. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 11 1/16 inch beyond the end of D. PARAMETER CHART the nozzle. This chart is a guide for basic setup parameters. (continued on following page) Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 12 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 13 The recommended position of the torch and direction of travel for welding aluminum are shown in figure 13. (continued on following page) 4. Follow steps 4 and 5 as in "Continuous Welding on Steel". Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 14 SPOTWELD 30 DEGREES NOZZLE PRESS NOZZLE FIRMLY AGAINST WORK CONTACT DIRECTION OF TRAVEL SPOTWELD WORK SHIELDING GAS WORK FIGURE 15. STITCH WELDING FIGURE 14. MIG SPOT WELDING Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

-

Page 15: Maintenance

(continued on following page) will help prevent the adherence of spatter to the torch components. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 16 BE SAFE - DON’T BE SORRY! contact tips..M3-T30, etc. gas nozzles .... M3T-N50 nozzle insulators ..M3T-B gas diffusers .... M3T-D steel liner(.020-.030) M103L-B steel liner(.035-.045) M104L-N Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

-

Page 17: Trouble Shooting Chart

Sand points or replace (CR1) relay. Loose or broken connection. Tighten or repair connection. - USE THIS IDENTIFIER, ALONG WITH THE SCHEMATIC DIAGRAM FOUND IN THE SERVICE (SYMBOL*) MANUAL, FOR TROUBLE-SHOOTING PURPOSES. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 18 Replace contact tip. Worn inlet guide(s). Clean or replace guides. Sticking pressure roll. Replace pressure roll. Feed roll tension incorrect. Adjust feed roll ten- sion. See page 7. (continued on following page) Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 19 Incorrect electrode wire. Use correct wire. Contaminated base material. Clean or etch base material. - USE THIS IDENTIFIER, ALONG WITH THE SCHEMATIC DIAGRAM FOUND IN THE SERVICE (SYMBOL*) MANUAL, FOR TROUBLE-SHOOTING PURPOSES. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 20 (Radio Shack #276-1372) be used where the diode makes contact with the aluminum heat sink. grease the threads on the di- ode. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

- Page 21 5) Remove any tension on the drive speed of the drive roll from "0" roll. thru "10". 6) Activate the torch trigger. 10)Adjustment is now complete! Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

-

Page 22: Connecting Tigit2 Or Mhg7 Spool Gun

1. Remove the thread cap from the PLUG "MHG7 SPOOL GUN" fitting. THREAD (PLUGGED INTO 2. Unscrew the selector hose from FUNCTION RECEPTACLE) the "MIG STANDARD" fitting. FIG. 18. BULKHEAD CONNECTIONS Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 23 3. Adjust the liner stickout length during the installation. Turn to Page 6 for correct nozzle to 3/4" as shown in fig. 19. adjustment. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

-

Page 24: Consumable Parts Breakdown

.020-.030 inch 10 feet M103L-B M3LS-B (Blue) .035 inch 10 feet M103AL M3-6ALS M3-THS 10 feet M104L-N .035-.045 inch M4LS-N (Natural) 12 feet M124L-N 3/64 inch 10 feet M104AL M3-6ALS M3-THS Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 25: Parts Breakdown - Mig Torch

ARE AVAILABLE FACTORY M3-308 M3-306 M3-120* INSTALLED ONLY. (2 REQD.) TORCH REBUILD PROGRAM 15 SERIES TORCHES CAN BE REBUILT BY THE M3-310A FACTORY FOR A NOMINAL LABOR + PARTS CHARGE. Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 26: Options - Tigit2, Mhg7 Spool Gun

250 Amps @ 60% duty cycle (installed on gun) 1 each M35-D Gas Diffuser Wire Feed Speed Range..50 to 650 inches per minute (installed on gun) Cooling Method ....Air (gas) Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... -

Page 27: Systematics , Inc. 1025 Saunders Lane West Chester, Pa. 19380

NOTES Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380... - Page 28 Systematics , Inc. 1025 Saunders Lane West Chester, PA. 19380...

Need help?

Do you have a question about the MP140 and is the answer not in the manual?

Questions and answers