Advertisement

Table of Contents

- 1 Table of Contents

- 2 Specifications

- 3 Safety Precautions

- 4 Principles of Operation

- 5 Fluids System Diagram

- 6 Major Components Diagram

- 7 Operation

- 8 Preparation

- 9 Application

- 10 Maintenance

- 11 Valve Adjustment

- 12 General Dimensions

- 13 Machine Orientation

- 14 Flow Rate

- 15 Rotary Fan Replacement

- Download this manual

Advertisement

Table of Contents

Summary of Contents for Curtis Dyna-Fog CyClone 2730

- Page 1 ™ Cyclone “Cold Fog” ULV/Mister MODEL 2730 & 2732 OPERATION AND MAINTENANCE MANUAL MANUFACTURED BY: CURTIS DYNA-FOG, Ltd. 17335 U.S. Highway 31 North WESTFIELD, INDIANA, U.S.A. www.dynafog.com US and Foreign patents pending...

-

Page 2: Table Of Contents

INDEX Page No SPECIFICATIONS ......... . SAFETY PRECAUTIONS . -

Page 3: Specifications

SPECIFICATIONS The Cyclone™ machine is an electric “Cold Fog” ULV that utilizes a rugged anodized aluminum nozzle and a high performance blower. This device is intended for applications of both Oil Based (following necessary precautions) and Water Based chemical treatments. -

Page 4: Safety Precautions

SAFETY PRECAUTIONS WARNING READ AND UNDERSTAND THESE SAFETY PRECAUTIONS BEFORE OPERATING MACHINE. FAILURE TO PROPERLY FOLLOW THESE PRECAUTIONS MAY LEAD TO A FIRE, EXPLOSION, OR ELECTRICAL SHOCK HAZARD. 1. Electric Power This machine uses electrical power at common commercially available voltages. - Page 5 danger of fire or explosion in an enclosed space, the enclosed volume fogging time and required formulation volume should be carefully calculated. 5. Proper and Improper Use. The following rules apply to the operation of this machine: Read the entire manual before operating the machine and pay particular attention to all CAUTIONS AND WARNINGS.

-

Page 6: Principles Of Operation

CYCLONE™ FLUID SYSTEM DIAGRAM Curtis Dyna-Fog, Ltd. 2008... -

Page 7: Major Components Diagram

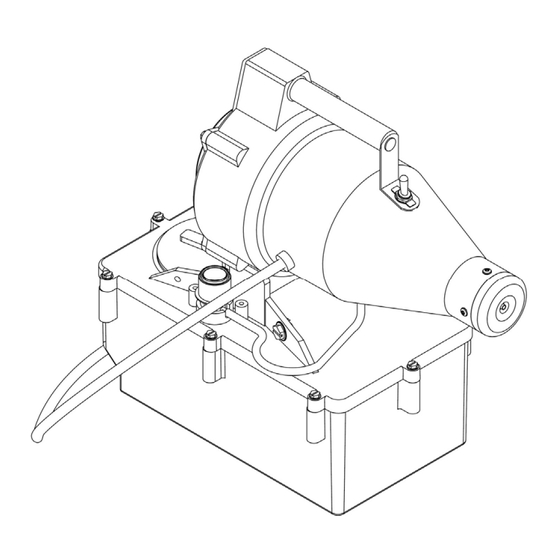

CYCLONE™ MAJOR COMPONENTS DIAGRAM Curtis Dyna-Fog, Ltd. 2008... -

Page 8: Operation

Operation Proper application of formulation with this machine requires 7 basic steps as follows: 1. Determine the APPLICATION RATE of the formulation from the formulation label. 2. Measure and calculate the ENCLOSED VOLUME to be treated in cubic feet. 3. Multiply the APPLICATION RATE by the ENCLOSED VOLUME to arrive at the AMOUNT REQUIRED. - Page 9 6. Hold the meter vertical and allow the liquid to flow through the brass orifice at the outlet end of the meter into an appropriate container. LINE N0. 1 7. Using a stopwatch or a watch with a sweep second hand, determine the FLOWABILITY TIME in seconds that it takes for the liquid level to COUNT SECONDS IT TAKES fall from the top line to the bottom line.

-

Page 10: Application

Application 1. Determine the required Machine Valve Setting and application time according to the instructions under PREPARATION. 2. Set the Machine Valve to the required setting. 3. Place sufficient formulation in the container to ensure that the Pickup Filter remains submerged during application. -

Page 11: Valve Adjustment

Valve Adjustment Satisfactory performance of the metering valve depends upon the proper tightness of the nut which retains the sealing gland. If the nut is too tight, the valve will be difficult to turn. If the nut is too loose, the valve may leak air causing loss of calibration. -

Page 12: General Dimensions

GENERAL DIMENSIONS The weight of the unit is 14.2 lbs. (6.4 kg) without liquid. The Formulation Tank capacity is 1 US Gallon (3.8 L) Machine Orientation The machine allows adjusting the angle from the horizontal position to 40° from the horizontal position to 20°... -

Page 13: Flow Rate

FLOW RATE Turning the knob of the Metering Valve regulates the Flow Rate. If the knob is rotated clockwise, the flow rate will be reduced. If the knob is rotated counterclockwise, the flow rate will be increased. As reference, the average flow rate is shown in the bottom table at ten different positions of the Metering Valve knob. - Page 14 IMPORTANT: This device is designed to dispense formulation in a SPRAY (Cold Fog) or MIST. Many of the formulations which may be dispensed with this machine require registration with or approval by various government agencies. Application Rate (Fluid Ounces Per 1000 Cubic Feet) 1:00 1:50 1,000...

- Page 15 Machine Flow Rate Fluid Ounces Per Minute 1.25 1.50 1.75 2.00 2.25 2.50 4:00 2:00 1:20 1:00 0:48 0:40 0:34 0:30 0:27 0:24 8:00 4:00 2:40 2:00 1:36 1:20 1:08 1:00 0:53 0:48 12:00 6:00 4:00 3:00 2:24 2:00 2:00 1:43 1:30 1:12...

-

Page 16: Rotary Fan Replacement

ROTARY FAN REPLACEMENT CAUTION: The Blower of your machine rotates at a high speed (approximately 20,000 RPM). The replacement of the Rotary Fan, if required, should be performed by a certified Dyna-Fog representative. If the machine has been working in a closed room, the intake air filter gets saturated, and liquid (chemical) is introduced to the blower.

Need help?

Do you have a question about the CyClone 2730 and is the answer not in the manual?

Questions and answers