Table of Contents

Advertisement

Quick Links

POWERFUL SOLUTIONS. GLOBAL FORCE.

L2988

Rev. C

Index:

English. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Français. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Deutsch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Italiano . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Español . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Nederlands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Portuguese . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Finnish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Norwegian . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

Swedish. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

中文 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . N/A

1.0 IMPORTANT RECEIVING INSTRUCTIONS

Visually inspect all components for shipping damage. Shipping

damage is not covered by warranty. If shipping damage is found,

notify carrier at once. The carrier is responsible for all repair and

replacement costs resulting from damage in shipment.

2.0 SAFETY

2.1 General Hydraulic Safety Precautions

Read all instructions, warnings and cautions

carefully. Follow all safety precautions to avoid

personal injury or property damage during system

operation. Enerpac cannot be responsible for damage or injury

resulting from unsafe product use, lack of maintenance or

incorrect product and/or system operation. Contact Enerpac

when in doubt as to the safety precautions and operations. If you

have never been trained on high-pressure hydraulic safety,

consult your distribution or service center for a free Enerpac

Hydraulic safety course.

Failure to comply with the following cautions and warnings could

cause equipment damage and personal injury.

A CAUTION is used to indicate correct operating or maintenance

procedures and practices to prevent damage to, or destruction

of equipment or other property.

A WARNING indicates a potential danger that requires correct

procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action may

cause serious injury or even death.

WARNING: Wear proper personal protective gear when

operating hydraulic equipment.

Never set the relief valve (pumps equipped with user-

adjustable relief valve only) to a higher pressure than the

maximum rated pressure of the pump. Higher settings

may result in equipment damage and/or personal injury.

WARNING: The system operating pressure must not

exceed the pressure rating of the lowest rated component

in the system. Install pressure gauges in the system to

monitor operating pressure. It is your window to what is happening

in the system.

02/11

Instruction Sheet

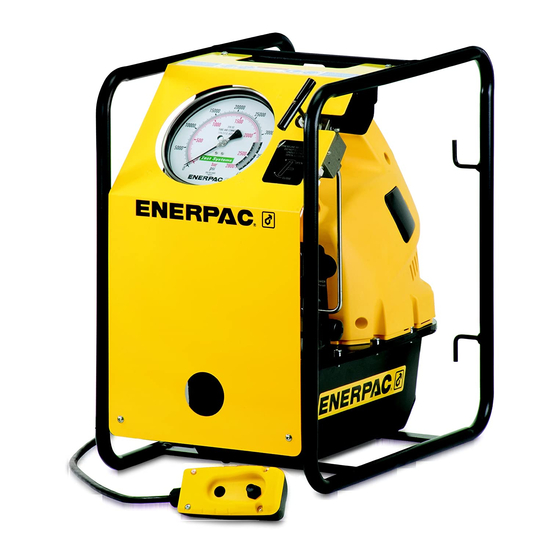

Model ZUTP-1500

1500 Bar Electric Pump

CAUTION: Avoid damaging hydraulic hose. Avoid

sharp bends and kinks when routing hydraulic hoses.

Using a bent or kinked hose will cause severe back-pressure.

Sharp bends and kinks will internally damage the hose leading to

premature hose failure.

Do not drop heavy objects on hose. A sharp impact

may cause internal damage to hose wire strands.

Applying pressure to a damaged hose may cause it

to rupture.

IMPORTANT: Do not lift hydraulic equipment by the

hoses or swivel couplers. Use the carrying handle or

other means of safe transport.

CAUTION: Keep hydraulic equipment away from

fl ames and heat. Excessive heat will soften packings

and seals, resulting in fl uid leaks. Heat also weakens

hose materials and packings. For optimum performance do not

expose equipment to temperatures of 65°C [150°F] or higher.

Protect hoses and cylinders from weld spatter.

DANGER: Do not handle pressurized hoses. Escaping

oil under pressure can penetrate the skin, causing

serious injury. If oil is injected under the skin, see a

doctor immediately.

IMPORTANT: Hydraulic equipment must only be

serviced by a qualifi ed hydraulic technician. For repair

service, contact the Authorized ENERPAC Service Center

in your area. To protect your warranty, use only ENERPAC oil.

WARNING: Immediately replace worn or damaged parts

with genuine ENERPAC parts. Standard grade parts will

break causing personal injury and property damage.

ENERPAC parts are designed to fi t properly and withstand high

loads.

WARNING: Do not use electric pumps in an explosive

atmosphere. Adhere to all local and national electrical

codes. A qualifi ed electrician must do installation and

modifi cation.

1

Advertisement

Table of Contents

Summary of Contents for Enerpac ZUTP-1500

- Page 1 For repair operating hydraulic equipment. service, contact the Authorized ENERPAC Service Center in your area. To protect your warranty, use only ENERPAC oil. Never set the relief valve (pumps equipped with user- WARNING: Immediately replace worn or damaged parts adjustable relief valve only) to a higher pressure than the with genuine ENERPAC parts.

-

Page 2: Specifications

Authorized Enerpac Service Center. • The Model ZUTP-1500 pump is designed to operate at a maximum working pressure of 21,750 psi [1500 bar]. Do not WARNING: To prevent damage to pump electric motor, exceed this pressure setting. -

Page 3: Installation

[1500 bar]. • Enerpac recommends the use of Enerpac HT 1500 Series thermoplastic hoses with the Model ZUTP-1500 pump. These hoses are rated at 21,750 psi [1500 bar]. Refer to Enerpac instruction sheet L2733 for use, safety and maintenance information. - Page 4 5.2 Pendant and Motor Jog Buttons Relief Valve (See Figures 5 and 6) Knob The pump motor can be controlled either by the pendant button or by the motor jog button (located on the pump front panel). Pendant Button MOTOR Locknut Figure 7, Relief Valve Figure 6, Motor Jog Button...

-

Page 5: Maintenance

6.2 Change Oil and Clean Reservoir before brush servicing is attempted. Enerpac HF oil is a crisp blue color. Frequently check oil condition 2. Remove both brush caps (A) by defl ecting the brush cap latch for contamination by comparing pump oil to new Enerpac oil. As (B) and gently prying outward. -

Page 6: Troubleshooting Guide

To determine the cause of the problem, the complete system must be considered in any diagnostic procedure. The following troubleshooting chart is intended to be used only as an aid in determining if a problem exists. For repair service, contact your Enerpac Authorized Service Center. Troubleshooting Guide... - Page 7 NOTES:...

- Page 8 Rep. office Enerpac For the location of your nearest authorized T +86 10 845 36166 Russian Federation Enerpac Integrated Solutions B.V. Enerpac Service Center, visit us at F +86 10 845 36220 Admirala Makarova Street 8 Opaalstraat 44 www.enerpac.com sales-cn@enerpac.com...

Need help?

Do you have a question about the ZUTP-1500 and is the answer not in the manual?

Questions and answers