Summary of Contents for KingKutter TG-48-XB

- Page 1 PO BOX 1200 305 Commerce Drive Winfield, Alabama 35594 TG-48-XB ROTARY TILLER OPERATOR MANUAL www.kingkutter.com Part No 999991...

- Page 3 TO THE PURCHASER This manual contains valuable information about your new King Kutter XB Rotary Tiller. It has been carefully pre- pared to give you helpful suggestions for operating, adjust- ing, servicing and ordering repair parts. Keep this manual in a convenient place for quick and easy reference.

- Page 4 It is the purchaser and/or operator’s responsibility to…. Read and understand the information contained in this manual. Operate, lubricate, assemble and maintain the equipment in accordance with all instructions and safety procedures in this manual. Inspect the equipment and replace or repair any parts that are damaged or worn which under contin- ued operation would cause damage, wear to other parts, or cause a safety hazard.

-

Page 5: Table Of Contents

CONTENTS ITEM PAGE Safety ................. 6 Assembly Instructions ..........8 Before Putting Into Service ........8 Safety Training ............11 Transportation Safety ..........15 Attaching To Tractor ..........16 Sizing PTO ............... 18 Operating Instructions ..........19 Maintenance ............20 Maintenance Safety .......... -

Page 6: Safety

It may also be used to alert against unsafe prac- tice. If you have any questions not answered in this manual or require additional copies or the manual is damaged, please contact your dealer or King Kutter, Inc. P.O. Box 1200 Winfield, AL 35594 (205) 487-3202 or www.kingkutter.com... -

Page 7: Equipment Safety Guidelines

EQUIPMENT SAFETY GUIDELINES Safety of the operator and bystanders is one of the main concerns in designing and develop- ing a tiller. However, every year accidents occur which could have been avoided by a few seconds of thought and a more careful approach to handling equipment. You, the operator, can avoid many accidents by observing the following precautions and insist those working with you, or for you, follow them. -

Page 8: Assembly Instructions

XB-ROTARY TILLER ASSEMBLY INSTRUCTIONS STEP 1 With rotary tiller still in crate, lay flat on a level surface. Cut banding straps on the two (2) upright crate posts. STEP 2 Remove the top & upper side sections of the crate, leaving the rotary tiller resting on the bottom section. - Page 9 STEP 4 Replace and tighten the (2) plugs and clean away any excess oil. STEP 5 Remove Breather Plug (Located at top of side gearbox, See (FIG. D point 1 on next page), there is also a plug at the bottom (Located in the side of the side gearbox) (FIG.

- Page 10 Figure E Figure D Figure F Figure G...

-

Page 11: Safety Training

SAFETY TRAINING Safety is a primary concern in the design and manufacturing of our product. Un- fortunately, our efforts to provide safe equipment can be wiped out by a single careless act of an operator or bystander. In addition to the design and configuration of equipment, hazard control and ac- cident prevention are dependent upon the awareness, concern, prudence and proper training of personnel involved in the operation, transport, maintenance and storage of this equipment. - Page 12 PREPARTION Never operate the tractor and tiller until you have read and completely under- stand this manual, the Tractor Operator’s Manual, and each of the safety mes- sages found on the safety signs on the tractor and tiller. Personal protection equipment including hardhat, safety glasses, safety shoes, and gloves are recommended during assembly, installation, operation, adjustment, maintenance, re- pairing, removal, or moving the implement.

- Page 13 OPERATIONAL SAFETY The use of this equipment is subject to certain hazards that cannot be protected against by the mechanical means or product design. All operators of this equip- ment must read and understand this entire manual, paying particular attention to safety and operating instructions, prior to using.

- Page 14 OPERATIONAL SAFETY continued... Never allow the tilling tines to contact such items. Never assume an area is clear. Always Check! Always stop the tractor, disengage PTO, set brake, shut off the tractor engine, remove the ignition key, lower implement to the ground and allow rotating pieces to come to a complete stop before dismounting tractor.

-

Page 15: Transportation Safety

OPERATIONAL SAFETY continued... Pass rotary tiller diagonally through sharp dips and avoid sharp drops to prevent “hanging up” tractor and rotary tiller. Practice will improve your skills in maneu- vering on rough terrain. Always cut down slopes, never across the face. Always check tractor manual for proper use on slopes. -

Page 16: Attaching To Tractor

ATTACHING TO TRACTOR WARNING Never stand between tractor and rotary tiller while backing up tractor to the hitch. STEP 1 Attach to tractor's category 1 three point hitch as described in the Tractor's Operator’s Manual. STEP 2 Determine if the PTO shaft needs to be shortened. NOTE: Due to the many variations in the tractor hitch points and distances between equipment gearbox input shaft and tractor PTO out put shafts, some combina-... - Page 17 ATTACHING TO TRACTOR continued..STEP 4 Pull apart PTO shaft and attach outer section to tractor PTO output shaft. NOTE: Be sure to pull on PTO shaft section to ensure yoke has locked into place. STEP 5 Place and hold inner PTO shaft section next to outer section and check if PTO shaft is too long.

-

Page 18: Sizing Pto

SIZING PTO SHAFT STEP 1 Cutting the PTO shaft to length. NOTE: Be sure to cut equal lengths of each PTO shaft section. Clamp end of PTO shaft in a vice and cut off shield where marked. (Figure 1 -A & 1-B) STEP 2 Figure 1-A Using cut section of the shield as a guide... -

Page 19: Operating Instructions

OPERATING INSTRUCTIONS STEP 1 Before each use perform the maintenance described in maintenance section (page 20). STEP2 Read, understand, and follow the information on safety training, preparation, starting and stopping safety, operational safety, transport safety warning sections of this man- ual (pages 12 thru 15). -

Page 20: Maintenance

NOTE: Do not allow the tractor engine or rotary tiller to bog down or stall. This causes undue wear and tear on the tiller and tractor. If this continues to happen reduce ground speed and raise tilling depth of rotary tiller. Never attempt to re- move objects from the rotor bar until the tractor has been shut down and the tiller tines have completely stopped. -

Page 21: Maintenance Safety

MAINTENANCE SAFETY Good maintenance is your responsibility. Poor maintenance is an invita- tion to trouble. Follow good shop practices. Keep service area clean and dry Be sure electrical outlets and tools are properly grounded Use adequate light for the job at hand. Make sure there is plenty ventilation. -

Page 22: Safety Decal's And Locations

SAFETY SIGN LOCATIONS The types of safety signs and locations on the equipment are shown in the illustration below. Good safety requires that you familiarize yourself with the various safety signs, the type of warning and the area, or particular function related to that area, that re- quires your SAFTY AWARENESS. -

Page 27: Pto Shaft Parts

22” PTO 147122 Ref. Part Name 147122 Safety Shield 124311 Roll Pin 170120 Male Tube End Yoke 151045 Female Tube End Yoke 151050 Tractor End Yoke 151035 Inner Tube 14 Series 151090 Outer Tube 14 Series 151091 Cross Kit # 4 170015 Quick Disconnect Pin 170110... -

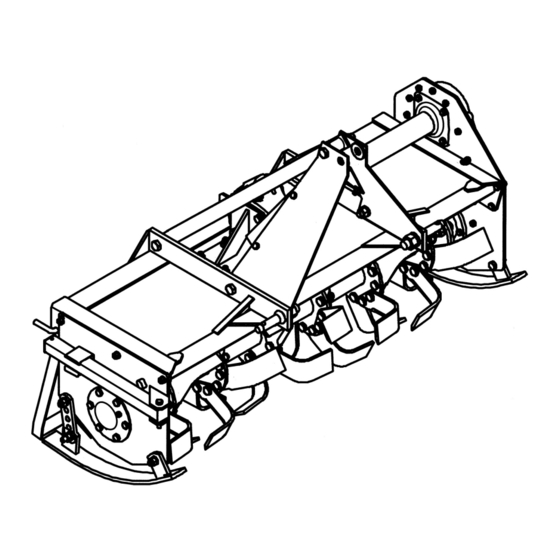

Page 28: Replacement Parts

XB TILLER: EXPLODED VIEW... - Page 29 TG-48-XB TILLER PARTS LIST Ref. Part Name Part Number TG-48-XB Lift Arm Brace 381001 Lift Arm (LH) 404404 Lift Arm (RH) 404405 Tail Rod Assembly 505116 Center Shield Assembly 505020 Lift Arm Spacer Kit 505021 Tine Pkg. (1-Right,1-Left) w/ Bolts 505002 Tine Pkg.

-

Page 30: Side Gearbox Parts

TG-48-XB SIDE GEARBOX PARTS... - Page 31 TG-48-XB SIDE GEARBOX PARTS LIST Ref. Part Name Part Number Side Gearbox Hub & Shaft w/Disc 100106 Oil Seal (HMSA7 21632) Bearing (1209) Snap Ring Spacer Spur Gear (27 Teeth) Snap Ring Housing Bearing (6010) Snap Ring Spur Gear (38 Teeth)

-

Page 32: Top Gearbox Parts

TG-48-XB SERIES TOP GEARBOX PARTS... - Page 33 TG-48-XB SERIES TOP GEARBOX PARTS LIST Ref. Part Name Part Number Housing Input Shaft Retaining Ring 30mm Bevel Pinion (13 Teeth) Bearing Cone (30305) Bearing Cup (30305) Bearing Cone (x32007x) Bearing Cup (x32007x) Retaining Ring Output Shaft Hub Cap Bearing (6307)

-

Page 34: Hub Parts

TG-48-XB HUB PARTS... - Page 35 Ref. Part Name Part Number Hub Stub Shaft w/Disc 100107 Bearing (6208) Oil Seal Snap Ring (40 x 1.5) Snap Ring (80 x 2.5) Gasket Mounting Plate Shield Cover Lock Washer (M10) Hex Cap Screw (M10—1.5 x 35) Nut (M10 -1.5) Grease Zerk (1/4”) 132018...

-

Page 36: Warranty

1. Limited Warranty. King Kutter, Inc. (“King Kutter”), P.O. Box 1200, Winfield, Alabama 35594, warrants to the original retail pur- chaser (“Purchaser”) that the product that is the subject of this sale is free from defects in material and work- manship at the time of sale.

Need help?

Do you have a question about the TG-48-XB and is the answer not in the manual?

Questions and answers