Table of Contents

Advertisement

Quick Links

Instantaneous

Hot Water Heater

Operating & Instruction

Manual

Read these Instructions before unpacking,

installation and use of the equipment.

Important Notice:

UK Exchangers Ltd cannot accept any warranty claims if the equipment is not handled,

positioned, installed, or operated as per the general guide lines contained within this manual.

The actual running conditions should be checked against the specification sheets for the heat

exchanger.

-1-

Advertisement

Table of Contents

Summary of Contents for UK Exchangers UKE-8-50

- Page 1 Important Notice: UK Exchangers Ltd cannot accept any warranty claims if the equipment is not handled, positioned, installed, or operated as per the general guide lines contained within this manual. The actual running conditions should be checked against the specification sheets for the heat...

-

Page 2: How It Works

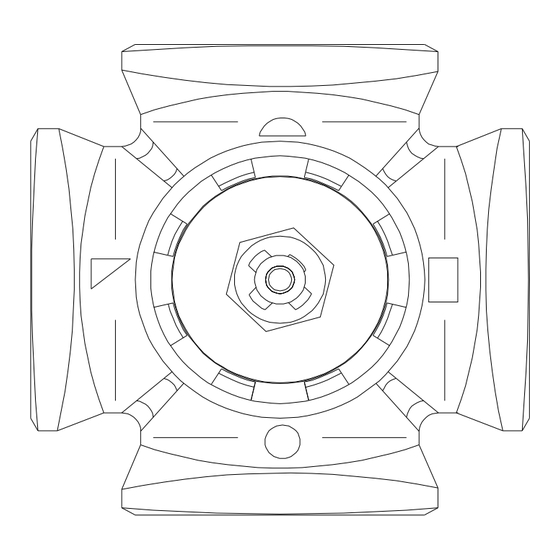

How it Works The unit is designed to heat domestic hot water (DHW) using low temperature hot water (LTHW). The primary circulating shunt pump mounted on the exchanger is for heat exchanger control only and is sized to pump the correct volume of LTHW through the heat exchanger to ensure efficient operation. - Page 4 4 PORT VALVE – Cast iron body type Before use, or if the system has been drained down for a period of time, it is important to check the operation of the valve – push the button slide forward on the side of the actuator – this frees the actuator drive from the valve –...

- Page 5 Control valve testing: Once filled with water, and before use, or if the system has been drained down for a period of time, it is important to check the operation of the valve – switch on the control panel and set the temperature to a high level (temperature altered by raising the set point).

- Page 6 Lifting Points to Avoid: Avoid lifting from the stainless steel threaded connections, control panel, pump, valves, or any of the pipe work and fittings not mentioned above. Maintenance Space: Leave a minimum of double the width of the exchanger, either side of the unit, to allow for access to the exchanger tie bolts, and to allow for removal of the heat transfer plates.

- Page 7 Pipe-work: To avoid damage to the unit, to prevent failure and to ease maintenance, we recommend the following: • Pipe-work - fully support to avoid weight/forces acting upon the unit / connections. • The fitting of flexible couplings if the pipe work is subject to vibration. •...

- Page 8 Electrical Installation: Connect the supply cable to the panel using a suitable isolation switch protected by a fuse or MCB rated at no more than 16 amps. The only connections required are the supply to the panel together with connection of secondary pump(s) if applicable.

- Page 10 2. Setting up the controller & Start-up: Shock: It is essential that the exchanger is not subjected to thermal or mechanical shock as this could lead to premature gasket failure. Operation in automatic mode: Once the pipe work and electrical connections have been made, all miniature circuit breakers (mcbs) located in the panel should be set to “on”...

- Page 11 Once all times are set the clock must be put into AUTO mode by repeatedly pressing the CH A MANUAL key and CH B MANUAL key until the indicator bar on the display is above the word AUTO for both channels.

- Page 12 5. Assembly: • Refer to the Plate Sequence Sheet to determine the order of the plates, & the type required. • Fit the start plate (see illustration on next page), ensuring the plate pattern is pointing in the correct direction as indicated on the plate sequence sheet. •...

- Page 13 Examples of Gasket and Plate types: -13-...

- Page 14 7. Trouble Shooting: Heat Exchanger Plate Pack Assembly: Nuts tight to turn: insufficient oil on threads Plates move out of alignment: remove plates & degrease, then dry. inspect plate hanging system for damage. Excessive pressure drops: Liquid flows higher than design: Check & adjust Plate channels blocked: Back flush, C.I.P., or dismantle to clean.

- Page 15 Trouble Shooting – continued: No Secondary Flow: Possible Causes: a) Electrical Fault b) Pump Tripped (Trip Lamp illuminated on control panel) c) High Limit Shut Down (High Temp. Lamp illuminated on control panel facia) d) Air Lock in system e) Not in correct mode of operation. Remedies: a) Check electrical supply to control panel together with the mcbs fitted within the panel b) Reset overload within the control panel using the blue reset button fitted on the relevant...

- Page 16 Trouble Shooting – continued: g ) Check for binding / seizure – remove actuator (see actuator removal section) and then try to rotate valve stem – you can use grips on the end of the stem as an aid but make sure that the stem is protected from damage from the grips.

- Page 17 To help identify the unit, it is necessary to quote the serial number as given on the nameplate. Replacement parts and other information can be obtained from: UK Exchangers Ltd Unit 55, Stilebrook Road, Olney, Buckinghamshire, MK46 5EA Tel : 01234 244320...

-

Page 18: Select Mode

Appendix 1: Parameter listing for Temperature Controller (For commissioning Engineers use only) High Alarm 2 DIN PROCESS CONTROLLERS Range Max value* Low Alarm 2 CONCISE PRODUCT MANUAL Range Min value* Band Alarm 2 CAUTION: Installation should be only performed by technically ... -

Page 19: Setup Mode

Usage Auto/manual Control (enabled) Automatic / Manual select selection Remote / Local setpoint select Setpoint Select shown in 0 to 20 mA DC input Operator Mode 4 to 20 mA DC input Setpoint ramp adjustment ... -

Page 20: Product Information

OPERATOR MODE PRODUCT INFORMATION First select Product information mode from Select mode (refer to section 2). This mode is entered at power on, or accessed from Select mode (see section 2). Press to view each parameter. To exit from Product Information mode, hold down Note: All Configuration mode and Setup mode parameters must be set as required before press to return to Select mode.

Need help?

Do you have a question about the UKE-8-50 and is the answer not in the manual?

Questions and answers

my hot water heater is not working and it seems the controller box has failed. please advise on how to get a new box and how it should be configured