Kohler K241 Owner's Manual

10/12/14/16hp

Hide thumbs

Also See for K241:

- Owner's manual (14 pages) ,

- Service manual (137 pages) ,

- Multi-language owner's manual (8 pages)

Advertisement

Table of Contents

- 1 Safety Precautions

- 2 California Proposition 65 Warning

- 3 Oil Recommendations

- 4 Cold Weather Starting Hints

- 5 Maintenance Instructions

- 6 Maintenance Schedule

- 7 Carburetor Troubleshooting and Adjustments

- 8 Troubleshooting

- 9 Parts Ordering

- 10 Major Repair

- 11 Model Designation

- 12 Specifications

- Download this manual

See also:

Service Manual

OWNER'S MANUAL

MODELS

'

K241/ K301

(10

hP)

(12

hp)

K321,&

K341

(14

hp)

operating & maintenance

instructions

(16

hP)

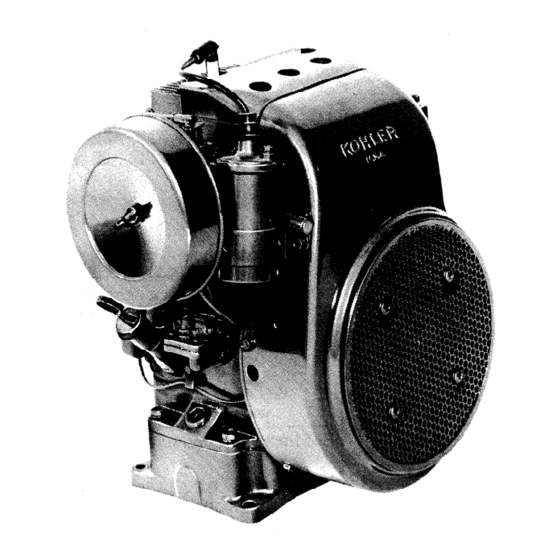

Congratulations

- You have selected a fine four-cycle,

single cylinder, air-cooled

engine. Kohler designs long

life strength and on-the-job

durability

into each engine. . . making a Kohler engine dependable..

.dependability

you can count on. Here are some reasons why:

0 Kohler engines are easy to service. All routine service areas (like the points, condenser,

air cleaner, spark

plug, and carburetor)

are easily and quickly accessible.

L

0

Parts subject to the most wear and tear (like the cylinders,

crankshafts,

and camshaft)

are made from

precision formulated

cast iron. Because the cast iron cylinders can be rebored, these engines can last even

longer.

0 Every Kohler engine is backed by a worldwide

network of over 10,000 distributors

and dealers. Service

support is just a phone call away. Call I-800-544-2444

(U.S. & Canada) for Sales & Service assistance.

To keep your engine in top operating condition, follow the maintenance

procedures

in this manual.

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Kohler K241

- Page 1 . . making a Kohler engine dependable.. .dependability you can count on. Here are some reasons why: 0 Kohler engines are easy to service. All routine service areas (like the points, condenser, air cleaner, spark plug, and carburetor) are easily and quickly accessible.

-

Page 2: Safety Precautions

Safety Precautions To insure safe operations please read the following statements and understand their meaning. Also refer to your equipment owner’s manual for other important safety information. This manual contains safety precautions which are explained below. Please read carefully. WARNING Warning is used to indicate the presence of a hazard that can cause severe personal injury, death, or substantial property damage if the warning is ignored. - Page 3 Safety Precautions (Cont.) WARNING WARNING WARNING Explosive Gas can cause fires and Carbon Monoxide can cause Accidental Starts can cause severe acid burns. severe nausea, fainting or death. severe injury or death. Charge battery only in a well Do not operate engine in closed or Disconnect and ground spark plug ventilated...

-

Page 4: Oil Recommendations

Spark Plug Ignition Coil Carbur ‘etor Cooling Blowe !r Air Filter Shrouds ,HOUSI Air lnta Oil Pan Screen Oil Drain *NOTE: Dipstick or oil fill plug is optional may vary depending on engine specification. Figure 1. Typical Command Horizontal Shaft Engine. Oil Recommendations Straight 30-weight oil is preferred. - Page 5 Fuel Recommendations Gasoline/Alcohol blends Gasohol (up to 10% ethyl alcohol, 90% unleaded gasoline by volume) is approved as a fuel for Kohler WARNING: Explosive Fuel! engines. Other gasoline/alcohol blends are not Gasoline is extremely flammable and its vapors can approved.

-

Page 6: Cold Weather Starting Hints

Place the choke control into the rron’y corrected. Do not jump start using another battery position. (refer to “Battery” below). See your Kohler Engine Service Dealer for trouble analysis. For a Warm Engine (normal operating temperatures) - Place the throttle control 3. -

Page 7: Maintenance Instructions

Have valve and tappet clearance checked2. Have cylinder head serviced214. ‘Perform these maintenance procedures more frequen fly under extreme/y dusty, dirty conditions. *Have a Kohler Engine Service Dealer perform this sewice. 30r annually whichever occurs first. 4250 hours hhen leaded gasoline is used. - Page 8 Check Oil Level NOTE: Make sure the oil level is checked BEFORE EACH USE and is maintained up to the “F” The importance of checking and maintaining mark on the dipstick. This includes engines proper oil level in the crankcase cannot be equipped with Oil SentryTM.

- Page 9 Do not wash the paper element or use pressurized air, as this will damage the element. Replace a dirty, bent, or damaged element with a genuine Kohler element. Handle new elements Precleaner carefully; do not use if the sealing surfaces are bent or damaged.

-

Page 10: Carburetor Troubleshooting And Adjustments

NOTE: Carburetor adjustments should be made only after the engine has warmed up. Kohler K241 through K341 engines are equipped with one of two basic types of carburetors - Kohler or Walbro - fixed main jet or adjustable main jet. - Page 11 1200 RPM. To ensure best Kohler Carburetor Adjustment results when setting the low idle fuel 1. With the engine stopped, turn the low and main needle, the low idle speed must not...

- Page 12 Walbro Fixed Jet out. Check the speed using a tachometer. Low Idle *NOTE: The actual low idle speed depends on K241 l-l I4 turns the application. Refer to the equipment 1-l /4 turns K301 manufacturer’s...

-

Page 13: Troubleshooting

Do not attempt to service or replace major engine components, or any items that require special timing or adjustment procedures. Have your Kohler Engine Service Dealer do this work. Possible Cause Improper Dirt In Dirty Incorrect... -

Page 14: Parts Ordering

5. warm from operation. See “Change Oil” on page 8. Always insist on genuine Kohler parts. All genuine Kohler parts meet strict standards for fit, reliability, 3 . Change oil in reduction gear unit, if so equipped. and performance. -

Page 15: Specifications

Our obligation under this warranty is expressly limited, at our option, to the replacement or repair at Kohler Co., Kohler, Wisconsin 53044, or at a service facility designated by us, of such part or parts as inspection shall disclose to have been defective. - Page 16 ENGINE DIVISION, KOHLER CO., KOHLER, WISCONSIN 53044 FOR SALES AND SERVICE INFORMATION IN U.S. AND CANADA, CALL I-800-544-2444 FORM NO.: TP-1346-C ISSUED: 1 O/87 REVISED: 8197 MAILED: LITHO IN U.S.A.

Need help?

Do you have a question about the K241 and is the answer not in the manual?

Questions and answers