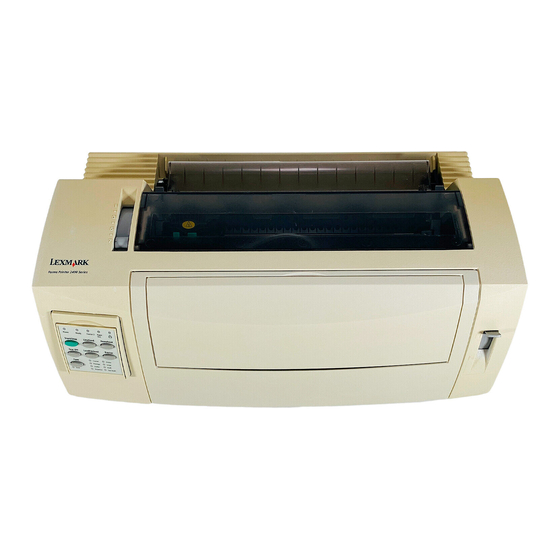

Lexmark Forms Printer 2400 Service Manual

2400 series forms printer

Hide thumbs

Also See for Forms Printer 2400:

- Specifications (2 pages) ,

- User manual (168 pages) ,

- Quick reference (19 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for Lexmark Forms Printer 2400

- Page 1 Lexmark Forms Printer 2400 Series 24XX-100 • Table of Contents • Start Diagnostics • Safety and Notices • Trademarks • Index • Manuals Menu Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries.

- Page 2 Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries. Other trademarks are the property of their respective owners.

-

Page 3: Table Of Contents

24xx Table of Contents Safety Information ........vii Preface . - Page 4 24xx Diagnostic Aids ........3-1 Power-On Self Test (POST) .

- Page 5 24xx Gears Removals ........4-31 Left Side Gears Removal .

- Page 6 24xx Preventive Maintenance ....... . .6-1 Lubrication ..........6-1 Lubrication Points .

-

Page 7: Safety Information

This product is designed, tested and approved to meet strict global safety standards with the use of specific Lexmark components. The safety features of some parts may not always be obvious. Lexmark is not responsible for the use of other replacement parts. •... - Page 8 Il prodotto è stato progettato, testato e approvato in conformità a severi standard di sicurezza e per l’utilizzo con componenti Lexmark specifici. Le caratteristiche di sicurezza di alcune parti non sempre sono di immediata comprensione. Lexmark non è responsabile per l’utilizzo di parti di ricambio di altri produttori.

- Page 9 Lexmark. Puede que las características de seguridad de algunas piezas no sean siempre evidentes. Lexmark no se hace responsable del uso de otras piezas de recambio. •...

- Page 10 Lexmark. Les característiques de seguretat d'algunes peces pot ser que no sempre siguin òbvies. Lexmark no es responsabilitza de l'us d'altres peces de recanvi. • La informació pel manteniment d’aquest producte està...

- Page 11 24xx...

-

Page 12: Preface

24xx Preface This manual is divided into the following chapters: • “General Information” contains a general description of the printer and the maintenance approach used to repair it. Special tools and test equipment are listed in this chapter, as well as general environmental and safety instructions. -

Page 13: General Information

24xx 1. General Information Printer Description The Lexmark Forms Printer 248X-100 and 249X-100 are small versatile tabletop printers suitable for use in the home or small business. They are especially well-suited for applications that use continuous or multipart forms. The 2481 and 2491 are wide-carriage versions of the 2480 and 2490. -

Page 14: Setup Mode

24xx Setup Mode Entering Setup Mode 1. Open the operator panel cover to access layer two. 2. Press Setup to put the printer in setup mode and print the Main Menu. 3. Press LineFeed to print a list of all the available options. 4. -

Page 15: Setup Menu Options

24xx Setup Menu Options Menus Function Forms Macro options Customize macros to print a variety of forms. Data options Defines how information is processed. Control options Defines how the printer performs basic tasks. Emulation options Determines how the printer interacts with software applications. -

Page 16: Setting The Tear Off Position

24xx Printer Settings Setting The Tear Off Position When Auto Tear Off is on, or set to One Second, it moves the top perforation of a continuous form to the tear off position, when all of the following are true: •... -

Page 17: Setting Top-Of-Form (Continuous - Pull Mode)

24xx Setting Top-Of-Form (Continuous - Pull Mode) 1. Turn the printer on. The Paper Out light blinks if no paper is loaded. 2. Move the paper select lever down to the continuous forms position. 3. Load continuous form paper on the pull tractor feed pins. 4. -

Page 18: Options

24xx Options The 24xx printers support the following options: • Auto Sheet Feeder (ASF) • Internal serial interface (RS232) • OKI emulation (9 wire only) • Tractor 2 Sheet Feeder Tools The basic tools necessary to service the 24xx-100 printers are: •... -

Page 19: Diagnostic Information

24xx 2. Diagnostic Information Start Make a quick visual check for defects (loose or broken parts, unplugged connectors, paper jams, and so on). Voltage, Ground, And Continuity Readings Voltage Readings All DC voltages must be within +5% through -10% of the values to be considered correct. -

Page 20: Error Indication Table

24xx Error Indication Table The following table describes the service check entries for the printer error indication codes. When an error indication changes after you have entered a service check, you have an intermittent problem. If this occurs, leave the service check and go to “Symptom Check Table”... - Page 21 24xx Status Alarm Action Power Beeps Home Position Error Ready Blinking Go to “Carrier Service Check” Paper Out Blinking times on page 2-16. Panel Lock Blinking Font Lock Blinking Tractor 2 Home Position Error If Tractor 2 is installed, remove it to determine whether the problem is with the carrier home position sensor or the Tractor 2 home...

- Page 22 24xx Status Alarm Action All LEDs None Power Failure Check the continuity of the power cord and the voltage of the user’s outlet. If they are correct, go to “Power Service Check” on page 2-27. Power None Operator Panel Failure Tractor 2 Go to “Operator Panel Service...

-

Page 23: Symptom Check Table

24xx Symptom Check Table 1. Select the symptom that best describes the problem. 2. Perform the appropriate action before you go to the indicated service check. Abnormal Indications Symptom Action 7 or more lights turn Disconnect the interface cable from the printer and on but do not turn turn the printer off and then on. - Page 24 24xx Abnormal Print Operation Problems Symptom Action Be sure the interface cable is connected properly. Printer will not print, or become ready. Abnormal operation, Go to “No Print or Abnormal Print Service incorrect characters, Check” on page 2-21. or incorrect line width.

-

Page 25: Error Indications

24xx Error Indications Symptom Action Ready and Paper Turn the printer off and then on. Out lights blink. Go to “Abnormal Indications” on page 2-5. Paper Out and Font Turn the printer off and then on. lights blink. Go to “Irrecoverable Operator Errors”... - Page 26 24xx Symptom Action Load/Unload Be sure the paper select lever is in the correct does not function position. when the push Go to “Paper Select Sensor Service Check” on tractor is installed. page 2-25. Form feed length is not correct. Load/Unload functions with cut sheets in use.

-

Page 27: Power Problems

24xx Symptom Action Lower feed roll shaft Be sure the paper select lever is in the correct rotates, but paper position. does not feed. Go to “Paper Feed Service Check” on Pressing FormFeed page 2-23. does not feed paper. Abnormal noise created while feeding. -

Page 28: Print Quality Problems

24xx Print Quality Problems Symptom Action No print, but carrier Adjust the form thickness lever to a lower number. moves as if printing. Be sure the printhead cables are not loose or damaged. Be sure the interface cable is connected properly. Check the ribbon cartridge for binds or damage. - Page 29 24xx Ribbon Feed Problems Symptom Action Check the ribbon cartridge for binds or damage. Ribbon comes off, becomes loose or Go to “Carrier Service Check” on page 2-16. folded, or jams. Ribbon feeds correctly but is noisy. 2-11 Diagnostic Information...

-

Page 30: Irrecoverable Operator Errors

24xx Irrecoverable Operator Errors Paper Out and Font lights blink. If this indication occurs, the problem may be with the paper present sensor or the paper select sensor. Check the following in the order listed and if the printer does not work correctly, go to the indicated service check. -

Page 31: Service Checks

24xx Service Checks Abnormal Noise Service Check Check the entire printer for loose parts. Action Ribbon Cartridge Remove and reinstall the ribbon cartridge. Printhead Disconnect the printhead cable(s). Run the print test (do not fold or damage the cables during the test). Go to “Print Test”... -

Page 32: Auto Sheet Feeder (Asf) Service Check

24xx Auto Sheet Feeder (ASF) Service Check Note: Be sure the sheet feeder is enabled in the Setup Mode. Go to “Setup Mode” on page 1-2. Auto Sheet Feeder Principles of Operation The Auto Sheet Feeder (ASF) feeds into the cut sheet paper entry throat. - Page 33 24xx Action Paper Select With the paper select lever in the cut sheet Sensor position, do the following: • Try to load a cut sheet with Load/Unload. (This button should not work) • If paper loads, go to “Paper Select Sensor Service Check”...

-

Page 34: Carrier Service Check

24xx Carrier Service Check Note: The Carrier Service Check includes the carrier drive, home position sensor and ribbon feed. Action Carrier Verify the carrier motor connector is connected to the logic board at CN2. If the carrier motor connector is connected properly, check the carrier belt and the ribbon cartridge for wear or damage. - Page 35 24xx Action Carrier Motor If the home position sensor is okay, verify the the resistance of the carrier motor windings are approximately 2 ohms for all printers. Check the resistance at the following pin locations: CN2 - 1 and CN2 - 3 CN2 - 2 and CN2 -4 Logic Board If all parts appear okay but the home position...

-

Page 36: Intermittent Problem Service Check

24xx Intermittent Problem Service Check FRU/Symptom Action The printer Check for the following: sometimes fails 1. Loose connectors. Reconnect all before POST is connectors to the logic board. complete. 2. Electrical noise or static discharge. Check the following: • Power supply ground. •... - Page 37 24xx FRU/Symptom Action Printer power The cause of this problem may be that the sometimes turns power circuit is failing, or the wiring is off. intermittently open. Check the following in sequence: 1. Check the user’s outlet voltage and be sure it is within tolerance.

- Page 38 24xx FRU/Symptom Action If the prior The following may cause undefined or suggestions have intermittent failures: not corrected the 1.Loose connector pins that fail to contact. problem. Check the following: • Reconnect the connectors of all FRUs and printer interface cables. •...

-

Page 39: No Print Or Abnormal Print Service Check

24xx No Print or Abnormal Print Service Check FRU/Function Action Logic Board If the print test does not complete correctly, replace the logic board and reset the bidirectional print adjustment. See “Bidirectional Print Adjustment” on page 4-4. Interface Cable Check the connection and continuity of the interface cable. -

Page 40: Paper Present Sensor Service Check

24xx Paper Present Sensor Service Check Action Paper Present With no paper in the printer, the tractor in the Sensor push position, and the paper select lever set to continuous forms, press Load/Unload; the gear train should turn forward to load paper. Activate the paper present sensor with a screwdriver and press Load/Unload again;... -

Page 41: Paper Feed Service Check

24xx Paper Feed Service Check Note: If paper creases or jams frequently, verify the paper is neither too thick nor thin. If necessary, refer the user to the User’s Guide for specifications of acceptable papers. If the paper does not stop in the correct location, see “Paper Present Sensor Service Check”... - Page 42 24xx FRU / Symptom Action Operator Panel If paper does not move at all, verify the Load/Unload button is working as follows: With the tractor in the push position, power off, power on and then press Load/Unload. The carrier should move to the center of the platen. If it does not, go to “Operator Panel Service Check”...

-

Page 43: Paper Select Sensor Service Check

24xx Paper Select Sensor Service Check If form feed length is off by about 1 inch (25 mm), enter Setup Mode and verify that the form length setting is correct. Go to “Setup Mode” on page 1-2. Action Paper Select Remove all paper from the printer and do the Sensor following:... -

Page 44: Post Service Check

24xx Action Pull Tractor A failed pull tractor sensor can cause Sensor Load/Unload to malfunction. With the tractor in the push position: • Press Load/Unload several times while alternately holding down and releasing the left pull tractor actuator. The paper should not park or load when the pull tractor actuator is held down. -

Page 45: Power Service Check

24xx Power Service Check Action Power Supply If the carrier does not move to the left after turning the printer off and then on, be sure the line cord voltage to the power supply is correct and the power supply outputs are +40 V dc at CN12-1, +40 V dc at CN12-2 and +5 V dc at CN12-6. -

Page 46: Print Speed Service Check

24xx Action Logic Board If no problem is found with the other components, but the power problem still remains, replace the logic board and reset “Bidirectional Print Adjustment” on page 4-4. Print Speed Service Check The speed of the 24xx printers varies with the font, forms thickness setting and printhead temperature. -

Page 47: Printhead Service Check

24xx Printhead Service Check Action Printhead Cables If the printout contains missing or extra dots or Printhead lines, do the following: • Check the continuity and connection of the printhead cables and the short flexible cable. • Be sure the voltages to the logic board are correct. - Page 48 24xx Printhead Impedance Tables 2480, 2490 - Approximately 5 ohms Connector CN400-13 & CN400-4 CN400-9 & CN400-6 CN400-15 & CN400-18 CN400-1 & CN400-7 CN400-17 & CN400-20 CN400-5 & CN400-2 CN400-19 & CN400-16 CN400-8 & CN400-3 CN400-10 & CN400- 14 2481, 2491 - Approximately 8 to 16 ohms Connector Connector CN300-1 &...

-

Page 49: Pull Tractor Sensor Service Check

24xx Pull Tractor Sensor Service Check The pull tractor sensor detects the tractor in the pull position and disables load/unload and auto tear-off. A failed sensor may prevent load/unload from functioning, with the tractor in the push position. Action Pull Tractor With the tractor in the push position, press Sensor Load/Unload several times while alternately... -

Page 50: Top-Of-Forms Service Check

24xx Top-Of-Forms Service Check Action Top-Of-Form Check that the top-of-form sensor and its flag Sensor are properly installed and are not damaged. Logic Board Remove the paper and set the paper select lever to the cut sheet position and turn the printer on. -

Page 51: Tractor 2 Service Check

24xx Tractor 2 Service Check The Tractor 2 in-place sensor opens during installation, when its actuator touches the printer cover. The home sensor detects the position of the slider: • When Tractor 2 is selected, the motor-driven Tractor 2 slider pushes the printer sub slider cam lever to engage the printer gear train which drives the Tractor 2 tractors. - Page 52 24xx Action Logic Board Remove Tractor 2 from the printer but leave the cable connected. Be sure the slider (the black plastic piece just above the right cover) moves after turning the printer off and then on. If the slider does not move after turning the printer off and then on: •...

- Page 53 24xx 3 Beeps and Tractor 2 LED blinks 3 times Tractor 2 selected from operator panel but printer does not detect Tractor 2 or detects that the Tractor 2 mechanism is not installed. Action Tractor 2 Check the Tractor 2 in-place sensor or the Board/Cable Asm.

-

Page 54: Signal Connections

24xx Tractor 2 Paper Feed Problems Action Tractor 2 Be sure the gear on the printer that drives Tractor 2 turns freely when the lever is not pressed, but remains still when the lever is pressed. Remove the Tractor 2 unit from the printer and remove all paper. -

Page 55: Diagnostic Aids

24xx 3. Diagnostic Aids The printer contains self tests to help find and solve problems. You do not need to connect the printer to a computer or terminal to run these tests. Types of self tests are: • Power-On Self Test (POST) •... -

Page 56: Power-On Self Test (Post)

24xx Power-On Self Test (POST) The following tests are automatically performed when the printer is turned on. • LEDs Test - Checks operation of LEDs on the operator panel. The LEDs turn on and off after the printer is turned on, then all LEDs turn on for a few seconds. -

Page 57: Print Test

24xx Print Test The print test helps you test and troubleshoot the printer. To start the print test: 1. Paper must be at the print position; test does not print if paper is parked. 2. Press and hold Line Feed and turn the printer on. 3. -

Page 58: Hex Trace Mode

24xx Hex Trace Mode The hex trace mode helps the user test and troubleshoot programs. Use the hex trace procedure to get a hexadecimal printout of the data stream sent to the printer. All data, including both control and character data, print in hexadecimal instead of ASCII. To activate hex trace mode: 1. -

Page 59: Printer Default Settings

24xx Printer Default Settings U.S. Defaults To initialize or reset the printer to the U.S. factory defaults: (Code page 437 Character Set 1, form length 11 inch) 1. Make sure paper and the ribbon cartridge are installed. 2. Turn the printer off. 3. -

Page 60: Clearing Paper Jams

24xx Clearing Paper Jams Cut Sheet Jams To clear cut form paper jams: 1. Turn the printer off. 2. Set the forms thickness lever to position 7. 3. Push the paper select lever down to the continuous forms position. 4. Gently pull out the sheet of paper from the front of the printer. 5. -

Page 61: Repair Information

24xx 4. Repair Information This chapter contains adjustments and removal procedures. Whenever parts are replaced, make sure that all adjustments are correct by running diagnostics procedures and checking adjustments as needed. Handling ESD-Sensitive Parts Many electronic products use parts that are known to be sensitive to electrostatic discharge (ESD). -

Page 62: Adjustments

24xx Adjustments CAUTION: Be sure to unplug the power cord whenever you are working on the printer with one of the covers removed. Printhead-to-Platen Gap Adjustment Perform the printhead-to-platen gap adjustment after replacing the carrier, platen, lower pinch roller, ribbon drive rack gear, left side frame, right side frame, paper separator, lower feed roller, or paper guide. - Page 63 24xx 8. Using a feeler gauge [1], slowly adjust the left gap adjust bushing [2] counterclockwise, until a gap of (within 0.33 and 0.37 mm) exists between the printhead [3] and the platen. 9. Move the printhead to the right edge of the rubber on the platen and using a feeler gauge [1], slowly adjust the right gap adjust bushing [2] clockwise, until a gap of (within 0.33 and 0.37 mm) exists between the printhead [3] and the platen.

-

Page 64: Bidirectional Print Adjustment

24xx Note: For maximum print quality, adjust the head gap on both the left and right sides of the printer to within +/- 0.01mm. If the gap value exceeds the specified range, return to step 4 and re-adjust both left and right gap adjust bushings. 11. -

Page 65: Removal Procedures

24xx Removal Procedures CAUTION: Be sure to unplug the power cord whenever you are working on the printer with one of the covers removed. Covers, Removals Repair Information... -

Page 66: Covers, Front Removal

24xx Covers, Front Removal 1. Rotate the front cover out and up about three inches from the bottom of the printer. 2. Push the front cover up and out of the printer. Covers, Ribbon Access Removal 1. Pull both gray spring loaded ribbon access cover release latches [A], on either side of the ribbon access cover, up toward the front of the printer. -

Page 67: Covers, Option Removal

24xx Covers, Option Removal 1. From the bottom, pull the option cover [A] outward and up, removing it from the printer. Repair Information... -

Page 68: Covers, Top Removal

24xx Covers, Top Removal 1. Turn the printer off and disconnect the power cord at the printer. 2. Remove the tractor assembly, if it is installed in the pull tractor position, by pressing the locking levers and pulling the tractor assembly out of the printer. - Page 69 24xx 8. Turn the printer upside down. 9. Insert a flat blade screwdriver into each of the four holes [A] in the bottom cover, releasing the top cover from the bottom cover. Repair Information...

- Page 70 24xx 10. Turn the printer right side up and insert a flat blade screwdriver into each of the two holes [A] in the back of the top cover. 11. Lift the top cover up and over the print unit assembly. Note: When replacing the top cover, be sure the operator panel cable is correctly aligned and inserted securely into the logic board.

-

Page 71: Covers, Operator Panel Assembly Removal

24xx Covers, Operator Panel Assembly Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Disconnect the operator panel cable from the operator panel card, on the inside of the top cover. 3. Push down on the two latches [A] at the top of the operator panel on the inside of the top cover, as shown. -

Page 72: Covers, Bottom Removal

24xx Covers, Bottom Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the logic board. Go to “Logic Board Removal” on page 4-14. 3. Remove the power supply unit. Go to “Power Supply Removal”... -

Page 73: Electronics Removals

24xx Electronics Removals EPROM Removal 1. Remove the options cover [A], by pulling it outward, up and out of the printer. 2. Remove the EPROM module. Note: When replacing the EPROM module, be sure the notch on the module is toward the front of the printer. 4-13 Repair Information... -

Page 74: Logic Board Removal

24xx Logic Board Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Disconnect all cables connected to the logic board. Go to “Logic Board (9w & 24w)” on page 5-3, for connector location details. Note: Do not twist the flexible cable when disconnecting the printhead cable(s). -

Page 75: Power Supply Removal

24xx Power Supply Removal CAUTION: The power supply may be hot. 1. Turn off the printer and disconnect the power cord at both ends. 2. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 3. Remove the print unit. Go to “Print Unit Removal”... -

Page 76: Carrier Removals

24xx Carrier Removals Carrier Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the printhead from the carrier. Go to “Printhead Removal” on page 4-27. 3. Loosen the carrier belt: Loosen the tension screw [A]. Remove tension from the belt, by pulling up on the belt. - Page 77 24xx 4. Remove the retaining wire [A] from the left side of the carrier shaft. 4-17 Repair Information...

- Page 78 24xx 5. Remove the screw [A] from the forms thickness lever and remove the lever. 4-18 Service Manual...

- Page 79 24xx 6. Remove the lower carrier motor mount screw [A]. 7. Remove the two screws [B] from the carrier shaft bushing bracket on the left end of the carrier shaft and remove the bracket. 8. Remove the E-clip from the right side of the carrier shaft. 4-19 Repair Information...

- Page 80 24xx 9. Push the carrier shaft [A] from the right side and out the left side of the printer. 10. Remove the carrier from the printer. Note: Following replacement, perform the Printhead-to-Platen Gap Adjustment. Go to “Printhead-to-Platen Gap Adjustment” on page 4-2.

-

Page 81: Carrier, Motor Assembly Removal

24xx Carrier, Motor Assembly Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Loosen the carrier belt Loosen the tension screw [A]. Remove tension from the carrier belt, by pulling up on the belt. Tighten the tension screw. - Page 82 24xx 4. Remove the screw [A] from the forms thickness lever and remove the lever. 4-22 Service Manual...

- Page 83 24xx 5. Remove the screw [A] securing the carrier motor bracket to the bottom cover. 6. Disconnect the printhead cable from the logic board and move it back and out of the way, as shown. 7. Remove the five screws [B] securing the carrier motor bracket to the print unit.

-

Page 84: Paper Handling Removals

24xx Paper Handling Removals Paper Select Lever Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Release the latch and remove the paper select lever from the right side frame. Paper Feed Motor Removal 1. -

Page 85: Form Thickness Lever Removal

24xx Form Thickness Lever Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the screw [A] from the lever and remove the form thickness lever. 4-25 Repair Information... -

Page 86: Print Handling Removals

24xx Print Handling Removals Platen Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the two platen screws [A] from each end of the platen. 3. Remove the platen from the paper tray. 4. -

Page 87: Printhead Removal

24xx Printhead Removal 1. Turn the printer off. 2. Disconnect the power cord at the printer and allow the printhead to cool for 15 minutes, prior to handling. 3. Set the form thickness lever to position 7. 4. Remove the ribbon access cover. Go to “Covers, Ribbon Access Removal”... -

Page 88: Print Unit Removal

24xx Print Unit Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Disconnect all cables from the logic board, except the power supply cable. 3. Remove the screw from the form thickness lever and remove the lever. - Page 89 24xx 5. Remove the two grommet anchored screws [A] from the right side of the print unit. 6. Remove the print unit from the bottom cover, by pulling up forcefully on both sides of the print unit. 4-29 Repair Information...

-

Page 90: Ribbon Drive Rack Gear Removal

24xx Ribbon Drive Rack Gear Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the carrier. Go to “Carrier Removal” on page 4-16. 3. Unsnap the white plastic end stop [A] from the top left side of the print unit. -

Page 91: Gears Removals

24xx Gears Removals Left Side Gears Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the three screws [A] from the serial interface card bracket. 4-31 Repair Information... - Page 92 24xx 3. Remove the four screws [A] from the paper feed motor bracket assembly. 4-32 Service Manual...

- Page 93 24xx 4. Remove the paper feed motor bracket assembly, exposing the gears, as shown. 4-33 Repair Information...

-

Page 94: Right Side Gears, Sub Frame Removal

24xx Right Side Gears, Sub Frame Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Unhook the wire retainer [A] from the carrier shaft. 3. Remove the two screws and washers [B] from the sub frame. 4. - Page 95 24xx 5. Remove the sub frame exposing the right side gears [A], as shown. 4-35 Repair Information...

-

Page 96: Rollers Removals

24xx Rollers Removals Roller, Upper Feed Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the screw from the print cable shield and remove the shield. 3. Remove the gear from the left end of the upper feed roller, as shown. - Page 97 24xx 4. Remove the two screws [A] from the right upper feed roller bracket. One screw also retains the upper feed roller ground clip. 5. Pull the upper feed roller from the left bracket and out of the printer. 6. Be sure to perform the Printhead-to-Platen Gap Adjustment procedure.

-

Page 98: Roller, Lower Pinch Removal

24xx Roller, Lower Pinch Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Slide the carrier to the far left of the printer. 3. Remove the four screws [A] from the paper feed motor bracket. 4. - Page 99 24xx 7. Unhook the spring clip [A] from the right end of the lower pinch roller shaft and push it off the gray slotted spring block [B] toward the back of the printer, as shown. 8. Slide the carrier to the right side of the printer. 4-39 Repair Information...

- Page 100 24xx 9. Unhook the spring clip [A] from the left end of the lower pinch roller shaft and push it off the gray slotted spring block [B] toward the back of the printer, as shown. 10. Slide the carrier to the center of the printer. 11.

-

Page 101: Roller, Lower Feed Removal

24xx Roller, Lower Feed Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the print unit. Go to “Print Unit Removal” on page 4-28. 3. Remove the carrier. Go to “Carrier Removal” on page 4-16. - Page 102 24xx 9. Remove the two screws [A] securing the platen to the side frames. 10. Remove the carrier motor bracket. Go to “Carrier, Motor Assembly Removal” on page 4-21. 11. Remove the five screws securing the left side frame and remove the frame.

-

Page 103: Sensors Removals

24xx Sensors Removals 4-43 Repair Information... -

Page 104: Sensor, Pull Tractor Removal

24xx Sensor, Pull Tractor Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the small screw securing the pull tractor sensor to the inside of the left frame. Go to “Sensors Removals” on page 4-43. -

Page 105: Sensor, Paper Select Removal

24xx Sensor, Paper Select Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Remove the print unit. Go to “Print Unit Removal” on page 4-28. 3. Turn the print unit upside down. 4. Remove the 4 small screws securing the paper select sensor to the left side frame. -

Page 106: Sensor, Home Position Sensor Removal

24xx Sensor, Home Position Sensor Removal 1. Remove the top cover. Go to “Covers, Top Removal” on page 4-8. 2. Disconnect the home position sensor cable from the logic board. 3. Unsnap the home position sensor [A] from the frame. 4-46 Service Manual... -

Page 107: Options Removals

24xx Options Removals Auto Sheet Feeder Gears Removal 1. Remove the right cover. 2. Release the joint gear latch [A] and remove the joint gear. 3. Release the idler gear latch and remove the idler gear. 4. Release the pick-up gear latch and remove the gear. 5. -

Page 108: Auto Sheet Feeder Pick-Up Roller Removal

24xx Auto Sheet Feeder Pick-up Roller Removal 1. Remove the covers and the cut sheet support. 2. Release the joint gear latch [A] and remove the joint gear, idler gear, and pick-up gear. 3. Remove the left and right roller bushings. 4. -

Page 109: Connector Locations

24xx 5. Connector Locations This chapter identifies the locations of specific parts of the printer. Connector Locations... -

Page 110: Signal Connections

24xx Signal Connections Power Supply (9w & 24w) Service Manual... - Page 111 24xx Connector Pin # Signal +40 V dc +40 V dc Power Gnd Power Gnd Signal Gnd +5 V dc Power Save Mode Connector Signal Fuse Connector Locations...

- Page 112 24xx Logic Board (9w & 24w) Service Manual...

-

Page 113: Logic Board - Parallel Interface Cable (9W & 24W)

24xx Logic Board - Parallel Interface Cable (9w & 24w) Connector Pin # Signal Pin # Signal -Strobe Signal Gnd Data 0 Signal Gnd Data 1 Signal Gnd Data 2 Signal Gnd Data 3 Signal Gnd Data 4 Signal Gnd Data 5 Signal Gnd Data 6... - Page 114 24xx Logic Board (9w & 24w) Service Manual...

-

Page 115: Logic Board - Serial Board (9W & 24W)

24xx Logic Board - Serial Board (9w & 24w) Connector Pin # Signal +5 V dc +5 V dc -CTS CN200 Signal Gnd SBSET Connector Pin # Signal +5 V dc +5 V dc -CTS Signal Gnd SBSET Connector Locations... - Page 116 24xx Logic Board (9w & 24w) Service Manual...

-

Page 117: Logic Board - Usb Cable (9W & 24W)

24xx Logic Board - USB Cable (9w & 24w) Connector Pin # Signal +5 V dc DMNS CN201 DPLS Signal Gnd Logic Board - DC Power (9w & 24w) Connector Pin # Signal +40 V dc +40 V dc Power Gnd CN12 Power Gnd Signal Gnd... - Page 118 24xx Logic Board (9w & 24w) 5-10 Service Manual...

-

Page 119: Logic Board - Printhead (9W)

24xx Logic Board - Printhead (9w) Connector Pin # Signal CN400 HDTHERMO +5 V dc 5-11 Connector Locations... - Page 120 24xx Logic Board (9w & 24w) 5-12 Service Manual...

-

Page 121: Logic Board - Printhead (24W)

24xx Logic Board - Printhead (24w) Connector Pin # Signal +40 V dc +40 V dc +40 V dc +40 V dc CN300 +40 V dc +40 V dc +40 V dc 5-13 Connector Locations... - Page 122 24xx Logic Board (9w & 24w) 5-14 Service Manual...

- Page 123 24xx Logic Board - Printhead (24w) Connector Pin # Signal HDTHERMO CN301 +5 V dc +40 V dc +40 V dc 5-15 Connector Locations...

- Page 124 24xx Logic Board (9w & 24w) 5-16 Service Manual...

-

Page 125: Logic Board - Gap Set Sensor (9W & 24W)

24xx Logic Board - Gap Set Sensor (9w & 24w) Connector Pin # Signal GAP1 Signal Gnd GAP2 Logic Board - Home Position Sensor (9w & 24w) Connector Pin # Signal HPSW Signal Gnd Logic Board - Paper Present Sensor (9w & 24w) Connector Pin # Signal... - Page 126 24xx Logic Board (9w & 24w) 5-18 Service Manual...

-

Page 127: Logic Board - Paper Select Sensor (9W & 24W)

24xx Logic Board - Paper Select Sensor (9w & 24w) Connector Pin # Signal TR/FR Signal Gnd Logic Board - Pull Tractor Sensor (9w & 24w) Connector Pin # Signal PLTR Signal Gnd Logic Board - Top Of Form Sensor (9w & 24w) Connector Pin # Signal... - Page 128 24xx Logic Board (9w & 24w) 5-20 Service Manual...

-

Page 129: Logic Board - Carrier Motor (9W & 24W)

24xx Logic Board - Carrier Motor (9w & 24w) Connector Pin # Signal Logic Board - Paper Feed Motor (9w & 24w) Connector Pin # Signal 5-21 Connector Locations... - Page 130 24xx Logic Board (9w & 24w) 5-22 Service Manual...

-

Page 131: Logic Board - Operator Panel (9W & 24W)

24xx Logic Board - Operator Panel (9w & 24w) Connector Pin # Signal +5 V dc SLATCH +5 V dc CN13 Logic Board Signal Gnd Signal Gnd SCLK Connector Pin # Signal +5 V dc SLATCH +5 V dc Operator Panel Signal Gnd Signal Gnd SCLK... - Page 132 24xx Logic Board (9w & 24w) 5-24 Service Manual...

-

Page 133: Logic Board - Dual Tractor Cable (9W & 24W)

24xx Logic Board - Dual Tractor Cable (9w & 24w) Connector Pin # Signal +40 V dc +40 V dc Power Gnd Power Gnd +5 V dc COCOM CN10 D-SET Signal Gnd D-H.P D-POS 5-25 Connector Locations... -

Page 134: Serial Board - Serial Cable (9W & 24W)

24xx Serial Board - Serial Cable (9w & 24w) Connector Pin # Signal Pin # Signal Chassis Gnd -CTS Signal Gnd 5-26 Service Manual... -

Page 135: Tractor 2 Cable Connectors

24xx Tractor 2 Cable Connectors The Tractor 2 cable is soldered to the Tractor 2 board at CN1; there is no connector. Connector Mode CN1-1 +26 V dc. CN1-2 +26 V dc. CN1-3 Frame GND. CN1-4 Not used. CN1-5 +5 V dc. CN1-6 Motor common. - Page 136 24xx 5-28 Service Manual...

-

Page 137: Preventive Maintenance

24xx 6. Preventive Maintenance This chapter describes procedures for printer preventive maintenance. Following these recommendations can help prevent problems and maintain optimum performance. Lubrication Warning: Petroleum-based lubricants can attack polycarbonate parts causing premature failure. Use only mineral oil-based lubricants. The following parts should be lubricated when replaced: •... -

Page 138: Lubrication Points

24xx Lubrication Points • Oil Felt (carrier block) • Tractor Shaft Grease • Side Frame (Left) and Gears • Side Frame (Right) and ASF Gears • Pinch Roller, Pinch Roller Springs and Paper Separator • ASF Side Frames, Gears and Combination Lock Mechanism •... -

Page 139: Lubrication Points (Oil)

24xx Lubrication Points (Oil) The oil felt [1] in the carrier block. The tractor shaft [1]. Preventive Maintenance... -

Page 140: Lubrication Points (Grease)

24xx Lubrication Points (Grease) Gear mounting studs on the right side frame [2]. The lower pinch roller [2]. Service Manual... - Page 141 24xx Lubrication Points (Grease) Continued Gear mounting studs on the left side frame [2]. Preventive Maintenance...

- Page 142 24xx Lubrication Points (Grease) Continued Gear mounting studs on the left ASF side frame [2]. Gear mounting studs on the right ASF side frame [2]. Service Manual...

-

Page 143: Parts Catalog

24xx 7. Parts Catalog How To Use This Parts Catalog SIMILAR ASSEMBLIES: If two assemblies contain a majority of identical parts, they are shown on the same list. Common parts are shown by one index number. Parts peculiar to one or the other of the assemblies are listed separately and identified by description. -

Page 144: Assembly 1: Covers

24xx Assembly 1: Covers Service Manual... - Page 145 24xx Asm- Part Description Index Number 1 - 1 12G3877 Guide, Left Paper 12G3873 Cover Asm., Front Unit (2480, 2490) 12G3874 Cover Asm., Front Unit (2481, 2491) 12G3878 Guide, Right Paper 12G3858 Cover, Ribbon Access Unit (2480) 12G3859 Cover, Ribbon Access Unit (2481) 12G3868 Cover, Ribbon Access Unit (2490) 12G3869...

- Page 146 24xx Assembly 1: Covers Service Manual...

- Page 147 24xx Asm- Part Description Index Number 1 - 8 12G3856 Cover, Bottom (2480, 2490) 12G3857 Cover, Bottom (2481, 2491) 12G3854 Tractor Unit (2480, 2490) 12G3855 Tractor Unit (2481, 2491) 12G3850 Frame, Right Side Tractor 12G3853 Tractors, Left and Right 79F4830 Support, Tractor Paper 12G3851 Shaft Set, Tractor (2480, 2490)

-

Page 148: Assembly 2: Carrier / Paper Feed Right Side

24xx Assembly 2: Carrier / Paper Feed Right Side Service Manual... - Page 149 24xx Asm- Part Description Index Number 2 - 1 12G3841 Carrier Roller Set 12G3894 Printhead Assembly (2480, 2481) 12G3895 Printhead Assembly (2490, 2491) 12G3838 Carrier Unit (2480) 12G3837 Carrier Unit (2481) 12G3840 Carrier Unit (2490) 12G3839 Carrier Unit (2491) 12G3889 Cable, Printhead (2480) 12G3888 Cable, Printhead (2481)

- Page 150 24xx Assembly 2: Carrier / Paper Feed Right Side Service Manual...

- Page 151 24xx Asm- Part Description Index Number 2 - 22 12G3832 Roller, Upper Feed (2480, 2490) 12G3833 Roller, Upper Feed (2481, 2491) Parts Catalog...

-

Page 152: Assembly 3: Carrier / Paper Feed Left Side

24xx Assembly 3: Carrier / Paper Feed Left Side 7-10 Service Manual... - Page 153 24xx Asm- Part Description Index Number 3 - 1 12G3905 Gears and Bushings, Parts Packet (248X) 12G3906 Gears and Bushings, Parts Packet (249X) 12G3907 Screws, Washers and Clips, Parts Packet 12G3942 Kit, Pull Tractor Actuator 12G3817 Frame, Left Side (2480, 2481) 12G3818 Frame, Left Side (2490, 2491) 12G3940...

- Page 154 24xx Assembly 3: Carrier / Paper Feed Left Side 7-12 Service Manual...

- Page 155 24xx Asm- Part Description Index Number 3 - 24 12G3931 Kit, Head Gap Adjustment 12G3947 Lever, Form Thickness 56P1224 Motor, Paper Feed (with BKT) 11A3274 Gear, Idle (248X) 11A3275 Gear, Idle (249X) 7-13 Parts Catalog...

-

Page 156: Assembly 4: Electronics

24xx Assembly 4: Electronics 7-14 Service Manual... - Page 157 24xx Asm- Part Description Index Number 4 - 1 12G3907 Screws, Washers and Clips, Parts Packet 12G3836 Kit, ESD Ground (2490, 2491) 12G3887 Kit, ESD Ground (2480, 2481) 12G3801 Power Supply Unit, LV 12G3800 Power Supply Unit, HV 12G3812 Module, EPROM (248X) 12G3813 Module, EPROM (249X) 12G3848...

-

Page 158: Assembly 5: Asf - Roller / Support

24xx Assembly 5: ASF - Roller / Support 7-16 Service Manual... - Page 159 24xx Asm- Part Description Index Number 5 - 1 12G3814 Support, ASF Cut Sheet W/ Guides (2480, 2490) 12G3908 Support, ASF Cut Sheet W/ Guides (2481, 2491) 95F6886 Roller, ASF Upper Feed (2480, 2490) 95F6896 Roller, ASF Upper Feed (2481, 2491) 95F6887 Roller, ASF Lower Feed (2480, 2490) 95F6897...

-

Page 160: Assembly 6: Asf - Side Frame / Covers

24xx Assembly 6: ASF - Side Frame / Covers 7-18 Service Manual... - Page 161 24xx Asm- Part Description Index Number 6 -1 95F6893 ASF Springs, Parts Packet 95F6892 ASF Gears and Bushings, Parts Packet 12G3920 Cover, ASF Right 95F6894 ASF Screws, Parts Packet 12G3921 Cover, ASF/TR2 Front (2480, 2490) 12G3930 Cover, ASF/TR2 Front (2481, 2491) 12G3945 Frame, ASF Side Right 12G3939...

-

Page 162: Assembly 7: Tractor 2 Option

24xx Assembly 7: Tractor 2 Option 7-20 Service Manual... - Page 163 24xx Asm- Part Description Index Number 7 - 1 12G3923 Table, Tractor 2 Paper W/ Guides (2480, 2490) 12G3924 Table, Tractor 2 Paper W/ Guides (2481, 2491) 11A3338 Guide, Tractor 2 Paper 12G3926 Tractor and Frame Assembly, Tractor 2 (2480, 2490) 12G3927 Tractor and Frame Assembly, Tractor 2 (2481, 2491) 12G3853...

-

Page 164: Coax / Twinax Adapter

24xx Coax / Twinax Adapter Asm- Part Description Index Number 12G3704 Adapter, Coax (Power Cable and Adapter) 12G3705 Adapter, Twinax (Power Cable and Adapter) 12G3709 Bracket, Adapter (Bracket Only) 13A0297 Cable, Coax (Cable Only) 13A0296 Cable, Twinax (Cable Only) 11A6109 Cable, Socket Power Coax, Twinax (Socket Power Cable Only) 7-22... - Page 165 24xx Index Abbreviations Entering Setup Mode Adjustments Error Codes Bidirectional Print Error Indication Table Printhead-to-Platen Gap ESD-sensitive parts Exiting Setup Mode Principles of Operation 2-14 General Information Connections Logic Board Carrier Motor 5-20 Hex Trace Mode DC Power Dual Tractor Cable 5-24 Gap Set Sensor 5-16...

- Page 166 24xx Paper Jams Removals Clearing Continuous Forms Clearing Cut Sheet Gears 4-47 Parts Pick-up Roller 4-48 Carrier 4-16 Roller/Support 7-16 Carrier Motor Assembly 4-21 Side Frame/Covers 7-18 Covers Carrier/Paper Feed Left Side 7-10 Bottom 4-12 7-12 Front Carrier/Paper Feed Right Side Operator Panel 4-11 Option...

-

Page 167: Index

24xx Safety Information Tools Service Checks 2-13 Abnormal Noise 2-13 Abnormal Print 2-21 Voltage, Ground, and Continuity Auto Sheet Feeder 2-14 Part Numbers Carrier 2-16 Intermittent Problem 2-18 11A3274 7-13 No Print 2-21 11A3275 7-13 Operator Panel 2-21 11A3283 7-21 Paper Feed 2-23 11A3284... - Page 168 24xx 12G3827 7-11 12G3889 12G3828 7-11 12G3890 12G3831 7-11 12G3891 12G3832 12G3893 7-17 12G3833 12G3894 12G3834 12G3895 12G3835 12G3896 7-11 12G3836 7-15 12G3897 12G3837 12G3898 12G3838 12G3900 12G3839 12G3901 12G3840 12G3902 7-11 12G3841 12G3903 7-15 12G3844 7-11 12G3904 7-15 12G3845 7-11 12G3905 7-11...

- Page 169 24xx 12G3943 12G3944 7-17 12G3945 7-19 12G3946 7-11 12G3947 7-13 12G3948 7-11 12G3999 13A0296 7-22 13A0297 7-22 1333275 7-17 1339517 1339518 1339519 1339520 1339521 1339522 1339523 1339524 1339525 56P1219 7-11 56P1224 7-13 56P1476 7-15 79F4757 79F4802 7-11 79F4830 79F4834 7-11 95F6885 7-17 95F6886...

- Page 170 24xx Service Manual...

Need help?

Do you have a question about the Forms Printer 2400 and is the answer not in the manual?

Questions and answers