Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Omron CPM1A

- Page 1 Cat. No. W317-E1-11 SYSMAC CPM1A Programmable Controllers OPERATION MANUAL...

- Page 2 CPM1A Programmable Controllers Operation Manual Revised October 2007...

- Page 4 1. Indicates lists of one sort or another, such as procedures, checklists, etc. OMRON, 1997 All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permis- sion of OMRON.

-

Page 6: Table Of Contents

....Initial System Checks and Test Run Procedure ....... . . - Page 7 TABLE OF CONTENTS Appendices A Standard Models ............

- Page 8 Section 4 describes SSS capabilities, how to connect the Programming Console, and how to perform the various Programming Console operations. Section 5 describes how to perform a test run and how to diagnose and correct the hardware and soft- ware errors that can occur during PC operation.

- Page 9 TABLE OF CONTENTS...

- Page 10 Warranty and Limitations of Liability Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á WARRANTY Á...

- Page 11 Application Considerations Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á SUITABILITY FOR USE Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á...

- Page 12 Disclaimers Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á CHANGE IN SPECIFICATIONS Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á Á...

- Page 14 This section provides general precautions for using the Programmable Controller (PC) and related devices. The information contained in this section is important for the safe and reliable application of the Programmable Con- troller. You must read this section and understand the information contained before attempting to set up or operate a PC system.

-

Page 15: Intended Audience

WARNING It is extremely important that a PC and all PC Units be used for the specified purpose and under the specified conditions, especially in applications that can directly or indirectly affect human life. You must consult with your OMRON representative before applying a PC System to the above-mentioned applications. -

Page 16: Operating Environment Precautions

When connecting a personal computer or other peripheral device to the CPM1A, either ground the 0 V side of the CPM1A or do not ground at all. Depending on the method of grounding, the 24-V power supply may short-circuit; do not ground the 24-V side as shown in the following diagram. -

Page 17: Application Precautions

Always heed these precautions. Failure to abide by the following precautions could lead to serious or possibly fatal injury. • Always connect to a ground of 100 Ω or less when installing the Units. Not con- necting to a ground of 100 Ω or less may result in electric shock. - Page 18 • Do not place objects on top of the cables. Doing so may break the cables. • When replacing parts, be sure to confirm that the rating of a new part is correct. Not doing so may result in malfunction or burning.

- Page 19 (The PC Setup setting in DM 6601 can be used to back up this data. Refer to details on the PC Setup later in this manual for details.) 2.

-

Page 20: Ec Directives

AR 1314 goes ON. • The data stored in flash memory will not be lost even if power remains off for a period exceeding the data backup period, because the data stored in flash memory will be read to the CPU Unit when the CPM1A is turned on. - Page 21 EC Directives All Expansion I/O Units except for the CPM1A-20EDR conform to EC Directives. To ensure that the machine or device in which the CPM1A PC is used complies with EC Directives, the PC must be installed as follows: 1, 2, 3...

-

Page 22: Revised Specifications

Revised Specifications Manufacturer: Fair Rite Products Corp. Revised Specifications The following table shows the changes that have been made in product specifi- cations beginning with lots produced in January 1998 (December 1997 for some models). Item Previous specifications New specifications... - Page 23 CX-Programmer Operation occurred). Manual (W425). The following table shows the changes that have been made in product specifi- cations beginning with the introduction of version-1 Units in May 2001 (April 2001 for some models). Item New specifications (V1 models) EC Directives All products with model numbers ending in “-V1”...

- Page 24 Revised Specifications In this manual, version-1 CPU Units are referred to as V1 CPU Units and the previous CPU Units are referred to as pre-V1 CPU Units. Unless otherwise specified, “CPM1A” refers to both V1 and pre-V1 CPU Units.

-

Page 25: Introduction

SECTION 1 Introduction This section describes the CPM1A’s special features and functions and shows the possible system configurations. Refer to the Programming Manual (W353) for details on programming actual operation. CPM1A Features and Functions .......... -

Page 26: Cpm1A Features And Functions

The CPM1A is equipped with a filter function to prevent incorrect operation caused by chatter or noise in the input signal. The user can select an input time constant of 1 ms, 2 ms, 4 ms, 8 ms, 16 ms, 32 ms, 64 ms, or 128 ms. Low-maintenance Design Flash memory provides memory backup without a battery. - Page 27 Up to 3 Analog I/O Units can be connected to provide analog inputs and outputs. Each Unit provides 2 analog inputs and 1 analog output, so a maximum of 6 ana- log inputs and 3 analog outputs can be achieved by connecting 3 Analog I/O Units.

-

Page 28: Cpm1A Functions

I/O control based on a “PC + remote I/O” configuration. The distributed CPU control makes equipment modular, so designs can be standardized, special needs can be addressed, and modules can be replaced easily in the event of a breakdown. CompoBus/S Master Unit... -

Page 29: I/O Terminal And Ir Bit Allocation

CPM1A Features and Functions Section 1-1 1-1-2 I/O Terminal and IR Bit Allocation The following table shows which IR bits are allocated to the I/O terminals on the CPM1A’s CPU Units and Expansion I/O Unit. CPU Units No. of I/O termi-... - Page 30 IR 251 Input Filter Function The input time constant for the CPM1A’s external inputs can be set to 1, 2, 4, 8, 16, 32, 64, or 128 ms. Increasing the input time constant can reduce the effects of chatter or noise in the input signal.

- Page 31 30CDR-j(-V1)/30CDT-D(-V1)/ 30CDT1-D(-V1)/40CDR-j(-V1)/ 40CDT-D(-V1)/40CDT1-D(-V1) Note When not using as interrupt input terminals, the input bits IR 00003 to IR 00006 can be used as normal input terminals. Caution Although IORF(97) can be used in interrupt subroutines, you must be careful of the interval between IORF(97) executions.

- Page 32 CPM1A PCs are equipped with an interval timer which can be set from 0.5 ms to (Scheduled Interrupts) 319,968 ms in units of 0.1 ms. The timer can be set to trigger a single interrupt (one-shot mode) or to trigger scheduled interrupts (scheduled interrupt mode).

- Page 33 CPM1A Features and Functions Section 1-1 The pulse output can be set to either the continuous mode, under which the out- put can be stopped by an instruction, or the single mode, under which the output can be stopped by the preset pulse rate (1 to 16,777,215).

-

Page 34: System Configuration

00002: Reset input 65535 subroutine numbers can be registered. Note In incremental mode, this input (00001) can be used as an regular input. System Configuration 1-2-1 CPU Unit and Expansion I/O Unit Configuration CPM1A CPU Units 10 I/O points... - Page 35 System Configuration Section 1-2 V1 CPM1A CPU Units 10 I/O points 20 I/O points 30 I/O points 40 I/O points Model number Number Inputs Outputs Power of I/O f I/O supply Relay outputs Transistor outputs terminals terminals Sinking outputs Sourcing outputs...

-

Page 36: Cpu Unit And Expansion Unit

Section 1-2 1-2-2 CPU Unit and Expansion Unit Up to 3 Expansion I/O Units or Expansion Units can be connected to a CPU Unit with 30 or 40 I/O points. There are three types of Expansion Units available: Analog I/O Units, Tempera- ture Sensor Units, the CompoBus/S I/O Link Unit, and the DeviceNet I/O Link Unit. - Page 37 (Outputs to the Master.) Note Only one CPM1A-TS002/TS102 Temperature Sensor Unit can be connected to the CPU Unit. If a CPM1A-TS002/102 is connected to the CPU Unit, only one additional Expansion Unit (other than a CPM1A-TS002/102) or one Expansion I/O Unit can be connected to the CPU Unit.

-

Page 38: Host Link Communications

System Configuration Section 1-2 1-2-3 Host Link Communications Host Link communications which allows up to 32 OMRON PCs to be controlled from a host computer. The computer-PC connections can be made connectors such as RS-232C and RS-422 Adapters. One-to-one Communications The following diagram shows the possible methods for a 1:1 connection between a CPM1A and an IBM PC/AT or compatible computer. -

Page 39: One-To-One Pc Link Communications

System Configuration Section 1-2 One-to-N Communications The following diagram shows how to connect up to 32 CPM1A PCs to an IBM PC/AT or compatible computer. IBM PC/AT or compatible RS-422 CPM1A CPU Units RS-232C Cable Adapters RS-422 Cable 3G2A9-AL004-E Link Adapter OMRON CPM1A PCs (32 PCs max.) -

Page 40: One-To-One Nt Link Communications

Section 1-2 1-2-4 One-to-one PC Link Communications A data link can be created with a data area in another CPM1A, CQM1, CPM1, CPM2A, CPM2C, SRM1(-V2) or C200HS PC or a C200HX/HG/HE PC. An RS-232C Adapter must be used to make the 1:1 connection. -

Page 41: Compobus/S I/O Link Connections

1-2-6 CompoBus/S I/O Link Connections A CompoBus/S I/O Link can be used to create an I/O link (remote I/O) of 8 input points and 8 output points with a CompoBus/S Master Unit or SRM1 PC. The connection is made through a CompoBus/S I/O Link Unit. - Page 42 Section 1-2 1-2-7 DeviceNet I/O Link Connections A DeviceNet I/O Link Unit can be used to create an I/O link (remote I/O) of 32 input points and 32 output points with a DeviceNet master, i.e., the CPM1A oper- ates as a DeviceNet slave. From the standpoint of the CPM1A CPU Unit, the area allocated to the DeviceNet I/O Link Unit can be treated just like the area allocated to an Expansion I/O Unit.

- Page 43 An IBM PC/AT or compatible personal computer running SSS or the SYSMAC- and SYSMAC-CPT Support CPT Support Software can be connected to the CPM1A as shown in the follow- Software ing diagram. Refer to 3-4-7 Host Link Connections for a diagram showing the standard wiring for the RS-232C cable.

-

Page 44: Unit Specifications And Components

SECTION 2 Unit Specifications and Components This section provides the technical specifications of the Units that go together to create a CPM1A PC and describes the main components of the Units. Specifications ............ -

Page 45: Specifications

Grounding Power interrupt time AC type: 10 ms min. DC type: 2 ms min. (A power interruption occurs if power falls below 85% of the rated voltage for longer than the power interrupt time.) CPU Unit AC type 400 g max. -

Page 46: Characteristics

The program, read-only DM area, and PC Setup area are backed up without a battery. Capacitor backup: The read/write DM area, error log area, HR area, and counter values are backed up by a capacitor for 20 days at 25_C. The capacitor backup time depends on the ambient temperature. - Page 47 Can preset the pulse rate (1 to 16,777,215). Input time constant Can be set to 1 ms, 2 ms, 4 ms, 8 ms, 16 ms, 32 ms, 64 ms, or 128 ms. Analog controls 2 controls, setting range: 0 to 200 BCD Note 1.

-

Page 48: I/O Specifications

(510 Ω) Note Figures in parentheses are for IN00000 to IN00002. Note Using the PC Setup, 1, 2, 4, 8, 16, 32, 64, or 128 ms can be selected. When IN00000 through IN00002 are used as high-speed counter inputs, the delays are as shown in the following table. - Page 49 Internal 820 Ω Circuits Note Using the PC Setup, 1, 2, 4, 8, 16, 32, 64, or 128 ms can be selected. Caution Do not apply voltage in excess of the rated voltage to the input terminal. It may result in damage to the product or fire.

- Page 50 24 VDC: 2 A Note 1. The service life of relay output contacts shown in the table assumes the worst conditions. The following graph shows the results of OMRON’s ser- vice life tests at a switching rate of 1,800 times/hour.

- Page 51 Note When using the OUT01000 or OUT01001 as a pulse output, connect dummy resistors as required to set the load current to 0.1 to 0.2 A. If the load current is below 0.1 A, the ON-to-OFF response time will become longer and high-speed pulse will not be output.

- Page 52 Note When using the OUT01000 or OUT01001 as a pulse output, connect dummy resistors as required to set the load current to 0.1 to 0.2 A. If the load current is below 0.1 A, the ON-to-OFF response time will become longer and high-speed pulse will not be output.

-

Page 53: Communications Adapter Specifications

200 g max. RS-422 Adapter Specifications Item Specification Function Converts between the CMOS format (PC CPU Unit side) and the RS-422 format (peripheral device side). Insulation The RS-422 (peripheral device side) is isolated by a DC/DC convertor and photocoupler. Power supply Power is supplied from the PC CPU Unit. -

Page 54: Unit Components

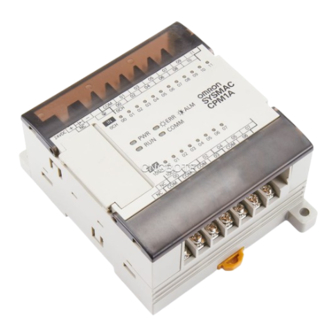

Unit Components Section 2-2 Unit Components 2-2-1 CPU Unit Components CPU Units with 10 I/O Terminals CPM1A-10CDR-j-V1/10CDT-j-V1/10CDT1-j-V1 3. Protective earth terminal 1. Power supply input terminals 5. Input terminals 8. Input indicators 10. Analog controls 9. Output indicators 11. Peripheral Port 7. - Page 55 CPU Unit Component Descriptions 1, 2, 3... 1. Power Supply Input Terminals Connect the power supply (100 to 240 VAC or 24 VDC) to these terminals. 2. Functional Earth Terminal ( ) (Pre-V1 CPU Units only) Be sure to ground this terminal (AC-type PCs only) to enhance immunity to noise and reduce the risk of electric shock.

-

Page 56: Expansion I/O Unit Components

These indicators are lit when the corresponding output terminal is ON. 10. Analog Controls Setting these controls sets the contents of IR 250 and IR 251 from 0 to 200. 11. Peripheral Port Connects the PC to a Peripheral Device, RS-232C Adapter, or RS-422 Adapter. - Page 57 Connects the Expansion I/O Unit to the Expansion Connector on the PC’s CPU Unit or another Expansion Unit. Caution Do not touch the Expansion I/O Unit Connecting Cable while the power is being supplied in order to prevent any malfunction due to static electricity. 6. Expansion Connector Connects to another Expansion Unit (Expansion I/O Unit, Analog I/O Unit, or CompoBus/S I/O Link Unit).

-

Page 58: Analog I/O Unit Components

Unit or another Expansion Unit. The cable is connected to the Analog I/O Unit and cannot be removed. Caution Do not touch the Expansion I/O Unit Connecting Cable while the power is being supplied in order to prevent any malfunction due to static electricity. 3. Expansion Connector Connects to another Expansion Unit (Expansion I/O Unit, Analog I/O Unit, or CompoBus/S I/O Link Unit). -

Page 59: Temperature Sensor Unit Components

1. Temperature Input Terminals Connect to a thermocouple or a platinum resistance thermometer. 2. DIP Switch Sets the temperature unit (°C or °F), and the number of decimal places used. Number of decimal places used OFF: Normal (0 or 1); ON: 2 Temperature unit OFF: °C;... -

Page 60: Compobus/S I/O Link Unit Components

Temperature Sensor Unit and cannot be removed. Caution Do not touch the expansion I/O connecting cable while the power is being sup- plied in order to prevent any malfunction due to static electricity. 5. Expansion Connector Connects to an additional Expansion I/O Unit or another Expansion Unit. -

Page 61: Devicenet I/O Link Unit Components

Connects the CompoBus/S I/O Link Unit to the Expansion Connector on the PC’s CPU Unit or another Expansion Unit. Caution Do not touch the Expansion I/O Unit Connecting Cable while the power is being supplied in order to prevent any malfunction due to static electricity. 5. Expansion Connector Connects to another Expansion Unit (Expansion I/O Unit, Analog I/O Unit, or CompoBus/S I/O Link Unit). - Page 62 PC’s CPU Unit or another Expansion Unit. This cable cannot be removed. Caution Do not touch the Expansion I/O Unit Connecting Cable while the power is being supplied in order to prevent any malfunction due to static electricity. 6. Expansion Connector...

-

Page 63: Communications Adapter Components

1, 2, 3... 1. Mode Setting Switch Set this switch to “HOST” when using a Host Link system to connect to a personal computer. Set this switch to “NT” when connecting to a Program- mable Terminal or PC for 1:1 PC Link. -

Page 64: Installation And Wiring

Installation and Wiring This section provides information on installing and wiring a CPM1A PC. Be sure to follow the directions and precautions in this section when installing the CPM1A in a panel or cabinet, wiring the power supply, or wiring I/O. -

Page 65: Design Precautions

Motor forward CPM1A 01006 Motor reverse In the interlock circuit above, MC1 and MC2 can’t be ON at the same time even if CPM1A outputs 01005 and 01006 are both ON (an incorrect PC operation). 3-1-3 Power Supply Voltage Caution Use the power supply voltages indicated in Section 2 Unit Specifications and Components. -

Page 66: Selecting An Installation Site

Momentary Power Failure Detection A momentary power failure lasting less than 10 ms with an AC power supply and 2 ms with a DC power supply is not detected and the CPU Unit continues to oper- ate. A momentary power failure lasting longer than 10 ms with an AC power supply and 2 ms with a DC power supply may or may not be detected in an uncertain area. -

Page 67: Panel/Cabinet Installation

• The PC will be easiest to access if the panel or cabinet is installed about 3 to 5 feet off of the floor. -

Page 68: Installing The Cpm1A

Do not install the CPM1A in either of the following positions. Incorrect Incorrect 3-3-2 CPM1A Installation The CPM1A can be installed on a horizontal surface or on a DIN track. Surface Installation Use the following pattern when installing a CPM1A on a horizontal surface. CPM1A-10CDR-j(-V1)/10CDT-j(-V1)/10CDT1-j(-V1) and... - Page 69 RS-422 Adapter 21 mm Temperature Sensor Unit 76 mm Allow 10 to 15 mm between the Units when installing an Expansion Unit, Expan- sion I/O Unit, or Communications Adapter next to the CPU Unit, as shown below. 21 mm 81 mm...

-

Page 70: Connecting An Expansion I/O Unit

Installing the CPM1A Section 3-3 Installation Lower the CPM1A so that the notch on the back of the PC catches the top of the DIN Track. Push the PC forward until the lock snaps into place. Removal Pry the lock down with a standard screwdriver and pivot the PC upward to remove it. - Page 71 Expansion I/O Unit Connector. 3. Attach the cover to the CPU Unit’s Expansion I/O Unit Connector by insert- ing the two pins on the inside of the cover into the holes on the case and pressing downward lightly and evenly.

- Page 72 Section 3-3 Pre-V1 Units 1, 2, 3... 1. Remove the cover from the CPU Unit’s or the Expansion I/O Unit’s Expan- sion I/O Unit Connector. Use a flat-blade screwdriver to remove the cover from the Expansion I/O Connector. Expansion I/O Unit connector cover 2.

-

Page 73: Wiring And Connections

With pre-V1 Units, attach the dustproof label provided before wiring. With V1 Units, leave the dustproof label in place while wiring. If scraps of wire get inside the Unit, malfunction will result. After completing wiring be sure to remove the label to avoid overheating. -

Page 74: Ground Wiring

Wiring and Connections Section 3-4 Floor Ducts Leave at least 200 mm between the wiring and the top of the duct, as shown in the following diagram. Control cables and Metal plate (iron) CPM1A I/O lines CPM1A power lines Power cables 200 mm min. -

Page 75: Power Supply Wiring

Always use crimp connectors for the CPM1A’s power lines and I/O lines or else use a solid wire (instead of a stranded wire). Do not connect bare stranded wires directly to terminals. Bare stranded wires connected directly to the terminal can cause a fire. - Page 76 AC power is mistakenly supplied to a CPU Unit that requires a DC power supply. 2. The power supply input terminals are at the top of the CPU Unit; the termi- nals at the bottom of the CPU Unit output 24-VDC power for external de- vices.

- Page 77 Wiring and Connections Section 3-4 Caution Do not perform a withstand voltage test on a CPU Unit with a DC power supply. The test might damage the PC’s internal components. Note 1. Do not conduct a withstand voltage test for the power supply section of the CPU Unit with a DC power supply.

-

Page 78: Input Wiring

Section 3-4 3-4-4 Input Wiring Wire the inputs to the CPM1A’s CPU Unit and Expansion I/O Unit as shown in the following diagrams. Use crimp connectors or solid wire (not stranded wire) to connect to the PC. Do not apply voltages exceeding the rated input voltage to the input terminals. - Page 79 Wiring and Connections Section 3-4 CPM1A-8ED Input 24 VDC devices Input devices Note Although the COM terminals are internally connected, be sure to wire them ex- ternally as well. CPM1A-20EDR/20EDR1/EDT/EDT1 Input devices 24 VDC j CH...

- Page 80 Wiring and Connections Section 3-4 Input Wiring Example An AC-type CPU Unit is shown. DC-type CPU Units don’t have power supply outputs. Input devices 0 CH 1 CH 10 CH 11 CH 24 VDC at – 0.2 A output External power supply:...

- Page 81 Wiring and Connections Section 3-4 Input Devices The following table shows how to connect various input devices. Device Circuit diagram Relay output Relay 5 mA/12 mA CPM1A COM (+) NPN open collector Sensor Sensor power supply Output CPM1A 5 mA/12 mA...

- Page 82 00001 01000 Note The SV of TIM 000 can be set to #0001 (0.1 s) to achieve a delay time of 100 ms, but the timer accuracy is 0 to 0.1 s, meaning that the timer’s Completion Flag may turn ON immediately after the timer input. The SV must thus be set to #0002 (0.2 s) or higher to allow for timer accuracy.

- Page 83 Always use crimp connectors for the CPM1A’s power lines and I/O lines or else use a solid wire (instead of a stranded wire). Do not connect bare stranded wires directly to terminals. Bare stranded wires connected directly to the terminal can cause a fire.

-

Page 84: Output Wiring

3-4-5 Output Wiring Relay Output Wiring Wire the outputs to the CPM1A’s CPU Unit and Expansion I/O Unit as shown in the following diagrams. Use crimp connectors or solid wire (not stranded wire) to connect to the PC. The power supply output terminals can be used with AC-type CPU Units. - Page 85 Wiring and Connections Section 3-4 Output Configurations 10 CH CPM1A-10CDR-j(-V1) Common 10 CH CPM1A-20CDR-j(-V1)/CPM1A-20EDR/20EDR1 Common Common CPM1A-30CDR-j(-V1) 10 CH 11 CH Common Common Common CPM1A-40CDR-j(-V1) 10 CH 11 CH Common Common Common Common...

- Page 86 Wiring and Connections Section 3-4 CPM1A-8ER 250 VAC/ 24 VDC 250 VAC/ 24 VDC...

- Page 87 Section 3-4 Transistor Output Wiring (Sinking Outputs) Wire the outputs to the CPM1A’s CPU Unit and Expansion I/O Unit as shown in the following diagrams. • Always use solid wire or attach crimp connectors if a stranded wire is used.

- Page 88 Wiring and Connections Section 3-4 CPM1A-8ET +10% 24 VDC –15% +10% 24 VDC –15% Caution Double-check the polarity of the power supply for the load before turning it on.

- Page 89 Section 3-4 Transistor Output Wiring (Sourcing Outputs) Wire the outputs to the CPM1A’s CPU Unit and Expansion I/O Unit as shown in the following diagrams. • Always use solid wire or attach crimp connectors if a stranded wire is used.

- Page 90 +10% 24 VDC –15% Caution Double-check the polarity of the power supply for the load before turning it on. Output Wiring Precautions Observe the following precautions to protect the PC’s internal components. Output Short Protection The output or internal circuitry might be damaged when the load connected to an output is short-circuited, so it is recommended to install a protective fuse (0.5 to...

- Page 91 Average rectified current must be 1 A. Inrush Current Considerations When switching a load with a high inrush current in the CPM1A relay output or transistor output model, such as an incandescent lamp, suppress the inrush cur- rent as shown below.

-

Page 92: Peripheral Device Connection

The CPM1A CPU Unit can be connected to a C200H-PRO27-E Programming Console with a standard C200H-CN222 (2 m) or C200H-CN422 (4 m) Connect- ing Cable. The CPM1A CPU Unit can be also connected to a CQM1-PRO01-E. The CQM1-PRO01-E is provided with a 2-m Connecting Cable. - Page 93 – – – The type of connector used will vary depending on the PT. Check the PT manual to ensure the correct connector is used. Note When the CPM1A is connected to a host computer or OMRON PT, set the RS-232C Adapter’s mode setting switch to “HOST.”...

- Page 94 2. Set the termination resistance switch to “ON” (upper side) for Adapters on both ends of the Host Link system. Always use crimp connectors when wiring the RS-422 Adapters. Use M3 termi- nal screws and tighten the screws securely to the torque of 0.5 N S m. Fork terminal Ring terminal 6.2 mm max.

-

Page 95: One-To-One Pc Link Connections

A CPM1A can be linked to a CPM1A, CQM1, CPM1, CPM2A, CPM2C, SRM1(-V2), C200HS or C200HX/HG/HE PC through an RS-232C Adapter. One PC acts as the Master and the other as the Slave to link up to 256 bits in the LR area (LR 0000 to LR 1515). -

Page 96: One-To-One Nt Link Connections

CPM1A CPU Unit RS-232C Cable RS-232C Adapter Note The 1:1 NT Link can only be used when the RS-232C Adapter (CPM1-CIF01) is connected. Set the DIP switch of the RS-232C Adapter (CPM1-CIF01) to the NT (bottom) side. The following diagram shows the wiring in the RS-232C cable used to connect a CPM1A to a Programmable Terminal. -

Page 97: Compobus/S I/O Link Unit Connections

Section 3-4 3-4-10 CompoBus/S I/O Link Unit Connections A CompoBus/S I/O Link Unit can be used to create an I/O link (remote I/O) of 8 input points and 8 output points with a CompoBus/S Master Unit or SRM1 PC. The connection is made through a CompoBus/S I/O Link Unit. -

Page 98: Devicenet I/O Link Unit Connections

Section 3-4 3-4-11 DeviceNet I/O Link Unit Connections A DeviceNet I/O Link Unit can be used to create an I/O link (remote I/O) of 32 input points and 32 output points with a DeviceNet master, i.e., the CPM1A oper- ates as a DeviceNet slave. - Page 99 Wiring and Connections Section 3-4 Network Connection Connect the DeviceNet I/O Link Unit to the DeviceNet transmission path as shown in the following diagram. DeviceNet I/O Link Unit (CPM1A-DRT21) Multidrop Connector Connector included with CPM1A-DRT21 (XW4B-05C4-TF-D) (XW4B-05C1-H1-D) Black (V–) Blue (CAN low)

-

Page 100: Using Peripheral Devices

This section outlines the operations possible with the SYSMAC Support Software (SSS) and the Programming Consoles. Actual SSS operating procedures are provided in the SSS Operation Manuals: Basics and C-series PCs. Programming Con- sole connection and operating procedures are provided in this section. -

Page 101: Support Software Capabilities

CPM1A. Programming Check Since the data area of the CQM1 is larger than that of the CPM1A, some parts of the area cannot be checked as the CPM1A PC. Pay careful attention to the usable data area when programming. -

Page 102: Offline Operations

Connect line Draws a line between two ladder diagram objects. Save program Writes all or part of the user program developed in the system work area to the data disk. Retrieve program Retrieves all or part of the user program stored on a data disk to the system work area. - Page 103 Copies the contents of the DM area of the system work area (data memory information). Fill Writes the same data to more than one data word in the system work area data memory area. Print Prints a specified range of DM words.

- Page 104 CVM1: Converts C2000H-family programs to CVM1 programs Create Library Creates a library on a floppy disk or hard disk for use as an LSS data disk. File Time Chart Accesses the time chart monitor data produced online. (C-series PCs only)

-

Page 105: Online Operations

Monitor Used to monitor DM area contents in the PC. (C-series PCs only) Go To Page Reads a specified page from the DM list of the DM area in the system work area or PC. (C-series PCs only) I/O Table Transfer I/O Table Transfers and compares the I/O table data between the computer and PC. -

Page 106: Offline And Online Operations

Group Name Description System Setup PC model Specifies the model of PC that is being programmed or that is connected to the (see note) computer. PC Interface C-series PCs: Specifies whether communications with the PC are performed through a SYSMAC NET Link Unit, peripheral interface, or a Host Link (RS-232C) interface and the computer port (COM1 or COM2) to use. -

Page 107: Using A Programming Console

CQM1-PRO01-E and the C200H-PRO27-E. The key functions for these Pro- gramming Consoles are identical. Press and release the Shift Key to input a letter shown in the upper-left corner of the key or the upper function of a key that has two functions. For example, the CQM1-PRO01-E’s AR/HR Key can specify either the AR or HR Area;... - Page 108 RUN or MONITOR but it cannot be removed when the switch is set to PROGRAM. Contrast Control The display contrast can be adjusted with the control on the right side of the Pro- gramming Console. Contrast control Buzzer Volume The C200H-PRO27-E’s buzzer volume can be adjusted with the lever on the...

-

Page 109: Changing The Cpm1A's Mode With The Mode Switch

Programming Console screen. Press CLR to clear the display so that key operations can be performed. • If the SHIFT Key is pressed while the mode switch is turned, the original dis- play will remain on the Programming Console’s screen and the mode display won’t appear. -

Page 110: Connecting The Programming Console

Note The default setting is 0000. If a Programming Console is not connected, the PC will automatically enter RUN mode. Be sure that it is safe for the PC to operate before turning on the PC without a Programming Console connected. -

Page 111: Preparation For Operation

The password prevents unauthorized access to the program. The PC prompts you for a password when PC power is turned on or, if PC power is already on, after the Programming Console has been connected to the PC. To gain access to the system when the “Password!”... - Page 112 If the Programming Console is connected to the PC when PC power is already on, the first display below will indicate the mode the PC was in before the Pro- gramming Console was connected. Ensure that the PC is in PROGRAM mode before you enter the password.

-

Page 113: Programming Console Operations

Checks for programming errors and displays the program address and error when errors are found. Bit, digit, word monitor Monitors the status of up to 16 bits and words, although only 3 can be shown on the display at one time. Multiple address monitor Monitors the status of up to 6 bits and words simultaneously. -

Page 114: Clearing Memory

MONTR Key is pressed. The HR Key is used to specify both the AR and HR Areas, the CNT Key is used to specify the entire timer/counter area, and the DM Key is used to specify the DM Area. -

Page 115: Clearing Memory Completely

5. Press the MONTR Key to clear the specified regions of memory. MONTR 4-3-3 Clearing Memory Completely This operation is used to clear all of memory, including the user program, PC Setup, all data areas, and the I/O comment area (set with version 2.0 or later of CX-Programmer). MONITOR PROGRAM The I/O comment function was supported for the CPM1A starting from version 2.0 of CX-Programmer. -

Page 116: Buzzer Operation

Before inputting a new program, any error messages recorded in memory should be cleared. It is assumed here that the causes of any of the errors for which error messages appear have already been taken care of. If the buzzer sounds when an attempt is made to clear an error message, eliminate the cause of the error, and then clear the error message. -

Page 117: Setting And Reading A Program Memory Address And Monitoring I/O Bit Status

4-3-7 Setting and Reading a Program Memory Address and Monitoring I/O Bit Status This operation is used to display the specified program memory address and is possible in any mode. In the RUN or MONITOR mode, the I/O bit status of bits in the program will be displayed. MONITOR... -

Page 118: Entering Or Editing Programs

MONITOR PROGRAM The same procedure is used to either input a program for the first time or to change a program that already exists. In either case, the current contents of Program Memory is overwritten. The program shown in the following diagram will be entered to demonstrate this operation. - Page 119 8. Input the third instruction (MOVE) and its operands. First input the instruc- tion by pressing the FUN Key and then the function code (21 in this case). To input the differentiated version of an instruction, press the NOT Key after the function code (FUN 2 1 NOT).

- Page 120 SHIFT Input the value of the operand from 0 to 65535. Note If an erroneous input is made, press the CLR Key to restore the status prior to the input. Then enter the correct input. 14. Restore the hexadecimal display.

-

Page 121: Instruction Search

MONITOR PROGRAM The ON/OFF status of any displayed bit will be shown if the PC is in RUN or MONITOR mode. 1, 2, 3... 1. Press the CLR Key to bring up the initial display. -

Page 122: Inserting And Deleting Instructions

Indicates the amount used by the user program in units of 0.1 Kwords. 4-3-11 Inserting and Deleting Instructions This operation is used to insert or delete instructions from the program. It is pos- sible in PROGRAM mode only. MONITOR PROGRAM... -

Page 123: Checking The Program

SRCH 3. Input the desired check level (0, 1, or 2). The program check will begin when the check level is input, and the first error found will be displayed. Note Refer to 5-5 Programming Errors for details on check levels and the errors that may be detected when the program is checked. -

Page 124: Bit, Digit, Word Monitor

MONITOR PROGRAM Program Read then Monitor When a program address is being displayed, the status of the bit or word in that address can be monitored by pressing the MONTR Key. 1, 2, 3... 1. Press the CLR Key to bring up the initial display. - Page 125 5. Press the SHIFT and CLR Keys to end monitoring altogether. SHIFT Note Press the SHIFT Key, CLR Key, and then CLR Key again to return to the initial Programming Console display with the multiple address monitoring state unchanged. Press the SHIFT Key and then the MONTR Key from the initial dis- play to return to the multiple address monitoring state.

-

Page 126: Differentiation Monitor

Down Arrow Key. The symbols “D@” will appear. ↓ SHIFT 3. The buzzer will sound when the specified bit goes from off to on (for up-dif- ferentiation) or from on to off (for down-differentiation). Note The buzzer will not sound if it has been turned off. -

Page 127: Three-Word Monitor

2. Press the SHIFT and then the MONTR Key to begin binary monitoring. The ON/OFF status of the selected word’s 16 bits will be shown along the bottom of the display. A 1 indicates a bit is on, and a 0 indicates it is off. SHIFT MONTR... -

Page 128: Signed Decimal Monitor

MONITOR PROGRAM 1, 2, 3... 1. Monitor the word that is to be used for decimal monitor with sign. During mul- tiple address monitoring, the leftmost word will be converted. (Multiple address monitor) 2. Press the SHIFT and TR Keys to display the leftmost word as signed deci- mal. -

Page 129: Three-Word Data Modification

Programming Console Operations Section 4-3 3. Press the CLR Key or the SHIFT and TR Keys to end the unsigned decimal display and return to normal monitoring. 4-3-19 Three-word Data Modification This operation is used to change the contents of one or more of the 3 con- secutive words displayed in the Three-word Monitor operation. -

Page 130: Hexadecimal, Bcd Data Modification

Programming Console Operations Section 4-3 Inputting a New SV This operation can be used to input a new SV constant, as well as to change an Constant SV from a constant to a word address designation and vice versa. The following examples show how to input a new SV constant and how to change the SV from a constant to an address. -

Page 131: Binary Data Modification

A flashing cursor will appear over bit 15. The cursor indicates which bit can be changed. 3. Three sets of keys are used to move the cursor and change bit status: a) Use the Up and Down Arrow Keys to move the cursor to the left and right. ↓ ↓... -

Page 132: Signed Decimal Data Modification

Programming Console Operations Section 4-3 b) Use the 1 and 0 Keys to change a bit’s status to on or off. The cursor will move one bit to the right after one of these keys is pressed. c) Use the SHIFT and SET and SHIFT and RESET Keys to force-set or force-reset a bit’s status. -

Page 133: Unsigned Decimal Data Modification

(Unsigned decimal monitor) 2. Press the CHG Key to begin decimal data modification. 3. Input the new PV and press the WRITE Key to change the PV. The operation will end and the decimal-without-sign monitoring display will return when the WRITE Key is pressed. -

Page 134: Clear Force Set/Reset

Programming Console Operations Section 4-3 2. Press the SET Key to force the bit ON or press the RESET Key to force the bit OFF. The cursor in the lower left corner of the display indicates that the force set/ reset is in progress. -

Page 135: Programming Example

(Multiple address monitor) 2. Press the TR Key to switch to ASCII display. The display will toggle between hexadecimal and ASCII displays each time the TR Key is pressed. Note 1. - Page 136 Programming Example Section 4-4 3. Clear the CPM1A’s memory by pressing the CLR, SET, NOT, RESET, and then the MONTR Key. Press the CLR Key several times if memory errors are displayed. RESET MONTR 4. Display and clear error messages by pressing the CLR, FUN, and then the MONTR Key.

-

Page 137: Example Program

Section 4-4 4-4-2 Example Program The following ladder program will be used to demonstrate how to write a pro- gram with the Programming Console. This program makes output IR 01000 flicker ON/OFF (one second ON, one second OFF) ten times after input IR 00000 is turned ON. -

Page 138: Programming Procedures

4-4-2 Example Program. The procedure is performed beginning with the initial display. (Clear the memory before entering a new program.) Note If an error occurs while inputting the program, refer to 5-4 Programming Console Operation Errors for details on correcting the error. Refer to the relevant Support Software Operation Manual for details on errors that appear when operating the SSS or SYSMAC-CPT Support Software. - Page 139 WRITE 4. Input the SV for T001 (#0010 = 1.0 s). WRITE (3) Inputting the The following key operations are used to input the 2-second timer. Two-second Timer 1, 2, 3... 1. Input the normally open condition IR 20000. WRITE 2.

- Page 140 3. Input the OUT instruction IR 01000. (It isn’t necessary to input leading zeroes.) WRITE (6) Inputting the END(001) Input END(01). (The display shows three digits in the function code, but only the Instruction last two digits are input for CPM1A PCs.) WRITE...

-

Page 141: Checking The Program

SRCH 3. Input the desired check level (0, 1, or 2). The program check will begin when the check level is input, and the first error found will be displayed. If no errors are found, the following display will appear. -

Page 142: Test Runs And Error Processing

SECTION 5 Test Runs and Error Processing This section describes procedures for test runs of CPM1A operation, self-diagnosis functions, and error processing to identify and correct the hardware and software errors that can occur during PC operation. Initial System Checks and Test Run Procedure . -

Page 143: Initial System Checks And Test Run Procedure

Section 5-1 Initial System Checks and Test Run Procedure 5-1-1 Initial System Checks Note Check the following items after setting up and wiring the CPM1A. Be sure to check the wiring and connections before performing a test run. Item Points to check... -

Page 144: Flash Memory Precautions

1, 2, 3... 1. If the power is turned off without changing the mode after having made chan- ges in the read-only DM area (DM 6144 through DM 6599), or PC Setup (DM 6600 through DM 6655), the contents of changes will not be written to flash memory. -

Page 145: The Cpm1A Cycle

Section 5-2 The CPM1A Cycle The overall flow of CPM1A operation is as shown in the following flowchart. The CPM1A is initialized internally when the power is turned on. If no errors are detected, the overseeing processes, program execution, I/O refreshing, and Peripheral Device servicing are executed consecutively (cyclically). -

Page 146: Self-Diagnosis Functions

An error has been detected in the PC Setup. Check flags AR 1300 to AR 1302, and correct as directed. AR 1300 ON: An incorrect setting was detected in the PC Setup (DM 6600 to DM 6614) when power was turned on. -

Page 147: Identifying Errors

AR 1310 ON: A checksum error has occurred in read-only DM (DM 6144 to DM 6599). Check and correct the settings in the read-only DM area. AR 1311 ON: A checksum error has occurred in the PC Setup. Initialize all of the PC Setup and reinput. -

Page 148: Programming Console Operation Errors

3. The instruction’s 2-digit BCD FALS number (01 to 99) will be written to SR 25300 to SR 25307. 4. The FALS number and time of occurrence will be recorded in the PC’s error log area if a Memory Cassette with a clock (RTC) is used. - Page 149 Check level 0 checks for type A, B, and C errors; check level 1, for type A and B errors; and check level 2, for type A errors only.

-

Page 150: Troubleshooting Flowcharts

Troubleshooting Flowcharts Section 5-6 Troubleshooting Flowcharts Use the following flowcharts to troubleshoot errors that occur during operation. Main Check Error PWR indicator lit? Check power supply. (See page 128.) Operation stopped. Check for fatal errors. RUN indicator lit? (See page 129.) ERR/ALM indicator Check for non-fatal errors. - Page 151 Is PWR indicator lit? Replace the CPU Unit. Note The PWR indicator will go out when there is a short circuit in the external power supply or an overload, only in the CPM1A-10CDR-j and CPM1A-20CDR-j CPU Units. In CPM1A-30CDR-j and CPM1A-40CDR-j...

- Page 152 Fatal Error Check RUN indicator not lit. Is the ERR/ALM indicator lit? Determine the cause Is PC mode displayed of the error with a on Peripheral Device? Peripheral Device. Is PC mode displayed Turn the power on Peripheral Device? supply OFF, and then ON again.

- Page 153 Troubleshooting Flowcharts Section 5-6 Non-fatal Error Check ERR/ALM indicator flashing. Determine the cause of the error with a Peripheral Device. Identify the error, eliminate its Is a non-fatal error indicated? cause, and clear the error. Flashing Is the ERR/ALM indi-...

- Page 154 Troubleshooting Flowcharts Section 5-6 I/O Check The I/O check flowchart is based on the following ladder diagram section. (LS1) (LS2) 00002 00003 01003 SOL1 01003 SOL1 malfunction. Malfunction of SOL1 Is the IR 01003 out- put indicator operat- ing normally? Check the voltage at the Wire correctly.

- Page 155 00003 terminals. screws loose? Operation O.K.? Operation O.K.? Is input wiring correct? Check operation by using a dummy input signal to turn the input ON and OFF. Wire correctly. Tighten the terminal screws Operation O.K.? Replace the CPU Replace the CPU Return to “start.”...

- Page 156 Consider using a temperature fan or cooler. below 55°C? Is the ambient Consider using a temperature above heater. 0°C? Is the ambient humidity Consider using an between 10% and air conditioner. 90%? Install surge pro- tectors or other Is noise being noise-reducing...

- Page 157 AR 1308 ON? errors, and clear the error. Check the error indicated by AR 1310 to Turned ON during the flag that is ON, correct set- AR 1312 ON? startup? tings as required, and write data to the flash memory.

-

Page 158: Maintenance Inspections

The standard period for maintenance checks is 6 months to 1 year, but depend- ing on the environment checks may need to be more regular. If the criteria are not met, adjust to within the specified ranges. -

Page 159: Handling Precautions

Note Before restarting operation, transfer the contents of the DM and HR areas to the CPU Unit that was changed and then start operation. • If a Unit is found to be faulty and is replaced, check the Unit again to ensure there is no error. - Page 160 SECTION 6 Expansion Memory Unit This section describes how to use the CPM1-EMU01-V1 Expansion Memory Unit. Follow the handling precautions and pro- cedures to properly use the Unit. Overview ............. . .

-

Page 161: Expansion Memory Unit

• Do not attempt to upload or download data between different types of PC. Do- ing so may result in malfunction. • Do not download when the PC is in RUN or MONITOR mode. If downloading is performed when the PC is running, it will automatically switch to PROGRAM mode and operation will stop. -

Page 162: Specifications And Nomenclature

DM 6144 to DM 6655 to EEPROM. Indicator DOWNLOAD to PLC Button UPLOAD Button Reads only PC user program to EEPROM. UPLOAD + DM Button UPLOAD Button Note The “PLC” in the “DOWNLOAD TO PLC” Button indicates PCs (Programmable Controllers). -

Page 163: Handling

1, 2, 3... 1. Lift up the lock lever. 2. Straighten the pins on the EEPROM, line up with the socket and lower into the socket, as shown in the following diagram. If the EEPROM is loose, place it in the center of the socket. -

Page 164: Pc Connections

CQM1H Pin 5: ON (see note) Pin 7: ON Note If pin 1 on the CPM2C or pin 5 on the CQM1H is OFF, connection is still possible if the peripheral port is set to the defaults. Peripheral Port The peripheral port must be set to the default communications settings shown Communications below. -

Page 165: Uploading Programs

EEPROM. DM6144 to 6655 Not affected. Note Use a Phillips screwdriver or other tool with a diameter of 3.0 mm max. and a blade length of 10 mm min. to press the upload button. 3.0 dia. max. 10 mm min. -

Page 166: Downloading Programs

See the note above. Remove the Expansion Memory Unit from the PC. 6-3-4 Downloading Programs Ladder programs and the contents of data memory can be downloaded from the EEPROM to the PC using the procedure given below. When downloading, note the following points. - Page 167 Section Caution If the PC is in RUN or MONITOR mode when downloading is started, it will auto- matically switch to PROGRAM mode and operation will stop. Confirm that no adverse effects will occur to the system before downloading. Not doing so may result in unexpected operation.

- Page 168 PC’s peripheral port. before connecting the CPM1-EMU01-V1. After 2 or 3 s, check if the indicator is Note If the indicator is not lit at all, lit red or lit green. blinks red, downloading will not be See the note on possible.

-

Page 169: A Standard Models

CPU Units V1 Units Model number Description Input Output Power points points supply Relay Transistor outputs outputs Sinking Sourcing CPU Units with 6 points 4 points CPM1A- CPM1A- CPM1A- 10 I/O points 10CDR-A-V1 10CDT-A-V1 10CDT1-A-V1 CPM1A- CPM1A- CPM1A- 10CDR-D-V1 10CDT-D-V1... - Page 170 Output signal ranges: 0 to 10 V, –10 to 10 V, or 4 to 20 mA, Resolution of 1/256 Input signal ranges: 0 to V 5, 0 to 10 V, 1 to 5 V, CPM1A-MAD11 –10 to 10 V, 0 to 20 mA, or 4 to 20 mA Output signal ranges: 0 to 10 V, 1 to 5 V, –10 to 10 V, 0 to 20 mA, or 4 to 20 mA...

- Page 171 RS-232C devices. RS-422 Adapter Converts data communications between CPM1-CIF11 the peripheral port and RS-422 devices. The CPM1-CIF01/CIF11 are used with the CPM1A, CPM1 and SRM1 only. Do not use them with a C200HS PC or other PC.

- Page 172 (3.5” disks (2HD) and CDROM) Expansion Memory Unit CPM1-EMU01-V1 Uploads the ladder program and DM 6144 to DM 6655 from the PC to the EEPROM and downloads the ladder program and DM 6144 to DM 6655 from the EEPROM to the PC.

-

Page 173: B Dimensions

Appendix B Dimensions All dimensions are in millimeters. CPM1A-10CDR-j-V1/10CDT-j-V1/10CDT1-j-V1 CPU Unit CPU Unit with DC Power CPU Unit with AC Power Two, 4.5 dia. CPM1A-10CDR-j/10CDT-j/10CDT1-j CPU Unit CPU Unit with DC Power CPU Unit with AC Power 56±0.2 CPM1A-20CDR-j-V1/20CDT-j-V1/20CDT1-j-V1 CPU Unit... - Page 174 Dimensions Appendix B CPM1A-20CDR-j/20CDT-j/20CDT1-j CPU Unit CPU Unit with DC Power CPU Unit with AC Power 76±0.2 CPM1A-30CDR-j-V1/30CDT-j-V1/30CDT1-j-V1 CPU Unit CPU Unit with DC Power CPU Unit with AC Power Four, 4.5 dia. CPM1A-30CDR-j/30CDT-j/30CDT1-j CPU Unit CPU Unit with DC Power CPU Unit with AC Power 120±0.2...

- Page 175 Dimensions Appendix B CPM1A-40CDR-j-V1/40CDT-j-V1/40CDT1-j-V1 CPU Unit CPU Unit with DC Power CPU Unit with AC Power Four, 4.5 dia. CPM1A-40CDR-j/40CDT-j/40CDT1-j CPU Unit CPU Unit with DC Power CPU Unit with AC Power 140±0.2 CPM1A-20EDj Expansion I/O Unit Two, 4.5 dia.

- Page 176 Dimensions Appendix B CPM1A-8jjj Expansion I/O Unit Two, 4.5 dia. Analog I/O Unit CPM1A-MAD01 CPM1A-MAD11 76±0.2 Two, 4.5 dia. Two, 4.5 dia. CPM1A-TSjjj Temperature Sensor Unit 76±0.2 Two, 4.5 dia.

- Page 177 Dimensions Appendix B CPM1A-SRT21 CompoBus/S I/O Link Unit Two, 4.5 dia. CPM1A-DRT21DeviceNet I/O Link Unit 56±0.2 Two, 4.5 dia.

- Page 178 Dimensions Appendix B CPM1-CIF01 RS-232C Adapter 90 81 CPM1-CIF11 RS-422 Adapter 90 81...

- Page 179 Dimensions Appendix B Dimensions with Peripheral Devices Attached CPU Unit with DC Power Supply CPU Unit with AC Power Supply Approx. 90 Approx. 125 *110 mm for V1 Units.

- Page 180 AUTOEXEC.BAT An MS-DOS file containing commands automatically executed at startup. back-up A copy made of existing data to ensure that the data will not be lost even if the original data is corrupted or erased. basic instruction A fundamental instruction used in a ladder diagram. See advanced instruction.

- Page 181 Glossary bit designator An operand that is used to designate the bit or bits of a word to be used by an instruction. bit number A number that indicates the location of a bit within a word. Bit 00 is the rightmost (least-significant) bit;...

- Page 182 Glossary Completion Flag A flag used with a timer or counter that turns ON when the timer has timed out or the counter has reached its set value. condition A symbol placed on an instruction line to indicate an instruction that controls the execution condition for the terminal instruction.

-

Page 183: Glossary

A unit of storage in memory that consists of four bits. digit designator An operand that is used to designate the digit or digits of a word to be used by an instruction. DIN track A rail designed to fit into grooves on various devices to allow the devices to be quickly and easily mounted to it. - Page 184 Processing that is performed in response to an event, e.g., an interrupt signal. exclusive NOR A logic operation whereby the result is true if both of the premises are true or both of the premises are false. In ladder-diagram programming, the premises are usually the ON/OFF states of bits, or the logical combination of such states, called execution conditions.

- Page 185 Each group of four binary bits is numerically equivalent to one hexadecimal digit. host computer A computer that is used to transfer data to or receive data from a PC in a Host Link system. The host computer is used for data management and overall sys- tem control.

- Page 186 I/O Units include Input Units and Output Units, each of which is available in a range of specifications. I/O word A word in the IR area that is allocated to a Unit in the PC System and is used to hold I/O status for that Unit. IBM PC/AT or compatible A computer that has similar architecture to, that is logically compatible with, and that can run software designed for an IBM PC/AT computer.

- Page 187 A type of programming where execution moves directly from one point in a pro- gram to another, without sequentially executing any instructions in between. jump number A definer used with a jump that defines the points from and to which a jump is to be made. ladder diagram (program) A form of program arising out of relay-based control systems that uses circuit- type diagrams to represent the logic flow of programming instructions.

- Page 188 The processes of copying data either from an external device or from a storage area to an active portion of the system such as a display buffer. Also, an output device connected to the PC is called a load.

- Page 189 NOT indicates an AND operation with the opposite of the actual status of the operand bit. The status of an input or output when a signal is said not to be present. The OFF state is generally represented by a low voltage or by non-conductivity, but can be defined as the opposite of either.

- Page 190 Glossary output bit A bit in the IR area that is allocated to hold the status to be sent to an output device. output device An external device that receives signals from the PC System. output point The point at which an output leaves the PC System. Output points correspond physically to terminals or connector pins.

- Page 191 The portable form of Programming Device for a PC. Programming Device A Peripheral Device used to input a program into a PC or to alter or monitor a program already held in the PC. There are dedicated programming devices, such as Programming Consoles, and there are non-dedicated devices, such as a host computer.

- Page 192 However, the program or data can be read as many times as desired. rotate register A shift register in which the data moved out from one end is placed back into the shift register at the other end. RS-232C interface An industry standard for serial communications.

- Page 193 One or more words in which data is shifted a specified number of units to the right or left in bit, digit, or word units. In a rotate register, data shifted out one end is shifted back into the other end. In other shift registers, new data (either specified data, zero(s) or one(s)) is shifted into one end and the data shifted out at the other end is lost.

- Page 194 The process of moving data from one location to another within the PC, or between the PC and external devices. When data is transferred, generally a copy of the data is sent to the destination, i.e., the content of the source of the transfer is not changed.

- Page 195 A switch used to write-protect the contents of a storage device, e.g., a floppy disk. If the hole on the upper left of a floppy disk is open, the information on this floppy disk cannot be altered.

- Page 196 22 displaying, Programming Console, 112 processing, 122 binary data, modifying, Programming Console, 108 data, modifying, Programming Console, 106, 107, 108, 109, bit status, force-set/reset, Programming Console, 110 bits, searching, Programming Console, 98 data link, 16, 72 buzzer operation, Programming Console, 93 decimal data with sign.

- Page 197 Index ERR/ALM indicator I/O terminals, IR bit allocation, 5 flashing, 123 incremental mode, 9 lit, 123 indicators errors CompoBus/S LED indicators, 38 communications, 123 flashing ERR/ALM indicator, 123 error processing, 119 lit ERR/ALM indicator, 123 fatal, 123 PC status indicators, 33...

- Page 198 NPN current output, connecting, 58 program, programming example, 112 NPN open collector, connecting, 58 program capacity, 23 NT Link, 3 program memory, setting address and reading content, Pro- gramming Console, 94 PROGRAM mode, description, 86 Programmable Terminal, 4 one-shot mode, 8...

-

Page 199: Index

58 status, monitoring, Programming Console, 101 weight SV, modifying, Programming Console, 106 CPU Unit, 22 syntax, checking the program, Programming Console, 100 Expansion I/O Unit, 22 Expansion Unit, 22 SYSMAC Support Software, 19 See also SSS wiring, 50... -

Page 200: Revision History

Page 61: Minor changes to first paragraph. Page 66: Information added to introduction. Pages 73, 80, 81, 83, 86, 87, 88, 89, 90, 93, 95, 97, 98, 104: Minor changes to screen messages. Page 98: Note added to middle graphic. - Page 201 Revised content May 2001 Pages xiv, xvii, xviii, 2, 4, 6, 7, 10, 20, 21, 25, 26, 28, 29, 39 to 41, 43, 44, 47, 53, 55, 57, 125, 137, 141, 142, and 145: Changed made for V1 Units. Pages 3, 12, 31, 40, 137, and 143: Information on new Analog I/O Unit added (MAD11).

Need help?

Do you have a question about the CPM1A and is the answer not in the manual?

Questions and answers