Summary of Contents for Prochem APEX

- Page 1 Operating Instructions (ENG) MODELS: APEX GAS APEX DIESEL Read instructions before operating the machine. 980217 06/29/06...

-

Page 2: Machine Data Log/Overview

RETURNED TO YOUR DEALER. PROFESSIONAL CHEMICALS CORPORATION 325 SOUTH PRICE ROAD CHANDLER, ARIZONA 85224 Information in this document is subject to change without notice and does not represent a commitment on the part of Professional Chemicals Corporation. APEX 980217 08/01/04... -

Page 3: Table Of Contents

Chemical Metering & Selector Valves ...4-11 Personal Protective Equipment......3-14 Pressure Regulators ........4-11 De-flooding Operations ........3-14 Adding/Draining Engine Coolant ....4-11 Freezing Protection ..........3-14 Troubleshooting ..........4-12 Winterizing Your Unit ......... .3-15 Removing Anti-freeze from Unit ......3-16 APEX 980217 08/01/04... -

Page 4: Table Of Contents

High Altitude Operations ....... 7-9 Removing Anti-freeze from Unit ......6-16 Check Valve (Solution Outlet) ....... 7-10 Chemical Pump ..........7-10 Packing Nut Adjustment for Chemical Metering & Selector Valves... 7-11 Pressure Regulators........7-11 Adding/Draining Engine Coolant ....7-11 Troubleshooting..........7-12 APEX 980217 12/23/04... - Page 5 Water Tank-Demand Pump (Optional) ....8-67 Auxiliary Water Tank With Pump ....... 8-69 Hose Reel (Optional).......... 8-71 Hose Diagram - Gas .......... 8-73 Hose Diagram – Diesel ........8-74 Wiring Diagram - Gas......... 8-75 Wiring Diagram – Diesel ........8-76 Warranty............. 8-78 APEX 980217 01/20/05...

-

Page 6: Receiving Your Unit

The dealer is also responsible for 9. Installation mounting plates. initial training of your operators and maintenance personnel in the proper operation 10. Operation and service manual for engine, water and maintenance of this unit. pump, and vacuum pump manuals. APEX 980217 12/23/04... - Page 7 NOTES: APEX 980217 12/23/04...

-

Page 8: How To Use This Manual

KIT INSTRUCTIONS which came with the kit. It contains replacement parts numbers needed for ordering future parts. NOTE: The 98# on the lower left corner of the front cover is the part number for this manual. APEX 980217 08/01/04... -

Page 9: Safety Instructions

Water under high pressure at high temperature can cause burns, severe personal injury, or fatality. Shut down machine, allow to cool down, and relieve system of all pressure before removing valves, caps, plugs, fittings, filters, and bolts. APEX 980217 08/01/04... - Page 10 Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality. CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. APEX 980217 08/01/04...

-

Page 11: Hazard Intensity Level

5. DISCONNECT ALL HOSES AND TOOLS. 6. DRAIN WASTE TANK INTO AN APPROVED SOURCE. SOLUTION OUTLETS Part # 790958 CARPET AND UPHOLSTERY SOLUTION (2) Warning labels required Warning label Part # 500769 Caution label Part # 500770 APEX 980217 08/01/04... -

Page 12: Technical Specifications

“.045”. Example: Tri-jet wand uses three 95015 jets (95° spray angle w/ 015 orifice). 015 x 3 = 045……….045 x 2 tools = 09 Upholstery tool jet size: 80015 Stair tool jet size: 9502 APEX 980217 08/01/04... -

Page 13: Installation Requirements

Ten percent (10%) of the overall unit weight should be on the tongue. Example: If loaded trailer weight is 2,000 lbs., tongue weight needs to be a minimum of 200 lbs. to tow properly. APEX 980217 12/10/04... -

Page 14: Chemical Requirements

It will also allow cleaning chemicals to be more PROCHEM chemical manual. effective in lower concentrations WATER REQUIREMENTS If you require a water softener, PROCHEM has a model to meet your needs. Please contact your Hard water deposits will adversely affect the nearest distributor for information, price, and plumbing and heat exchange systems on this unit. -

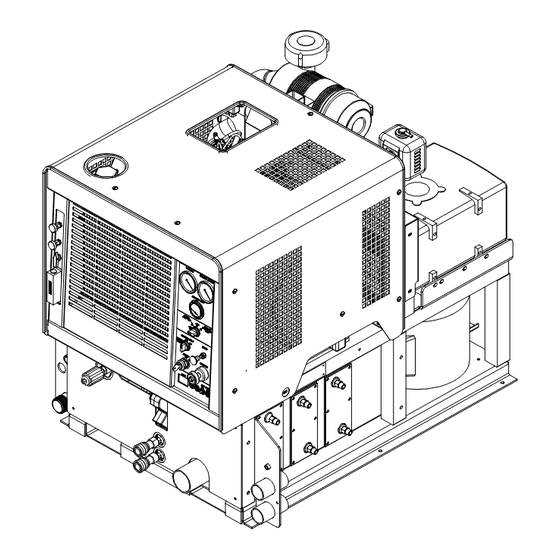

Page 15: Components

3. SET THROTTLE TO IDLE POSITION AND OPEN FLOW SIMULATOR VALVE, ALLOWING THE WATER TEMPERATURE TO COOL DOWN. 4. TURN OFF IGNITION SWITCH. 5. DISCONNECT ALL HOSES AND TOOLS. 6. DRAIN WASTE TANK INTO AN APPROVED DISCHARGE POINT. SOLUTION OUTLETS CARPET AND UPHOLSTERY SOLUTION APEX 980217 04/17/06... - Page 16 This switch serves to energize the magnetic 14. OIL CUP clutch to turn the water pump on or off. Turn clockwise for activating the pump and counter The oil cup allows lubricant spray to reach the clockwise for deactivating the pump. vacuum blower. APEX 980217 08/01/04...

- Page 17 21. WARM WATER OUTLET The warm water outlet allows the cleaning technician to drain hot water from the water box for mixing chemical. Water from this valve is hot. APEX 980217 08/01/04...

- Page 18 28. PANEL LIGHT balance and stabilize the solution temperature within the system. This light is useful if the machine is used in a poorly lit area or night use. It is helpful in reading the instruments and gauges. APEX 980217 08/01/04...

-

Page 19: Water Pumping And Heat Transfer System

This allows the engine coolant to travel in a counter rotating direction to the cleaning water during the exchange process creating a very efficient transfer of heat out of the engine and into the cleaning solution. APEX 980217 08/01/04... - Page 20 WATER PUMP ENGINE THERMOSTAT RADIATOR TO PRESSURE GUAGE 3-WAY BALL VALVE ACCUMULATOR MANIFOLD WATER INLET LOW PRESSURE REGULATOR WARM WATER OUTLET TEMPERATURE BALANCE ORIFICE VALVE OUTLET CHECK VALVE OUTLET CHEMICAL Y-STRAINER INJECTION SOLUTION OUTLETS SOLUTION OUTLET MANIFOLD APEX 980217 08/01/04...

-

Page 21: Chemical Injection System

The chemical is picked up from the container and fed through the flow meter to the chemical pulse The chemicals are then mixed with hot pressurized pump where it is pressurized. water that make up a solution for cleaning application. APEX 980217 08/01/04 3-10... -

Page 22: Waste Pump

***Change engine crankcase oil and filter after the first 50 hours ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first APEX 980217 12/23/04... - Page 23 ***Change engine crankcase oil and filter after the first 50 hours ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first APEX 980217 12/23/04...

-

Page 24: Key Checkpoints

To keep your solution supply system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer. APEX 980217 08/01/04... -

Page 25: Engine

NOTE: Using less than service class SF or SG an authorized Kubota Service Center. You will oil or extending oil change intervals longer than need to provide the serial number of the engine. recommended can cause engine damage. APEX 980217 08/01/04... -

Page 26: Vacuum Pump

3. Drain, flush and replace oil every 1500 hours or premium mineral oil. NOTE: AEON PD (Part# 05-008039) is the oil which PROCHEM puts in the vacuum pump at the factory. Topping off or adding petroleum oil to synthetic oil is NOT recommended. -

Page 27: Water Pump

If adjustment is required, shut the unit down and adjust the vacuum relief valve locking nut tension. Start your unit and read the vacuum gauge. Repeat this process until the relief valve opens at 13" Hg. APEX 980217 11/30/04... -

Page 28: Water Pump Drive Belt

200 hours. Keeping these valve packings properly adjusted will eliminate possible leakage from the valve stems and add to overall valve life. For the procedure, see the "General Service Adjustments” section in this manual for details. APEX 980217 08/01/04... -

Page 29: Nitrogen Accumulator

1000 hours of use. ENGINE COOLANT REPLACEMENT PRESSURE REGULATOR Annually the coolant in the Prochem machine should be replaced. This coolant is an integral part of the Lubricate the o-rings every 50 hours. Use o-ring heating system and needs to be maintained as any lubricant Part #05-008035. -

Page 30: General Service Adjustments

The ultimate users of the SI engines must comply with the regulations through the installation of the appropriate altitude compensation kit for the altitude range where the engine will be operated. APEX 980217 08/01/04... -

Page 31: Check Valve (Solution Outlet)

Use 5/16 Allen Wrench to remove NOTE: Improper seating of the check valve poppet, damaged spring or o-rings will cause poor operation of the chemical system. 6. Lubricate the o-rings with o-ring lubricant Part #05-008035 and reinstall. APEX 980217 08/01/04 4-10... -

Page 32: Packing Nut Adjustment For Chemical Metering & Selector Valves

Use a 70:30 coolant to water ratio in this unit’s cooling system. NOTE: See the “Maintenance Chart” for specific details. 1. To drain the coolant, remove the radiator cap and turn the lower engine radiator draincock counter- clockwise. APEX 980217 08/01/04 4-11... -

Page 33: Troubleshooting

Defective quick-connect on one or Replace defective quick-connects(s) on more of the high pressure hoses. high pressure hoses(s). Cleaning tool valve is malfunctioning. Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. APEX 980217 12/23/04 4-12... - Page 34 Internal leak in chemical valve Tighten valve packing nut (see “General causing continual flow through prime Service Adjustments” section in this tube returning to container. manual). Replace valve, if necessary. APEX 980217 08/01/04 4-13...

- Page 35 Oil pressure switch (located on Test these components. If any are engine), anti-diesel solenoid defective, replace. Consult the Kubota (located on engine), high Engine Operation and Maintenance temperature switch (located on Manual. engine). APEX 980217 08/01/04 4-14...

- Page 36 After inspecting waste pump to determine Pump-out circuit breaker on connectors and heat shrink. the cause of the tripped circuit breaker, control panel has been tripped. Inspect connection for press the reset button. watertight seal. APEX 980217 08/01/04 4-15...

- Page 37 NOTES: APEX 980217 10/19/04 4-16...

- Page 38 APEX DIESEL APEX-D 980217 12/23/04...

-

Page 39: Safety Instructions

Water under high pressure at high temperature can cause burns, severe personal injury, or fatality. Shut down machine, allow to cool down, and relieve system of all pressure before removing valves, caps, plugs, fittings, filters, and bolts. APEX-D 980217 12/23/04... - Page 40 Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality. CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. APEX-D 980217 12/23/04...

-

Page 41: Hazard Intensity Level

5. DISCONNECT ALL HOSES AND TOOLS. 6. DRAIN WASTE TANK INTO AN APPROVED SOURCE. SOLUTION OUTLETS Part # 791103 CARPET AND UPHOLSTERY SOLUTION (2) Warning labels required Warning label Part # 500769 Caution label Part # 500770 APEX-D 980217 12/23/04... -

Page 42: Technical Specifications

“.045”. Example: Tri-jet wand uses three 95015 jets (95° spray angle w/ 015 orifice). 015 x 3 = 045……….045 x 2 tools = 09 Upholstery tool jet size: 80015 Stair tool jet size: 9502 APEX-D 980217 12/23/04... -

Page 43: Installation Requirements

Ten percent (10%) of the D902-E Oil filter cartridge 200 Hrs overall unit weight should be on the tongue. Example: If loaded trailer weight is 2,000 lbs., tongue weight needs to be a minimum of 200 lbs. to tow properly. APEX-D 980217 12/23/04... -

Page 44: Chemical Requirements

It will also allow cleaning chemicals to be more PROCHEM chemical manual. effective in lower concentrations WATER REQUIREMENTS If you require a water softener, PROCHEM has a model to meet your needs. Please contact your Hard water deposits will adversely affect the nearest distributor for information, price, and plumbing and heat exchange systems on this unit. -

Page 45: Components

3. SET THROTTLE TO IDLE POSITION AND OPEN FLOW SIMULATOR VALVE, ALLOWING THE WATER TEMPERATURE TO COOL DOWN. 4. TURN OFF IGNITION SWITCH. 5. DISCONNECT ALL HOSES AND TOOLS. 6. DRAIN WASTE TANK INTO AN APPROVED DISCHARGE POINT. SOLUTION OUTLETS CARPET AND UPHOLSTERY SOLUTION APEX-D 980217 04/17/06... - Page 46 This four-position switch is for activating the heat. waste pumpout device. It also serves to activate the fresh water transfer pump. For turning on pumps, rotate clockwise. For turning off pumps, rotate counter clockwise. APEX-D 980217 12/23/04...

- Page 47 Clockwise rotation of the knob closes inside the tank automatically turns off and on the valve. Counter clockwise rotation opens the when the solution level reaches certain points. valve, allowing more chemical to enter the system. APEX-D 980217 12/23/04...

- Page 48 28. PANEL LIGHT balance and stabilize the solution temperature within the system. This light is useful if the machine is used in a poorly lit area or night use. It is helpful in reading the instruments and gauges. APEX-D 980217 12/23/04...

-

Page 49: Water Pumping And Heat Transfer System

This allows the engine coolant to travel in a counter rotating direction to the cleaning water during the exchange process creating a very efficient transfer of heat out of the engine and into the cleaning solution. APEX-D 980217 12/23/04... - Page 50 WATER PUMP ENGINE THERMOSTAT RADIATOR TO PRESSURE GUAGE 3-WAY BALL VALVE ACCUMULATOR MANIFOLD WATER INLET LOW PRESSURE REGULATOR WARM WATER OUTLET TEMPERATURE BALANCE ORIFICE VALVE OUTLET CHECK VALVE OUTLET CHEMICAL Y-STRAINER INJECTION SOLUTION OUTLETS SOLUTION OUTLET MANIFOLD APEX-D 980217 12/23/04...

-

Page 51: Chemical Injection System

The chemical is picked up from the container and fed through the flow meter to the chemical pulse The chemicals are then mixed with hot pressurized pump where it is pressurized. water that make up a solution for cleaning application. APEX-D 980217 12/23/04 6-10... -

Page 52: Vacuum System

The air is then filtered and rushes into the vacuum pump. VACUUM INLET HEATER COIL #1 HEATER COIL #2 VACUUM GAUGE HEATER COIL #3 LUBRICATION VACUUM SILENCER PUMP VACUUM RELIEF VALVE LEVEL SENSOR WASTE TANK STRAINER FILTER APEX-D 980217 12/23/04 6-11... -

Page 53: Pre-Run Inspections

Connect the hose to the water supply faucet. NOTE: Never use your waste pump outlet hose as a water inlet hose. Use only clean hoses for water inlet. 2. Turn the water supply faucet on. The water will fill the water box. APEX-D 980217 12/23/04 6-12... -

Page 54: Priming The Chemical Pump

DO NOT use a hose smaller than 5/8" I.D. NEVER use your automatic waste pump outlet hose as a water inlet hose. APEX-D 980217 12/23/04 6-13... -

Page 55: Upholstery Cleaning

Units with auxiliary water tanks must be stored in a heated building when not in use. APEX-D 980217 12/23/04 6-14... -

Page 56: Winterizing Your Unit

After completing these procedures, shut the unit cycle and re-use the anti-freeze. down. The unit is now winterized. Repeat this procedure with all the remaining tools. After all tools and pressure hoses have been filled with anti-freeze, disconnect and store them. APEX-D 980217 12/23/04 6-15... -

Page 57: Removing Anti-Freeze From Unit

6. Open the tool valves and drain the anti-freeze local laws and regulations. Do not drain onto the into an approved container until the flow is clear ground or into storm drainage systems and all anti-freeze is purged from the tools and hoses. APEX-D 980217 12/23/04 6-16... -

Page 58: Maintenance Service Schedule

***Change engine crankcase oil and filter after the first 50 hours ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first APEX-D 980217 12/23/04... - Page 59 ***Change engine crankcase oil and filter after the first 50 hours ****Perform drive belt, pulley and hub maintenance after the first 25 hours of operation, and then again at 100 hours *****If using AEON PD synthetic lubricant, 4500 hours or every 2 years, whichever comes first APEX-D 980217 12/23/04...

-

Page 60: Key Checkpoints

To keep your solution supply system functioning properly, follow the chemical pump and solution outlet maintenance in the Maintenance Schedule in this manual. Refer any additional questions to your dealer. APEX-D 980217 12/23/ 04... -

Page 61: Engine

4. Clean the air cleaner element every 200 hours. Replace the element yearly. 5. Check the engine idle RPM every 200 hours and adjust, if necessary. NEVER adjust engine RPM without a tachometer. Refer to Kubota Engine Operation and Service Manual. APEX-D 980217 11/15/05... -

Page 62: Vacuum Pump

3. Drain, flush and replace oil every 1500 hours or premium mineral oil. NOTE: AEON PD (Part# 05-008039) is the oil which PROCHEM puts in the vacuum pump at the factory. Topping off or adding petroleum oil to synthetic oil is NOT recommended. -

Page 63: Water Pump

Check for belt ride in the groove. nut tension. Start your unit and read the vacuum gauge. Repeat this process until the relief valve opens at 13" Hg. APEX-D 980217 12/23/04... -

Page 64: Water Pump Drive Belt

200 hours. Keeping these valve packings properly adjusted will eliminate possible leakage from the valve stems and add to overall valve life. For the procedure, see the "General Service Adjustments” section in this manual for details. APEX-D 980217 12/23/04... -

Page 65: Nitrogen Accumulator

1000 hours of use. ENGINE COOLANT REPLACEMENT PRESSURE REGULATOR Annually the coolant in the Prochem machine should be replaced. This coolant is an integral part of the Lubricate the o-rings every 50 hours. Use o-ring heating system and needs to be maintained as any lubricant Part #05-008035. -

Page 66: General Service Adjustments

DO NOT attempt to adjust without a tachometer and NEVER adjust the engine above 2850 RPM (No Load). Permanent damage may occur. HIGH ALTITUDE OPERATIONS CONSULT YOUR LOCAL KUBOTA DEALER FOR FURTHER INFORMATION ON THIS PROCEDURE. APEX-D 980217 12/23/04... -

Page 67: Check Valve (Solution Outlet)

Use 5/16 Allen Wrench to remove NOTE: Improper seating of the check valve poppet, damaged spring or o-rings will cause poor operation of the chemical system. 6. Lubricate the o-rings with o-ring lubricant Part #05-008035 and reinstall. APEX-D 980217 12/23/04 7-10... -

Page 68: Packing Nut Adjustment For

Use a 50/50 coolant to water ratio in this unit’s cooling system. NOTE: See the “Maintenance Chart” for specific details. 1. To drain the coolant, remove the radiator cap and turn the lower engine radiator draincock counter- clockwise. APEX-D 980217 12/23/04 7-11... -

Page 69: Troubleshooting

Defective quick-connect on one or Replace defective quick-connects(s) on more of the high pressure hoses. high pressure hoses(s). Cleaning tool valve is malfunctioning. Repair or replace valve. Hose inner lining is constricted. Remove restriction or replace hose. APEX-D 980217 12/23/04 7-12... - Page 70 Internal leak in chemical valve Tighten valve packing nut (see “General causing continual flow through prime Service Adjustments” section in this tube returning to container. manual). Replace valve, if necessary. APEX-D 980217 12/23/04 7-13...

- Page 71 Test these components. If any are Oil pressure switch (located on defective, replace. Consult the Kubota engine), high temperature switch Engine Operation and Maintenance (located on engine). Manual. Defective fuel shut down solenoid Test. Replace. APEX-D 980217 12/23/04 7-14...

- Page 72 After inspecting waste pump to determine Pump-out circuit breaker on connectors and heat shrink. the cause of the tripped circuit breaker, control panel has been tripped. Inspect connection for press the reset button. watertight seal. APEX-D 980217 12/23/04 7-15...

Need help?

Do you have a question about the APEX and is the answer not in the manual?

Questions and answers